Thermocable ProReact DSCU-EN User manual

Page 1 of 17 Revision 1.1 Sept 2019

Document No. ProReact DSCU-EN Installation Manual

ProReact Digital Sensor Control Unit

(DSCU-EN)

Installation Instructions

World leading linear detection

Page 1 of 17 Revision 1.1 Sept 2019

Document No. ProReact DSCU-EN Installation Manual

www.thermocable.com

Linear Detection Technology Made Simple

Page 2 of 17 Revision 1.1 Sept 2019

Document No. ProReact DSCU-EN Installation Manual

Contents:

Important Guidelines – read before commencing installation Page 3

General Overview Page 4

Technical Specications Page 5

Installation Page 6

- Overview

- Connections Diagram

Operating Modes Page 7

- Wiring Diagram: Independent

- Wiring Diagram: Interlock

Useful Information Page 9

- Leader Cable

- Mounting Dimensions

- Static Discharge Cautionary

Commissioning Page 10

- Normal Operation

- Fault / Alarm Conditions

Testing and Verication Page 14

Two-wire RS-485 Modbus RTU/ASCII Communications Page 15

Resetting the ProReact DSCU-EN Page 16

Glossary Page 17

Page 3 of 17 Revision 1.1 Sept 2019

Document No. ProReact DSCU-EN Installation Manual

Important Guidelines

Please read this instruction leaet thoroughly before commencing installation.

Install the Digital Sensor Control Unit (DSCU-EN) accordingly to meet local and country

installation requirements.

The DSCU-EN must be installed in accordance with BS 5839-1:2017 (or country

equivalent) and IEC 60364 and authorities having jurisdiction.

Ensure the product is installed, commissioned and maintained by qualied

professionals according to good engineering practices and who have received

sucient training on the unit.

Only use Thermocable ProReact EN Digital Linear Heat Detection cable with the

DSCU-EN sensor control unit.

Test the Digital Linear Heat Detection cable before connecting it to the DSCU-EN using

a multimeter.

Ensure the end of line resistor (3.6kohm) is securely connected at the end each linear

heat detection cable.

If only one zone is required leave the end of line resistor (3.6kohm) connected across

the terminals of the unused zone.

Ensure any cable glands used are tightened to form a secure and moisture proof seal

around the detection cable and any other cable in or out of the unit.

Do not exceed the maximum operating voltage of the DSCU-EN (36Vdc).

Do not connect lengths of linear heat detection cable in ‘T’ connections or spurs.

Page 4 of 17 Revision 1.1 Sept 2019

Document No. ProReact DSCU-EN Installation Manual

General Overview

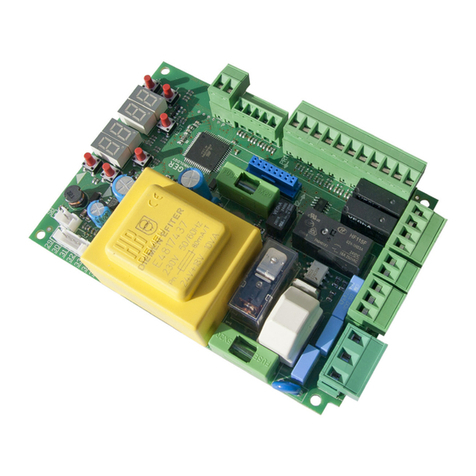

Digital Sensor Control Unit

The Thermocable ProReact Digital Sensor Control Unit (DSCU-EN) is a

dual zone module for monitoring up to two zones of Thermocable

ProReact EN Digital Linear Heat Detection (LHD) Cable. If an overheat or

re situation triggers either zone of the Digital LHD cable the unit

automatically calculates and displays the distance along the cable, in feet

and metres, to the alarm point. The two zones can operate independently

of each other, or in interlock mode and a separate alarm and normally

conducting fault output are provided for each zone. The unit is intended

to be installed between the Digital Linear Heat Detection cable and

a conventional or addressable re alarm control panel. It has power,

fault and alarm lights, as well as volt free outputs for fault and alarm,

corresponding to each zone. It may also be connected to a industrial

process control system using the two wire RS-485 Modbus RTU/

ASCII output.

