Thermolab Sartorius MC5 User manual

Liquid Handling

Application Notebook

Tips on how to pipette

2

3

Contents

Pipetting terms ........................................................................................................ 4

Types of pipettes ..................................................................................................... 4

General guidelines and pipetting techniques .......................................................... 7

Recommendations for pipetting different compounds ......................................... 10

Pipetting guidelines for selected compounds ....................................................... 11

Pre enting cross-contamination ............................................................................ 14

Finntip Filter tests .................................................................................................. 15

The plastics of arious Finntips ............................................................................. 15

Troubleshooting .................................................................................................... 16

Calibrating your pipettes ....................................................................................... 17

Formulas for calculating results ............................................................................ 21

Con ersion tables .................................................................................................. 23

Ensuring optimum performance ........................................................................... 24

Factors affecting the accuracy of air displacement pipettes ................................. 26

Maintenance of your Finnpipette .......................................................................... 27

Autocla ing ........................................................................................................... 27

UV resistance ........................................................................................................ 27

General guidelines for decontaminating Pipettes

when Working with Different Liquids .................................................................... 28

Chemical compatibility of plastics ......................................................................... 29

Frequently asked questions .................................................................................. 31

Making your lab work lighter ................................................................................. 34

Finnpipette Warranty Policy ................................................................................... 35

4

Pipetting terms

Aspirate - to draw up the sample

Dispense - to deli er the sample

Blow-out - to empty the tip completely

Calibration check - checking the difference between the dispensed olume

and the selected olume

Ad ustment - altering the pipette so that the dispensed olume is within the

specifications

Types of pipettes

Although Thermo Labsystems supplies pipettes for all application needs, most lab-

oratories are equipped with two types of pipettes.

Air displacement pipettes are meant for general use with aqueous solutions.

Positi e displacement pipettes are used for high iscosity and olatile liquids.

Both types of pipettes ha e a piston that mo es in a cylinder or in a capillary. In

air displacement pipettes, a certain olume of air remains between the piston and

the liquid. In positi e displacement pipetting, the piston is in direct contact with

the liquid.

Air displacement pipetting

Air displacement pipetting, used for standard pipetting applications, is highly accu-

rate. Howe er, conditions such as atmospheric pressure as well as the specific

gra ity and iscosity of the solution may ha e an effect on the performance of air

displacement pipettes.

• Finnpipettes for air displacement pipetting:

Finnpipette Digital, Finnpipette Colour, Finnpipette Fixed Volume,

Finnpipette BioControl, Finnpipette Multistepper, Finnpipette Varichannel

• Finntips for air displacement pipetting:

Finntip (standard), Finntip Filter, Finntip BioCon, Finntip Multisteppper,

Finntip Band 4, Finntip Wide

5

How does an air displacement pipette work?

1. The piston mo es to the appropriate position when the olume is set.

2. When the operating button is pressed to the first stop, the piston expels the

same olume of air as indicated on the olume setting.

3. After immersing the tip into the liquid, the operating button is released.

This creates a partial acuum and the specified olume of liquid is aspirated

into the tip.

4. When the operating button is pressed to the first stop again, the air dispenses

the liquid. To empty the tip completely the operating button is pressed to the

second stop (blow out).

2.

4.

1.

3.

6

Positive displacement pipetting

Positi e displacement pipetting is used for applications like PCR and other DNA

amplification techniques. The microsyringe tips used in positi e displacement pi-

pettes are disposable. This helps to a oid sample-to-sample cross-contamination

(also known as sample carry-o er), and contamination due to the aerosol effect.

• Finnpipettes for positive displacement pipetting:

Finnpipette Stepper, Finnpipette PDP

• Finntips for positive displacement pipetting:

Finntip Stepper, Finntip PDP

How does a positive displacement pipette work?

1. The piston mo es to the appropriate position when the olume is set.

2. When the operating button is pressed to the first stop, the piston descends

to the tip opening.

3. After the tip is immersed into the liquid, the operating button is released.

The plunger is then raised and a partial acuum is created. This causes

the liquid to enter the tip.

4. When the operating button is pressed again, the piston descends, expelling

the liquid from the tip.

1. 2. 3. 4.

