Thermo Forma 923 Operating instructions

Model:

923/983

Ultra Low Temperature

Upright Freezer

23 cu. ft. capacity

Operating and Maintenance Manual

Manual No: 7020923 Rev. 7

Model 923/983_______________________________________________________________________________________

i

The material in this manual is for information purposes

only. The contents and the product it describes are subject to

change without notice. Thermo Forma makes no representations

or warranties with respect to this manual. In no event shall

Thermo Forma be held liable for any damages, direct or inciden-

tal, arising out of or related to the use of this manual.

IMPORTANT!

Read This Instruction Manual

Failure to read, understand and follow the instructions in

this manual may result in damage to the unit, injury to operating

personnel and poor equipment performance.

CAUTION! All internal adjustments and maintenance must be

performed by qualified service personnel.

MANUAL NO. 7020923

-- 20775/SI-8506 6/4/02 Updated to 40°C Pepi thermostat from 43°C Klixon ccs

7 20762/FR-1606 5/20/02 Added ‘Normally Open’ description to expansion tank solenoid valve ccs

20845/FR-1616 5/22/02 Updated refrigerant charge on schematics (oil return issue) ccs

-- 20684/FR-1596 3/28/02 Added sample pull-down chart after specs ccs

6 20644/FR-1557 3/8/02 Added two expansion tanks to refrig system ccs

5 20251/FR-1526 2/19/02 Cordset connector aks

4 20522/FR-1557 12/7/01 Updated 917 schematic FLA to 12 ccs

3 20400/FR-1557 11/16/01 Added expansion tank with solenoid and relay timer (release 11) ccs

-- 19363/FR-1429 10/18/00 New thermostat hot condenser temp of 43°C ccs

2 19404/FR-1441 9/22/00 New temperature control board ccs

1 19154/FR-1421 9/1/00 Updated parts and refrigeration drawings (dryer part number) ccs

0 6/30/00 New Manual aks

REV ECR/ECN DATE DESCRIPTION By

ii

Model 923/983_________________________________________________________________________________Service

Model 923/983__________________________________________________________________________________Safety

iii

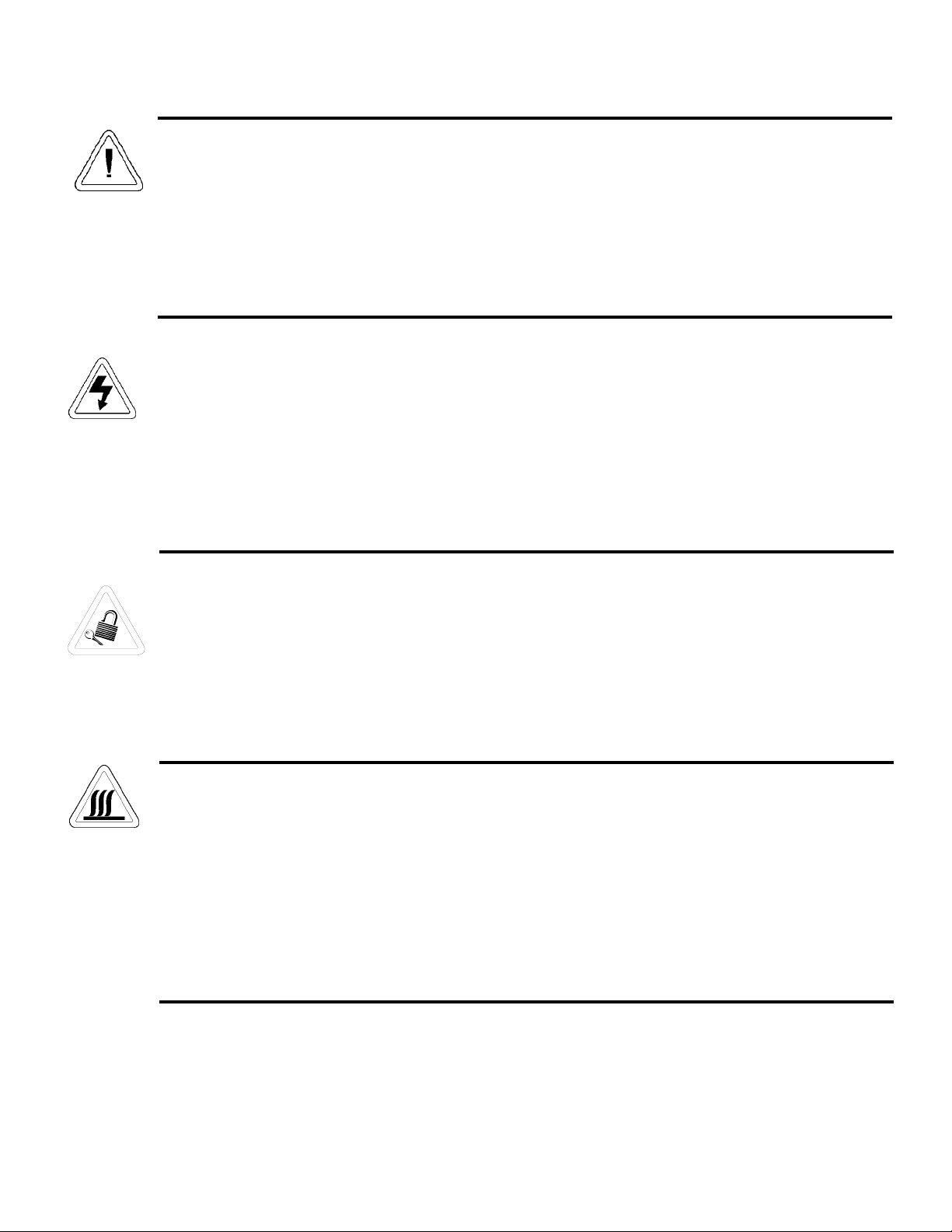

Important operating and/or maintenance instructions. Read the accompanying text carefully.

