2

GENERAL SAFETY INFORMATION

INSTALLATION

Before commencing any work on the product, make certain it is isolated from the mains power supply.

The product must be installed in conformity with the laws and standards applicable in the country of installation. The liability

of the manufacturer is limited to the supply of the product. The product must be installed adopting best professional prac-

tices, by suitably qualified persons working for a company that will assume full responsibility for the completed installation.

The manufacturer cannot be held responsible for consequences deriving from the unauthorised modification of the product

or from the use of non-original spare parts.

b Do not expose the product to the elements. It is not designed for use outdoors

ELECTRICAL CONNECTIONS

The system and/or the controller must be installed and connected by persons qualified under current statutory regulations.

Where an electronic controller is installed, connect the power cable of the device to a two pole switch complete with fuses

(power supply 230Vac 50Hz). It is indispensable that the system be properly connected to earth.

b

The control unit must be connected on the upstream side to the mains supply by way of a main differential switch in

accordance with current regulations. The correct operation of the control unit is guaranteed only when used in con-

junction with the motor for which it was designed and built. The manufacturer acknowledges no liability for improper

use of the control unit.

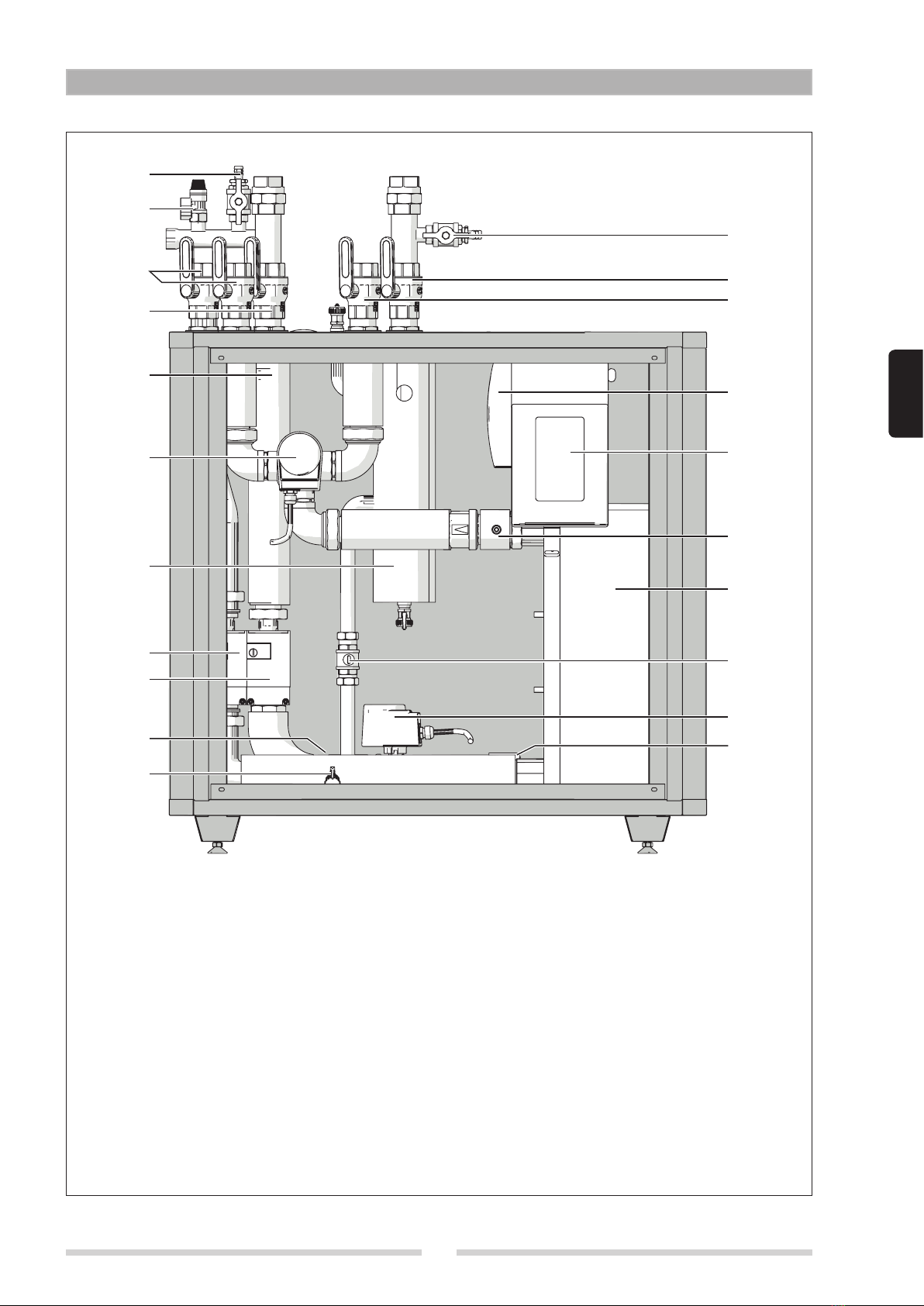

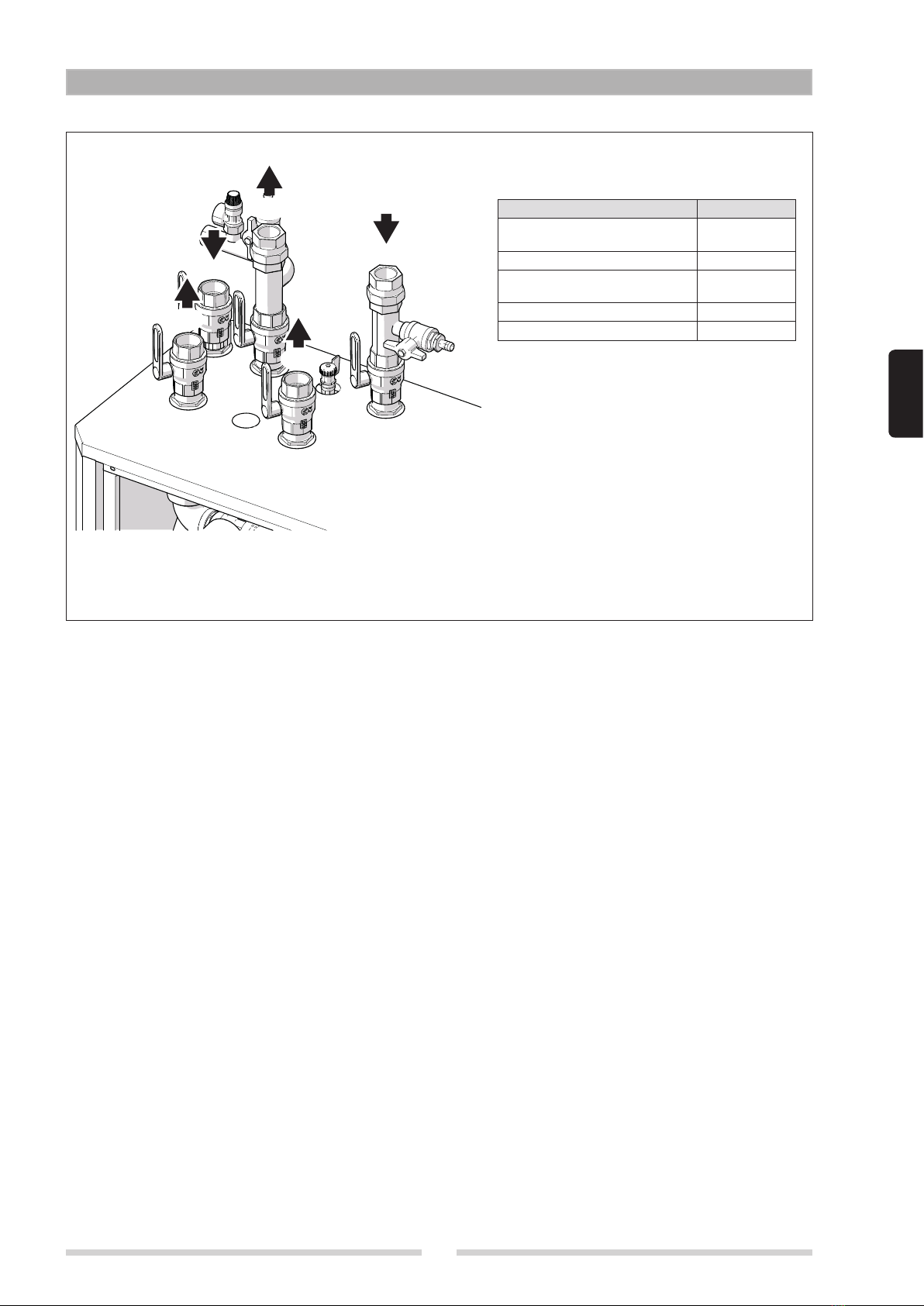

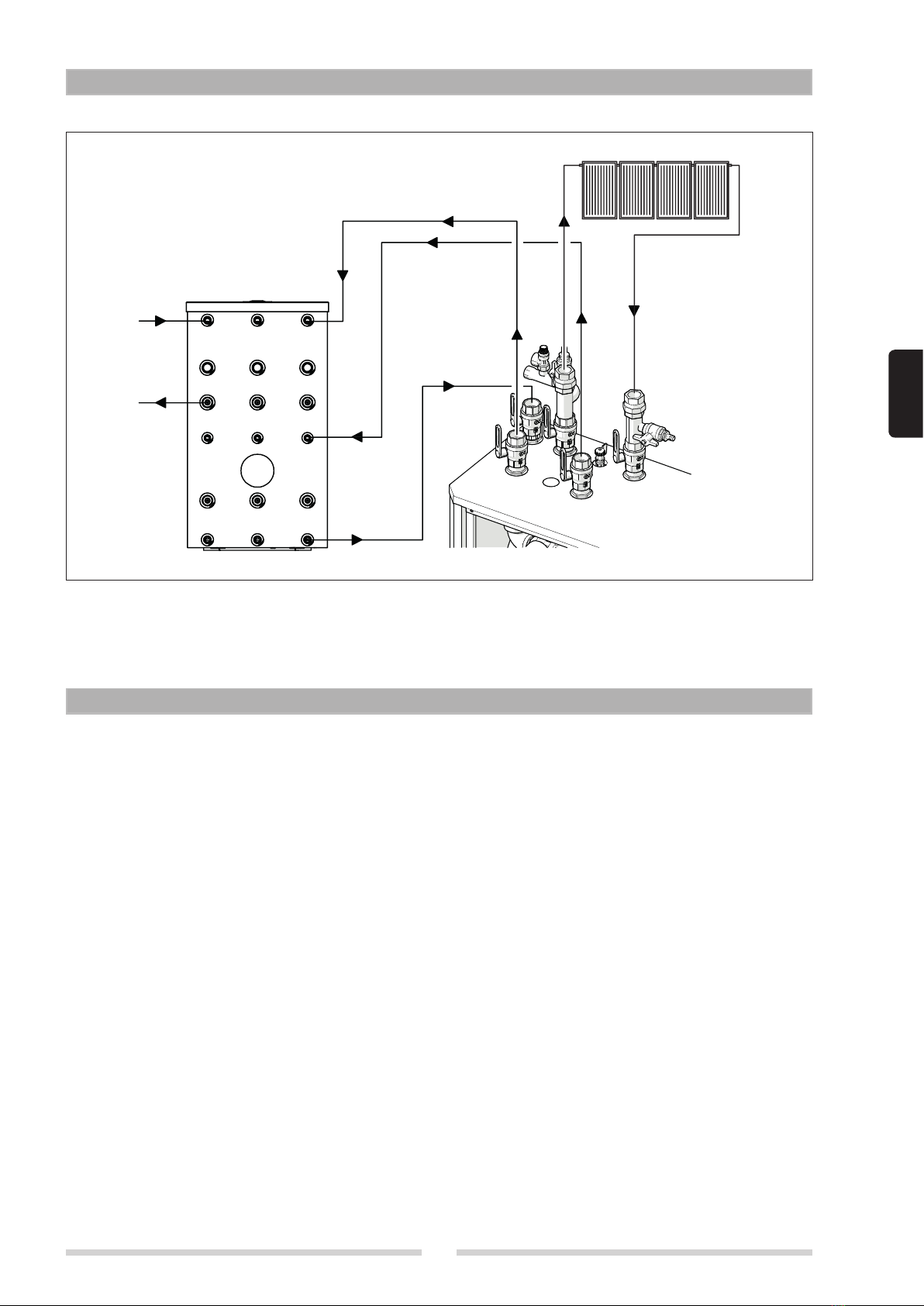

WATER CONNECTIONS

Having transported/handled the module into position, proceed to tighten all the ring nuts of the various pipe fittings. Take

particular care when connecting the module to the water system: during the step of tightening the pipe that connects the

water supply, the torque applied to the ring nut must be counteracted by applying a second wrench to the fitting, so that the

pipes of the module will not be strained and damaged.

b

All installation, connection and testing operations must be entrusted to skilled professionals who can be relied upon to

observe current standards and follow the instructions given in the accompanying manual. N.B. All pipelines must be

insulated in accordance with statutory regulations.

In any event, it is fundamentally important to observe certain general rules when using the product:

- Do not touch hot parts of the equipment, such as water inlet and outlet pipelines. Any contact with these parts could result

in serious scalding.

- Do not splash the module with water and other liquids.

- Do not stand or place any extraneous object on the module.

- Do not expose the module to steam rising from a cooker or hob.

- Do not allow children and inexpert persons to use the module.

- Do not touch the module with wet or damp body parts and/or bare feet.

- Do not tug or pull electrical cables.

- Put on protective gloves and safety footwear before handling the product.