7

General guidelines

and pipetting techniques

General guidelines

- Check your pipette at the beginning of your working day for dust and dirt on

the outside. If needed, wipe with 70% ethanol.

- Set the olume within the range specified for the pipette.

- Hold the pipette so the ‘grippy finger rest’ rests on your index finger.

- To maximise accuracy, the pipette, tip and liquid should be at the same

temperature.

- Check that you are using tips recommended by the manufacturer. To ensure

accuracy, use only high-quality tips made from contamination-free

polypropylene.

- Tips are designed for single use. They should not be cleaned for reuse as their

metrological characteristics will no longer be reliable.

- Pre-rinsing (three - fi e times) the tip with the liquid to be pipetted impro es

accuracy, especially when using positi e displacement tips.

- A oid turning the pipette on its side when there is liquid in the tip. Liquid might

go to the interior of the pipette and contaminate the pipette.

- A oid contamination to or from fingers by using the tip ejector.

- Always store pipettes in an upright position when not in use. Finnpipette

stands are ideal for this purpose.

- Check calibration regularly, depending on the frequency of use and on the

application, but at least once a year. If used daily, a three-month inter al is

recommended. Follow the instructions for recalibration in the instruction

manual (see also page 17).

8

Forward pipetting

1. Press the operating button to the first stop.

2. Dip the tip into the solution to a depth of 1 cm, and slowly release the

operating button. Wait 1-2 seconds and withdraw the tip from the liquid,

touching it against the edge of the reser oir to remo e excess liquid.

3. Dispense the liquid into the recei ing essel by gently pressing the operating

button to the first stop. After one second, press the operating button to the

second stop. This action will empty the tip. Remo e the tip from the essel,

sliding it up the wall of the essel.

4. Release the operating button to the ready position.

Reverse pipetting

The re erse technique is used for pipetting solutions with a high iscosity or a ten-

dency to foam. This method is also recommended for dispensing small olumes.

Re erse pipetting is only possible with air displacement pipettes.

1. Press the operating button to the second stop.

2. Dip the tip into the solution to a depth of 1 cm, and slowly release the

operating button. This action will fill the tip with a olume that is larger than

the set olume. Wait 1-2 seconds and withdraw the tip from the liquid, touching

it against the edge of the reser oir to remo e excess liquid.

3. Dispense the liquid into the recei ing essel by pressing the operating button

gently and steadily to the first stop. This olume is equal to the set olume.

Hold the button in this position. Some liquid will remain in the tip, and this

should not be dispensed.

4. The liquid remaining in the tip can be pipetted back into the original solution or

disposed together with the tip.

5. Release the operating button to the ready position.

Ready position 1 2 3 4

First stop

Second stop

Ready position 1 2 3 4 5

First stop

Second stop

9

Repetitive pipetting

This technique is intended for repeated pipetting of the same olume.

1. Press the operating button to the second stop.

2. Dip the tip into the solution to a depth of 1 cm, and slowly release the

operating button. Withdraw the tip from the liquid, touching it against the edge

of the reser oir to remo e excess liquid.

3. Dispense the liquid into the recei ing essel by gently pressing the operating

button to the first stop. Hold the button in this position. Some liquid will remain

in the tip, and this should not be dispensed.

4. Continue pipetting by repeating steps 2 and 3.

Pipetting whole blood

Use forward technique steps 1 and 2 to fill the tip with blood (do not prerinse the

tip). Wipe the tip carefully with a dry clean cloth.

1. Dip the tip into the blood and press the operating button to the first stop.

Make sure the tip is sufficiently below the surface.

2. Release the operating button slowly to the ready position. This action will fill

the tip with blood. Do not remo e the tip from the solution.

3. Press the operating button to the first stop and release slowly. Repeat this

process until the interior wall of the tip is clear.

4. Press the operating button to the second stop and completely empty the tip.

Remo e the tip by sliding it along the wall of the essel.