Ce symbole attire l'attention de l'utilisateur sur des instructions importantes de fonctionnement et/ou d'entretien. Il

peut être utilisé seul ou avec d'autres symboles de sécurité. Lire attentivement le texte d'accompagnement.

Wichtige Betriebs- und/oder Wartungshinweise. Lesen Sie den nachfolgenden Text sorgfältig.

Importante instruccions de operacion y/o mantenimiento. Lea el texto acompanante cuidadosamente.

Potential electrical hazards. Only qualified persons should perform procedures associated with this symbol.

Ce symbole attire l'attention de l'utilisateur sur des risques électriques potentiels. Seules des personnes qualifiées

doivent appliquer les instructions et les procédures associées à ce symbole.

Gefahr von Stromschlägen. Nur qualifizierte Personen sollten die Tätigkeiten ausführen, die mit diesem Symbol

bezeichnet sind.

Potencial de riesgos electricos. Solo personas das capacitadadas deben ejecutar los procedimientos asociadas con

este simbulo.

Equipment being maintained or serviced must be turned off and locked off to prevent possible injury.

Risques potentiels liés à l'énergie. L'équipement en entretien ou en maintenance doit être éteint et mis sous clé pour

éviter des blessures possibles.

Geräte, an denen Wartungs- oder Servicearbeiten durchgeführt werden, müssen abgeschaltet und abgeschlossen wer-

den, um Verletzungen zu vermeiden.

El equipo recibiendo servicio o mantenimiento debe ser apagado y segurado para prevenir danos.

Hot surface(s) present which may cause burns to unprotected skin or to materials which may be damaged by elevat-

ed temperatures

Présence de surface(s) chaude(s) pouvant causer des brûlures sur la peau non protégée, ou sur des matières pouvant

être endommagées par des températures élevées.

Heiße Oberfläche(n) können ungeschützter Haut Verbrennungen zufügen oder Schäden an Materialien verursachen,

die nicht hitzebeständig sind.

Superficias calientes que pueden causar quemaduras a piel sin proteccion o a materiales que pueden estar danados

por elevadas temperaturas.

;Always use the proper protective equipment (clothing, gloves, goggles etc.).

;Always dissipate extreme cold or heat and wear protective clothing.

;Always follow good hygiene practices.

;Each individual is responsible for his or her own safety.

General Safety Notes used in this Manual

Model 923/983_________________________________________________________________________Table of Contents

iv

Table of Contents

Section 1 - Installation and Start-Up

1.1 Unloading and Moving the Freezer . . . . . . . . . . . . . . . . .1-1

1.2 Getting to Know Your Freezer . . . . . . . . . . . . . . . . . . . . .1-1

1.3 Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.4 Installing the Wall Bumpers . . . . . . . . . . . . . . . . . . . . . . .1-3

1.5 Installing the Shelves . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.6 Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.7 Connecting the Alarm Battery . . . . . . . . . . . . . . . . . . . . .1-3

1.8 Remote Alarm Contacts . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.9 Optional Temperature Recorder . . . . . . . . . . . . . . . . . . . .1-4

a. Connecting recorder battery . . . . . . . . . . . . . . . . . . . .1-4

b. Installing the chart paper . . . . . . . . . . . . . . . . . . . . . .1-4

1.10 Attaching the Power Cord . . . . . . . . . . . . . . . . . . . . . . .1-4

1.11 Power Switch (mains disconnect) . . . . . . . . . . . . . . . . .1-4

1.12 Water-cooled Condenser . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1.13 Electrical Requirement and Connection . . . . . . . . . . . . .1-4

1.14 Factory Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1.15 Start Up and Loading . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Section 2 - Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.1 Changing the Control Temperature Set Point . . . . . . . . .2-1

2.2 Changing the Over Temperature Alarm Set Point . . . . . .2-1

2.3 Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.4 Silencing the Over Temperature Alarm . . . . . . . . . . . . . .2-2

Section 3 - Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.1 Temperature Display Calibration . . . . . . . . . . . . . . . . . .3-1

3.2 Recorder Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

a. Changing the recorder range: . . . . . . . . . . . . . . . . . . .3-1

b. Calibrating the chart recorder: . . . . . . . . . . . . . . . . . .3-1

Section 4 - Routine Maintenance . . . . . . . . . . . . . . . . . . . .4-1

4.1 Cleaning the Cabinet Exterior . . . . . . . . . . . . . . . . . . . . .4-1

4.2 Cleaning the Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4.3 Cleaning the Condenser . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

a. Cleaning the Water-cooled Condenser . . . . . . . . . . . .4-1

4.4 Defrosting the Chamber . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4.5 Cleaning the Door Gasket . . . . . . . . . . . . . . . . . . . . . . . .4-1

4.6 Cleaning the Vacuum Relief Port . . . . . . . . . . . . . . . . . . .4-1

4.7 Replacing the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

4.8 Preparing the Unit for Storage . . . . . . . . . . . . . . . . . . . .5-1

Section 5 - Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.1 Servicing the Refrigeration System . . . . . . . . . . . . . . . . .5-1

5.2 Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Section 6 - Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Section 7 - Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

Section 8 - Refrigeration Schematics . . . . . . . . . . . . . . . . . .8-1

Section 9 - Electrical Schematics . . . . . . . . . . . . . . . . . . . . .9-1

Section 10 - Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-1

Model 923/983______________________________________________________________________________Installation

1-1

Section 1 - Installation and Start-Up

1.1 Unloading and Moving the Freezer

To remove the freezer from the pallet, use the 7/16"

wrench to remove all the bolts securing the shipping bracket to

the pallet.

