Programmable Vacuum Oven 1-1Thermo Scientific

Section 1 Introduction

The Thermo Scientific Programmable Vacuum Oven is designed to

operate with reduced pressures and/or with inert atmospheres. As such, it

is equipped with separate vacuum and gas ports - each with its own

control valve. Additionally, a special digital readout display indicates time

of day, chamber temperature, pressure and schedules for programmed oven

operation.

Temperature settings and vacuum pump operation can be controlled at

the touch of a button. A 7-day programmable timer provides automatic

temperature/vacuum control in real-time programmable steps. The dual

displays provide constant day/time, and temperature/pressure updates

every 5 seconds. hamber temperature and pressure can be externally

recorded by connecting to the recorder outputs located on the back of the

control board. PURGE and VA UUM valves, conveniently located under

the control panel, provide access for a vacuum pump and/or the presence

of inert gases into the chamber.

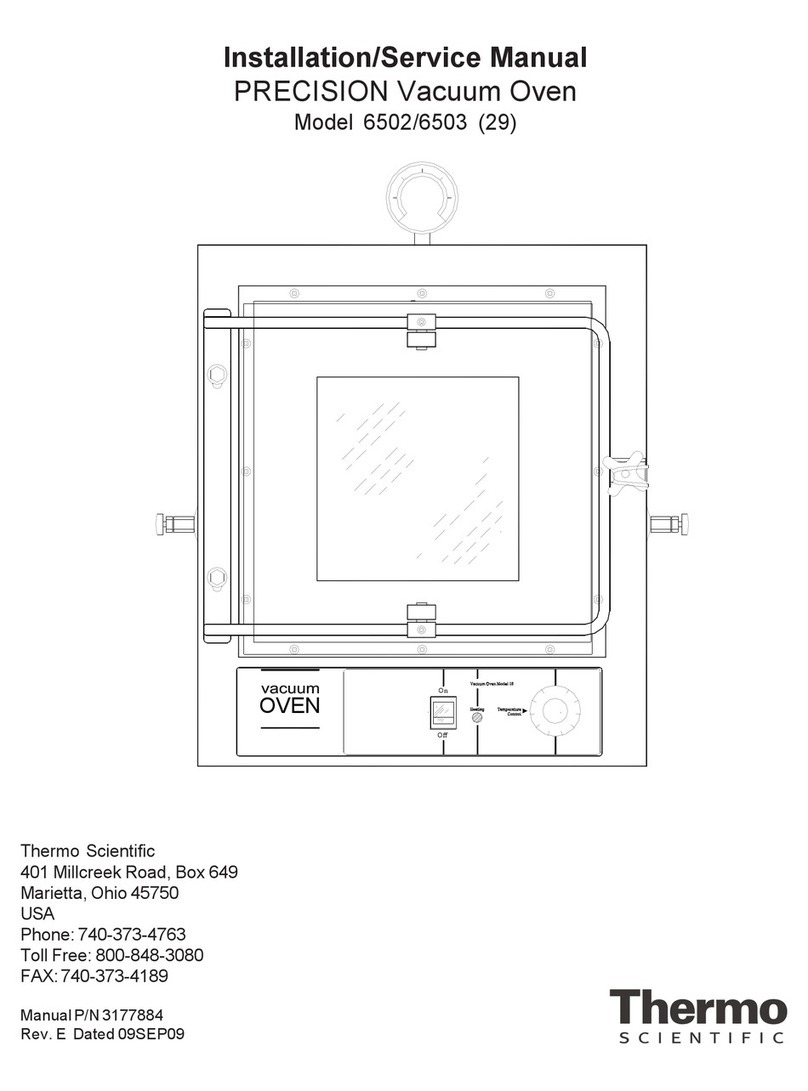

The Vacuum Oven design features a 1.5 cubic-foot stainless steel chamber

with fully adjustable shelves. An additional feature is a chamber door with

full view, and tempered safety glass.

The stainless steel chamber permits performance of practically every

laboratory need associated with general drying, curing, conditioning,

desiccating, annealing, and moisture tests. Additional applications include

vacuum embedding, out-gassing solids and liquids, aging tests, plating, and

electronic process control.

Five built-in, self diagnostic features – open thermocouple, over-

temperature, power failure, low battery, and calibration data corruption -

on the front panel display to alert the operator of a malfunction and thus

prevent damage to both samples and equipment.

Warning This unit is not explosion proof. Do not use in the presence of

flammable or combustible materials; fire or explosion may result. Unit

contains components that may ignite such materials. Do not place volatile

items in the chamber. Fumes and spillage from acidic solutions cause

corrosion of the stainless steel chamber and the door gasket. are should

be taken to maintain neutral pH at all times. s