5. Release the operating button to the ready position.

Ready position 1 2 3 4

First stop

Second stop

Ready position 1 2 3 4 5 6

First stop

Second stop

10

Recommendations for pipetting

different compounds

Solution/compound

Aqueous solution

Viscous solution

Volatile compounds

Nucleotide solutions

Radioactive compounds

Acid/alkalis

Toxic samples

Examples

Buffers, diluted salt solutions

Protein and nucleic acid solutions,

glycerol, T een 20/40/60/80

Methanol, hexane

Genomic DNA, PCR products

14

Carbonate,

3

H-thymidine

H

2

SO

4

, HCl, NaOH

Pipette

Air displacement

Air displacement

Positive displacement

Positive displacement

Air displacement

Air displacement

Positive displacement

Air displacement

Positive displacement

Air displacement

Positive displacement

Tip

Standard

Standard or ide orifice

Positive displacement

Positive displacement

Filter

Filter or ide orifice

Positive displacement

Filter

Positive displacement

Filter

Positive displacement

Pipetting

technique

For ard

Reverse

For ard

For ard

For ard

For ard

Comments

Pipette slo ly to avoid bubble formation.

Pipette rapidly to avoid evaporation. Carbon filter tips

prevent vapor going into the pipette very effectively

For genomic DNA ide orifice tips can be used to

eliminate mechanical shearing.

11

Pipetting guidelines for selected

compounds

Body Fluids

Whole Blood

Pipette + tip combination:

Choose an air displacement pipette and a standard or wide orifice tip.

Technique:

Use the whole blood pipetting technique. Re erse pipetting should be used if high

accuracy is needed.

Notice:

Some blood can remain in the tip and on the outer surface. Wipe the tip against

the edge of the essel to remo e excess liquid outside the tip before dispensing.

Serum

Pipette + tip combination:

Choose an air displacement pipette and a standard or wide orifice tip.

Technique:

Use the whole blood pipetting technique. Re erse pipetting should be used if high

accuracy is needed.

Notice:

Residual serum can sometimes be found on the outer surface of the tip. Wipe the

tip against the edge of the essel to remo e excess liquid outside the tip before

dispensing.

Oily fluids

Glycerol

Pipette + tip combination:

Choose an air displacement pipette and a standard or wide orifice tip.

Technique:

For high accuracy of performance, use the re erse pipetting technique.

Notice:

Oily fluids are difficult to pipette because of formation of air bubbles. Filling must

be done ery slowly to pre ent air bubbles. Wipe the tip against the edge of the

12

essel to remo e excess liquid outside the tip before dispensing. The use of a pos-

iti e displacement pipette and tip is also useful for pipetting glycerol.

Tween 20, 10% solution

Pipette + tip combination:

Choose an air displacement pipette and a standard or wide orifice tip.

Technique:

Use the re erse pipetting technique.

Notice:

Tween has a ery high iscosity; to make pipetting easier, it should be diluted to a

10% solution. In any case pipetting will not be accurate; some liquid will stay in-

side the tip. Aspiration and dispensing should be done slowly. The use of a posi-

ti e displacement pipette and tip is also ad isable for pipetting Tween 20.

Bronidox L, 10% (preservative)

Pipette + tip combination:

Choose an air displacement pipette and a standard or wide orifice tip

Technique:

Use the re erse pipetting technique.

Notice:

Bronidox L is ery iscose; the aspiration and dispensing should be done slowly or

a positi e displacement pipette and tip should be used.

Salt solutions

10 x PBS, 0.1M

NaCl, 3M

Pipette + tip combination:

Choose an air displacement pipette and a standard tip.

Technique:

Use the forward pipetting technique. Prewetting of the tip before aspiration in-

creases accuracy.

13

Concentrated acids and bases

H2SO4

Pipette + tip combination:

Choose an air displacement pipette and a filter tip.

Technique:

Use the forward pipetting technique.

NaOH

Pipette + tip combination:

Choose an air displacement pipette and a filter tip.

Technique:

Use the forward pipetting technique.

Notice:

Some acids or bases aporise easily (e.g. trifluoroacetic acid). Do the pipetting

quite rapidly to minimise apour formation.

Nucleic acids

DNA & RNA solutions

Pipette + tip combination:

Choose an air displacement pipette and a filter tip or a positi e displacement

pipette and tip.

Technique:

Use the forward pipetting technique

Notice:

For genomic DNA wide orifice tips can be used to eliminate mechanical shearing.