Remove the shipping bracket. Remove the ramp boards from the

pallet and place the slotted end over the ramp brackets on the

pallet. The support blocks on the ramps will be facing down.

Before moving the freezer, make sure the casters are unlocked

and moving freely. Align the caster with the ramp boards. Use

adequate personnel to roll the freezer off the pallet.

The freezer can be easily pushed to the desired

approved location, described in Section 1.6. If necessary, the

doorstop may be removed to allow the door to swing fully open

to move the unit through tight openings. When the freezer is in

position, set the front caster brakes.

If tipped more than 45°, allow the unit to sit

upright for 24 hours before start up. The freezer must not be moved with the product

load inside.

1.2 Getting to Know Your Freezer

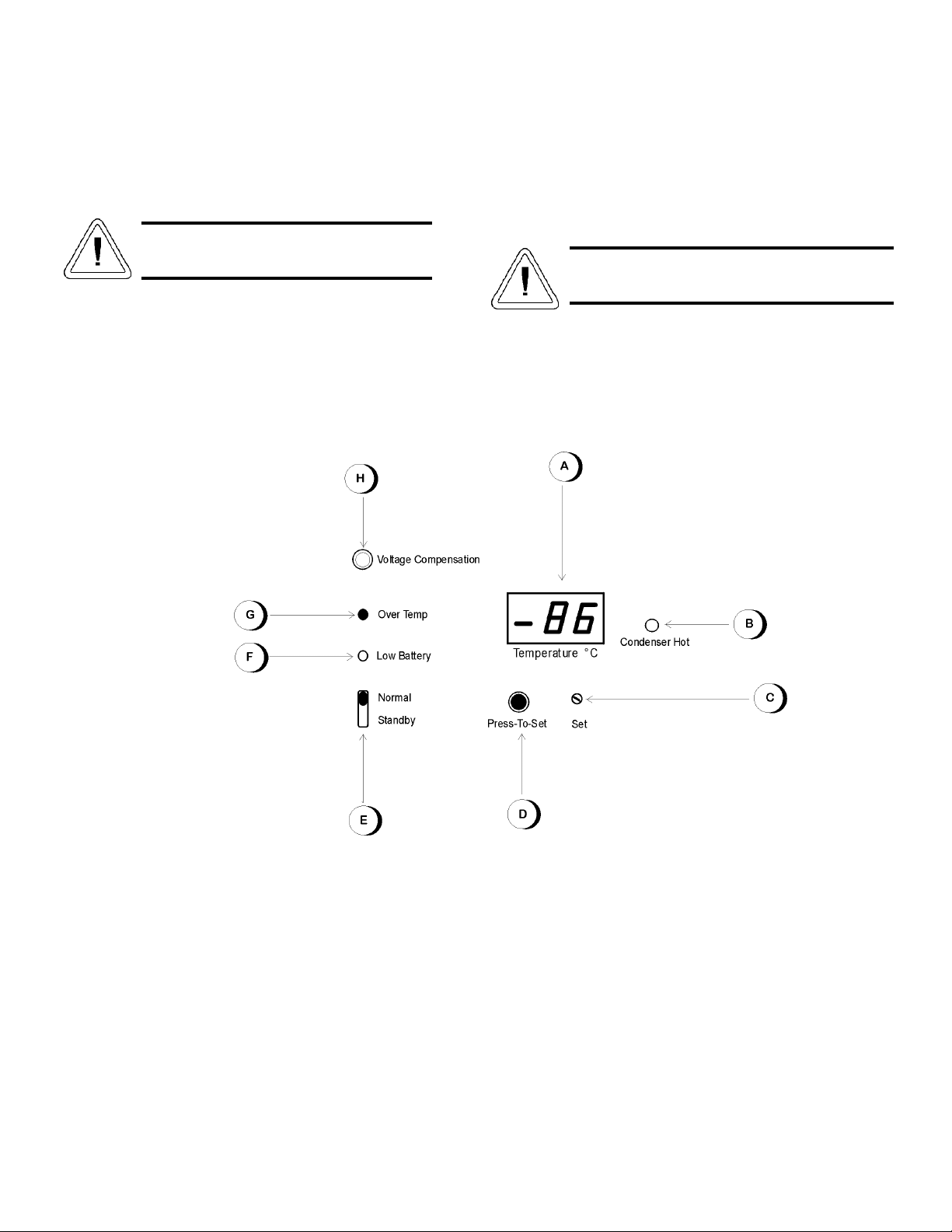

Figure 1-1, Control Panel

ALED display - Shows actual chamber temperature and indi-

cates the control temperature set point when the Press-To-Set

button is pressed.