Figure 1: Typical Installation of the ProReact Digital Sensor Control Unit

ProReact EN

Digital LHD

Cable

ProReact EN

Digital LHD

Cable

Page 5 of 17 Revision 1.1 Sept 2019

Document No. ProReact DSCU-EN Installation Manual

Technical Specications

Thermocable Part Number: A1397

Thermocable Part Description: ProReact Digital Sensor Control Unit

UL Model Number: DSCU-EN

UL File Number: S36157

Revision: 1.9.2-EN

Approvals: EN54-28:2016

Enclosure:

...Dimensions H180mm x W120mm x D60.5mm (H7.1in x W4.72in x D2.38in)

...Rating NEMA 4, 4X (IP65)

...Finish Light Gray with clear lid

...Display 2 line, 16 character backlit display showing zone status

Power Requirements: All circuits power limited if powered from a power limited supply

Min. Nominal Max.

...Operating Voltage 12Vdc — 24Vdc — 36Vdc

Current Consumption:

...Normal Operation (standby) <15mA <7mA <5mA

...Alarm <40mA <23mA <15mA

Operating Temperature Range: -20°C – +50°C (-4°F – +122°F)

Terminal Blocks:

...Spacing 5mm Rising Clamp

...Rating 16A

...Wire Size 0.08mm2(28AWG) to 4mm2(11AWG)

Supervised Circuits: Power, Input Zone 1 & Input Zone 2

Inputs: Up to two Class B zones of Thermocable ProReact EN Digital

LHD Cable

...Max Zone Length 1000m (3,280ft)

...Min Zone Length 1m

...End of line resistor 3.6kohm (included)

...Short circuit current 0.5mA

...Max Zone Voltage 5V

Outputs:

...Communications Two wire RS-485 Modbus RTU/ASCII

...Sounder 2.4kHz 92dBa @ 10cm Buzzer

...Alarm 2x Form C volt-free relay contacts (resistive, common)

Max V 30Vac or 42.4Vdc

Max Current 2A

Max Switching Power 60W, 62.5VA

...Fault 2x Optoisolated phototransistor output (resistive, common)

Max V 35Vdc

Max Current 80mA

Max Power Dissipation 150mW

Page 6 of 17 Revision 1.1 Sept 2019

Document No. ProReact DSCU-EN Installation Manual

Overview

The DSCU-EN allows accurate location of an alarm point along a length of Thermocable ProReact EN Digital Linear Heat Detection (LHD) cable.

It continuously monitors up to two zones of Digital LHD cable for a fault (open circuit) or an alarm (overheat or re condition). Because of the wide

range of applications that Digital LHD cable can be used for, it may not always be possible, or be too time consuming, to locate where along the cable

an alarm has occurred. Using the DSCU-EN, when an alarm occurs the distance to the overheat condition is immediately calculated and displayed on the

integrated display.

If a fault is detected, the corresponding fault output stops conducting, triggering a fault at the re alarm control panel. If an alarm is detected, the

corresponding alarm output changes state, triggering an alarm at the re alarm panel. The fault outputs also stop conducting on power loss to the unit or

microprocessor fault, triggering a fault at the re alarm control panel.

The two wire RS-485 Modbus RTU/ASCII output also outputs the current state of both zones. See the section “Modbus RTU/ASCII Communications” for

more detail.

There are two primary congurations of the DSCU-EN (see gure 1):

1) The Digital LHD cable can be connected directly to the DSCU-EN

2) The Digital LHD cable is connected to a length of leader cable which is connected to the DSCU-EN. In this scenario the leader cable must be

“calibrated out” during commissioning of the DSCU-EN.