Volatile compounds

Pipette + tip combination:

Choose an air displacement pipette and filter tip or positi e displacement

pipette and tip.

Technique:

Use the forward pipetting technique.

14

Notice:

1. To get accurate results, calibrate the pipette with the olatile compound you

want to pipette. If you use air displacement pipettes, aspirate and dispense the

liquid a few times keeping the tip in the liquid. By doing so, the air inside the

pipette will be saturated with apour of the olatile compound.

2. Pipette rapidly to a oid e aporation when using air displacement pipettes.

3. It is recommended to use positi e displacement pipettes for highly olatile

compounds, since the built-in piston tip is in direct contact with the liquid.

Preventing cross-contamination

Pipette-to-sample

A contaminated pipette or contaminated tips can cause contamination of samples.

Pre ention:

• Use sterilised tips or sterilised filter tips and if possible autocla e the pipette.

• Change the tip after pipetting of each sample.

Sample-to-pipette

Samples or aerosols from samples can enter the cone of the pipette.

Pre ention:

• Keep the pipette ertical when pipetting in order to pre ent liquid from running

into the pipette body.

• Release the push-button slowly.

• To a oid aerosol contamination, use filter tips or use a positi e displacement

pipette and tips.

• Store the pipette ertically.

Sample-to-sample (carry-over)

The remains of sample A can mix with next sample B inside the tip and may cause

a false test result.

Pre ention:

• Change the tip after each sample.

• If you suspect that your pipette is contaminated, autocla e or clean your pipette

(see “Maintenance of your Finnpipette” and “Autocla ing”, page 27).

15

Finntip Filter tests

Acid test

• 35% and 5% trifluoroacetic acid (TFA) was used as test liquid.

• Finntip Filters pre ented acids apours of a 35% TFA solution of coming

through the filter.

• When pipetting a 5% solution of TFA using a standard tip, no apour came into

the interior of the pipette.

DNA test

• DNA aerosols with sample concentrations of 20, 50 and 100 µg µl-1 were blown

onto the filters.

• Finntip Filters pre ented DNA aerosol of these concentrations coming through

filter into the interior of the pipette.

The plastics of various Finntips

PE=Polyethylene Autoclavable (121°C,20 min)

PP=polypropylene

Finntip Racks

Standard tips - Finntips

®

Finntip Filters

Tip

Filter

Finntip PDP

Piston

Tip

Temperatures reater than 121°C dama e piston

Finntip Stepper

Piston

Tip

16

Troubleshooting

Finnpipette

®

Digital

Problem Possible cause Solution

Leakage Tip incorrectly attached. Attach tips firmly, keeping pipette vertical and

pressing pipette evenly to rack. Do not bang.

Wrong tip size or shape. Check that the size and shape are correct.

Pipette incorrectly assembled after Check the assembly according

taking apart. to the instructions.

Foreign bodies bet een the piston, Clean tip cone module; attach ne tips.

0-ring and tip cone.

Insufficient amount of grease on Clean and grease 0-ring and tip cone;

cylinder and 0-ring. apply grease.

Damaged 0-ring. Change the 0-ring.

Inaccurate Incorrect operation. Follo instuctions carefully.

dispensing

Pipette incorrectly assembled Reassemble according to the instructions.

after disassembling.

Un anted substances inside the pipette. Clean the interior of the pipette.

Calibration altered; caused by

misuse, for example:

• Faulty calibration - High viscosity Recalibrate according to the instructions.

fluids may require recalibration

• Uneven dispensing Recalibrate ith the liquids in question.

Make sure that temperatures of tip

and liquids used are the same.

Aseptic Contaminated tips. Autoclave at 121°C for 20 minutes,

working orking ith gloves.

Finnpipette

®

BioControl

Problem Possible cause Solution

Leakage Tip incorrectly attached. Attach tips firmly.

Foreign bodies bet een Clean and grease 0-ring and tip cone.

the piston, 0-ring and tip cone. Use silicon grease.

Insufficient amount of grease Clean and grease 0-ring and tip cone.

on cylinder and 0-ring. Use silicon grease.

Damaged 0-ring. Change the O-ring.