BCondenser Hot indicator - Lights when the thermostat on the

condenser reaches approximately 40°C, indicating typically a

dirty air filter, a clogged condenser, a fan failure or high ambient

temperature.

CSet Point Adjustment screw - Used to set the control temper-

ature set point.

DPress-To-Set button - Press to display control temperature set

point.

ENormal/Standby switch - Silences the audible alarm.

FLow Battery indicator - Flashes when the battery needs to be

replaced.

GOver Temp indicator - Flashes when the chamber tempera-

ture rises above the Over Temperature Alarm setting.

HVoltage Compensation indicator - Indicates when the in-

coming electrical power is being automatically adjusted to

ensure that the compressor operates within specification.

Model 923/983_____________________________________________________________________________Installation

1-2

Figure 1-2

Freezer Exterior, front view

Figure 1-3

Freezer Base, rear view

Figure 1-4, Vacuum Relief Port

and Chamber Probe

Figure 1-5, Vacuum Relief Port and Chamber

Probe Assembly (without cover)

Model 923/983______________________________________________________________________________Installation

1-3

1.3 Environmental Conditions

The ULT Freezers are designed to be electrically safe in the fol-

lowing environmental conditions:

• Indoors

• Altitude: Up to 2,000 meters

• Temperature: 5°C to 43°C

• Humidity: 80% RH at or below 31°C, decreasing linearly to

50% RH at 40°C

• Mains Supply Fluctuations: ± 10% of nominal.

• Installation Category II 1

• Pollution Degree 2 2

• Class of Equipment I

• Climatic Class T (Tropical)3

1Installation category (overvoltage category) defines the level

of transient overvoltage which the instrument is designed to

withstand safely. It depends on the nature of the electricity sup-

ply and its overvoltage protection means. For example, in CAT

II which is the category used for instruments in installations sup-

plied from a supply comparable to public mains such as hospital

and research laboratories and most industrial laboratories, the

expected transient overvoltage is 2500V for a 230V supply and

1500V for a 120V supply.

2Pollution degree describes the amount of conductive pollution

present in the operating environment. Pollution degree 2

assumes that normally only non-conductive pollution such as

dust occurs with the exception of occasional conductivity caused

by condensation.

3 Class T (Tropical) means that the freezers are electrically safe

in a 43°C ambient.

1.4 Installing the Wall Bumpers (Refer to Figure 1-3)

The parts bag, located inside the cabinet, contains the

following parts.

2 510016 1/4-20 x 5-1/2" Bolt Wall Bumper

2 380520 Neoprene Cap Cap Protector

Install the bolts into the pre-tapped holes on the back of

the compressor section. Install a neoprene cap on each bolt.

Refer to Figure 1-3 for the locations of the pre-tapped holes.

1.5 Installing the Shelves

Install the shelf clips into the shelf pilasters (front and

back) at the desired shelf level. Install the shelves in the cabinet

onto the clips.

1.6 Location

Locate the freezer on a firm, level surface in an area

with an ambient temperature between 18°C and 32°C. Provide

ample room to reach the mains disconnect switch (power switch)

located on the rear of the freezer.

1.7 Connecting the Alarm Battery

NOTE: The battery must be connected upon start-up so that the

alarm will activate during an Overtemperature condition.

1. To gain access to the battery, remove the grille on the front of

the freezer. The grille is attached to the freezer by friction

plugs on each of the four corners and is readily pulled off.

The battery is the rectangle fastened by Velcro to the com-

pressor compartment frame and has a connector with red and

black wires. Another red and black wire set with connector

is secured to the wiring harness passing through the area of

the freezer. Join the two wire connectors and replace the

grille.

2. When the battery is connected, the OVERTEMP light will

flash and the alarm will sound. Turn the NORMAL/STAND-

BY switch to the STANDBY position. This will silence the

alarm. The alarm will remain silent until the unit is below

alarm setpoint. The alarm setpoint is factory set for -65°C. If

another setpoint is required, see Section 2.2.

1.8 Remote Alarm Contacts

Remote alarm contacts are located on the rear of the unit. See

Figure 1-6 for pin description, shown in the alarm state. The

Thermo Forma part number

for the plug required is

195482. Maximum rating for

this plug is 1.0A @ 30VAC.

Qty. Stock # Description Purpose

Figure 1-6

Remote Alarm Contact

For proper ventilation and airflow, a minimum

clearance of 5” at the rear, at the top and on the side

of the freezer is required. Allow adequate space in

the front of the freezer for door opening.

Model 923/983_____________________________________________________________________________Installation

1-4

1.9 Optional Temperature Recorder

a. Connecting recorder battery

Open the glass door of the recorder and connect the 9-

volt battery. The green light on the recorder will come on.

b. Installing the chart paper

1. Open the glass door of the recorder and press button #3

until the pen begins to move outward.

2. Unscrew the knob at the center of the chart and remove the

paper.

3. Install the new chart paper, position the paper to the correct

time line and replace the knob.

4. Remove the cap from the felt pen and press button #3.

Figure 1-9

Recorder Buttons

12

3

9-volt battery

Green LED

Program selection and

calibration buttons

12

3

Figure 1-8

Chart Recorder, detail view

1.10 Attaching the Power Cord

1. Insert the power cord into the power outlet module (A).

2. Tighten screws (B) on the power cord retainer.

Figure 1-10

Power Cord Assembly

Make sure the power cord connection is

completely seated.

