Thermo King Super II SR+ User manual

SuperIISR+

with µP IV+

TK 50234-0-2-MM (6/98)

Copyright©1998 Thermo King Corp., Minneapolis, MN, U.S.A.

Printed in U.S.A.

The maintenance information in this manual covers unit models:

Super II SR+ with uP IV+

For further information, refer to…

di 2.2 and se 2.2 Engine Overhaul Manual TK 8009

X430 Compressor Overhaul Manual TK 6875

Diagnosing TK Refrigeration System TK 5984

Tool Catalog TK 5955

Parts Manual TK 40638

Principles of Evacuation for Field Application TK 40612

ElectroStatic Discharge (ESD) Training Guide TK 40282

THERMOGUARD uP IV Microprocessor Controller

Revision 04XX Software

SB-III SR+, Super-II SR+, and RMN SR+ Operations & Diagnosis Manual TK 40893

The information in this manual is provided to assist owners, operators and service people in the proper

upkeep and maintenance of Thermo King units.

This manual is published for informational purposes only and the information so provided should not be considered

as all-inclusive or covering all contingencies. If further information is required, Thermo King Corporation should be

consulted.

Sale of product shown in the Manual is subject to Thermo King’s terms and conditions including, but not limited to,

the Thermo King Limited Express Warranty. Such terms and conditions are available upon request.

Thermo King’s warranty will not apply to any equipment which has been “so repaired or altered outside the manu-

facturer’s plants as, in the manufacturer’s judgment, to effect its stability.”

No warranties, express or implied, including warranties of fitness for a particular purpose or merchantabil-

ity, or warranties arising from course of dealing or usage of trade, are made regarding the information, rec-

ommendations, and descriptions contained herein. Manufacturer is not responsible and will not be held

liable in contract or in tort (including negligence) for any special, indirect or consequential damages,

including injury or damage caused to vehicles, contents or persons, by reason of the installation of any

Thermo King product or its mechanical failure.

Recover Refrigerant

At Thermo King, we recognize the need to preserve

the environment and limit the potential harm to the

ozone layer that can result from allowing refrigerant

to escape into the atmosphere.

We strictly adhere to a policy that promotes the

recovery and limits the loss of refrigerant into the

atmosphere.

In addition, service personnel must be aware of

Federal regulations concerning the use of refriger-

ants and the certification of technicians. For addi-

tional information on regulations and technician

certification programs, contact your local THERMO

KING dealer.

Table of Contents

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Maintenance Inspection Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Unit Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Sequence Of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Unit Model Super II SR+ w/THERMOGUARD IV+ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Design Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Protection Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Unit Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Switch Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Microprocessor Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Basic Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Unit Instruments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Unit Protection Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Unit Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Pre-Trip Inspection (Before Starting Unit). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Manually Starting Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Starting CYCLE-SENTRY Equipped Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

After Start Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Pre-Load Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Loading Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Post Load Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Post Trip Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Electronic Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

SR+ Control Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Control Panel switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

On-Off Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Preheat-Start Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Manual Defrost Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Unit Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

uP IV+ Microprocessor Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Microprocessor Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Select Key Prompts and Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

uP IV+ Microprocessor Standard Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Changing the Setpoint. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Selecting CYCLE-SENTRY or CONTINUOUS MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Viewing Select Key Display Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Starting the Diesel Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Initiating a Manual Defrost Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Viewing and Clearing Alarm Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Software Revision 04xx Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Running a Full Pretrip Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table of Contents (continued)

Electronic Controls (continued)

Displaying the Software Revision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Operating Service Test Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Service Test Mode Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Service Test Mode Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Service Test Mode Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Service Test Mode Function Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Electrical Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Alternator (Australian Bosch) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Charging System Diagnostic Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Full Field Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Unit Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Charging System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Glow Plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Fuse Link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

THERMOGUARD µP IV+ Microprocessor Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Defrost System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Defrost Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Air Switch Testing and Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Oil level switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Switch Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Bench Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Sensor Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Sensor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Return Air Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Discharge Air Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Coil Temperature Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Engine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Engine Lubrication System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Engine Oil Change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Oil Filter Change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Engine Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Antifreeze Maintenance Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Bleeding Air from the Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Engine Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Engine Fuel System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Bleeding the Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Water Separator/Fuel Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Water Separator/Fuel Filter Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Engine Speed Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