Inaccurate Incorrect operation. Follo instructions carefully.

dispensing Tips attached incorrectly. Attach tips firmly.

Calibration altered Recalibrate.

possibly by misuse.

Inappropriate calibration. Recalibrate.

High viscosity liquids may

require recalibration.

isplay is Battery is discharged. Mount the pipette in the recharge stand, and

blank make sure that the light beside the display is on.

Po er is OFF. Move the pipette slightly.

CALIBRATE Pipette is in reset mode. Lock the latch and select the module.

text on the pipette Press the dual stop trigger to the

won’t operate second stop.

Pipette won’t Tip cone module is Release the latch, attach module firmly

operate improperly attached. to the pipette and lock the latch;

press trigger to the second stop.

Module does Ne module. Close the latch ithout the module. Accept

not engage the volume range. Drive the coupler out of the

pipette and keep pressing the trigger. Open

the latch and push the module in the pipette

a fe times. Release the trigger and try again.

17

Calibrating your pipettes

Calibration of Pipettes

Calibration of pipettes officially means determining the difference between the dis-

pensed olume and the selected olume. Adjustment means altering the pipette

so that the dispensed olume is within certain specifications.

All Finnpipettes are factory calibrated and adjusted to gi e the olumes as spec-

ified with distilled or deionised water. During factory calibration, performance is

checked with fi e different weighings at both the maximum olumes of the range

and at the minimum or 10% of the maximum olume, whiche er is higher. Finnpi-

pettes are designed to permit recalibration and adjustment for different tempera-

tures and arious iscous liquids.

Pipette calibration standards

The most common standards concerning pipette calibration are in a state of

change. The German DIN 12650 is most commonly used in Europe, but a new er-

sion of the international standard ISO 8655 is coming in the near future, which will

be a further de elopment of DIN 12650. The latest drafts of both standards specify

the gra imetric test method for accuracy, precision and permitted errors. The spec-

ifications of all Finnpipettes conform to both DIN 12650 and ISO 8655 standards.

Calibration of Pipettes in a Quality System

The main objecti e of pipette calibration in a quality system is to ensure that meas-

urements are made with the intended accuracy. Very often error limits are taken

from the manufacturer’s specifications, while far less accuracy is required to per-

form the work. If these limits are not easily obtained, or ary, another option is to

set the limits according to accepted standards (DIN 12650 or ISO 8655). Howe er

if the laboratory work requires the highest accuracy, the manufacturer’s limits

should be used. Basically e ery user should define their own limits, according to

the application used and the ambient conditions.

Finnpipette Calibration Software is a Windows-based program designed for cal-

ibrating Finnpipettes and pipettes of any other brand.

To use the calibration software, simply install it according to the instructions.

Set the en ironmental conditions and start the calibration. Follow the on-screen

menus to complete the procedure. Once the settings are entered, the program cal-

culates the mean olume, accuracy and precision of the pipetted olume based on

up to 15 separate weighings. When using Sartorius or Precisa balances, the pro-

gram can be linked directly to the balance. The ad anced Finnpipette Calibration

Software automatically generates complete documents with passed/failed marks

depending on the limits in use for the quality system.

