ThermOmegaTech THERM-O-MIX WWM Programming manual

THERM-O-MIX®WWM STATION

Troubleshooting Manual

www.ThermOmegaTech.com | 1-877-379-8258

Table of Contents

Page 1

Topic

Introduction .................................................................................................................

Denitions and Terminology .......................................................................................

Recommended Tools .................................................................................................

Checklist .................................................................................................................

Operating Sequence and Failure Modes ...........................................................................

Normal Operating Sequence For Therm-O-Mix Station ...................................................

Failure Modes .......................................................................................................

V1 Failure Mode ...............................................................................................

WWM Diaphragm Actuator Failure Mode ............................................................

V4 Failure Mode ..............................................................................................

Troubleshooting ...........................................................................................................

Troubleshooting Warning Statement ...........................................................................

Decommissioning the Therm-O-Mix Station for Troubleshooting and Repairs.....................

Analyzing Component Failure by Conditions .................................................................

Adjustments and Repairs ...............................................................................................

V1 Mixing Valve Adjustment Instructions with the Unit Running ......................................

V1 Mixing Valve Adjustment Instructions with the WWM Diaphragm Removed..................

WWM Diaphragm Actuator/VI Mixing Valve Replacement Instructions.............................

V4 Control Valve Replacement Instructions .................................................................

Appendices

Therm-O-Mix Safety Shower Station Schematic..................................................................

Therm-O-Mix Safety Shower Station Flow Chart................................................................

Station Line Drawing......................................................................................................

Therm-O-Mix WWM Safety Shower Station Checklist.........................................................

WWM Diaphragm Actuator/V1 Mixing Valve Line Drawing....................................................

WWM Diaphragm Actuator/V1 Mixing Valve Adjustment Photos...........................................

V4 Control Valve Photo...................................................................................................

Section

1.0

1.1

1.2

1.3

2.0

2.1

2.2

2.2.1

2.2.2

2.2.3

3.0

3.1

3.2

3.3

4.0

4.1

4.2

4.3

4.4

A1

A2

A3

A4

AS

A6

A7

Section 1.0: Introduction

This manual is designed to aid selected companies/qualied personnel to troubleshoot and re-

pair Therm-OmegaTech’s Therm-O-Mix WWM Safety Shower Stations. Any qualied personnel

assigned to troubleshoot or repair a Therm-O-Mix Safety Shower Station should read the entire

manual before proceeding. If you have any questions or concerns about the information found in

this manual please contact ThermOmegaTech Inc. at 1-877-379-8258.

Section 1.1: Denitions and Terminology

• System = safety shower/eyewash station

• Station = Therm-O-Mix Station tempered water unit

• Normal Range = tepid/moderately warm/lukewarm potable water not to exceed lOO°F

• Flow Pressure = gauge pressure measured during ow ( dynamic pressure)

• V1 = primary mixing valve; mixes cold inlet water with hot inlet water

• V4 = normally closed; nal safety control; senses water temperature out of mixing valve V1;

V4 opens if the outlet water temperature is too high, short circuiting the WWM Diaphragm

Actuator, closing the hot port of V1 and reducing hot water ow

• WWM Diaphragm Actuator = normally retracted for standard mixing mode; pressure

sensitive diaphragm overrides and closes hot port during over-temperature or loss of hot

water supply at V1

Page 2

Section 1.2: Recommended Tools

Section 1.3: Check List

The following is a list of recommended tools needed to properly troubleshoot and repair a

Therm-O-Mix WWM Safety

• 1/8, 3/16 Hex Keys

• Open-end wrenches including 7/16”, ½, 1”, 1-1/8”, 1½”)

• Channel lock/ Alligator Pliers

• (2) 12” or 14” Pipe wrenches

• (2) 12” or 14” Spud wrench w/ 2-5/8” Capacity

• Thermometer or Thermocouple w/ reader

• Phillips screwdriver

Review the checklist below before troubleshooting the Therm-O-Mix WWM Safety Shower

Station. See Appendix #4 for the printable checklist.

• Does the plant have adequate Hot Water Flow Pressure? (Recommended min. 45 PSIG/ max.

100 PSIG)

• Is the station’s hot water supply line properly sized? (Recommended min. 1” IPS)

• Does the plant have adequate Cold Water Flow Pressure? (Recommended min.

45 PSIG/ max. 100 PSIG)

• Is the station’s cold water supply line properly sized? (Recommended min. 1” IPS)

• Is the station supplying tempered water to anything other than the Safety Shower Station?

• Are freeze and scald protection valves installed correctly? (As required for outdoor

applications)

• Is the cold water supply line in contact with or being overheated by another source? (Steam

supply lines, solar radiation or steam tracing)

Page 3

Section 2.0: Operating Sequence and Failure Modes

The V1 mixing valve blends the cold inlet water with the hot inlet water to produce the set-point

outlet water temperature. If the water temperature out of V1 is high, V4 opens which short

circuits the WWM Diaphragm Actuator reducing the hot water ow to the mixing valve outlet.