High Speed Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Injection Pump Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Injection Pump Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Table of Contents (continued)

Engine Maintenance (continued)

Adjusting Engine Valve Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Front Pulley Bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Crankcase Breather . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Engine Air Cleaner (Filter). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Refrigeration Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Refrigerant Charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Refrigerant Leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Checking Compressor Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

High Pressure Cutout Switch (HPCO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Three-Way Valve Condenser Pressure Bypass Check Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

Modulation Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Modulation Valve Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

Hot Gas Solenoid Valve (HG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Hot Gas Solenoid Valve Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Thermax-V System (TF+ Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Thermax-V Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Refrigeration Service Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Condenser Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Discharge Vibrasorber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

In-line Condenser Check Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

Condenser Check Valve Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Bypass Check Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Receiver Tank. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Filter Drier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

Expansion Valve Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

Heat Exchanger. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Evaporator Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Accumulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Suction Vibrasorber. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Three-way Valve Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

Three-way Valve Condenser Pressure Bypass Check Valve Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

Pilot Solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

High Pressure Cutout Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

High Pressure Relief Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Throttling Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Modulation Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

Hot Gas Solenoid Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

Liquid Line Check Valve Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

Liquid Line Check Valve Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

Thermax-v Expansion Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

Table of Contents (continued)

Structural Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Unit And Engine Mounting Bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Unit Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Condenser, Evaporator, and Radiator Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Defrost Drains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Defrost Damper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Fan Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Fan Shaft Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Fan Shaft Assembly Overhaul . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Condenser Fan Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Evaporator Blower Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Electrical Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Possible Cause . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Remedy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Fault Indication Diagnosis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Shutdown Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Check Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Stored Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Alarm Code Legend . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Alarm Code Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Mechanical Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Possible Cause . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Remedy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Refrigeration Diagnosis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Symptom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Possible Causes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Refrigeration Cycle Without Modulation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Refrigeration Cycle With Modulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

i

Safety Precautions

GENERAL PRACTICES

1. ALWAYS WEAR GOGGLES OR SAFETY

GLASSES. Refrigerant liquid and battery acid can per-

manently damage the eyes (see First Aid under Refrig-

erant).

2. Never operate the unit with the compressor discharge

valve closed.

3. Keep your hands, clothing and tools clear of the fans

and belts when the unit is running. This should also be

considered when opening and closing the compressor

service valves.

4. Make sure gauge manifold hoses are in good condition.

Never let them come in contact with a belt, fan motor

pulley, or any hot surface.

5. Never apply heat to a sealed refrigeration system or

container.

6. Fluorocarbon refrigerants, in the presence of an open

flame or electrical short, produce toxic gases that are

severe respiratory irritants capable of causing death.

7. Make sure all mounting bolts are tight and are of cor-

rect length for their particular application.

8. Use extreme caution when drilling holes in the unit.

The holes may weaken structural components, and

holes drilled into electrical wiring can cause fire or

explosion.

9. Use caution when working around exposed coil fins.

Painful laceration can be inflicted from the fins.

10. Use caution when working with a refrigerant or refrig-

eration system in any enclosed or confined area with a

limited air supply (for example, a bus or garage).

Refrigerant tends to displace air and can cause oxygen

depletion resulting in suffocation and possible death.

REFRIGERANT

Although fluorocarbon refrigerants are classified as safe

refrigerants, certain precautions must be observed when

handling them or servicing a unit in which they are used.

When exposed to the atmosphere from the liquid state, fluo-

rocarbon refrigerants evaporator rapidly, freezing anything

they contact.

First Aid

In the event of frost bite, the objectives of First Aid are to

protect the frozen area from further injury, to warm the

affected area rapidly and to maintain respiration.

• EYES: For contact with liquid, immediately flush eyes

with large amounts of water and get prompt medical

attention.

