Thermo Forma 1200 Series Operating instructions

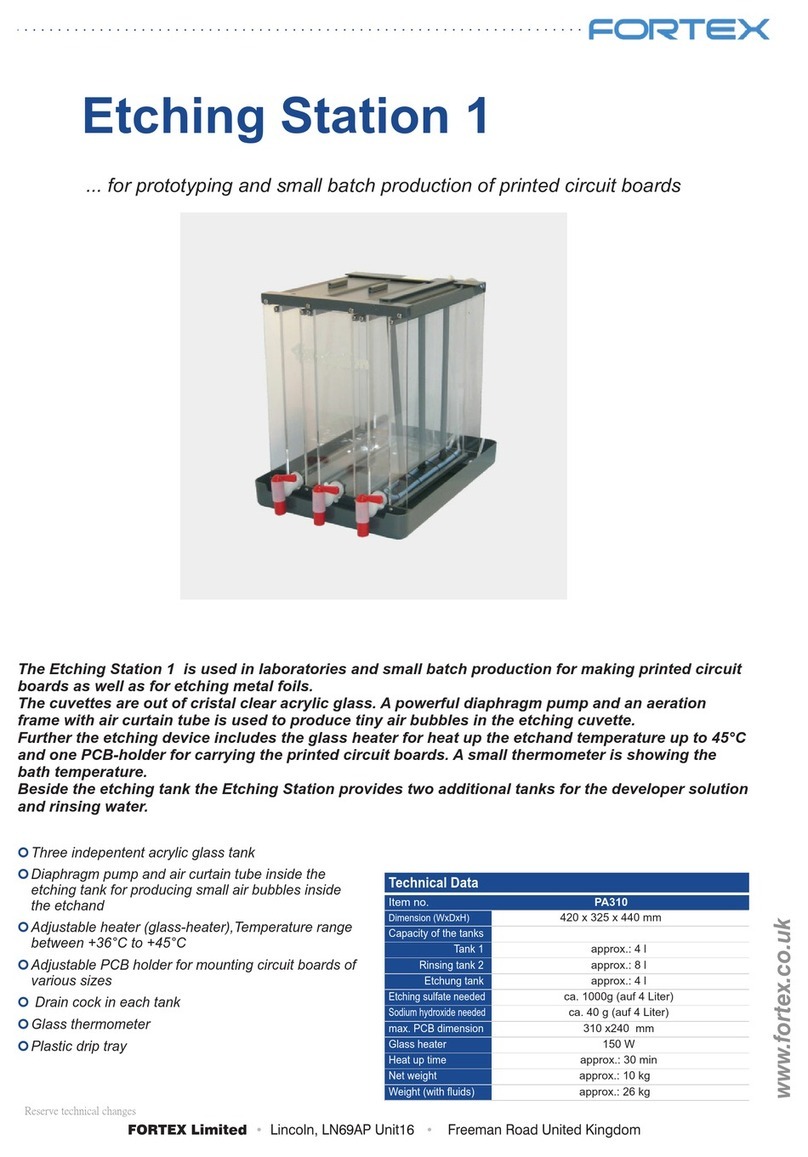

Models:

1200 Series*

4 foot and 6 foot Biological Safety Cabinets

Class II, Type A

Operating and Maintenance Manual

Manual No: 7011200 Rev. 6

*Refer to listing of all models on Page i.

Model 1200 Series ___________________________________________________________________________

i

Read This Instruction Manual.

Failure to read, understand and follow the instructions in

this manual may result in damage to the unit, injury to operat-

ing personnel, and poor equipment performance.

CAUTION! All internal adjustments and maintenance must

be performed by qualified service personnel.

Refer to the serial tag on the back of this manual.

The material in this manual is for information purposes

only. The contents and the product it describes are subject to

change without notice. Thermo Forma makes no representations

or warranties with respect to this manual. In no event shall

Thermo Forma be held liable for any damages, direct or inciden-

tal, arising out of or related to the use of this manual.

MANUAL NUMBER 7011200

-- 21077/HD-1376 9/19/02 Removed certifiers list, added reference to website ccs

6 -- 8/11/00 Quark format ccs

5 19029/HD-1295 6/15/00 Clarified receptacle amps on schematics ccs

4 18739/HD-1284 2/24/00 Added rear plumbing connections ccs

- 18826/HD-1286 -- Added mercury warning for Vermont ccs

REV ECR/ECN DATE DESCRIPTION By

4-Foot Models

Model No. Window Style Electrical Data

1200 Slide 115V, 60Hz

1201 Slide 230V, 50Hz

1206 Hinge 115V, 60Hz

1220 Slide 100V, 50Hz

6-Foot Models

Model No. Window Style Electrical Data

1205 Slide 230V, 50Hz

1210 Hinge 115V, 60Hz

1214 Slide 115V, 60Hz

1230 Slide 100V, 50Hz

Contains Parts and Assemblies

Susceptible to Damage by

Electrostatic Discharge (ESD)

CAUTION

Model 1200 Series ___________________________________________________________________________

ii

Alerts the user to important operating and/or maintenance instructions. May be used alone or with other safety sym-

bols. Read the accompanying text carefully.