If the outlet water temperature is above 95°F prior to activating the system the V4 will short

circuit the WWM Diaphragm Actuator holding the hot water port closed until the outlet water

temperature falls below 85°F. The water supply lines should have pressure regulators installed

as per the factory’s installation instructions. The hot water ow pressure should be slightly

higher than the cold water ow pressure but not more than 10 PSIG higher. Refer to Appendix

#1 for the Station Schematic and Appendix #2 for the Station Flow Chart.

If Vl failed with cold port closed (hot port open): only hot water ows to mixing valve outlet.

V4 will open and short circuit the WWM Diaphragm Actuator when the Station outlet exceeds

approximately 95°F, thus closing the hot inlet port on the mixing valve. With the hot port

closed, no hot water can ow to the mixing valve, so the Station outlet is cold water only.

Station will start to cycle hot - cold as the V4 sees cold water.

If V1 failed with hot port closed (cold port open): no hot water can ow to V1 mixing valve;

system supplied with cold water only. V1 is probably jammed open with debris.

If Diaphragm Actuator failed retracted (normal mixing mode): will not be noticed unless there is

an over-temperature situation or loss of hot water supply to the Station.

If Diaphragm Actuator failed extended (override mode): no hot water can ow to V1 mixing

valve; system supplied with cold water only.

If V4 failed closed: no signicance unless V1 also fails or outlet temperature is over 95°F for

more than 15 seconds.

If V 4 failed open: mixing valve hot port will be closed, so only cold water ows from the

Station. Debris may be stuck to the seat area inside the V 4 not allowing a good seal.

Section 2.1: Normal Operating Sequence For Therm-O-Mix Station

Section 2.2: Failure Modes

Section 2.2.1: V1 Failure Mode

Section 2.2.2: WWM Diaphragm Actuator Failure Mode

Section 2.2.3: V4 Failure Mode

Page 4

Troubleshooting a Therm-O-Mix Station in the eld may require turning off the hot and cold

water supply to the emergency safety shower/eyewash system. As such, please contact the

plant safety manager/supervisor and follow proper procedures for tagging, locking out, and other

possible issues relating to servicing and temporarily rendering the safety equipment unusable.

Notify all personnel working in the area that the emergency safety shower/eyewash equipment

will be temporarily disabled.

Follow the steps listed below to properly decommission the Therm-O-Mix Station for

troubleshooting and repairs:

1. Close the hot water supply line valve to the station.

2. Activate the shower and eyewash system for a minimum of two minutes to deplete the hot

water pressure trapped between the supply shutoff valve and the station. A longer period of

time may be needed, depending on the size and length of supply piping.

3. With the system activated close the cold water supply valve to the station.

4. See Section 4.0, for individual valve adjustment and/or replacement.

5. Once Therm-O-Mix has been repaired, open the hot and cold water supply valves to the

station. Allow station to run for at least one minute to purge the system.

6. Insert the temperature-reading device into the eyewash nozzle. Activate the eyewash and

record the temperature several times over a 5-10 minute cycle. Repeat this step for the

shower, attaching the temperature-reading device to the shower head. Record temperatures

on the Unit Checklist (see Appendix# 4).

CAUTION: THERM-O-MIX PIPING MAY BE HOT AND CARE SHOULD BE TAKEN

DURING REPAIRS. BE CAREFUL WHEN REMOVING PARTS FOR REPAIR OR

REPLACEMENT; HOT WATER MAY BE TRAPPED IN THE STATION.