Connections Diagram

Figure 3 shows the connections diagram for the DSCU-EN unit. The unit is provided with a 3.6kohm end of line resistor in each zone input. If only one zone

is required, leave the 3.6kohm resistor connected across the zone which is not in use. Otherwise the 3.6kohm resistor should be connected at the end of the

Digital Linear Heat Detection cable.

Figure 3: Wiring Diagram for the Thermocable ProReact DSCU-EN

Installation

Page 7 of 17 Revision 1.1 Sept 2019

Document No. ProReact DSCU-EN Installation Manual

Operating Modes Wiring Diagram Independent

There are two operating modes for the Digital Sensor Control Unit:

1. Independent – This is when the DSCU-EN is used as a two zone system. When a fault or overheat condition occurs on a Digital LHD zone, the corresponding

fault or alarm output respectively is triggered. The two zones operate independently and both sets of outputs should be connected to a re alarm control

panel. If the zone is not required leave the 3.6kohm resistor in the zone input terminals as supplied. In this mode, the two zones can either contain identical

rated temperature Digital LHD cables or two different rated temperature Digital LHD cables.

Zone/Switch/

IO Module

Zone/Switch/

IO Module

Zone/Switch/

IO Module

ProReact Digital Sensor

Control Unit

ProReact

end-of-line

unit (EOLU-EN)

The EOL and A resistor are usually provided with the fire alarm panel or zone/switch/IO module. For

more information please refer to the Fire alarm panel or addressable module installation instructions.

On each zone output group, the Fault '-' (negative terminal) and alarm NO terminal are connected

by a jumper on the DSCU-EN PCB. Do not remove or break this jumper when the system is used with

an EN54 fire alarm system in the wiring configuration shown.

DSCU-EN

Alarm Relay

DSCU-EN

Fault Output

ProReact EN Digital Linear Heat Detection Cable Zones

Page 8 of 17 Revision 1.1 Sept 2019

Document No. ProReact DSCU-EN Installation Manual

Operating Modes Wiring Diagram Interlock

2. Interlock – this mode is for applications which require a fail-safe guarantee that an alarm is only triggered when an overheat condition has been detected.

This mode may also be known as coincidence detection. In this case, the same rated temperature Digital LHD cable should be attached to both zones of the

DSCU-EN. The alarm output is only activated when both Digital LHD cables trigger an alarm due to an overheat condition. If one Digital LHD cable zone input

registers an alarm but the second does not, the alarm output will not be activated. This is to prevent an alarm if a mechanical or other issue has triggered one

Digital LHD cable and not an overheat condition.

• Only use Zone 1 fault and alarm outputs in Interlock mode.

• Two linear heat detection cables with the same temperature rating must be used and a

minimum of two linear heat detection cables must be installed in each protected space.

See the ProReact EN Digital LHD Installation Instructions for the linear spacing specication.

Zone/Switch/

IO Module

Zone/Switch/

IO Module

ProReact Digital Sensor

Control Unit

ProReact EN Digital Linear Heat Detection Cable Zone

The EOL and A resistor are usually provided with the fire alarm panel or zone/switch/IO module. For

more information please refer to the Fire alarm panel or addressable module installation instructions.

On each zone output group, the Fault '-' (negative terminal) and alarm NO terminal are connected

by a jumper on the DSCU-EN PCB. Do not remove or break this jumper when the system is used with

an EN54 fire alarm system in the wiring configuration shown.

DSCU-EN

Alarm Relay

DSCU-EN

Fault Output

ProReact

end-of-line

unit (EOLU-EN)

Page 9 of 17 Revision 1.1 Sept 2019

Document No. ProReact DSCU-EN Installation Manual

Leader Cable

In certain applications it may be desirable or necessary to use non-

sensing leader cable between the ProReact DSCU-EN unit and the

Digital LHD cable. For example, if the the DSCU-EN unit is located some

distance away from the area protected by the Digital LHD cable. This

may be required if the expected ambient temperature range, or other

environmental conditions, where the Digital LHD cable is to be used is

greater than the maximum ambient temperature range for the DSCU-EN

unit. (see steps 8, 9 and 10 in the Commissioning section on pages 10-11).