Potential electrical hazards. Only qualified persons should perform the instructions and procedures associated with

this symbol.

Hazard. Do not touch. Instructions associated with this symbol should only be carried out when using special hand-

ing equipment or when wearing special, protective clothing.

Potential biological hazards. Proper protective equipment and procedures must be used when following instructions

associated with this symbol. Reference O.S.H.A. Regulation 1910-1030.

Potentially hazardous energy. Equipment being maintained or serviced must be turned off and locked off to prevent

possible injury. Reference O.S.H.A. Regulation 1910-147.

Hot surface(s) present which may cause burns to unprotected skin or to materials which may be damaged by elevated

temperatures

Warning. Skin damage and/or eye injury can result from the light produced by ultra violet light sources installed in

this equipment. Never work in this unit with the ultra violet light operating.

* Always use the proper protective equipment (clothing, gloves, goggles etc.).

* Always dissipate extreme cold or heat, or wear protective clothing.

* Always follow good hygiene practices.

* Each individual is responsible for his/her own safety.

Model 1200 Series ___________________________________________________________________________

iii

Model 1200 Series ___________________________________________________________________________

iv

Table of Contents

Section 1 - Installation . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 1

1.1 Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 1

1.2 Leveling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 1

1.3 Power Connection . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 1

1.4 Plumbing Connection . . . . . . . . . . . . . . . . . . . . . . . .1 - 1

1.5 Exhaust System Connections . . . . . . . . . . . . . . . . . . .1 - 1

a. Canopy (thimble) Connection . . . . . . . . . . . . . . . .1 - 1

1.6 Exhaust Requirements . . . . . . . . . . . . . . . . . . . . . . . .1 - 1

a. Direct Room Exhaust . . . . . . . . . . . . . . . . . . . . . .1 - 1

b. External Exhaust System . . . . . . . . . . . . . . . . . . .1 - 1

c. Duct Connection . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 2

d. Optional Thermo Forma Exhaust Transitions . . . .1 - 2

e. Nominal Exhaust Requirements - 4 foot models .1 - 2

f. Nominal Exhaust Requirements - 6 foot models .1 - 2

Section 2 - Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 1

2.1 General Recommendations . . . . . . . . . . . . . . . . . . . .2 - 1

2.2 Using Auxiliary Equipment in the Cabinet . . . . . . . .2 - 1

2.3 Cabinet Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 1

2.4 Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 1

2.5 Cabinet Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 1

2.6 Control and Indicating Devices . . . . . . . . . . . . . . . . .2 - 2

Section 3 - Certification Testing Procedures . . . . . . . . . . .4 - 1

3.1 Certification of the Cabinet . . . . . . . . . . . . . . . . . . . .4 - 1

a. On-site Certification . . . . . . . . . . . . . . . . . . . . . . . .4 - 1

Section 4 - Routine Maintenance . . . . . . . . . . . . . . . . . . .4 - 1

4.1 Checking the Static Pressure Gauge “Zero” . . . . . . .4 - 1

4.2 Measuring Blower Motor Voltage . . . . . . . . . . . . . . .4 - 1

Section 5 - Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 1

5.1 Replacing the Exhaust HEPA Filter . . . . . . . . . . . . . .5 - 1

5.2 Replacing the Supply HEPA Filter . . . . . . . . . . . . . .5 - 1

5.3 Adjusting the Damper . . . . . . . . . . . . . . . . . . . . . . . .5 - 1

5.4 Replacing the Blower and/or Motor . . . . . . . . . . . . .5 - 1

5.5 Replacing the Blower Speed Control . . . . . . . . . . . .6 - 1

Section 6 - Troubleshooting . . . . . . . . . . . . . . . . . . . . . . .6 - 1

6.1 Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . .6 - 1

Section 7 - Specifications . . . . . . . . . . . . . . . . . . . . . . . . .7 - 1

Section 8 - Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . .8 - 1

Section 9 - Electrical Schematics . . . . . . . . . . . . . . . . . . .9 - 1

Section 1 - Installation

(Refer to illustrations at the end of this section)

1.1 Location

Locate the cabinet on a level surface in an area of mini-

mum temperature change. The cabinet should be placed away

from personnel traffic, air-conditioning or heating ductwork,

and/or laboratory windows and doors. Proper cabinet location is

essential as drafts can disrupt critical air flow characteristics

and allow room contaminants to enter or escape the cabinet

work area.