Section 3.1: Trouble Shooting/Repair Warning Statement

Section 3.2: Decommissioning the Therm-O-Mix Station For Troubleshooting

and Repairs

Section 3.0: Trouble Shooting and Repairs

Page 5

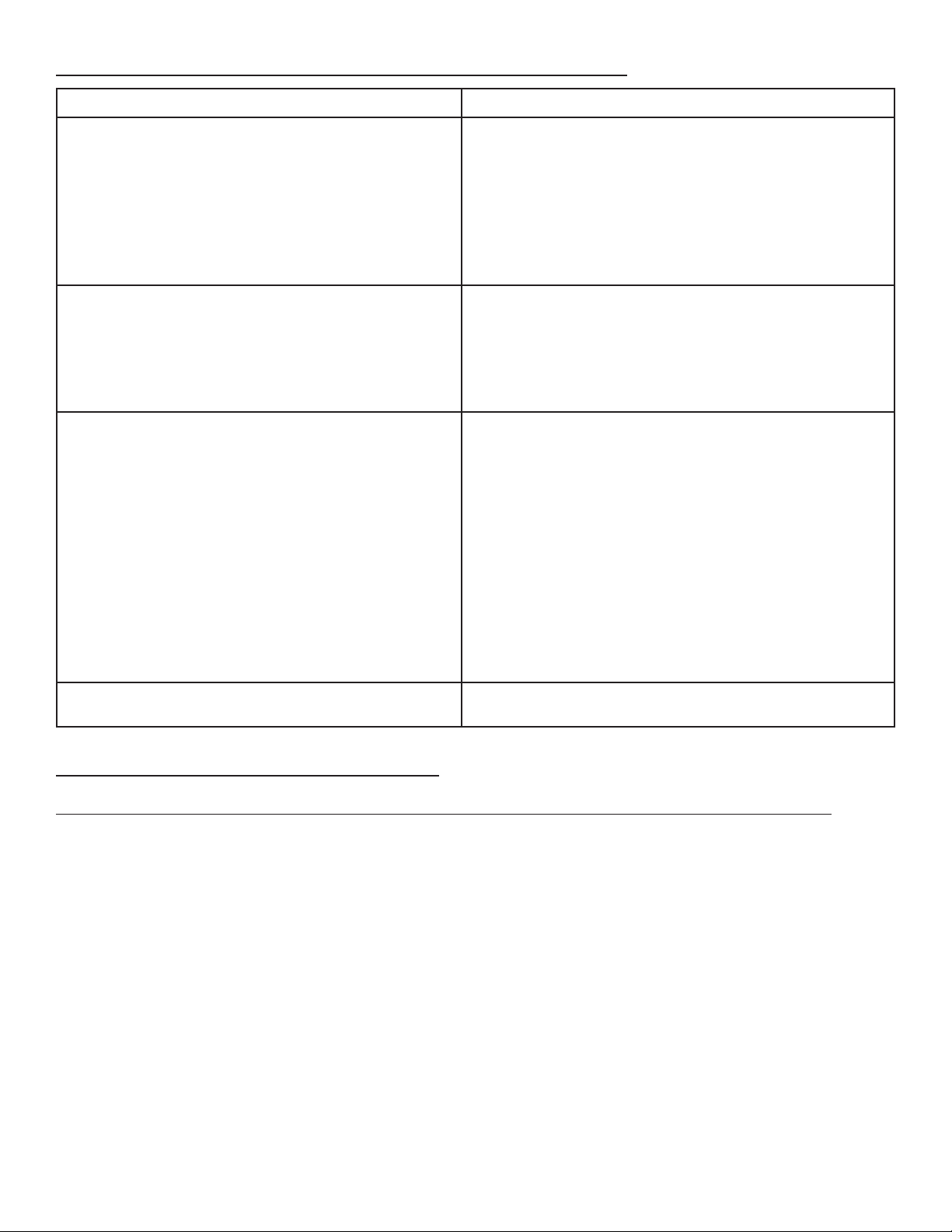

Section 3.4: Analyzing Component Failure by Conditions

Section 4.0: Adjustments and Repairs

Section 4.1: V1 Mixing Valve Adjustment Instructions with the Unit Running

CONDITION COMPONENT FAILURE

If the outlet temperature remains above the

normal range for long periods of time

without uctuation in the outlet temperature.

Follow Section 3.1 & 3.2 to decommission the

station for repair. Follow Section 4.2 to adjust

the V1 Mixing Valve outside the unit. If the valve

cannot be adjusted correctly a replacement WWM

Diaphragm Actuator is required. If the outlet

temperature is above 95°F, replacement of the V4

Control Valve is required. (See section 4.3 &4.4 for

replacement instructions)

If the outlet temperature uctuates, rising

above the normal range and then drops

below the normal range.

Follow Section 3.1 & 3.2 to decommission the

station for repair. Follow Section 4.2 to adjust

the V1 Mixing Valve outside the unit. If the valve

cannot be adjusted correctly a replacement WWM

Diaphragm Actuator is required. (See section 4.3 for

replacement instructions)

Cold Water Only

Verify that the hot water ow pressure is adjusted

slightly high than the cold water ow pressure as

per the factory’s installation instructions. Follow

Section 3.1 & 3.2 to decommission the station for

repair. Remove the V4 Control Valve for testing

(See section 4.4). If the V4 tests correctly Follow

Section 4.2 to adjust the V1 Mixing Valve outside

the unit. If the valve cannot be adjusted correctly a

replacement WWM Diaphragm Actuator is required.

If the V1 Mixing Valve is properly adjusted verify

that the hot water supply is not blocked before

replacing the WWM Diaphragm Actuator by slowing

opening the hot water supply valve.

Unit Runs Slightly Off Set-Point Minor adjustments can be made to the V1. (See

section 4.1)

1. Remove the cap nut located on the top of the diaphragm head with a 1” wrench.

2. Loosen calibration lock nut with a 7/16” wrench.

3. Use a marking pen to make a reference mark so that the calibration screw can be reset to

the original location if needed.

4. Use a 1/8” hex key to adjust the calibration screw while the unit is running. Turning the

screw counter clock-wise will raise the temperature and turning the screw clock-wise will

lower the temperature. The calibration screw should only be adjusted a ½ turn at a time.