PRE-INSTALLATION WARNINGS AND INDICATIONS

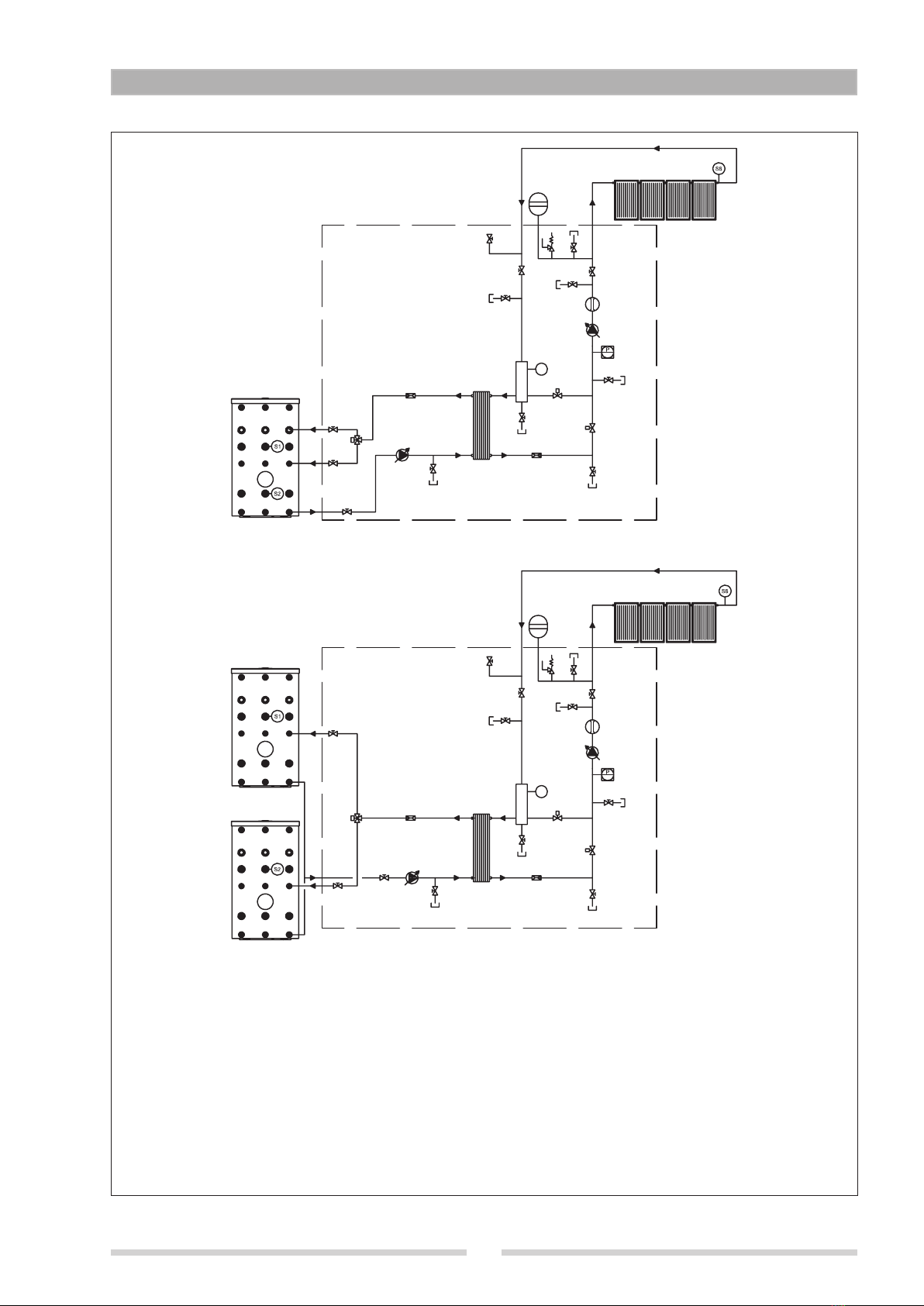

- When electrical power failures occur, the motorised valves are liable to lock up in the open position, causing the SOL 300

to overheat

- Any work required on electrical connections must be entrusted to an expert service technician.

- Water circulating inside the SOL 300 module may be very hot and highly pressurised. Before the module is disassembled

for whatever reason, the system should be drained of water, and the shut-off valves securely closed.

- Installation and all other work on the system must be carried out in compliance with local regulations.

- In the event of malfunctions occurring, whatever their nature, always contact your regular plumber. Carrying out repairs

without authorisation is forbidden, as unforeseen damage can occur

The manufacturer declines responsibility for any damage caused by inappropriate use of the product. The module must not

be connected directly to a heat generator.