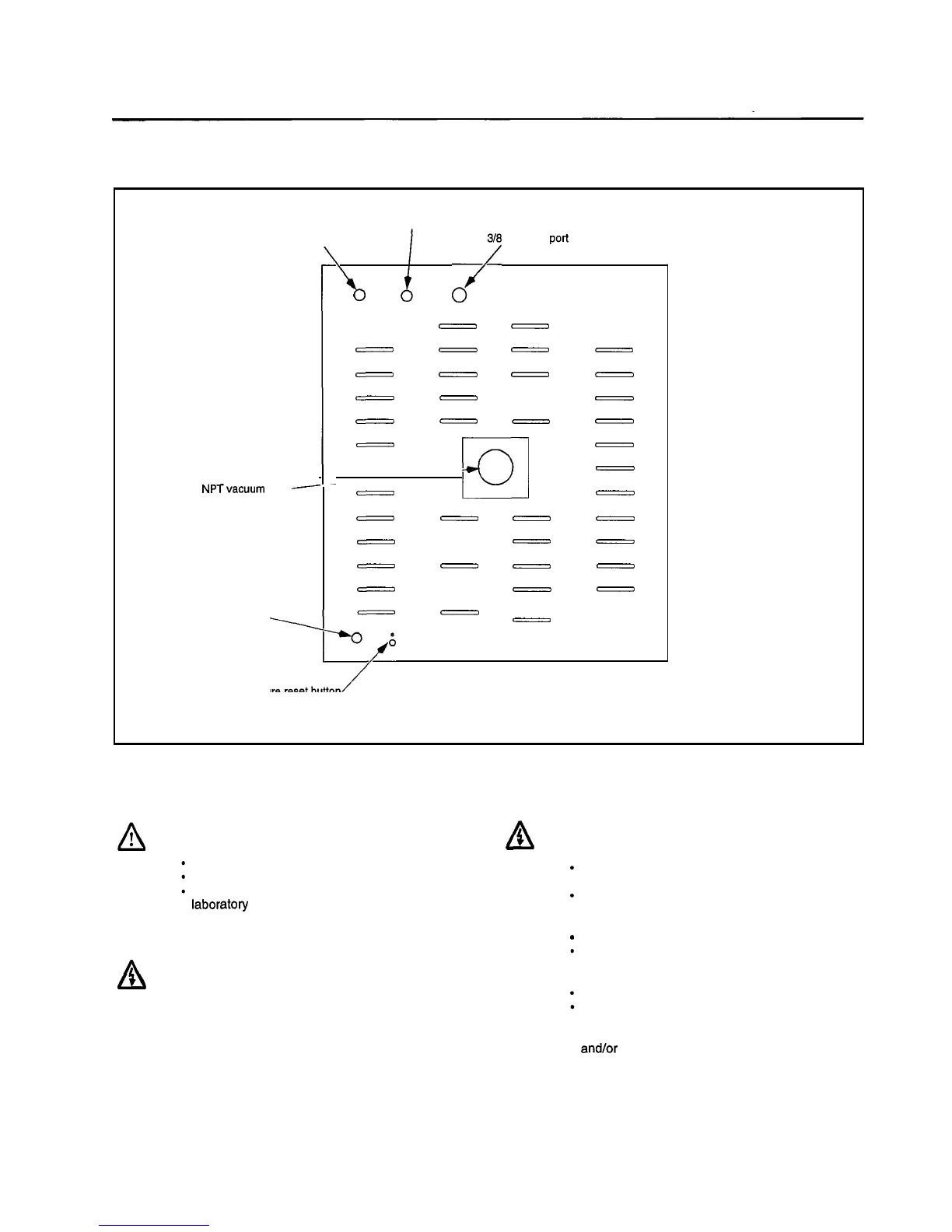

Installationand Operation

Laboratory Vacuum Ovens

5.2

Setting the Temperature

To set the temperature to the desired setpoint, complete the

following steps:

1. Press

a

or

7

until the desired setpoint is indicated on the

bottom line of the display.