Allow the unit to stabilize for at least one minute after adjustment before trying to make

other adjustments.

5. Once the necessary adjustments are made tighten the lock nut onto the calibration screw.

6. Re-install the cap nut making sure the face seal does not get pinched. Snug the acorn nut

with a 1” wrench.

Before beginning repairs read and understand Section 3.1. The Station should be tested after all

adjustments are completed.

Section 4.2: V1 Mixing Valve Adjustment Instructions with the WWM

Diaphragm Removed

Before beginning repairs read and understand Section 3.1 and follow the steps in Section 3.2

to decommission the Therm-O-Mix Station. The Station should be tested after all repairs are

completed.

1. Label each hose connection going to the diaphragm housing for easy re-installation. (See

Appendix #3)

2. Disconnect hoses from the diaphragm housing only.

3. Use a 1-1/2” wrench or spud wrench to loosen diaphragm valve assembly. Once unthreaded,

pull diaphragm valve out. Some resistance may be felt due to O-ring seal.

4. Remove cap nut and loosen calibration lock nut with a 7/16” wrench.

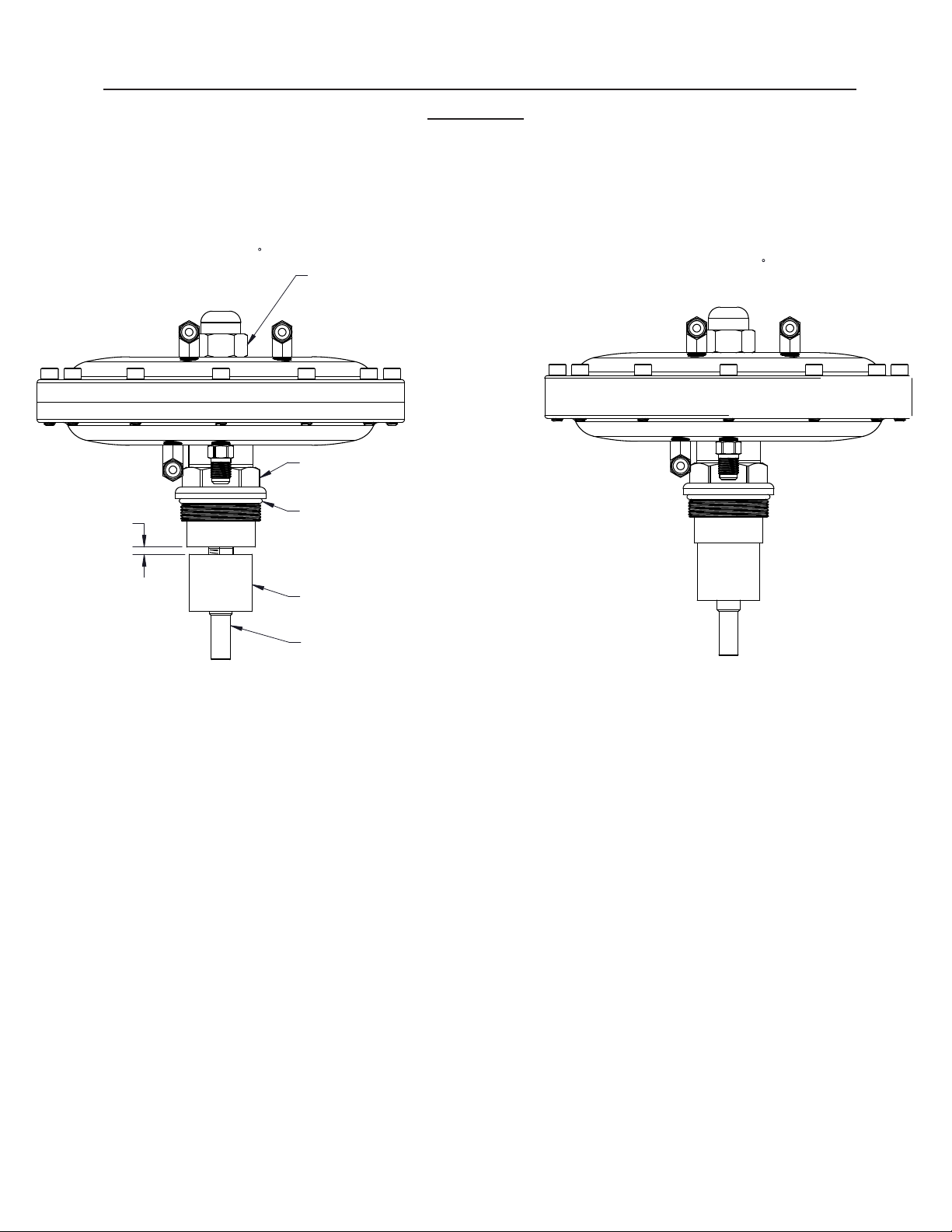

5. Place the stainless steel sensor into a water bath with a temperature 5F over the set point

for ve minutes. *Note: The sensor should be at or below 75F prior to being placed into the

water bath for proper calibration. Use calibration screw to adjust the valve spool so that the

opening between the spool and the cap is .160-.175 in. (See Appendix #5 & #6).