If space permits, twelve inches should be clear on each

side of the cabinet for maintenance and best cabinet perform-

ance. A twelve inch space should also exist from the top of the

cabinet to the ceiling.

1.2 Leveling

Place a bubble-type level on the work surface and check to

see if the cabinet is level. Adjust the leveling feet until the cabi-

net is level and the most comfortable working height is

achieved. Make sure that all four leveling feet are fully flush

against the floor to prevent vibration.

1.3 Power Connection

Refer to the electrical schematics in the back of this manu-

al or to the electrical data plate mounted on the unit.

1.4 Plumbing Connection

Two petcocks are piped on each side of the cabinet work

area and are connected to 3/8” FPT couplings in the inner side-

walls. An optional third plumbed line may also be added to the

cabinet.

Access to all internal couplings is through one-inch,

plugged access holes in each side panel and both sides of the

back panel of the cabinet.

It is not recommended that flammable gases be

used in the cabinet. Observe all labels pertaining

to restrictions and operating pressures.

1.5 Exhaust System Connections

a. Canopy (thimble) Connection

Per NSF Standard, NSF 49-1992, Page E2:

“When a canopy (thimble) is used, the opening in the

canopy should be checked with a smoke stick when the cabinet

is recertified to ensure that internal air turbulence does not

cause outward air leakage. If the type A cabinet is hard connect-

ed to an exhaust system, the cabinet should be interlocked with

the blower in the duct or the building system to prevent pres-

surization of the exhaust system. In addition, type A cabinets

hard connected to an exhaust system should not be turned off

while the exhaust system is functioning.”

It is also recommended that the building exhaust system

should be sized to exhaust 30% more air than the cabinet

exhausts, the balance to be made up with room air. This will

help to insure proper cabinet air balance at the front access

opening and thus adequate containment.

1.6 Exhaust Requirements

Filtered air from the cabinet may be exhausted directly into

the room or, if safety requires, be vented to the atmosphere

through an external exhaust system.

a. Direct Room Exhaust

When directing exhaust air into the room, adequate space

must be provided between the cabinet and the ceiling to allow

discharged air to flow freely.

1. Remove the cardboard cover plate from the top of the

unit.

2. Remove the cap nuts and washers (located on top of

unit, installed at factory) that will secure the exhaust fil-

ter grille.

3. Install the exhaust filter grille.

b. External Exhaust System

When an external exhaust is required, the cabinet must be

connected to a dedicated exhaust system. The exhaust system

should be prepared before moving the cabinet to its location.

The exhaust system should have safeguards

against exhaust failure. It is recommended that a

bio safety officer or industrial hygienist review

the agents and chemicals used within the cabinet

to determine if additional filtration treatment is

necessary before venting to the atmosphere.

Model 1200 Series _____________________________________________________________________Installation

1 - 1

c. Duct Connection

The connection at the duct measures 8” in diameter.

d. Optional Thermo Forma Exhaust Transitions

With Damper Order Number

Thimble 191478

Airtight 191478

e. Nominal Exhaust Requirements - 4 foot models

Nominal 258 CFM Direct Method

Nominal 335 CFM Direct Method when sizing to exhaust

30% more air (than the cabinet exhausts)

Nominal 291 CFM Calculated Method

Nominal 378 CFM Calculated Method when sizing to

exhaust 30% more air (than the cabinet exhausts)

f. Nominal Exhaust Requirements - 6 foot models

Nominal 417 CFM Direct Method

Nominal 542 CFM Direct Method when sizing to exhaust

30% more air (than the cabinet exhausts)

Nominal 412 CFM Calculated Method

Nominal 536 CFM Calculated Method when sizing to

exhaust 30% more air (than the cabinet exhausts)

Model 1200 Series _____________________________________________________________________Installation

1 - 2

Model 1200 Series _____________________________________________________________________Installation

1 - 3

Figure 1-1

Model 1200 Front View

Model 1200 Series _____________________________________________________________________Installation

1 - 4

Figure 1-2

Model 1200 Side View

Model 1200 Series _____________________________________________________________________Installation

1 - 5

Figure 1-3

Model 1214 Front View

1 - 6

Model 1200 Series ______________________________________________________________________________Installation

Figure 1-4

Model 1214 Side View

Model 1200 Series _____________________________________________________________________Installation

1 - 7

Figure 1-5

Section 2 - Operation

2.1 General Recommendations

• Keep the activity in the room to a minimum when the cabi-

net is in use.