2. Press

SETIENT

to register the new setpoint.

5.3

Setting the OvertemperatureProtection(OTP)

Temperature

The high limit alarm system with the temperature controller

disables theheater output. To set the alarm on the temperature

controller (typically 5°C above the desired main temperature

setpoint), complete the following steps:

1. Press and hold

SETENT

for 3 seconds, until

A1

is displayed

on the upper line.

2. Press

A

or

V

until the desired overtemperature limit

setpoint shows onthe bottom line of the display.

3. Press

SETENT

to register the new overtemperature alarm

setpoint.

4. Press and hold

SETENT

for 3 seconds to return to the normal

display.

5.4

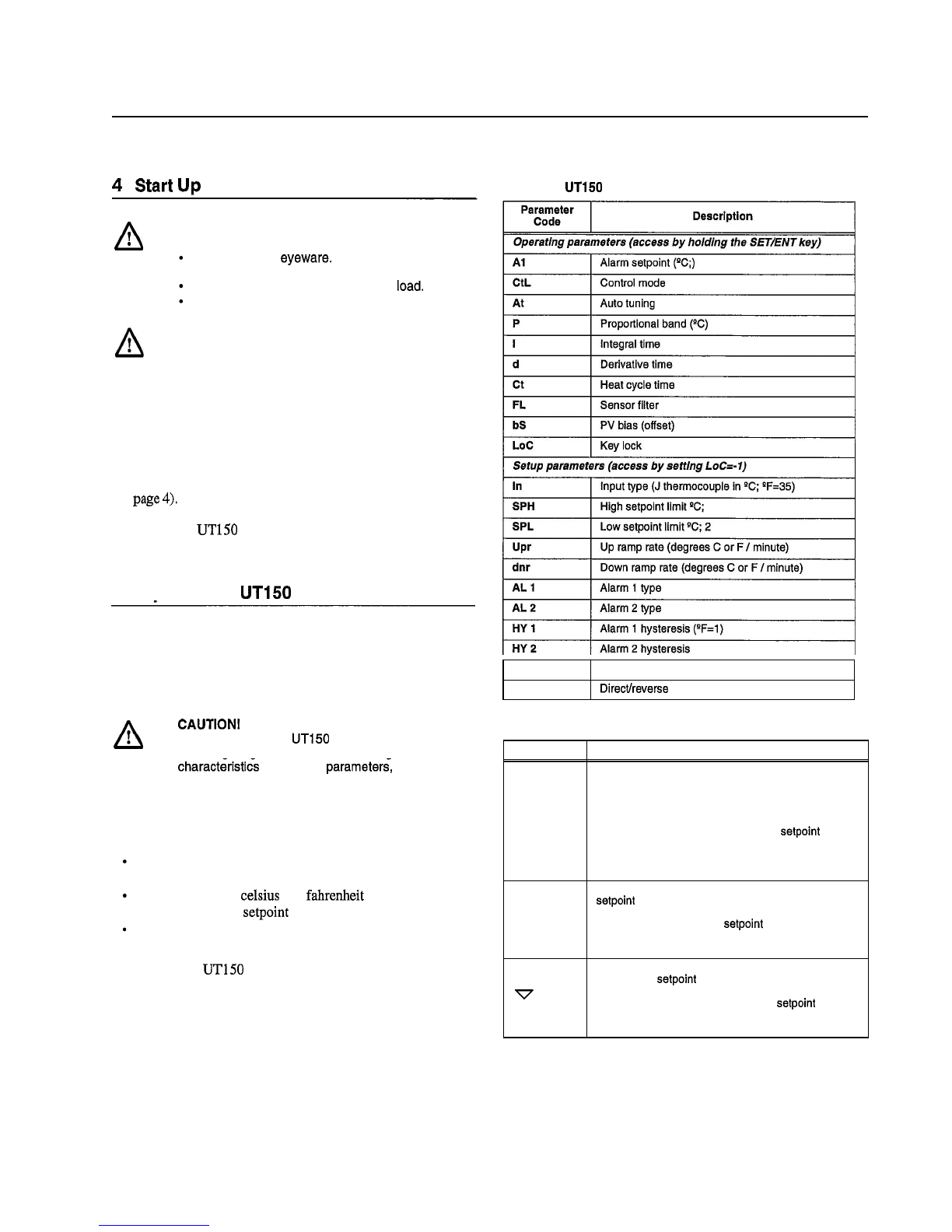

Changing Between Celsius and Fahrenheit

The controller isfactory

-

set to operate with degrees Celsius. To

change the display modes and parameter settings to the

Fahrenheit scale, you will need to change the Input Type

parameter

In

and also the values of various scale

-

dependent

parameters. If during this procedure the buttons are inactive for

more than two minutes, the controller will return to the standard

display.

To change from Celsius to Fahrenheit:

1.With the controller operating, access the Operating

Parameters menu by pressing and holding

SETIENT

for3

seconds.

2. Press and release

SETIENT

repeatedly until theupper display

reads LoC.

3. Press

V

until the displayed value of LoCis

-

1; then press

SETIENT

to access the Setup Parameters menu (refer to

Table 2 on page

5).

4. The first setup parameter displayed is Input 'Qpe (In). Press

tochange its value from

5

to 35. After making this

adjustment (andall following parameter adjustments) be sure

topress and release

SETIENT

again to register the change.

5. Press and release

SETIENT

to advance to theSPH parameter

and change its value to 500.

6. Press and release

SETIENT

to advance to theSPL parameter

and change its value to 32.

7.

Press and release

SETENT

to advanceto the HY1 parameter

and change its value to

1.

8.

Press and hold

SETENT

for 3 seconds to exit theSetup

Parameters Menu.

9.

Press and hold

SETIENT

for 3 seconds toenter the Operating

Parameters Menu anddisplay the A1 parameter.

10.Usethe Abutton to set the

A1

parameter to the desired

overtemperature limit in OF.