6. Place stainless steel sensor into a water bath with a temperature 5°F below the set point for

ve minutes. Verify that the top of the spool is sitting on the bottom of the cap.

7. Once properly adjusted, tighten the calibration lock nut and replace cap nut.

8. Thread WWM Diaphragm Actuator back into the V1 Mixing Valve Tee assembly and tighten

with 1-1/2” wrench.

9. Position the diaphragm housing so that the adaptor ttings are pointing to the side of the

body with the braided hoses. *Note: To position the diaphragm housing, rotate clockwise

when looking down on the Therm-O-Mix® Station/WWM to prevent the valve internals from

loosening.

10. Reconnect the braided hose lines by hand tightening the hose swivel ttings onto the

adaptor ttings. Use a 9/16” open end wrench to tighten the swivel nut 1 to 1-1/2 hex

ats or 60 to 90 past hand tight. *Use second 1/2” wrench as a back-up wrench to

prevent hose from twisting.

*If braided hose connections containing orice plates are opened, the orice plate must be

replaced. Orice plates have been included in the replacement kit in case they are needed.

(See Appendix #3)

Page 7

Before beginning repairs read and understand Section 3.1 and follow the steps in Section 3.2

to decommission the Therm-O-Mix Station. The Station should be tested after all repairs are

completed.

1. Label each hose connection going to the diaphragm housing for easy re-installation.

(See Appendix #3)

2. Disconnect hoses from the diaphragm housing only.

3. Use a 1-1/2” wrench or spud wrench to loosen diaphragm valve assembly. Once unthreaded

pull diaphragm valve out. Some resistance may be felt due to O-ring seal.

4. Remove old body O-ring.

5. Install new #221 Quad O-ring supplied with replacement kit.

6. Install new diaphragm valve assembly and tighten with 1-1/2” wrench.

7. Position the diaphragm housing so that the adaptor ttings are pointing to the side of the

body with the braided hoses. *Note: To position the diaphragm housing, rotate clockwise

when looking down on the Therm-O-Mix® Station/WWM to prevent the valve internals from

loosening.

8. Reconnect the braided hose lines by hand tightening the hose swivel ttings onto the adaptor

ttings. Use a 9/16” open end wrench to tighten the swivel nut 1 to 1-1/2 hex ats or 60

to 90 past hand tight. *Use second 1/2” wrench as a back-up wrench to prevent hose from

twisting.

*If braided hose connections containing orice plates are opened, the orice plate must be

replaced. Orice plates have been included in the replacement kit in case they are needed.

(See Appendix #3)

Section 4.3: V1 Mixing Valve Replacement Instructions

Page 8

Before beginning repairs read and understand Section 3.1 and follow the steps in Section 3.2

to decommission the Therm-O-Mix Station. The Station should be tested after all repairs are

completed.

1. Label each hose going to the V4 Control Valve to ensure proper orientation during

re-assembly.

2. Using a 9/16” wrench disconnect the 3 hose connections on the V4 Control Valve.

*Note: two orice plates will drop out of the upper and lower hose connections.

3. Unthread the V4 Control Valve from the V1 Valve Mixing Tee assembly using a 1-1/8”

wrench.