• SKIN: Flush area with large amounts of lukewarm

water. Do not apply heat. Remove contaminated cloth-

ing and shoes. Wrap burns with dry, sterile, bulky

dressing to protect from infection/injury. Get medical

attention. Wash contaminated clothing before reuse.

• INHALATION: Move victim to fresh air and use CPR

if necessary. Stay with victim until arrival of emer-

gency medical personnel.

REFRIGERATION OIL

Avoid refrigeration oil contact with the eyes. Avoid pro-

longed or repeated contact of refrigeration oil with skin or

clothing. Wash thoroughly after handling refrigeration oil to

prevent irritation.

First Aid

In case of eye contact, immediately flush with plenty of

water for at least 15 minutes. Wash skin with soap and

water. CALL A PHYSICIAN.

ii

1

Specifications

ENGINE—SE 2.2

Model Thermo King se 2.2

Fuel Type No. 2 diesel fuel under normal conditions

No. 1 diesel fuel is acceptable cold weather fuel

Oil Capacity: Crankcase 15 quarts (14.2 liters) crankcase

16 quarts (15.2 liters) crankcase and filter

Fill to full mark on dipstick

Oil Type*: API Petroleum Type CD

API Synthetic Type CD After first 500 hrs.

Oil Viscosity** Above 80 F (27 C): SAE 40

50 to 90 F (10 to 32 C): SAE 30

20 to 70 F (-7 to 21 C): SAE 20-20W

-15 to 40 F (-26 to 4 C): SAE 10W

Below 0 F (-18 C) continuously: SAE 5W

Engine rpm:Low Speed Operation

High Speed Operation 1425 to 1475 rpm

2175 to 2225 rpm

Engine Oil Pressure 50 to 65 psi (276 to 448 kPa) low speed engine

operation

Intake Valve Clearance .016 in. (0.40 mm)

Exhaust Valve Clearance .016 in. (0.40 mm)

Valve Setting Temperature 70 F (21 C)

Fuel Injection Timing .02 in. (0.5 mm) at 14°BTDC (timed on No. 1

cylinder)

Engine Coolant Thermostat 180 F (82 C)

Coolant System Capacity 10 quarts (9.5 liters)

Radiator Cap Pressure 7 psi (48 kPa)

Drive Direct to compressor; belts to fans, alternator and

water pump

* Thermo King synthetic oil is compatible with petroleum lubricants so there is no danger if accidental

mixing occurs or if an emergency requires addition of petroleum oil. Mixing is not recommended, how-

ever, since it will dilute the superior performance properties of the synthetic oil.

**Multi-viscosity weight oil with the recommended API classification may be used based on the ambient

temperature and straight weight viscosity recommendations above. The above recommendations are

written for mineral oil based lubricants.

BELT TENSION Tension No. on TK Gauge P/N 204-427

12 V Alternator Belt 35

Fan Belt 50

Specifications (Rev 6/98)

2

REFRIGERATION SYSTEM

Compressor Model Thermo King X430

Refrigerant Charge—Type 13 lb (5.9 kg)—R-404A

Compressor Oil Charge 4.1 quarts (3.9 liters)*

Compressor Oil Filter Oil Charge 0.75 quarts (0.71 liters)

Compressor Oil Type Polyol Ester type P/N 203-413

Throttling Valve Setting 23 to 25 psi (159 to 172 kPa)

Heat/Defrost Method Hot gas

High Pressure Cutout 450 ± 10 psi (3103 ± 69 kPa)

Automatic reset @ 375 ± 38 psi (2586 ± 262 kPa)

* When the compressor is removed from the unit, oil level should be noted or the oil removed from the

compressor should be measured so that the same amount of oil can be added before placing the

replacement compressor in the unit.