1.12 Water-cooled Condenser

An accessory available for your freezer is the water-

cooled condenser. Details for the use of this condenser follow:

Water Supply

• Connections:

Inlet - ½" compression

Outlet - ½" compression

• Maximum water pressure:

150 PSIG

• Water usage:

City water - 65°F (18°C), 1 GPM (3.4 liters)/HP

Tower water - 85°F (29°C), 3GPM (11.4 liters)/HP

Water Strainer (P/N 780268)

Included in the parts bag within the freezer is a water

strainer recommended to be installed in the water inlet line. The

connection size is ½" FPT.

1.13 Electrical Requirement and Connection

The freezer should be operated on a dedicated grounded

service. Check the voltage rating on the serial tag of the unit and

compare it with the outlet voltage. Then with the power switch

turned off, plug the line cord into the wall outlet.

1.14 Factory Settings

· Temperature: -80°C

· High Temperature Alarm: -65°C

If you wish to change any of these settings, see the

appropriate section(s) in Section 2.

1.15 Start Up and Loading

· Turn the freezer on and allow it to run empty over night.

· When the empty freezer has stabilized over night at the control

temperature set point, load the chamber with pre-frozen product.

1.11 Power Switch (mains disconnect)

The power switch is located on the rear of the unit,

directly above the power cord. The power switch is also a cir-

cuit breaker that protects the entire unit.

The freezer was designed for the storage of pre-frozen

product only. The addition of warm product may

cause a temporary rise in the cabinet temperature.

Model 923/983___________________________________________________________________________Operation

2-1

Section 2 - Operation

2.1 Changing the Control Temperature Set Point

1. Remove the screwdriver on the front left corner of the control

panel.

2. Press and hold in the PRESS-TO-SET key on the control

panel.

3. Using the screwdriver, turn the SET screw until the desired

temperature is displayed. Clockwise lowers the temperature

and counter clockwise raises the temperature. The approved

operating temperature range for the unit is -50°C to -86°C.

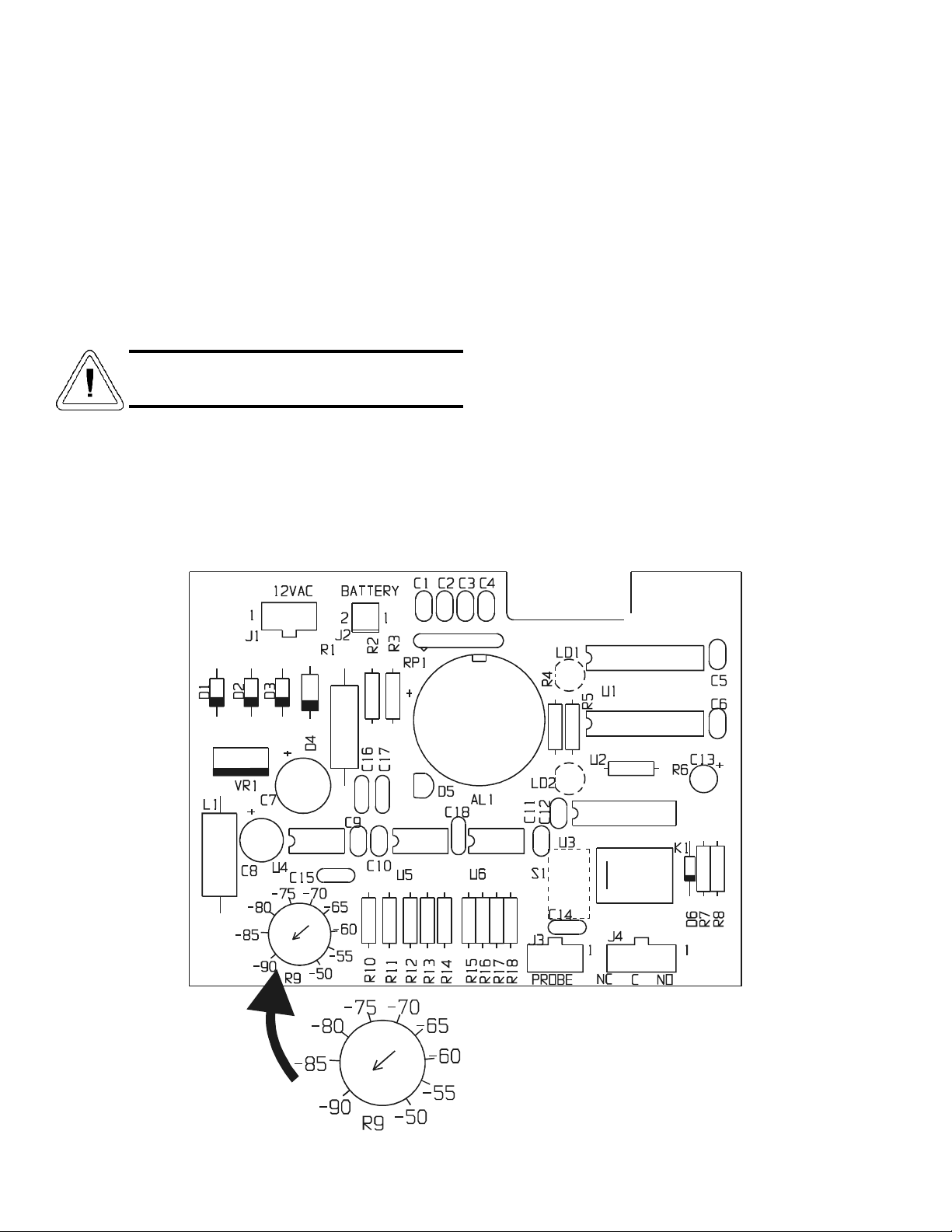

2.2 Changing the Over Temperature Alarm Set Point

The following procedure sets the alarm for a precise

temperature during initial set up. If a precise temperature is not

required, set R9 to the desired temperature.