• Keep all laboratory doors closed to prevent drafts that will

disturb critical air flow characteristics.

• Pre-plan cabinet use, and place everything required in the

cabinet so that nothing passes through the air barrier (in or

out) during the procedure.

• Segregate clean and dirty materials.

• Do not place anything on the intake or exhaust grilles.

• Wear long sleeves and surgical gloves when working in the

cabinet.

• Practice good aseptic technique to insure safe use of the

cabinet.

• Cover discarded pipettes before removing them from the

cabinet.

• If a spill occurs, clean it up immediately. Decontaminate

the work area and all affected equipment.

2.2 Using Auxiliary Equipment in the Cabinet

Any appliance used in the work area will cause turbulence

and disturb the air flow. Therefore, any auxiliary equipment

should be placed at the rear of the work space where air turbu-

lence will have a minimal effect.

The duplex electrical receptacles on the sides of the work

area are protected by 7 Amp, 250 Volt time-delay fuses.

Plugging devices drawing 5 amps or more into these recepta-

cles may exceed the fuse limits.

2.3 Cabinet Check

1. Verify that the drain valve is closed (handle in a hori-

zontal position), so that if a spill should occur on the

work surface, it will remain in the drain system and not

drain onto the laboratory floor.

2. Verify that the service petcocks are closed (handles in a

horizontal position).

3. Check the supply and exhaust filters for leaks. See

Section 3.

2.4 Start-Up

1. Turn on the lights.

On cabinets equipped with ultra violet lights, the

lights must be turned off when working in the

unit. Potential eye damage may result from view-

ing the light produced by these ultra violet

sources.

2. Check the intake and exhaust grilles to ensure that they

are not blocked.

3. Turn on the blower to purge the work area of contami-

nated air. When the proper air flow balance has been

attained, record the reading shown on the static pressure

gauge. This reading will serve as a base line indication

of subsequent air filter loading. When the reading has

increased by about 50%, re-check the air flow balance.

Filter replacement may be required.

4. Wash your hands and lower arms with germicidal deter-

gent.

5. Disinfect the entire work area.

6. Place everything needed in the cabinet.

7. Do not block the intake or exhaust grilles.

8. Place everything at least 4” (10.2 cm) inside the work

area.

9. Segregate clean and contaminated items.

10. On sliding window models, position the viewing win-

dow at 10” height.

2.5 Cabinet Shutdown

Do not use strong alkaline or caustic agents.

Stainless steel is corrosion-resistant, not corro-

sion-proof. Do not use solutions of sodium

hypochlorite (bleach) as they may also cause pit-

ting and rusting.

1. Decontaminate all surfaces with the appropriate disin-

fectant, and/or enclose all equipment that has been in

direct contact with the research agent.

2. Cover trays of discarded pipettes and glassware.

3. Allow the cabinet to run for at least thirty minutes with

no activity to allow time for all airborne contaminants to

be purged from the work area.

4. Remove all equipment.

5. Wipe down all interior surfaces with a disinfectant

appropriate to the work performed.

6. If the drain system has been used, thoroughly flush it

with a disinfectant solution, then rinse it with water.

Model 1200 Series ___________________________________________________________________Operation

2 - 1

2.6 Control and Indicating Devices

(Refer to the illustrations at the end of Section 1)

•Blower Switch - The blower switch controls the on/off

power to the blower.

•Light Switch - The light switch controls power to the fluo-

rescent lamps in the work area or the optional ultra-violet

lamp.

•Ultra-Violet Light (Optional) - Cabinets may be equipped

with an ultra-violet germicidal light as optional equipment.

These lamps lose their effectiveness over a period of time

and should be replaced when intensity drops below the

optimum level (approximately every six months).

Eyes or skin should not be exposed

to ultra-violet light. (Refer to Section

4.24.2 of NSF International

Standard, NSF 49-1992.)

Recommended usage is only when

the lab is not in use.

•Static Pressure Gauge (In. W.G.) - The static pressure

gauge, located on the control panel, measures the air pres-

sure differential across the filters, providing an indication

of filter “loading”. As the filters become loaded, the resist-

ance to air passage increases, and the reading on the static

pressure gauge increases accordingly. When the reading

increases by 50% from the original measurement, cabinet

airflow should be checked with a thermoanemometer, by a

qualified service technician. The filters must be replaced if

proper airflow cannot be obtained.

The static pressure gauge must never be used as a

direct measure of air flow.