11. Press and release

SETIENT

to advanceto the P parameterand

change its value to 16.2.

12. Press and hold

SETIENT

for 3 seconds to exit theOperating

Parameters Menu.

13. The new temperature units are now effective. Follow the

instructions inSection 5.2 to reset the temperature setpointin

"

E

14. Apply the OF label over the "C label on the control panel.

5.5

Setting the Ramp to SetpointRate

The Ramp Ratefeature allows the chamber to beheated or

cooled at any rate slower than the maximum capability of the

unit. To fine tune ramp rates, you may need to test using loads

with similar mass and thermal properties to loads you intend to

usein oven applications.

To set the ramp to setpoint time, complete the following steps. If

during this procedure the buttons are inactive for more than two

minutes, the controller will return to the standard display.

1.

With the controller operating, press and hold

SETIENT

for

3

seconds to enter the Operating Parameters menu.

2. Press and release

SETIENT

until the LoC parameter is on the

upper display.

3. Press the down arrow button toshow '-I1,and press

SETIENT

once to enter theSetup Parameters menu.

4.

Press and release

SETIENT

until the Upr parameter is on the

upper display.

5. Press the arrow buttons to select the new Up Ramp Rate

value, in OC per minute or OF per minute, or 'OFF'. Press and

release

SETENT

to register the value change.

6. Press and release

SETIENT

until the dnrparameteris on the

upper display.

7.

Press the arrow buttons to select the new Down Ramp Rate

value, in OC per minute or OF per minute, or 'OFF'. Press and

release

SETIENT

to register the value change.

8.

Press and hold

SETENT

for three seconds to exit the Setup

Parameters menu.

9.

The new Ramp Rates are now effective.

10. Follow theinstructions inSection 5.2 toreset thetemperature

setpoint.

Note:

The ramp rate begins when the

SET/ENT

buttonis

pressedafter the target setpoint is selected. The setpoint

display on the controllerwill show the changing setpoint

at the selected ramp rate.

To view the target setpoint during theramp rate,press andrelease

an arrow button. Thelower display will show the setpointnext to

the selected target setpoint. Return to the ramping setpoint

display by pressing and releasing the other arrow button.