18

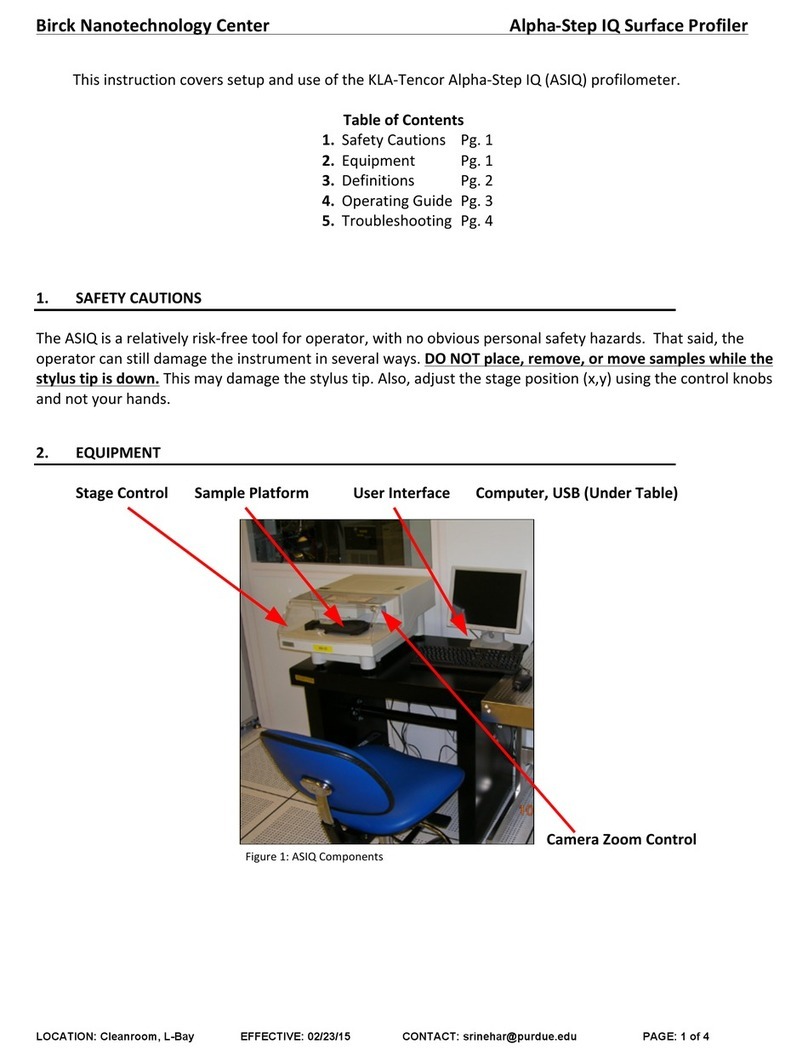

Device requirements and test conditions

Balance:

The scale graduation alue of the balance should be chosen according to the se-

lected pipette olume.

Volume range Readable graduation Sartorius model (example)

Under 10 µl 0.001 mg Sartorius MC5

10 - 100 µl 0.01 mg Sartorius MC210

Abo e 100 µl 0.1 mg Sartorius MC210

Note:

Check the calibration of your balance regularly using known weights.

Test liquid:

Water, distilled or deionised, “Grade 3”, conforming to ISO 3696. The test water is

held in the calibration room for at least 2 hours before calibration to reach equilibri-

um with the test room conditions.

Test room:

Tests are performed in a draught-free room at a constant (± 0.5°C) temperature of 20°C

to 25°C. Relati e humidity must be abo e 55%. Especially with olumes under 50 µl,

the air humidity should be as high as possible to reduce the e aporation loss effect.

- The pipette, the water and the air in the test room should be at the same

temperature.

- A new tip should be pre-wetted 3 to 5 times to impro e the accuracy.

- Always pipette water from a reser oir, do not take it back from the balance.

- Check the calibration regularly, depending on the frequency of use and on the

application, but at least once a year. If used daily, a three-month inter al is

recommended.

Procedures to check calibration:

Perform the calibration check using the pipetting technique you use in your appli-

cations.

Manual single channel pipettes

- The pipette is held in the calibration room for at least 2 hours before calibration

to reach equilibrium with the test room conditions.

- The pipette is checked at the maximum olume (nominal olume) and at the

minimum olume or 10% of the maximum olume, whiche er is higher.

For example, Finnpipette 0.5 - 10 µl is tested at 10 µl and 1 µl.

- A series of ten pipettings is performed with both olumes.

- Calculate the accuracy and precision using the formulas below. If the calculated

results are within the limits gi en in the Instructions-for-use booklet, the pipette

calibration is correct. If not, the pipette has to be adjusted (see page 19) with

the lower olume and checked again.

19

Manual multichannel pipettes

- The pipette is held in the calibration room for at least 2 hours before calibration

to reach equilibrium with the test room conditions.

- The pipette is checked at the maximum olume (nominal olume) and at the

minimum olume or 10% of the maximum olume, whiche er is higher.

For example, Finnpipette 0.5 - 10 µl is tested at 10 µl and 1 µl.

- Both olumes are tested with the two end channels.