AIR SWITCH SETTING 1.40 ± 0.08 in. (35.6 ± 2.0 mm) H2O

ELECTRICAL CONTROL SYSTEM

Voltage 12.5 Vdc

Battery One, group C31, 12 volt battery

Unit Fuse 40 amp

Control Circuit DC Fuse 15 amp

Microprocessor Power Fuse 1.5 amp

Modulation Valve Fuse 1.5 amp

Battery Charging 12 volt alternato

37 amp, brush type

Voltage Regulator Setting 13.8 to 14.2 volts @ 75.2 F (25 C)

Specifications (Rev 6/98)

3

ELECTRICAL COMPONENTS

NOTE: Disconnect components from unit circuit to check resistance.

Current Draw

(Amps)

at 12.5 Vdc

Resistance—Cold

(Ohms)

Fuel Solenoid 1.4 8.8

Damper Solenoid: Large

Small 5.7

2.9 2.2

4.3

High Speed (Throttle) Solenoid 2.9 4.3

Glow Plug (One) 7.1 1.8

Pilot Solenoid 0.7 17.0

Starter Motor—Gear Reduction Type 250-375*

Modulation Valve (Optional) 1.7** 7.6

Hot Gas Bypass Valve (Optional) 1.1 11.1

* On-the-engine cranking check. Bench test is approximately 100 amps on the direct drive starter and

approximately 80 amps on the gear reduction starter.

** Test at 12.5 Vdc

THERMOGUARD®MICROPROCESSOR TEMPERATURE CONTROLLER

Temperature Controller:Type Electronic THERMOGUARD Microprocessor with

digital thermostat, thermometer and fault indicator

monitor

Setpoint Range -20 to 80 F (-29 to 27 C)

Programmable setpoint range to 90 F (32 C)

DigitalTemp. Display -40 to 99.9 F (-40 to 40 C)

Internal Defrost Timer: Temp. Pulldown 4 hrs. std. (can be set to 2, 4. 6, 8, 10, or 12 hrs.)

Temp. In-range 6 hrs. std. (can be set to 4. 6, 8, 10, or 12 hrs.)

Defrost Initiation: Coil Sensor Coil must be below 45 F (7.2 C)

Defrost Termination:Coil Sensor Terminates defrost with coil temperature above

57 F (13.9 C)

Interval Timer Terminates defrost 30 or 45 minutes (programmable)

after initiation if coil sensor has not terminated

defrost

4

5

Maintenance Inspection Schedule

Pretrip

Every/

1,500

Hours

Annual/

4,500

Hours Inspect/Service These Items

MICROPROCESSOR

•Run Pre-trip (See Pre-trip in uP IV+ Microprocessor Operation).

ENGINE

•Check fuel supply.

•Check engine oil level.

•••

Inspect belts for condition and proper tension (belt tension tool

No. 204-427).

•••

Check engine oil pressure hot, on high speed. Minimum 276 kPa

(40 psi).

•••

Listen for unusual noises, vibrations, etc.

•Check air cleaner indicator.*

••

Change engine oil** (hot) and oil filters and fuel filters.

••

Clean crankcase breather.

••

Drain water from fuel tank and check vent.

•Inspect/clean fuel transfer pump inlet strainer.

•Check and adjust engine speeds (high and low speed).

•Check condition of engine mounts.

•Change engine coolant.

••

Replace fuel filter (replace water separator every 3000 hours).

Test fuel injection nozzles at least every 10000 hours.

ELECTRICAL

•••

Check ammeter for charge and discharge (glow plug) operation.

••

Inspect battery terminals and electrolyte level.

••

Inspect wire harness for damaged wires or connections.

•Check air switch setting.

•Inspect alternator.

* Change air cleaner when indicator reaches 22 in.

**NOTE: Petroleum oil rated “CD” must be used in the engine to allow 1500 hour extended

maintenance intervals.

Maintenance Inspection Schedule (Rev 6/98)

6

REFRIGERATION

•••

Check refrigerant level.

•••

Check for proper suction pressure.

•Check compressor oil level and condition.

••

Check throttling valve regulating pressure on defrost.

•Check compressor efficiency and pump down refrigeration system.

•Replace dehydrator and check discharge and suction pressure.

