Hints

a. When pipetting serum or other biological fluids, a liquid film may be retained in the tip that

may change the pipetted volume. Pre-wetting the tip with the liquid to be pipetted can

reduce this effect.

b. Smoothly depress and release the plunger and maintain the same speed of action for all

samples. Do not let the plunger snap back.

c. Fully depress the plunger before inserting the pipette tip into a solution. This will prevent

an air bubble from forming in the solution.

d. Hold the pipette as vertically as possible at all times. Insert the tip to the same depth

each time.

e. If an air bubble forms in the tip during intake, return the sample, discard the tip and apply

a fresh tip.

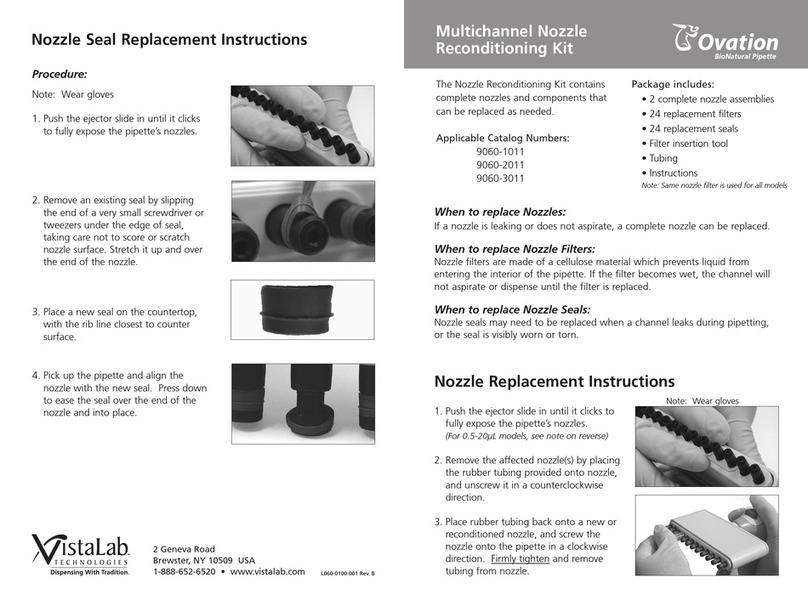

f. Remove and clean the nozzle insert daily. Replace the nozzle insert if necessary.

g. Check that the nozzle assembly is screwed firmly into the pipette body.

Calibration

Calibration is accomplished by adjusting the plunger shaft. Digital Pipettes are factory calibrat-

ed at three settings across the pipetting range. Factory tests and calibration are performed

at 21.5 ± 2oC using distilled water. To change calibration proceed as follows:

a. Determine the pipette delivered volume by testing the pipette at the lowest volume setting.

NOTE: Gravimetric or colorimetric techniques may be used to determine the pipette

delivered volume. A procedure for the gravimetric method, or information about a

MLA Pipette Calibration Kit using a color dilution principle, can be obtained from the

Technical Service Department.

b. While holding the plunger between the thumb and forefinger, unscrew and remove the

plunger cap by rotating it in a counterclockwise direction. The plunger can be extended

for easier holding by increasing the digital display to a higher volume.

c. Allow plunger cover to drop down to release the plunger gear shaft.

d. With a small bladed straight slot screwdriver or fingers, rotate the plunger shaft clockwise

to decrease the volume and counterwise to increase the volume.

e. The approximate change in volume for a 1/2 turn is 2.5µL for the 10-50µL, 5µL for the

50-200µL and 25µL for the 200-1000µL Digital Pipette.

f. Pull the plunger cover up and re-engage plunger gear shaft. Hold the plunger cover up

and replace the plunger cap.

g. Retest the pipette volume delivery at the low setting.

h. Test the pipette at mid and high settings.

If further adjustments are required, return the pipette to the low volume setting and adjust

plunger shaft as needed. Retest the pipette volume delivery at the low setting before continu-

ing to the mid and high settings. Ensure that each setting is within the acceptable volume

range. For specifications, see Specifications Table.