The maximum length of leader cable that can be used per zone is

dependent upon the leader cable diameter’. The following is a guideline

for typical cable sizes and maximum length:

Leader Cable Size Max Leader Cable Length

20AWG

(16x0.2mm or 0.8mm dia, copper) 1000m

Mounting Dimensions

The DSCU-EN is intended to be wall-mounted. 4 holes should be drilled

according to the mounting dimensions given in gure 2. The

corresponding mounting holes on the DSCU-EN unit can be found by

removing the lid of the device. The mounting holes are located adjacent to

the lid screw positions. Suitable screws for the type of wall the DSCU-EN

is to be mounted on will need to be provided for separately. The maximum

screw head diameter is 7mm and the maximum screw thread diameter is

4mm.

Static Discharge Cautionary

The following items are cautionary notes that will help prevent

equipment damage or malfunction caused by static discharge:

CAUTION

Static charges produce voltages high enough to damage electronic

components. Follow these precautions when installing, servicing, or

operating the DSCU-EN:

• Work in a static-free area.

• Discharge any static electricity you may have accumulated.

• Discharge static electricity by touching a known, securely

grounded object.

• Do not handle the printed circuit board (PCB) without proper

protection against static discharge.

In the event that the DSCU-EN malfunctions after encountering a static

discharge correct operation of the unit can be restored by interrupting

power to unit for a brief period (approximately 10 seconds). Setup

information can be veried by following the steps in the Commissioning

section (page 10 onwards). In the event of the setup information

being corrupted the unit should be reset following the Resetting the

DSCU-EN procedure.

Figure 2: Mounting Dimensions for the Thermocable ProReact DSCU-EN

Useful Information

Page 10 of 17 Revision 1.1 Sept 2019

Document No. ProReact DSCU-EN Installation Manual

1. After wiring the unit up (see wiring diagram) power up the device.

Device will show screen including software revision number.

2. If the unit is being setup for the rst time the following options will

be shown. If the unit has previously been installed the display will

automatically cycle through the options, showing the stored settings.

3. After the initial title screen the next screen will show a menu (see

right) with three options: Load Congs, New Congs and Self Test. On a

previously congured device, after 10s of no button press the device will

automatically proceed to loading saved congs.

4. If “Load Congs” is selected or no button has been pressed after 10s

on a previously congured device, the screen will show “Loading Saved

Congs”. The previously saved parameters will then be displayed.

5. Select the operating mode. (see “Operating modes” (pages 7-8)

for more detail.

Independent: the two zones operate independently of each

other (default).

Interlock: Both fault outputs activate when a fault occurs on either zone

1 or zone 2. Both alarm outputs activate only when both Digital LHD

zones trigger an alarm.

6. Select the relevant operating programme for Zone 1 based on the

table below:

7. Select the relevant operating programme for Zone 2 based on the table

below:

8. If leader cable is connected between the Digital LHD cable and the

DSCU-EN unit and/or the LHD cable is installed in a hazardous area and IS

barriers are being used, the voltage drop to the start of the LHD cable

must be measured by the DSCU-EN unit in order to ensure correct

operation and accurate distance location. In order to do this, with the

leader cable and/or IS barriers and LHD cable connected to the DSCU-EN

unit, short out the connection at the start of the LHD cable. Select “Yes”

and press Set to continue.

Commissioning

ProReact DSCU-EN

SW REV 1.6

MAIN MENU

LOAD CONFIGS

LOADING SAVED

C O N F I G S...