STRUCTURAL

•••

Visually inspect unit for fluid leaks.

•••

Visually inspect unit for damaged, loose or broken parts (includes air

ducts and bulkheads).

••

Inspect tapered roller bearing fanshaft and idlers for leakage and

bearing wear (noise).

••

Clean entire unit including condenser and evaporator coils and

defrost drains.

••

Check all unit and fuel tank mounting bolts, brackets, lines, hoses,

etc.

••

Check evaporator damper door adjustment and operation.

Pretrip

Every/

1,500

Hours

Annual/

4,500

Hours Inspect/Service These Items

7

Unit Description

The Super II SR+ uP IV+ is a one-piece, self-contained, die-

sel powered refrigeration-heating units. The unit mounts on

the front of the trailer with the evaporator portion extending

into the trailer. The unit uses hot gas to heat and defrost.

Power is provided by an se 2.2, a four-cylinder, water-

cooled, direct injection diesel engine rated at 27.8 continu-

ous horsepower (20.7 kilowatts) at 2200 rpm. An in-line

power pack provides direct drive power transfer from the

engine to the compressor. A belt drive system transfers

energy to the fans, the alternator, and the water pump.

The engine uses a spin-on, dual element, full flow/bypass

oil filter and “CD”rated petroleum engine oil for extended

1,500 hour maintenance intervals.

Additional unit features include the Thermo King X430

compressor and the THERMOGUARD uP IV+ Micropro-

cessor.

Thermo King X430 Compressor

The unit is equipped with a Thermo King X430, four-cylin-

der compressor with 492 cm3(30 cu. in.) displacement.

THERMOGUARD uP IV+ Microprocessor

The THERMOGUARD uP IV+ is a microprocessor control

system designed for use with transport temperature control

systems. The uP IV+ has the following features:

•Thermostat

•Digital Thermometer

•Hourmeters

•Oil Pressure Gauge

•Water Temperature Gauge

•Ammeter

•Voltmeter

•Tachometer

•Mode Indicator

•Refrigeration System Controller

•Diagnostic System

The microprocessor mounts inside a weather tight control

box. The LCD display and alarm light are clearly visible

through a transparent door. Opening the control box door

provides quick access to the microprocessor keypad. The

keypad is used to control the operation of the microproces-

sor. See the Operation and Diagnosis Manual (TK 40893)

for details.

The CYCLE-SENTRY system and an integral defrost timer

are standard features. The refrigeration modulation system,

data recording, Tracker (a satellite communication system

interface) and remote indicator lights are optional features.

CYCLE-SENTRY Start-Stop Controls

A CYCLE-SENTRY Start-Stop fuel saving system provides

optimum operating economy. Select Continuous or

CYCLE-SENTRY operation using the selector switch

located on the switch panel.

WARNING: When the unit On-Off switch is in the

ON position, the unit may start at anytime without

prior warning.

NOTE: A buzzer sounds when the unit is automatically

preheating.

The CYCLE-SENTRY system automatically starts the unit

on microprocessor demand, and shuts down the unit when

all demands are satisfied. As well as maintaining the box

temperature, engine block temperature and battery charge

levels are monitored and maintained. If the block tempera-

ture falls below 30 F (-1.1 C), the engine will start and run

until the block temperature is above 90 F (32 C). If the bat-

tery voltage falls to the programmed limit selected by

CYCLE-SENTRY Battery Voltage (typically 12.2 volts)

and CYCLE-SENTRY mode is selected, the engine will

start and run until the battery is recharged.

Unit Description (Rev 6/98)

8

Features of the CYCLE-SENTRY system are:

•Offers either CYCLE-SENTRY or Continuous Run

operation.

•Microprocessor controlled all season temperature con-

trol.

•Maintains minimum engine temperature in low ambient

conditions.

•Battery Sentry keeps batteries fully charged during unit

operation.

•Variable glow plug preheat time.

•Preheat indicator buzzer.