•Blower Speed Control -

The blower speed control,

located on the printed circuit

control board, is used to

adjust the air velocity from

the blower motor (refer to

Figure 2-2.) A clockwise turn

of the screw adjustment (as

viewed from the top of the

control panel) will increase

air velocity.

Note: Blower speed is set at the

factory and should only be

changed by a qualified techni-

cian.

•Reset Button - The Reset button is an in-line circuit break-

er. If an overload condition occurs, the circuit breaker trips

and the button protrudes from the panel. Depress the button

to reset the circuit breaker.

•Receptacle Fuses - (2) 7A 250 volt time-delay fuses pro-

tect the two electrical outlets inside the work area. Do not

exceed 5 amp maximum load total on receptacles.

•Electrical Outlets - (2) duplex 115 Volt (5 amp total)

receptacle are located on the left and right side walls of the

work area on all cabinets except Models 1201 and 1205.

•Drain Valve - The drain valve, located on the right front

side of the cabinet, provides for the safe drainage of the

drain pan in the event of a major spill. This valve should

always remain closed while work is being performed in the

cabinet.

If an accidental spill occurs, immedi-

ately consult a biological safety offi-

cer or other qualified individuals for

proper procedures. To insure proper

containment of a spill, connect a

sealed hose from the valve to a

sealed container.

•Service Petcocks - Two petcock valves are standard with

each cabinet. These valves are located on the right and left

side of the work station and may be identified with the type

of service they supply.

•Exhaust Filter Guard - The exhaust filter guard, located

on top of the exhaust filter, prevents the storage of objects

on the housing and helps protect exhaust air flow.

•Sliding Window Alarm - The cabinet’s sliding window

permits the user to place auxiliary equipment and research

implements in the work area. The work opening must be

held to 10 inches during work procedures. If the sliding

window is raised higher than the designated 10 inches, the

air barrier at the front of the cabinet will be weakened and

containment will be seriously impaired. When this occurs,

an audible alarm will sound and a warning light will signal

the unsafe condition.

Model 1200 Series ___________________________________________________________________Operation

2 - 2

Figure 2-2

•Alarm By-Pass Switch - For loading and unloading the

work area, an alarm by-pass switch is located in the light

canopy which de-activates the alarm for about 5 minutes.

This by-pass is for operator convenience only and must not

be used when working inside the unit.

Do not disconnect, disable, or silence the audible

window alarm. The alarm is intended to draw

attention to an unsafe operating condition and is

installed for the operator’s protection.

•Removable Vortex Channels - The stainless steel vortex

channels located on either side of the work area are remov-

able for cleaning (Figures 2-3 and 2-4.) These air-directing

devices must be in place for proper cabinet operation.

Model 1200 Series ___________________________________________________________________Operation

2 - 3

removable vortex

channels

Figure 2-4

Figure 2-3

Section 3 - Certification Testing Procedures

A list of certification companies is included on the Thermo

Forma website, or call the Services deparment. See Page iii.

3.1 Certification of the Cabinet

Certification is recommended:

• Annually

• If the cabinet is moved

• After replacing the HEPA filter(s)

• After service work has been performed inside cabinet

a. On-Site Certification

Due to the stress of shipping and handling and the fragile

nature of the HEPA filters, the cabinet must be thoroughly test-

ed when it has been placed in its final location. The following

tests should be performed:

• HEPA Filter Leak Test (DOP Test)

• Downflow Velocity Profile Test

• Face Velocity Air Flow Test

• Voltage Test

These tests must be performed by qualified service special-

ists who are familiar with the methods and procedures of certi-

fying biological safety cabinets.

The certification should be performed upon installation,

annually thereafter, after filter changes, and after cabinet reloca-

tion.

Note: Unless this certification was expressly called for in the

specification, quotes and/or purchase order, the cost for this on-

site testing is to be paid for by the customer.

Section 4 - Routine Maintenance

4.1 Checking the Static Pressure Gauge “Zero”

In order to provide an accurate reading, the indicating nee-

dle of the static pressure gauge should be precisely at zero

when the cabinet is completely shut off. If the cabinet is con-

nected to a central exhaust system, the exhaust system must

also be shut off.

After replacing the HEPA filter, the static pressure gauge

should be checked for proper zeroing when the cabinet is shut

off. When the cabinet is started up and the proper airflow bal-

ance has been attained, take a reading on the gauge and record

it. This initial reading will serve as a baseline indication of sub-

sequent filter loading. when the reading increases by about

50%, re-check the airflow balance. Filter replacement may be

required.

4.2 Measuring Blower Motor Voltage (qualified per-

sons only!)