- A series of ten pipettings is performed with both olumes.

- Calculate the accuracy and precision using the formulas below. If the calculated

results are within the limits gi en in the Instructions-for-use booklet, the pipette

calibration is correct. If not, the pipette has to be adjusted with the lower

olume (see below) and both end channels ha e to be checked again.

Finnpipette BioControl single channel module

- The pipette is held in the calibration room for at least 2 hours before calibration

to reach equilibrium with the test room conditions.

- Use the Finnpipette BioControl calibration software that comes with

the pipette.

- The pipette is checked at the maximum olume (nominal olume) and at the

lower calibration olume, which can be found from the Instructions-for-use

booklet or from the Finnpipette BioControl calibration software.

- A series of ten pipettings is performed with both olumes.

- Calculate the accuracy and precision of both series using the formulas below

and compare to the limits gi en in the “Checking the calibration” chapter in the

Instructions-for-use booklet. If the calculated results are within the selected

limits, the pipette calibration is correct. If not, adjust the pipette as

described below.

Finnpipette BioControl multichannel module

- The pipette is held in the calibration room for at least 2 hours before calibration

to reach equilibrium with the test room conditions.

- The pipette is checked at the maximum olume (nominal olume) and at the

lower calibration olume, which can be found from the Instructions-for-use

booklet or from the Finnpipette BioControl calibration software.

- Both olumes are tested with the two end channels.

- A series of ten pipettings is performed with both olumes.

- Calculate the accuracy and precision of both series using the formulas below

and compare to the limits gi en in the “Checking the calibration” chapter in the

Instructions-for-use booklet. If the calculated results are within the selected

limits, the pipette calibration is correct. If not, adjust the pipette as

described below.

Procedures to ad ust the pipette:

Manual single channel pipettes

- The adjustment is done at the lower olume.

- Place the ser ice tool that comes with the pipette into the openings of the

20

calibration nut at the top of the handle.

- Turn the ser ice tool clockwise to increase the olume or counter clockwise to

decrease the olume.

- After the adjustment, check the calibration as described abo e.

Manual multichannel pipettes

- The adjustment is done at the lower olume with one of the middle channels.

- Place the ser ice tool that comes with the pipette into the openings of the

calibration nut at the top of the handle.

- Turn the ser ice tool clockwise to increase the olume or counter clockwise to

decrease the olume.

- After the adjustment, check the calibration as described abo e.

Finnpipette BioControl single channel module

- Adjustment is done in the calibration mode. To change the current calibration,

do as follows:

1. Start the calibration software that comes with the pipette.

2. Choose the olume range.

3. Enter the mean olume of the ten pipettings performed with both olumes

(done in the calibration check) to the fields.

4. Take the pipette and determine the alues of the HK- and PK-factors: push

down the MODE-button and keep it down and then push the + and -

buttons as well. CALIBRATE text is now blinking, push SET to accept. The

current HK-factor is now blinking followed by the PK-factor. Note: These

factors ha e different alues depending on the module, so please check

that you choose the right module.

5. Enter these factors to the OLD FACTORS fields of the calibration software.

6. To get the new factors, click the CALCULATE button. The new factors will

be displayed.

- Alternati ely the Finnpipette Calibration Software may be used to determine the

new HK- and PK-factors.

- Take the pipette again and change the HK- and PK-factors with + and - buttons,

then accept the new alues by pushing the SET button.

- After the adjustment, check the calibration as described abo e. When using the

Finnpipette Calibration Software, continue according to the on-screen menus

after entering the new alues for HK- and PK-factors to the handle unit.

Finnpipette BioControl multichannel module

- Adjustment is done in the calibration mode. To change the current calibration,

do as follows:

1. Start the calibration software that comes with the pipette.

2. Choose the olume range.

3. Enter the mean olume of the ten pipettings performed with both olumes

(done in the calibration check) to the fields.

4. Take the pipette and determine the alues of the HK- and PK-factors: push

down the MODE-button and keep it down and then push the + and -

buttons as well. CALIBRATE text is now blinking, push SET to accept. The

current HK-factor is now blinking followed by the PK-factor. Note: These

This manual suits for next models

1

Table of contents