Refrigeration Modulation System (Optional)

The refrigeration modulation system provides precise con-

trol of the refrigeration system and the temperature of the

cargo area. As the temperature of the return air begins to

approach the setpoint, the microprocessor begins to close

the modulation valve in the suction line between the evapo-

rator and the heat exchanger. The microprocessor closes the

modulation valve more as the return air temperature gets

closer to the setpoint. When the temperature is near set-

point, the modulation valve is closed to its limit and the hot

gas bypass valve is opened. When the temperature begins to

move away from the setpoint, the modulation valve begins

to open. The hot gas bypass valve remains open until the

modulation valve is completely open, then the hot gas

bypass valve closes. This provides very smooth and steady

temperature control and the temperature does not oscillate

above and below setpoint as much as it does in a unit that

does not have modulation.

Data Recording (Optional)

The microprocessor records operational data and alarm

codes at preset intervals. This trip data can be retrieved (but

not erased) from the microprocessor memory using the

THERMOGUARD Data Pac™/ Mini Pac™portable

microcomputer. The microcomputer is connected to the

Data Pac interface on the front of the control box. A brief

graphical or tabular report can then be printed on the Data

Pac microprinter. More detailed reports may be printed in

either a graphical or tabular format on a high speed printer

external to the portable microcomputer. Trip data can also

be retrieved through the Tracker.

Tracker (Optional)

The Tracker is an optional system that can be included in

the microprocessor. The Tracker interfaces a satellite com-

munication system (SCS) located in the tractor. The Tracker

and the SCS are connected with a data cable. The Tracker

transmits data (recorded in the microprocessor) through the

SCS to a central location for processing. The Tracker trans-

mits data at preset intervals or on demand depending on the

type of SCS. Data can also be transmitted through a Tracker

to the microprocessor with some systems.

SEQUENCE OF OPERATION

When the unit is turned ON the LCD display, which nor-

mally shows the setpoint, the return air temperature, and the

operating mode, is illuminated. The microprocessor relays

and unit loads energize, and the unit can now be started

manually, or it may start automatically if the microprocessor

energizes the CYCLE-SENTRY system and the selector

switch in on CYCLE-SENTRY.

OPERATING MODES

The microprocessor uses a complex program to determine

which operating mode the unit should be in. Therefore, it is

difficult to predict which operating mode the unit should be

in by comparing the setpoint to the box temperature. Also,

the different versions of software that are used have some

operational differences.

Unit Description (Rev 6/98)

9

Modulation

Modulation is disabled if the setpoint is out of the modula-

tion range, if the unit is in defrost, or if the unit is in

CYCLE-SENTRY.

The lower limit of the modulation range is fixed at -5 C

(24 F). Setpoints below -5 C (24 F) disable modulation.

The upper limit of the modulation range is adjustable from

27 C (80 F) to -5 C (24 F). The default setting for the upper

limit is 27 C (80 F). Setpoints above this limit disable mod-

ulation.

If the upper limit of the modulation range is set at -5 C

(24 F), modulation is disabled.

No Modulation or Modulation Disabled

Units that are not equipped with modulation and units that

are equipped with modulation but have modulation disabled

use the following operating modes:

•High Speed Cool

•Low Speed Cool (or Null on Auto Start-Stop on tem-

perature rise only)

•Low Speed Heat (or Null on Auto Start-Stop)

•High Speed Heat

•Defrost

Modulation Enabled

Units that are equipped with modulation and have modula-

tion enabled use the following operating modes:

•High Speed Cool

•Low Speed Cool

•Low Speed Modulated Cool

•Low Speed Modulated Heat

•Low Speed Heat

•High Speed Heat

•Defrost

Defrost

Defrost mode can be initiated by the manual defrost switch,

air switch, or by the microprocessor defrost timer any time

the evaporator coil temperature is below 7.2 C (45 F). If the

unit is in the Null mode (Auto Start-Stop operation), manu-

ally initiating defrost will cause the unit to start and operate

in the defrost mode. When a defrost cycle is initiated, the

microprocessor energizes the damper solenoid, pilot sole-

noid and defrost light. The microprocessor maintains the in-

range signal during defrost.