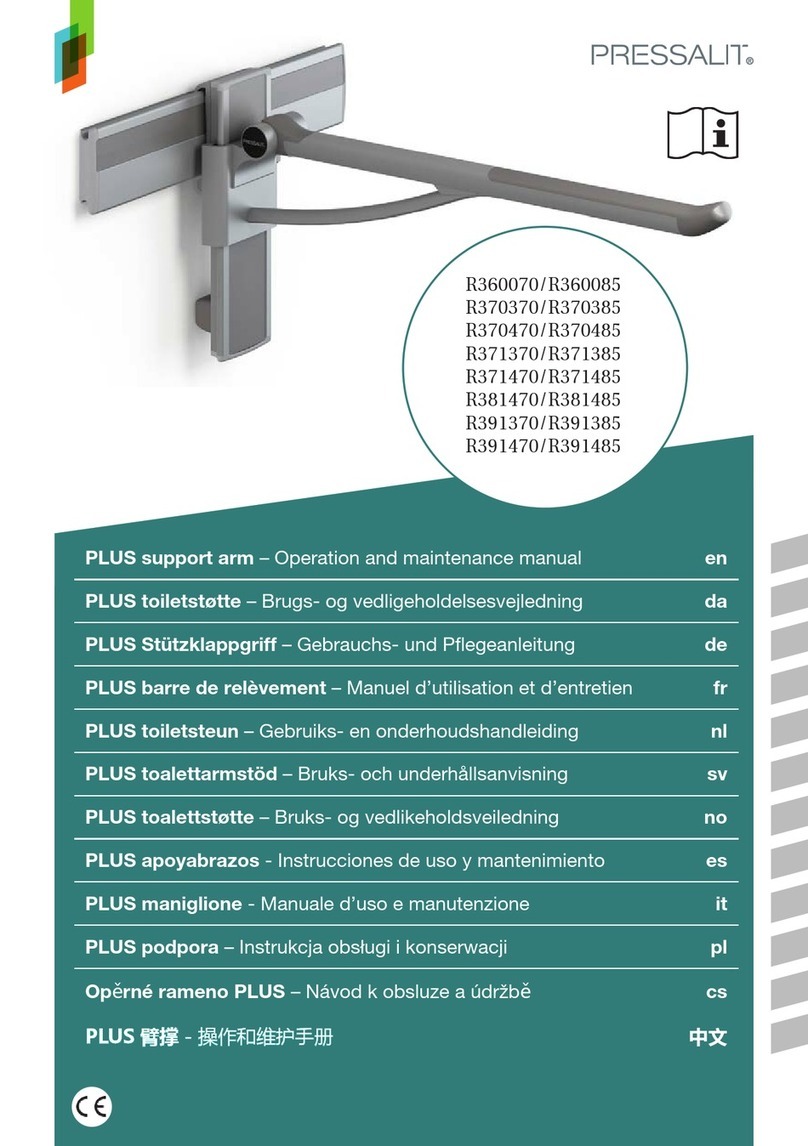

4. Place V4 Control Valve stainless steel sensor into a water bath at 98F or above for ve

minutes.

5. Using a compressed air nozzle, blow air into the upper angled hose tting. (See Appendix #8)

If air can be felt coming from the center hose tting, the V4 Control Valve has failed and must

be replaced. If not, continue to the next step.

6. Place V4 Control Valve stainless steel sensor into a water bath at 85F or below for ve

minutes.

7. Using a compressed air nozzle, blow air into the lower straight hose tting. (See Appendix #8)

If air can be felt coming from the center hose tting, the V4 Control Valve has failed and must

be replaced. If not, continue to the next step.

8. If the V4 Control Valve is working correctly, thread the valve back into the 3/8 NPT port. Use

teon tape or equal pipe thread sealant on all NPT threads.

9. The 2 outside connections on the V4 Control Valve require orice plates to be installed. Place

an orice plate in the female end of the hose and carefully thread the hose on to the proper

male tting. *Note: the middle connection of the V4 Valve does not receive an orice plate.

1. Label each hose going to the V4 Valve to ensure proper orientation during re-assembly.

2. Using a 9/16” wrench disconnect the 3 hose connections on the V4 Valve.

3. Unthread the V4 Valve from the V1 Valve Mixing Tee assembly using a 1-1/8” wrench.

4. Thread the replacement V4 Valve into the 3/8 NPT port. Use teon tape or equal pipe thread

sealant on all NPT threads.

5. The 2 outside connections on the V4 Valve require orice plates to be installed. Place an

orice plate in the female end of the hose and carefully thread the hose on to the proper male

tting. *Note: the middle connection of the V4 Valve does not receive an orice plate.

6. Thread tting until hand tight. Use a 9/16” wrench to tighten the swivel nut 1 full revolution

to crush the orice plate. Now turn swivel nut 1 to 1-1/2 hex ats or 60 to 90 to complete

tightening the hose.

*Use a second 1/2” wrench as a backup wrench to prevent hose from twisting.

Section 4.4: V4 Control Valve Replacement Instructions

V4 Control Valve Test

V4 Control Valve Replacement

10. Thread tting until hand tight. Use a 9/16” wrench to tighten the swivel nut 1 full

revolution to crush the orice plate. Now turn swivel nut 1 to 1-1/2 hex ats or 60 to 90

to complete tightening the hose.

*Use a second 1/2” wrench as a backup wrench to prevent hose from twisting.

Page 9

Appendices

Appendix #1

The Station schematic shows related valves and ow directions.

Appendix #2

The station ow chart shows the standard operating conditions and their relation to the Station

as a unit.

Appendix #3

The Station line drawing shows the unit with callouts for each valve or referenced part.

Appendix #4

The Station checklist should be used whenever troubleshooting or repair work is done on a

unit. The Station Serial Number is located on the V1 Mixing Body. The checklist can be sent to

[email protected] or faxed to # 215-674-8594, Attn: Engineering, if any additional

troubleshooting is required.

Appendix #5

Line drawing for WWM Diaphragm Actuator/V1 Mixing Valve adjustment.

Appendix #6

V1 Mixing Valve adjustment photos.

Appendix #7

V4 Control Valve test photo.