Z1 Cable Type:

T078-V10-A045

Z2 Cable Type:

T078-V10-A045

Operating Mode:

INDEPENDENT

Alarm (or activation)

temperature

Cable Set-Up

T078-V10-A045 T088-V10-A065

78°C (EN78) 3

88°C (EN88) 3

Alarm (or activation)

temperature

Cable Set-Up

T078-V10-A045 T088-V10-A065

78°C (EN78) 3

88°C (EN88) 3

In this example, the rst option has been chosen

for an alarm temperature of 78°C

In this example, the rst option has been chosen

for an alarm temperature of 78°C

Zone 1 ldr cable

Yes

Page 11 of 17 Revision 1.1 Sept 2019

Document No. ProReact DSCU-EN Installation Manual

Commissioning (Cont.)

9. If “Yes” was selected in step 8, the DSCU-EN unit will then ask if the

zone is ready to be calibrated. Ensure that the connection between the

leader cable and/or the IS barriers and the start of the Digital LHD cable is

securely shorted out between the two cores. When this is done, press the

“Set” button to continue.

10. The DSCU-EN unit will display the voltage drop across the leader

cable. If necessary, press “Select” to perform the calibration measurement

again. The DSCU-EN unit will display the updated voltage drop in mV

(milli-volts). The displayed value should be equal to approximately the

loop resistance in ohms from the DSCU-EN unit, with the short in place,

divided by 8. Once the voltage drop has been conrmed correct, press

“Set” to continue. Now remove the short at the start of the LHD cable.

11. If the Linear Heat Detection cable is connected directly to the DSCU-

EN then select No and press the Set button to continue.

12. Select whether you would like the alarm outputs for both zones to

be latching. If set to Yes, then if an alarm is triggered the unit will either

require the power supply to be interrupted (min. 2s) or the Set button

to be pressed to reset to normal once the alarm conditioned has

been cleared.

13. Select whether the Modbus output should be enabled. If this is not

enabled then proceed to step 17.

14. Select required Modbus type, either RTU or ASCII.

15. Set the Modbus address for this device (1-247).

16. Cycle through the possible Baud Rates for the Modbus RTU/ASCII

output. (2400, 4800, 9600, 19200, 38400, 57600, 115200).

17. Select the number of data bits for the Modbus RTU/ASCII output.

(7 or 8)

18. Select the number of stop bits for the Modbus RTU/ASCII output.

(1 or 2).

19. Select the parity for the Modbus RTU/ASCII output.

(even/odd/none).

Modbus TYPE

RTU

Modbus address

1

Latching outputs

No

Modbus output on

yes

R ea dy to

ca lib r ate?

Zone 2 cal:

109 mV

ZONE 2 ldr cable

no

BAUD RATE

2400

DATA BITs

7

Stop BITs

1

PariTY

Even

Page 12 of 17 Revision 1.1 Sept 2019

Document No. ProReact DSCU-EN Installation Manual

Zone 1: OK

Zone 2: OK

{Zone 1: OK

{Zone 2: OK

LED Illustration

Either of the display screens above and a single ashing Power light (green colour) should be visible

when ProReact DSCU-EN unit is in normal operation.

Independent mode

Interlock mode

Normal Operation

20. Once the unit has been commissioned, the display will show the zone

status. In normal operation, the display unit in independent mode will

show:

Zone 1: OK

Zone 2: OK

The display unit in interlock mode will show:

{Zone 1: OK

{Zone 2: OK

This indicates the two zones of LHD cable are linked and an alarm is only

transmitted if both zones are triggered.

Page 13 of 17 Revision 1.1 Sept 2019

Document No. ProReact DSCU-EN Installation Manual

Zone 1: OK

Zone 2: I/F FAULT

Zone 1: FAULT

Zone 2: OK

{Zone 1: 300M

{Zone 2: OK

{Zone 1: 300M

{Zone 2: 301M

Fault/Alarm Conditions

LED Illustration

21. If an alarm condition occurs the DSCU-EN automatically calculates the

distance along the cable to the trigger point and rst displays this value

in metres.