The unit remains on defrost until the evaporator coil tem-

perature rises to 13.9 C (57 F) or the microprocessor defrost

timer terminates defrost after 30 or 45 minutes.

NOTE: The microprocessor will not respond to a tempera-

ture out-of-range condition for 45 minutes after the termi-

nation of a defrost cycle. This allows for normal

temperature recovery after the defrost cycle.

Unit Description (Rev 6/98)

10

UNIT MODEL

SUPER II SR+

W/THERMOGUARD IV+

DESIGN FEATURES

se 2.2 Diesel Engine •

X430 Compressor w/Synthetic Compressor Oil •

Thermo King Radiator •

Stainless Steel Grille •

Stainless Steel Evaporator Hardware •

Tapered Roller Bearing Fanshaft and Idlers •

Premium Drive Belts •

Heavy Duty Dry Element Air Cleaner Inside Unit Frame •

THERMOGUARD uP IV+ Microprocessor Controller •

Defrost Timer (Built into THERMOGUARD uP IV+) •

Fuel Filter with Water Separator •

Spin-On Full Flow/Bypass (Dual Element) Oil Filter •

Dealer Installed Synthetic Engine Oil Opt.

Compressor Oil Filter Opt.

CYCLE-SENTRY System •

37 Amp Alternator •

Refrigerant 404A •

Silicone Coolant Hoses Opt.

Fuel Heater Opt.

Frost Plug Heater Opt.

Condenser Shutters Opt.

Refrigeration Modulation System Opt.

Remote Indicator Lights Opt.