PORT A

TEPID WATER

OUTLET

DIAPHRAGM DRAIN HOSE

1-1/4" NPT

FEMALE

DIAPHRAGM

DRAIN HOSE

V4 DRAIN HOSE

DIAPHRAGM HEAD

V1 VALVE

PORT C

COLD WATER

INLET

1" NPT

FEMALE

V4 VALVE

COLD WATER

TEPID WATER

HOT WATER

DIAPHRAGM SUPPLY WATER

DIAPHRAGM DRAIN WATER

THERMAL SENSING LINE

DIAPHRAGM SUPPLY HOSE

B

DIAPHRAGM

SUPPLY HOSE

PORT

HOT WATER

INLET

1" NPT

FEMALE

Page 10

APPENDIX #1: Therm-O-Mix Safety Shower Station Schematic

Page 11

APPENDIX #2: Therm-O-Mix Safety Shower Station Flow Chart

IS HOT

WATER

AVAILIBLE?

IS

MIXING VALVE

OUTLET

ABOVE 95 F?

V4 OPEN,

DIAPHRAGM ACT.

OVERRIDE

MIXING VALVE (V1)

BLENDS HOT &

COLD WATER

TO SET POINT

IS COLD

WATER SUPPLY

ABOVE 95 F?

V4 OPEN,

DIAPHRAGM ACT.

OVERRIDE

DIAPHRAGM ACT.

OVERRIDE

TEPID WATER

TO EYEWASH/

SAFETY SHOWER

END

START

Page 12

APPENDIX #3: Station Line Drawing

ORIFICE

HOSE ASSEMBLY 7.5"

ORIFICE

ORIFICE

ORIFICE

V4, CONTROL VALVE

V1, MIXING VALVE

CAP NUT

DIAPHRAGM HEAD

PORT B

HOT WATERINLET

1" NPT

FEMALE

FEMALE

1-1/4" NPT

HOSE ASSEMBLY 7.5"

PORT C

COLD WATER

INLET

1" NPT

FEMALE

PORT A

TEPID WATER

OUTLET

HOSE ASSEMBLY 15" HOSE ASSEMBLY 9"

HOSE ASSEMBLY 9"

Page 13

APPENDIX #4: Therm-O-Mix WWM Safety Shower Station Checklist

Run #1

Run #2

Company_________________________________

Plant Location_____________________________

Serviceman/Company_______________________

Station/Serial Number_______________________

Contact___________________________________

Phone____________________________________

Date_____________________________________

Unit Location______________________________

Eyewash Temperature:_________________ F / C

Shower Temperature:__________________ F / C

Eyewash Start-up Spike:________________ F / C

Shower Start-up Spike:_________________ F / C

Eyewash Temperature:_________________ F / C

Shower Temperature:__________________ F / C

Eyewash Start-up Spike:________________ F / C

Shower Start-up Spike:_________________ F / C

Does the plant have adequate hot water ow pressure? (Recommended min. 45 PSIG/

max. 100 PSIG________________

Is the stations hot water supply line properly sized? (Recommended min. 1” IPS)_______________

Does the plant have adequate cold water ow pressure? (Recommended min. 45 PSIG/

max. 100 PSIG________________

Is the stations cold water supply line properly sized? (Recommended min. 1” IPS)______________

Is the station supplying tempered water to anything other than the Safety Shower Station?

YES/NO

If “YES,” explain:__________________________________________________________________________

__________________________________________________________________________________________

Are freeze and scald protection valves installed correctly? YES/NO

If “NO,” please explain:____________________________________________________________________

__________________________________________________________________________________________

Is the cold water supply line or the tempered water outlet in contact with or being overheated

by another source? (Steam supply lines, steam tracing or solar radiation) YES/NO

If “YES,” please explain:___________________________________________________________________

__________________________________________________________________________________________

Comments:_______________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

___________________________________________________________________________________

Page 14

APPENDIX #5: WWM Diaphragm Actuator/V1 Mixing Valve Line

Drawing

SET POINT -5 F

CARTRIDGE CAP

O-RING

SPOOL

THERMOSTATIC

ACTUATOR

CAP NUT FOR

ADJUSTMNET

SET SCREW

1" HEX

1-1/2 HEX

SET POINT +5 F

.160

.175

Page 15

APPENDIX #6: WWM Diaphragm Actuator/V1 Mixing Valve Adjustment

Photo

Loosen lock nut.

Adjust calibration screw.