22. The display alternates showing the distance along the cable to the

trigger point in metres and in feet.

23. The unit monitors for relay faults. If an alarm condition occurs but the

relay does not switch state (due to a coil failure for example) the device

will go into relay fault and show the screen to the right, depending upon

which zone is in fault

24. The unit monitors for interference faults when the input may be

changing between alarm, ok and fault conditions, for example, too rapidly.

In this case an I/F fault is displayed on the corresponding zone. Check all

cable teminations are securely fastened and for other sources of noise.

25. The unit monitors for cable faults (i.e. an open circuit). An open circuit

will be displayed as fault (as per zone 1 shown right).

26. In interlock mode, the alarm outputs are only activated when both

LHD cables are triggered. If one cable triggers but not the other the

display will show the distance to the alarm on the triggered zone and the

corresponding alarm LED will ash slowly.

27. In interlock mode, if both cables go into an alarm, the alarm outputs

will be activated and the display will show the distance to the alarm for

each zone. The zone 1 and zone 2 alarm LEDs will light continuously.

Zone 1: RLY FLT

Zone 2: OK

Zone 1: 1751 ft

Zone 2: OK

Zone 1: 534 m

Zone 2: OK

Page 14 of 17 Revision 1.1 Sept 2019

Document No. ProReact DSCU-EN Installation Manual

Testing & Verication

1. If self test mode is selected the device will rst load the saved congs

then proceed to cycle through normal operation, alarm and fault.

This is to allow the installer/maintenance engineer verify that the unit

is corrected to an external system correctly. The screen will ash “SELF

TEST/MODE” every few seconds.

2. In self test mode the device cycles between normal operation, alarm

and fault every approx. 8 seconds. In normal operation the display will

show ok. The alarm relays will be off and the fault output normally

conducting (on).

3. In self test mode and alarm condition the display will show alarm.

The alarm relays will be on. After approx. 8 seconds the unit will go into

fault condition.

4. In self test mode and fault condition the display will show fault.

The fault outputs will stop conducting (off). After approx. 8 seconds the

unit will return to normal condition. To exit self test mode, press and hold

both SET and SELECT buttons for 10s or more until the device resets.

Zone 1: OK

Zone 2: OK

{Zone 1: OK

{Zone 2: OK

Zone 1: ALM

Zone 2: ALM

{Zone 1: ALM

{Zone 2: ALM

Zone 1: FAULT

Zone 2: FAULT

{Zone 1: FAULT

{Zone 2: FAULT

SELF TEST

MODE

LED Illustration

Independent mode

Independent mode

Independent mode

Interlock mode

Interlock mode

Interlock mode

Page 15 of 17 Revision 1.1 Sept 2019

Document No. ProReact DSCU-EN Installation Manual

Two-wire RS-485 Modbus RTU/ASCII Communications

The Thermocable ProReact DSCU-EN includes a two wire RS-485 Modbus output which can be enabled to

output the status of each zone of Digital Linear Heat Detection cable. The DSCU-EN Modbus output

supports the Modbus RTU/ASCII protocol and the following functions:

• Function code 4 (Read Input Registers)

The request for reading the input registers should be constructed in the following manner:

• Address of rst register to be read (16-bit)

• Number of registers to read (16-bit)

The DSCU-EN will respond in the following manner:

• Number of bytes of register values to be read (8-bit)

• Register values (16-bits per register)

The DSCU-EN stores the information for each zone of the Digital LHD cable in the following format:

Register Description Possible Values

0 Zone 1 status -1 or 65535=fault on zone

0=zone ok

1-32767=distance in metres to trigger point

1 Zone 2 status -1 or 65535=fault on zone

0=zone ok

1-32767=distance in metres to trigger point

2 Zone 1 cable type 1 = T078-V10-A045 (EN78), 2 = T088-V10-A065 (EN88)

3 Zone 2 cable type 1 = T078-V10-A045 (EN78), 2 = T088-V10-A065 (EN88)

If the start address plus the requested number of registers exceed 4, the DSCU-EN will return an

ILLEGAL DATA ADDRESS error.