1. Set the unit to operate at the desired alarm point (see Section

2.1) and allow the unit to operate until it reaches the set point.

2. Remove the top two screws securing the control panel and

loosen the bottom two screws. Carefully remove the control

panel.

3. Remove the six screws securing the cover of the box attached

to the inside of the control panel to expose the alarm board.

4. Turn the switch on the control panel to the NORMAL posi-

tion.

5. If the unit alarms, slowly adjust R9 clockwise (warmer) until

the alarm turns off. If the unit is not in alarm, slowly adjust

R9 counterclockwise (colder) until the alarm turns on.

6. The alarm is now set for the desired temperature. Reinstall the

box cover and secure with screws. Carefully install the control

panel to its proper location and secure with screws.

7. Set the unit to the desired control temperature. See Section

2.1.

The unit should NEVER be set to operate below

-86°C.

R-9

Figure 2-1, Temperature

Alarm Circuit Board

showing R-9 Control

Model 923/983_______________________________________________________________________________Operation

2-2

2.3 Alarms

Alarm Description Visual Audible Cause Action Required

Over Temperature Flashing (red) On · Unit is above alarm setpoint · Check freezer operation.

· Addition of excessive product

load

Condenser Hot On (red)* --- · Filter and/or condenser dirty. · See section 4.2 and 4.3 for

· Operating freezer in greater cleaning filter and condenser.

than 40°C ambient.

Low Battery Flashing (red) --- · Rechargeable battery not · See Section 1.6.

connected. · Replace battery. See section 4.7

· Rechargeable battery for battery replacement instructions.

needs replaced. See spare parts list for battery

part number.

Voltage Compensation On (green) --- · Incoming voltage too high · Check if line voltage is

or too low within operating range.

See 6 - Electrical. If within

specification no action required.

2.4 Silencing the Over Temperature Alarm:

· Move the switch from the NORMAL position to the STAND-

BY position. When the alarm condition has been corrected,

the alarm will sound. The switch must then be returned to the

NORMAL position.

NOTE: When the problem has been corrected and the alarm

condition no longer exists an alarm will sound remind-

ing the operator to press Standby to exit the STANDBY

mode.

If the unit is left in the STANDBY mode, none of

the alarms listed will sound, alarm lights only will

turn on.

Model 923/983______________________________________________________________________________Calibration

3-1

Section 3 - Calibration

Required equipment: Accurate low temperature remote bulb

thermometer or thermocouple of known accuracy.

3.1 Temperature Display Calibration

Place a measuring device near the probe cover. See Figures 1-4

and 1-5.

1. Allow the unit to stabilize at the operating temperature.

2. Remove the top two screws securing the control panel and

loosen the bottom screws.

3. Carefully remove the control panel.

4. Remove the six screws securing the cover of box attached to

the inside of the control panel. Remove the cover.

5. Adjust R17 until the control panel display matches the inde-

pendent measuring device. Several turns of R17 may be

required to achieve the desired temperature.

6. Reinstall cover to the box and secure.

7. Check the control temperature set point. Set point may have

been altered during the calibration procedure.

3.2 Optional Recorder Calibration

a. Changing the recorder range:

The chart recorder contains eight temperature ranges

and is factory-programmed for the freezer.

1. Press and hold button #3 for one second, then let the pen

move off the chart paper.

2. Press and hold for five seconds either button #1 or button #2.

3. Release the button and the green LED will begin to flash.

Count the number of flashes to determine the present program

setting.

4. To change the program setting, press the left or right arrows to

increase or decrease the count.

5. When the desired program number is flashing, press button #3

to bring the pen arm back onto the chart. Recording will

begin in the new program.

NOTE: Changing ranges may require an offset calibration as

outlined in Section 3.2.b.

Program No. Range

Program 1 -40°C to 30°C

Program 2 0°C to 60°C

Program 3 -100°C to 38°C

Program 4 -5°C to 50°C

Program 5 0°C to 100°C

Program 6 -100°C to -200°C

Program 7 -115°C to 50°C

Program 8 -10°C to 70°C

b. Calibrating the chart recorder:

The recorder must be in service for 24 hours before per-

forming the following calibration procedure.

1. Place an accurate thermometer in the chamber next to the

recorder probe.

2. Temperature probes for the recorder are located in the left

front corner of the freezer chamber (Figure 1-4).

3. After about three minutes, compare the thermometer reading

with the chart recorder reading.

4. If an adjustment is necessary, press the #1 button to move the

pen to the left or the #2 to move the pen to the right. The but-

ton must be held about five seconds before the pen begins to

move. Release the button when the pen position matches the

thermometer.

NOTE: The felt-tip pen on the recorder requires periodic

replacement. Usually the ink will appear to fade before

replacement becomes necessary. Additional pen tips

may be purchased from Thermo Forma. Refer to Parts

List, Section 7.

Calibration must be performed when the unit is at

operating temperature.