Page 16

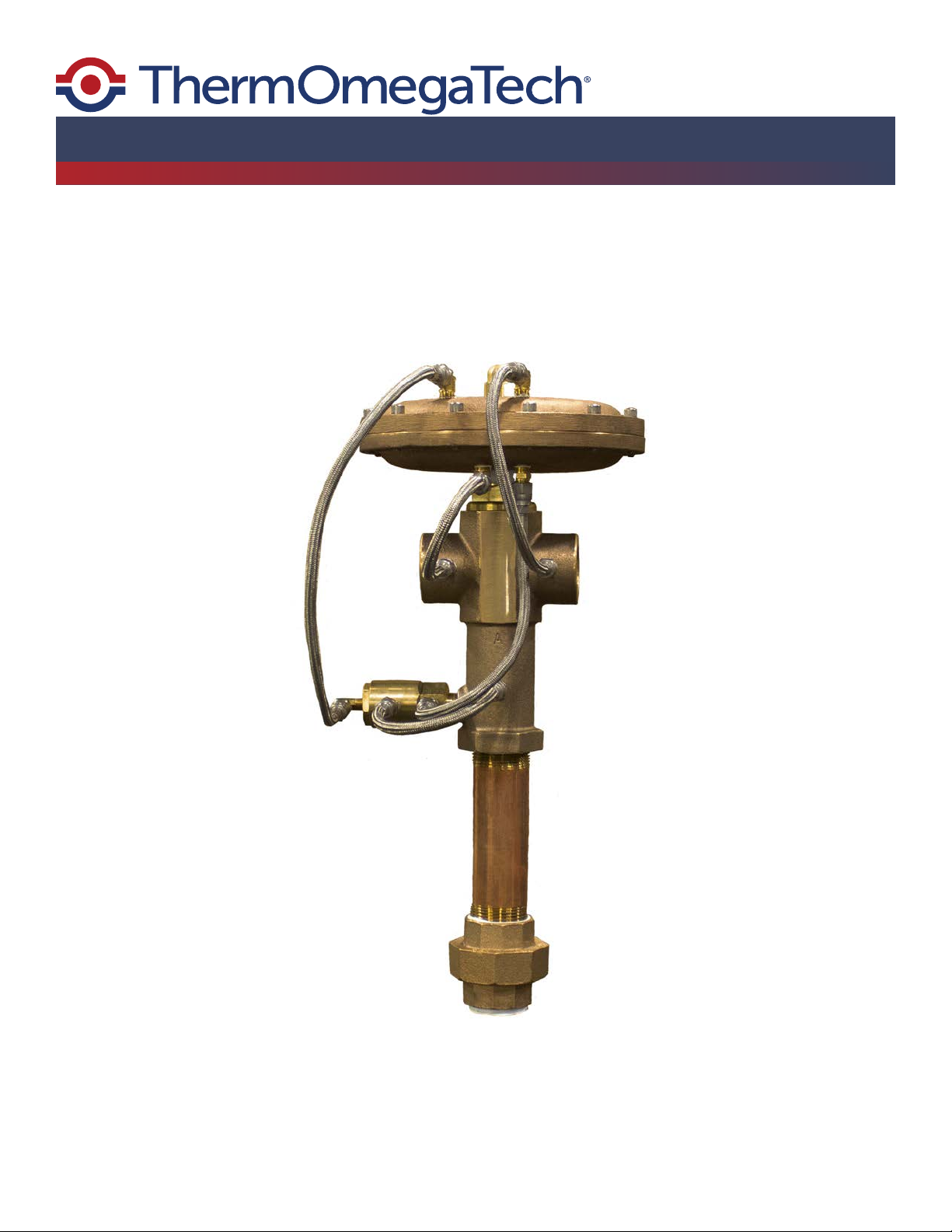

APPENDIX #7: V4 Control Valve Test Photo

Middle Hose

Adaptor, Dumps

to Outlet

Upper Hose

Adaptor, From

Outsie WWM

Diaphraghm

Actuator

Lower Hose

Adaptor, From

Inside WWM

Diaphragm

Actuator

WARNING: This product can expose you to chemicals, for example lead, nickel, acrylonitrile, which are known to the

State of CA to cause cancer, birth defects, or reproductive harm. For more information, go to www.P65Warnings.ca.gov

ThermOmegaTech®, Inc.

353 Ivyland Road 1-877-379-8258

Warminster, PA 18974 www.ThermOmegaTech.com

TOMix WWM

Rev: 10/2/20

Table of contents

Popular Safety Equipment manuals by other brands

Pressalit

Pressalit PLUS R360070 Operation and maintenance manual

Honeywell

Honeywell Howard Leight VERISHIELD VS 321 User instructions

ECOSAFE

ECOSAFE DLI92 instruction manual

Dupont

Dupont Tychem 6000 F Cat.III CHA5 Instructions for use

Apollo

Apollo Bio-Full Face Mask instruction manual

Argos

Argos 653/2651 manual

bolle SAFETY

bolle SAFETY OMF167 quick start guide

HELLY HANSEN

HELLY HANSEN HH Safe 150N user manual

Thiele

Thiele TWN 0812 Mounting instructions

RITE-HITE

RITE-HITE Dok-Lok STR-4000 installation manual

CMC Rescue

CMC Rescue 3D Important information

Guardian Fall Protection

Guardian Fall Protection CB-18 Anchor instruction manual