Both blower motor voltage and line voltage are measured

at the three terminal connectors at the top of the circuit board.

Refer to Figure 4-1.

Live voltage is present on the control

terminals of the switches and dials on

the front of the blower panel. Use

extreme care to avoid touching these

controls when reaching into the

drawer and making any adjustments.

Figure 4-1

Model 1200 Series _____________________________________________________________Routine Maintenance

4 - 1

Section 5 - Service

Service to the unit must be performed by qualified

personnel. The cabinet should then be recertified.

Before service is performed or any

filter replaced, the unit must be

decontaminated!

5.1 Replacing the Exhaust HEPA Filter

Access to the exhaust HEPA filter is through the Exhaust

Housing Access Panel on the front of the cabinet, or, if possi-

ble, from the top of the exhaust housing. (Refer to Figure 1-1.)

1. Remove the screws securing the front dress and access

panels, and remove the panels.

2. Loosen and remove the front filter clamps.

3. Loosen the rear filter clamps.

4. Remove the filter and dispose of it per established lab

procedures. Consult a bio-safety officer or other appro-

priate party, as needed.

5. Clean the filter seat.

6. Place the new filter in its correct position and verify that

it is properly seated on the flange.

7. Replace the filter clamps, and tighten them alternately a

few threads at a time to ensure an even seal around the

filter. Do not overtighten.

8. After filter replacement, recertify the cabinet.

5.2 Replacing the Supply HEPA Filter

Access to the supply HEPA filter is through the Supply

Housing Access Panel on the front of the cabinet above the

work chamber. (Refer to Figure 1-1.)

1. Remove the screws securing supply filter dress panels.

2. Remove the front access panel.

3. Loosen and remove the filter clamps.

4. Remove the filter and dispose of it per established lab

procedures. Consult a bio-safety officer or other appro-

priate party, as needed.

5. Clean the filter flange.

6. Place the new filter in its correct position and verify that

it is properly seated on the flange.

7. Replace the filter clamps, and tighten them alternately a

few threads at a time to ensure an even seal around the

filter. Do not overtighten.

8. After filter replacement, recertify the cabinet.

5.3 Adjusting the Damper

Since the HEPA filter resistance may vary considerably

from filter to filter (even filters of the same size), a damper has

been installed in the cabinet exhaust system for maintaining

proper airflow balance. The damper regulates the exhaust air to

maintain the proper intake and exhaust velocities. The damper

is set at the factory and should not be adjusted unless the proper

velocities cannot be attained.

1. The damper adjustment is located in the center of the

front of the cabinet.

2. Remove the Damper Adjustment Access Cap with a flat-

blade screwdriver. (Figure 1-1.)

3. Using the flatblade screwdriver, turn the adjustment

clockwise to close the damper and decrease the exhaust,

or turn the adjustment counterclockwise to open the

damper and increase the exhaust.

5.4 Replacing the Blower and/or Motor

Disconnect the unit from the power source before

starting procedure.

Access to the blower is through the blower housing access

panel at the bottom of the cabinet under the work area. (Refer

to Figure 1-1)

1. Remove the dress panel and the screws that secure the

blower housing access panel to the cabinet, and remove

the panel. (Refer to Figure 3-1.)

2. Loosen the set bolt on the blower hub from inside the

left side of the scroll.

3. Remove the four bolts and washers securing the motor

to the scroll on the right side of the blower assembly.

4. Disconnect the wiring.

5. Remove the blower motor, and replace it with the new

motor. Align the blower wheel, and tighten.

6. Reconnect the wiring.

7. Replace the blower housing access panel on the front of

the cabinet, and tighten all the screws.

8. After replacement of the blower/motor, the cabinet must

be recertified.

Model 1200 Series _________________________________________________________________________Service

5 - 1

5.5 Replacing the Blower Speed Control

Turn the unit off and unplug it before continuing.

The blower speed control may be replaced without decont-

aminating the cabinet.

1. Remove the two screws that secure the control panel.

2. Pull out the control panel, and locate the blower speed

control on the right side of the control box.

3. Disconnect the wiring to the control, and make note of

the wiring configuration.

4. Remove the speed control from the inside of the control

box.

5. Install the new blower speed control by reversing the

above procedure.

Note: After replacing the blower speed control, the cabinet

must be recertified.

Section 6 - Troubleshooting

6.1 Troubleshooting Guide

Before service is to be performed on the cabinet,

the cabinet must first be decontaminated.

Servicing of the unit must be performed by quali-

fied service personnel only.

Problem: Air flow in the cabinet work area and through the

exhaust filter is inadequate.

Possible Causes:

1. Exhaust filter is blocked by laboratory materials or the

protective shipping cover.