Figure 3-1, Temperature Control

Board, showing R-17 Location

Table 3-1

Recorder Range Chart

PREVENTIVE MAINTENANCE

SUVA Freezers

Your Thermo Forma equipment has been thoroughly tested and calibrated before shipment. Regular preventive maintenance is important to keep

your unit functioning properly. The operator should perform routine cleaning and maintenance on a regular basis. For maximum performance and

efficiency, it is recommended that the unit be checked and calibrated periodically by a qualified service technician.

The following is a condensed list of preventive maintenance requirements. See the specified section of the instruction manual for further details.

Thermo Forma has qualified service technicians, using NIST traceable instruments, available in many areas. For more information on Preventive

Maintenance or Extended Warranties, please contact us at the number below.

Cleaning and calibration adjustment intervals are dependent upon use, environmental conditions and accuracy required.

Tips:

• Fill an upright by starting at the bottom near the probe and add racks to one shelf at a time. Allow freezer to recover to setpoint between shelves.

• Fill a chest by starting at the left side near the probe. Filling with room temperature racks will result in a long pull-down time.

• Fill unit with frozen product to help overall performance; frozen water jugs, for example.

•Millcreek Road, Box 649 •Marietta, Ohio 45750 USA •740-373-4763

3-2

Preventive Maintenance for 900 Series Freezers

Refer to Manual Section Action Monthly Yearly Every

2 Years

-- Verify ambient temperature, <90°F ;

-- * Adjust door handle for firm latching, as needed ;

Figure 1-4 probe location 4.5 Check and clean probe and cover, gaskets, hinges and doors of ice and snow. ;

More frequent cleaning may be

required, depending on use and

environmental conditions.

4.2 Check air filter. Clean or replace as needed ;

1.7 Check alarm back-up battery. ;** Replace

-- Check condenser fan motor for unusual motor noise or vibration. ;

-- * Verify and document calibration, at the minimum, annually. ;

4.3 * Clean condenser compartment and wipe off condenser ;

* Qualified service technicians only

** Dispose of properly, according to all state and federal regulations.

3-3

Model 923/983______________________________________________________________________Routine Maintenance

4-1

Section 4 - Routine Maintenance

4.1 Cleaning the Cabinet Exterior

Wipe down the freezer exterior using soap and water

and a general use laboratory disinfectant. Rinse thoroughly with

clean water and dry with a soft cloth.

4.2 Cleaning the Air Filter (minimum of twice a year*)

1. Locate the grille on the right side of control panel. See Figure

1-2. Grasp the corner of the grille and gently pull to remove.

2. Remove the filter material and wash, using water and a mild

detergent.

3. Dry by pressing between two towels.

4. Install the filter back into the grille and attach the grille.

* Depending upon environmental conditions, the filter may need

to be cleaned or replaced more frequently. If the filter becomes

torn or excessively dirty, a replacement can be purchased from

Thermo Forma. See the exploded parts list, Section 7, for filter

part number. A filter kit (set of 5) part number 195517 is also

available.

4.3 Cleaning the Condenser (minimum of twice a year*)

1. Locate the grille on the right side of control panel. See Figure

1-2. Grasp the corner of the grille and gently pull to remove.

2. Using a vacuum cleaner, exercising care to not damage the

condenser fins, clean the condenser.

3. Install the grille.

* Depending upon environmental conditions, the condenser may

need to be cleaned more frequently.

a. Cleaning the Water-cooled Condenser

The water-cooled condenser can be cleaned-in-place by

using the CIP procedure. Cleaning solutions can be used,

depending on type of deposits or build-up to be removed.

Do not use liquids that are corrosive to stainless

steel or the brazing material (copper or nickel). Do

not leave the unit on stand-by after cleaning.

CIP (Clean-In-Place) Procedure

1. Disconnect the unit from the water supply.

2. Drain the unit.

3 . Rinse with fresh water and drain the unit again.

4. Fill with fresh water.

5. Add cleaning agent (solution and concentration dependent on

deposits or build-up).

6. Circulate cleaning solution (if feasible).

7. Drain the cleaning solution.

8. Add and circulate a passivating liquid for corrosion inhibi-

tion of plate surfaces.

9. Drain this liquid.

10. Rinse with fresh water and drain.

11. Reconnect the water supply and fill the unit.

12 . Return to service.

4.4 Defrosting the Chamber

1. Remove all product and place it in another freezer.

2. Turn the unit off and disconnect it from the power source.

3. Turn the Alarm switch to Standby, or disconnect the battery.

4. Open all of the doors and place towels on the chamber floor.

5. Allow the frost to melt and become loose.

6. Remove the frost with a soft cloth.

7. After defrosting is complete, clean the interior with a non-

chloride detergent. Rinse thoroughly with clean water and dry

with a soft cloth.

8. Plug unit in and turn power switch on.

9. Allow the freezer to operate empty overnight before reloading

the product.

4.5 Cleaning the Door Gasket (minimum monthly*)

Using a soft cloth, remove any frost build-up from the

gasket and door(s).

*The door gasket may need to be cleaned more frequently if dirt

or excessive frost build-up prevents the door from closing prop-

erly.

4.6 Cleaning the Vacuum Relief Port (minimum monthly*)

Using a soft cloth, remove any frost build-up from the

vacuum relief, located in the front left corner of the chamber.

See Figure 1-4 and 1-5.