Maintenance

During factory assembly, the internal parts of the pipette (plunger, seals, etc.) are lubricated

with grease. Unless the pipette is used with corrosive chemicals or solvents, routine cleaning

and lubrication should only be necessary at 6 month intervals. Lubrication is necessary if the

plunger movement is rough or does not return to the “up”position.

The nozzle and the nozzle insert in particular should be cleaned regularly. In case of acci-

dental sample aspiration the nozzle assembly and insert should be cleaned immediately.

Cleaning should be done with a lint-free cloth dampened with alcohol. Refer to Figure 2 for

nozzle insert removal.

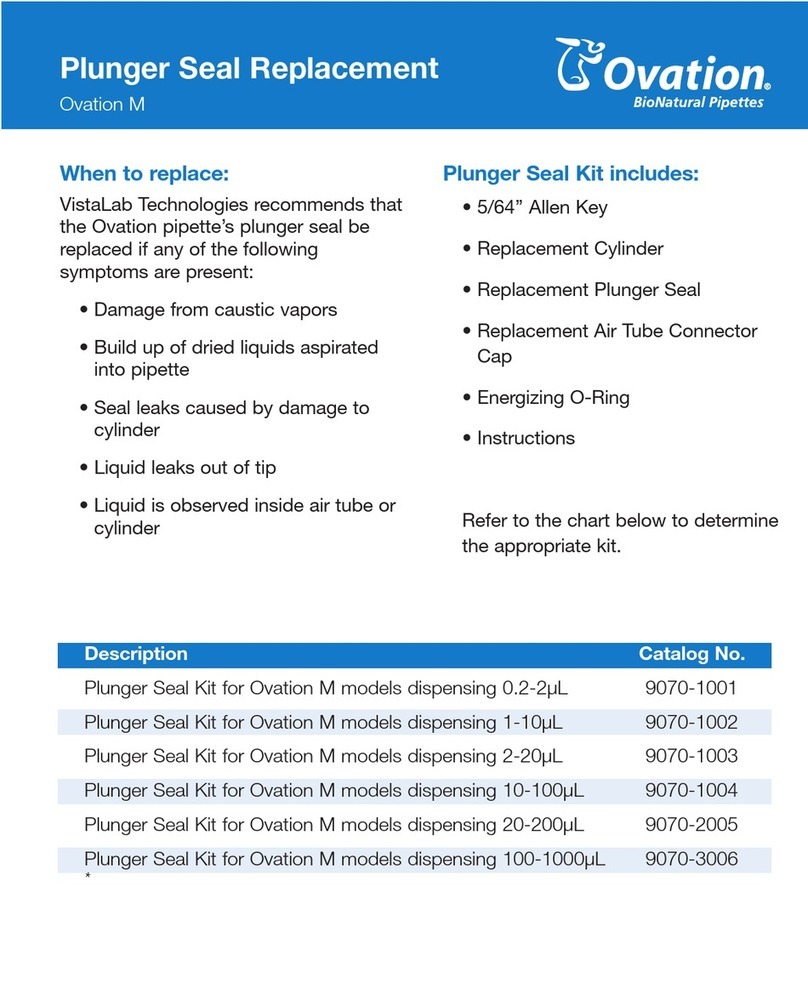

Should the pipette fail to operate or if the delivered volume is low, the seals should be

checked for wear and replaced if necessary. Instructions for pipette disassembly and seal

replacement can be found in the appropriate seal kit. When reassembling the pipette, align

the display cutout on the pipette sleeve with the digital display. Twisting the sleeve once

placed onto the pipette body can cause the alignment pins to break.

MLA Digital Pipette Assembly

10 to 50µL and 50 to 200µL

200 to 1000µL

Sleeve

Alignment Pin

Plunger

Plunger

Plunger

Cap

Body

Bonnet

Seals

Nozzle Cover

Nozzle Assembly

Spring Cap

Assembly

Display Cutout

Plunger

Cap

Body

Seal

Digital

Display

Bonnet

Sleeve

Nozzle Cover

Display Cutout

Nozzle Assembly

Alignment Pin

Digital

Display

Figure 2:

Nozzle

Insert

Removal

Figure 1:

D-Tipping