If the request contains a function code other than those supported the DSCU-EN will return an

ILLEGAL FUNCTION error.

Page 16 of 17 Revision 1.1 Sept 2019

Document No. ProReact DSCU-EN Installation Manual

Resetting the ProReact DSCU-EN

WARNING: This procedure will erase ALL stored settings and reset the Thermocable ProReact

DSCU-EN unit back to its factory default state. The cable types, leader cable calibration,

latching output selection and Modbus setup will all require selecting after this procedure.

To reset the ProReact DSCU-EN unit back to the factory state, when the unit is powered up and in normal

operation (see step 20 in the Commissioning procedure), press and hold the SET and SELECT buttons for a

minimum of 10 seconds continuously. While the SET and SELECT buttons are held down the power LED will

ash quickly to conrm this procedure is about to take place. After approximately 10 seconds, the unit will

restart and return to step 1 in the Commissioning procedure. The settings are only erased if the menu option

“New Congs” is selected.

www.thermocable.com

Call: +44 1274 882359

•

M

A

D

E

I

N

T

H

E

U

K

•

M

A

D

E

I

N

T

H

E

U

K

Email: info@thermocable.com

Thermocable (Flexible Elements) Ltd,

Pasture Lane, Bradford, BD14 6LU

United Kingdom

Glossary

Alarm condition – A re or overheat around the Digital LHD cable which activates the cable and triggers the

DSCU-EN unit.

Cable glands – Used to form a dust-proof and weatherproof seal around a cable entering the DSCU-EN unit.

Digital linear heat detection cable – a sensing cable comprised of a pair of twisted low resistance

conductors that fuse together at a specic temperature and induce an alarm on a re panel or interface

module.

End of line resistor – A component which allows a residual current ow through a circuit to monitor the

integrity of the circuit. In the event of a break in the circuit, current will stop owing completely and a

trouble or fault signal will be triggered.

Fault condition – A break in one or both cores of the Digital LHD cable or a malfunction of the DSCU-EN

unit.

Independent mode – The mode on the DSCU-EN unit where both zones operate separately. Each zone can

trigger a fault or alarm, or be in the normal state, regardless of the state of the other zone.

Interlock mode – The mode on the DSCU-EN unit where the alarm relay outputs will only activate when

both Digital LHD cables go into alarm. If one cable triggers but not the other, the alarm relay outputs will

not be triggered.

Junction box – A secure, dust-proof and weatherproof enclosure to protect a join between two lengths of

Digital LHD cable or a length of Digital LHD cable and leader cable.

Leader cable – A non-temperature sensing cable which transmits the signals between two components in

the system, e.g. the DSCU-EN unit and the Digital LHD cable. Does not provide re detection and may be

re-rated to continue functioning even in a re condition.

Two-wire RS-485 Modbus RTU/ASCII Communications – An industry standard, signalling protocol used to

communicate information between components in a system, for example a SCADA system or PLC. Often

used to provide more information to be communicated than simple open or closed status communicated

by a relay output.

Zone – a single circuit of ProReact linear heat detection cable connected across either a ProReact DSCU-EN

or a re panel and an end of line resistor

This manual suits for next models

1

Table of contents

Popular Control Unit manuals by other brands

Lutron Electronics

Lutron Electronics PPS-9312 Operation manual

ILX Lightwave

ILX Lightwave LDC-3916558 user guide

Amersham Pharmacia Biotech

Amersham Pharmacia Biotech INV-907 instructions

Rohm

Rohm LAPIS Semiconductor ML22Q663 manual

Roger Technology

Roger Technology H70/104AC Instruction and warnings for the installer

EBS

EBS CPX200NW user manual