2. If the biological safety cabinet is connected to an

exhaust system, inadequate exhaust may exist. The sys-

tem must then be rebalanced to handle the correct air

volume. Consult with building maintenance engineers.

3. Low electrical voltage to the blower motor.

4. Blower motor or speed control is defective.

5. If the static pressure gauge reading has increased

approximately 50% from its initial readings, the filter

has likely loaded with dirt and the speed control must be

adjusted. If proper airflows cannot be reached by adjust-

ing the speed control, decontaminate the cabinet and

replace all HEPA filters.

Problem: Ultra violet light malfunction

Possible Causes:

1. Verify that the lamp is properly installed into the fixture.

2. Starter for U/V light defective. Locate starter on far right

side of U/V light and remove by twisting counter-clock-

wise. Replace starter.

Problem: Fluorescent light malfunction

Possible Causes:

1. Verify that the lamp is properly installed into the fixture.

Problem: Non-functioning static pressure gauge

Possible Causes:

1. Verify that the hose is tightly attached to a high pressure

port of the gauge and to the cabinet (front top right of

the service box). If properly tightened, the static pres-

sure gauge is likely defective and should be replaced.

Problem: Loud screeching noise

Possible Causes:

1. Bad bearings in the motor blower unit.

2. Blower scroll rubbing against housing.

Model 1200 Series _________________________________________________________________Troubleshooting

6 - 1

Model 1200 Series ___________________________________________________________________Specifications

7 - 1

Section 7 - Specifications

All Model 1200 Series units use a 3/4 HP motor.

Model 1200

Console Size/Window 4 foot/Sliding

Work Area Dimensions 46.5”W x 25.3”H x 25.0”F-B

(118.1 x 64.3 x 63.5cm)

Exterior Dimensions 51.5”W x 79.1”H x 34.5”F-B**

(130.8 x 200.9 x 87.6cm)

Electrical 115V, 60Hz, 15 FLA

Breaker Required 20 Amps

Shipping weight 730 lbs. (331kg)

Model 1201

Console Size/Window 4 foot/Sliding

Work Area Dimensions 46.5”W x 25.3”H x 25.0”F-B

(118.1 x 64.3 x 63.5cm)

Exterior Dimensions 51.5”W x 79.1”H x 34.5”F-B**

(130.8 x 200.9 x 87.6cm)

Electrical 230V, 50Hz, 10 FLA

Breaker Required 15 Amps

Shipping weight 730 lbs. (331kg)

Model 1206

Console Size/Window 4 foot/Hinged

Work Area Dimensions 46.5”W x 25.3”H x 25.0”F-B

(118.1 x 64.3 x 63.5cm)

Exterior Dimensions 51.5”W x 79.1”H x 34.5”F-B**

(130.8 x 200.9 x 87.6cm)

Electrical 115V, 60Hz, 15 FLA

Breaker Required 20 Amps

Shipping weight 730 lbs. (331kg)

Model 1220

Console Size/Window 4 foot/Sliding

Work Area Dimensions 46.5”W x 25.3”H x 25.0”F-B

(118.1 x 64.3 x 63.5cm)

Exterior Dimensions 51.5”W x 79.1”H x 34.5”F-B**

(130.8 x 200.9 x 87.6cm)

Electrical 100V, 50Hz, 14 FLA

Breaker Required 20 Amps

Shipping weight 730 lbs. (331kg)

Model 1205

Console Size/Window 6 foot/Sliding

Work Area Dimensions 70.5”W x 25.3”H x 25.0”F-B

(179.1 x 64.3 x 63.5cm)

Exterior Dimensions 75.5”W x 79.1”H x 34.5”F-B**

(191.8 x 200.9 x 87.6cm)

Electrical 230V, 50Hz, 11.5 FLA

Breaker Required 15 Amps

Shipping weight 940 lbs. (426.4kg)

Model 1214

Console Size/Window 6 foot/Sliding

Work Area Dimensions 70.5”W x 25.3”H x 25.0”F-B

(179.1 x 64.3 x 63.5cm)

Exterior Dimensions 75.5”W x 79.1”H x 34.5”F-B**

(191.8 x 200.9 x 87.6cm)

Electrical 115V, 60Hz, 16 FLA

Breaker Required 20 Amps

Shipping weight 950 lbs. (430.9kg)

Model 1210

Console Size/Window 6 foot/Hinged

Work Area Dimensions 70.5”W x 25.3”H x 25.0”F-B

(179.1 x 64.3 x 63.5cm)

Exterior Dimensions 75.5”W x 79.1”H x 34.5”F-B**

(191.8 x 200.9 x 87.6cm)