*The vacuum relief port may need to be cleaned more frequently

if dirt or excessive frost buildup prevents the door from closing

properly.

Avoid the excessive use of water around control

area due to the risk of electrical shock. Damage to

the controls may also result.

The vacuum relief port contains a small heating

element. If the freezer is not disconnected from the

electrical supply or turned off at the power switch,

the heating element will continue to operate and

may cause injury to personnel cleaning the freezer

chamber.

Model 923/983_________________________________________________________________________________Service

5-1

4.7 Replacing the Battery

1. Turn off the power switch and unplug the unit from the AC

power supply

2. To gain access to the battery, remove the grille on the front of

the freezer. The grille is attached to the freezer by friction

plugs on each of the four corners and is readily pulled off.

The battery is the rectangle fastened by Velcro to the com-

pressor compartment frame and has a connector with red and

black wires. Another red and black wire set with connector is

secured to the wiring harness passing through this area of the

freezer.

3. Disconnect the two wire connectors, replace the battery pack

and secure with the Velcro.

4. Reconnect the battery and replace the grille.

5. Plug unit in and turn power switch on.

4.8 Preparing the Unit for Storage

Defrost the unit as described in Section 4.4. This will

prepare the unit for storage.

Section 5 - Service

5.1 Servicing the Refrigeration System

Before opening the refrigeration system, use the trou-

bleshooting chart to check out the electrical system. Electrical

schematics and refrigeration drawings with parts are included

with this manual.

Refer to the troubleshooting chart on the following page.

For a consistent and dependable charge, replace

the battery every 2 years. Replacement batteries

must be rechargeable and are available from

Thermo Forma. Refer to the parts list for stock

number and description of the replacement batter-

ies.

Dispose of the used batteries in a safe manner and

in accordance with good environmental practices.

The battery must be disconnected to prevent the

battery from becoming completely discharged

during storage.

Servicing must only be performed

by service personnel who are

qualified to repair cascade refrig-

eration systems. Always use stan-

dard safety practices when servic-

ing the equipment.

Model 923/983________________________________________________________________________________Service

5-2

No Temperature Display • Power line cord disconnected or not properly installed

• External power circuit breaker tripped/open

• Main power switch OFF

• 24 volt transformer fuses open.

Symptom Possible Cause

Chamber Temperature Deviates from Set Point • Too much warm product added

• Door open too long

• Inadequate air circulation

• Calibration

• Dirty condenser

• High ambient temperature

Too Much Frost Build-Up • Door not properly sealed.

Freezer not Being Refrigerated (unit is receiving power) • Compressor thermal overload open

• Loss of refrigerant in either system

• Defective compressor(s)

• Defective temp control

• Defective high pressure cut-off

Display Problems in General • Defective temp control board.

Condenser Hot Light On • Clogged air filter

• Clogged condenser

• Fan failure

5.2 Troubleshooting Chart

Model 923/983____________________________________________________________________________Specifications

6-1

Section 6 - Specifications

MODEL 923/983

Temperature Range -50°C (-58°F) to -86°C (-123°F)

Exterior Dimensions 40.8" W x 77.9" H x 37.0" F-B

(103.6cm x 197.9cm x 94.0cm)

Add 3.0" (7.6cm) to W for latch/hinge; add 6.5" (16.5cm) to F-B for control panel/wall spacer.

23 cu. ft. freezer will pass through a 34.0" (86.4cm) doorway with door open and base front panel removed.

Interior Dimensions 30.6" W x 51.5" H x 25.25" F-B

(77.7cm x 130.8cm x 64.3cm)

Capacity 23 cu. ft. (651.3 liters)

Refrigeration Cascade system, (2) hermetically-sealed compressors

Insulation Non-CFC, foamed-in-place urethane;

5.0" (12.7cm) sides; 4.5" (11.4cm) door

Electrical 923, 983

230VAC, 1 PH, 50/60 Hz, 12.0 FLA

Operating Range: 208VAC - 240VAC

Breaker 923, 983: 15 Amp, 230V

Requirements

Automatic Voltage Low:

Cut In: 210V Cut Out: 220V Volts Boost: 18

High:

Cut In: 235V Cut Out: 225V Volts Buck: 18

Shipping Weight Ocean: 1140 lbs. (517.1 kg)

Air/Container: 880 lbs. (399.2 kg)

Motor: 880 lbs. (399.2 kg)

Model 923/983________________________________________________________________________________Specifications

6-2

Thermo Forma - Representative Pulldown and Cycling Curve

-95

-90

-85

-80

-75

-70

-65

-60

-55

-50

-45

-40

-35

-30

-25

-20

-15

-10

-5

0

5

10

15

20

0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180 190 200 210 220 230

Time (5 minute intervals)

Temperature (°C)

Sample Chart

for 23 Ft. -86°C Freezers

3

23ft3-86.xls 2/02

7-1

Model 923/983______________________________________________________________________________Parts List

This manual suits for next models

1

Table of contents

Other Thermo Forma Laboratory Equipment manuals

Thermo Forma

Thermo Forma Cryomed 1010 Operating instructions

Thermo Forma

Thermo Forma 3940 Operating instructions

Thermo Forma

Thermo Forma 1284 Operating instructions

Thermo Forma

Thermo Forma 3911 Operating instructions

Thermo Forma

Thermo Forma 3920 Operating instructions

Thermo Forma

Thermo Forma 1200 Series Operating instructions