Table of contents

Other Thermo King Control System manuals

Popular Control System manuals by other brands

Crestron Electronics

Crestron Electronics UC-B30-T quick start

sky vision

sky vision Linx 300 Preinstallation manual

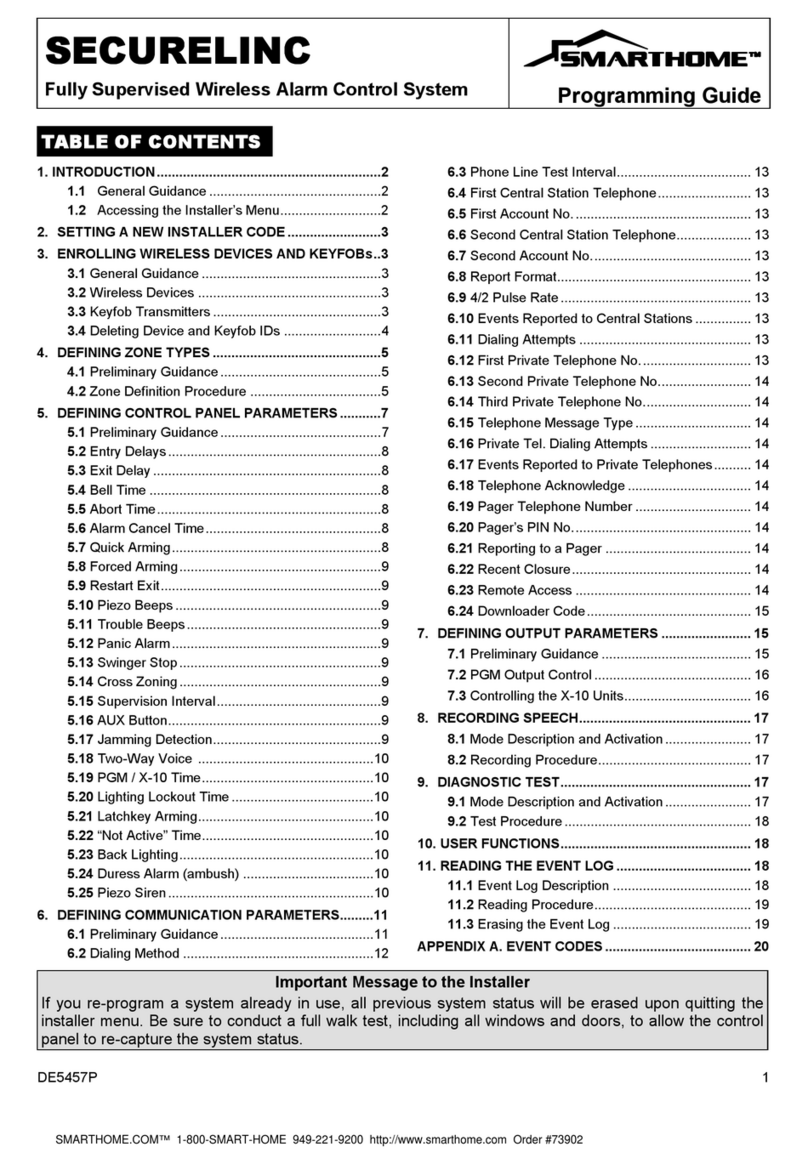

smart home

smart home Securelinc Programming guide

Little Giant

Little Giant OA1S Series owner's manual

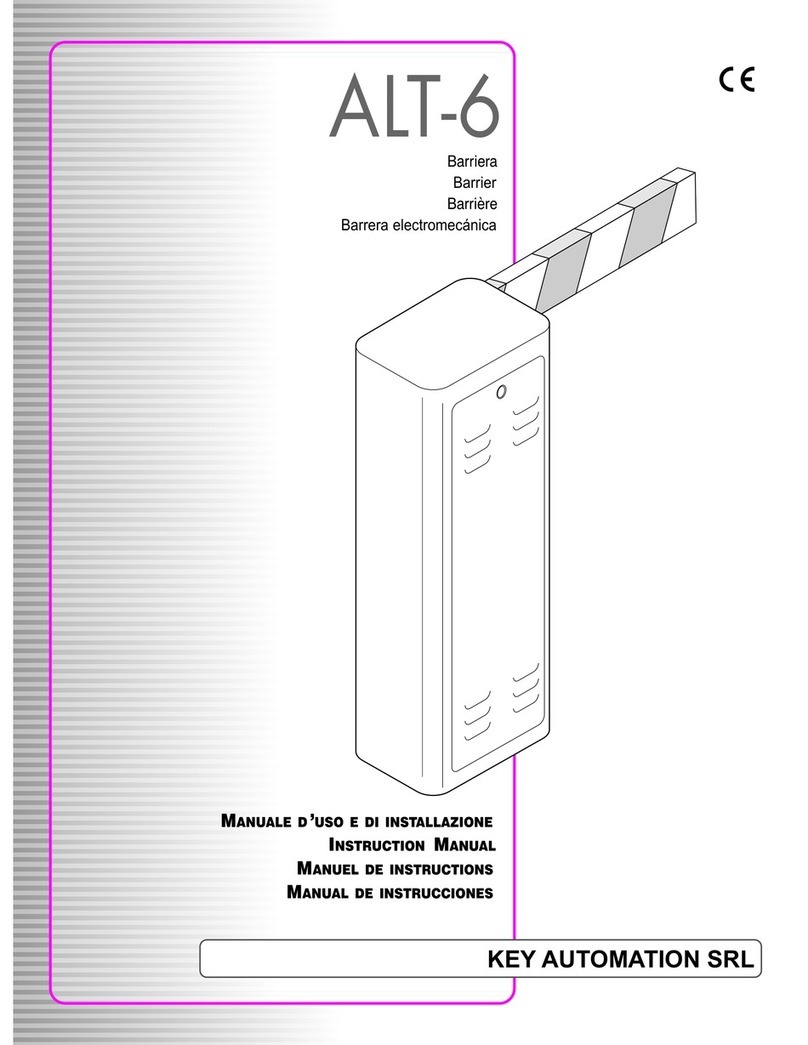

Keyautomation

Keyautomation ALT-6 instruction manual

Astral Pool

Astral Pool RP 9 pH only Installation and operating instructions