Electrical 115V, 60Hz, 16 FLA

Breaker Required 20 Amps

Shipping weight 940 lbs. (426.4kg)

Model 1230

Console Size/Window 6 foot/Sliding

Work Area Dimensions 70.5”W x 25.3”H x 25.0”F-B

(179.1 x 64.3 x 63.5cm)

Exterior Dimensions 75.5”W x 79.1”H x 34.5”F-B**

(191.8 x 200.9 x 87.6cm)

Electrical 100V, 50Hz, 15 FLA

Breaker Required 20 Amps

Shipping weight 940 lbs. (426.4kg)

*Height reflects cabinet with feet in minimum position. An

additional 3.0” must be added to total height for exhaust grille.

**Deduct 3.5” for light canopy.

Model 1200 Series _____________________________________________________________________Spare Parts

Section 8 - Spare Parts

Stock # Description

230182 Fuse, 7A 250V Time Delay

105051 Glass, Clear Laminated Safety,

for 4-foot sliding window

105054 Glass, Clear Laminated Safety,

for 6-foot sliding window

105052 Glass, Clear Laminated Safety,

for 4-foot hinged window

105055 Glass, Clear Laminated Safety,

for 6-foot hinged window

129025 Pneumatic Spring, 60#, for hinged window

(2 per window)

156106 Motor, 3/4 HP

170090 Run Capacitor, Motor

225250 Ballast, Fluorescent Lamp

500009 Ballast, UV Lamp F30T8

360146 Rocker Switch, DPST

500006 Starter, UV Lamp

141024 Lamp, Fluorescent, F42T12/CW/HO (4-foot )

141025 Lamp, Fluorescent, F64T12/CW/HO (6-foot)

104008 Gauge, MAG

360106 Switch, Micro-Door Warning

760021* Filter, Supply HEPA, 24 x 48 x 5-7/8

(4-foot), Donaldson part #AB045629300,

Pressure Range: 0.60”- 0.90” at 1000 cfm,

filter pressure drop range tested per

IES-RP-CC001.3

760070* Filter, Supply HEPA, 24 x 72 x 5-7/8

(6-foot), Donaldson part #AB045629500,

Pressure Range: 0.40”- 0.60” at 1000 cfm,

filter pressure drop range tested per

IES-RP-CC001.3

760059* Filter, Exhaust HEPA, 24 x 24 x 5-7/8

(4-foot), Donaldson part #AB045629000,

Pressure Range: 0.60”- 0.90” at 525 cfm,

filter pressure drop range tested per

IES-RP-CC001.3

760166* Filter, Exhaust HEPA, 24 x 36 x 5-7/8

(6-foot), Donaldson part #P196848-AAK,

Pressure Range: 0.45”- 0.66” at 805 cfm,

filter pressure drop range tested per

IES-RP- CC001.3

249013 Index Button, “AIR”, Orange

249014 Index Button, “VAC”, Yellow

249016 Index Button, “GAS”, Blue

249017 Index Button, “NITROGEN”, Black

190396 Motor Speed Control

141014 UV Lamp

* See following pressure drop conversion formula

*Filter Pressure Drop Conversion

Pressure drop across a HEPA filter is linear, which allows

accurate prediction of the pressure drop at various CFM,

if given a starting value. It is a straight proportion from

one setting to the other.

Example:

A filter rating of 0.31” of water at 352 CFM needs to be

converted to 530 CFM.

The formula is as follows:

0.31 = x

352 530

Solving for x (the needed pressure drop at 530 CFM)

x =(0.31)*530

352

x =0.47” of water (rounded)

4/10/97

8 - 1

This manual suits for next models

7

Table of contents

Other Thermo Forma Laboratory Equipment manuals

Thermo Forma

Thermo Forma 3911 Operating instructions

Thermo Forma

Thermo Forma 3940 Operating instructions

Thermo Forma

Thermo Forma 1284 Operating instructions

Thermo Forma

Thermo Forma 923 Operating instructions

Thermo Forma

Thermo Forma Cryomed 1010 Operating instructions

Thermo Forma

Thermo Forma 3920 Operating instructions

Popular Laboratory Equipment manuals by other brands

Witeg

Witeg Wisd HG-15D operating manual

Thermo Scientific

Thermo Scientific HM 450 instruction manual

erlab

erlab Captair 834 Smart Assembly instructions

IKA

IKA LR-2.ST operating instructions

VERDER

VERDER Carbolite Gero HT 5/220 Installation, operation and maintenance instructions

Powerfiller

Powerfiller Powermax 3+ user manual