Thermopatch NL-28 User manual

NL-28

thermopatch.com

NL-28

V. 1.0 ENG

Jan2015

User manual

CATTENTION!

All persons involved in installation, commissioning,

operation, maintenance and repair of this product

should be made available to these instructions.

thermopatch.com

Manual NL-28 / mn_ENG_V1.0 original

2

V. 1.0 ENG

Jan2015

Copyrights

© 2016, Thermopatch bv, Almere, The Netherlands.

No part of this publication may be reproduced by any means

without the prior written permission of Thermopatch bv,

The Netherlands.

Thermopatch and the Thermopatch logo, Thermoseal and

Thermocrest are registered trademarks of Thermopatch.

thermopatch.com

Manual NL-28 / mn_ENG_V1.0 original

3

V. 1.0 ENG

Jan2015

Introduction

Dear User,

Welcome to the growing group of Thermopatch users. Your

purchase has been manufactured with the utmost care

to ensure that you benet as long as possible from your

Thermopatch product.

The products by Thermopatch are designed with special

attention to your convenience. Should you discover any fault

or damage upon receipt of this product, please contact your

local Thermopatch vendor.

The manual has been prepared in accordance with NEN 5509

and in conformity with the Machinery Directive 2006/42/EC.

This user manual is intended not only for all users of the

machine, but also for those who install and maintain the

NL-28. The goal is to familiarize you with the operation,

to provide for safe working instructions and guidelines for

periodical maintenance.

CATTENTION!

In order to make safe and optimal use of the NL-28, it is important to take note of and

understand the contents of this manual.

thermopatch.com

Manual NL-28 / mn_ENG_V1.0 original

4

V. 1.0 ENG

Jan2015

Contents

Copyrights 2

Introduction 3

Contents 4

DECLARATION OF CONFORMITY 5

1. General description 6

1.1 Delivery 6

1.2 Conditions of warranty 6

2. Intended use 7

3. Technical specications 8

3.1 Specifications of the NL-28 8

4. Overview of safety tips and warnings 9

4.1 Safety tips and warnings 9

5. Transport and storage 10

5.1 Transport 10

6. Operating instruction 11

6.1 Installation 11

6.2 Operating the NL-28 12

6.3 Using ‘DRY’ Mode (Optional) 13

6.4 Using the control panel 13

6.5 Press time and temperature settings 14

6.6 Pressure Adjustment 17

7. Assembly and installation 18

7.1 Installation 18

8. Maintenance instructions 19

8.1 Maintenance 19

9. Technical annexes 20

Parts list 01 20

Trouble shooting 21

Drawing 01 22

Drawing 02 23

10. End of life 24

thermopatch.com

Manual NL-28 / mn_ENG_V1.0 original

5

V. 1.0 ENG

Jan2015

DECLARATION OF CONFORMITY

We,

Thermopatch B.V.

Draaibrugweg 14

1332 Almere

The Netherlands

herewith declare, on our own responsibility, that the

machinery:

Thermopatch NL-28,

which this declaration refers to, is in accordance with the

conditions of the following Directive(s):

2006/42/EG (Machinery directive)

2014/35/EG (EMC directive)

The Netherlands, Almere, 01-04-2016

Jan Bausch,

Director

thermopatch.com

Manual NL-28 / mn_ENG_V1.0 original

6

V. 1.0 ENG

Jan2015

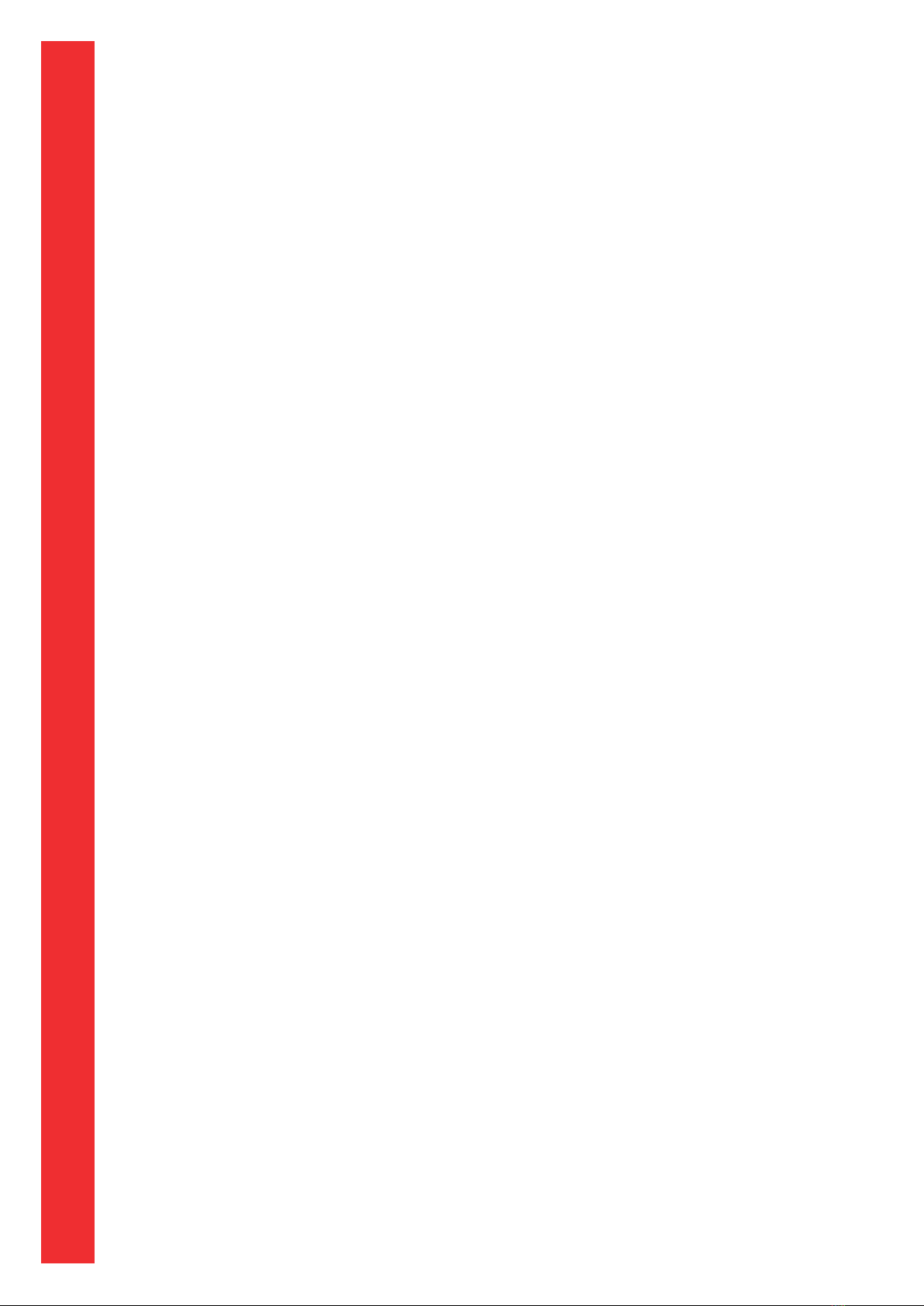

1. General description

The NL-28 is a practical and universal heat seal press with a

sliding and reversible sealing pad for optimal use.

Textile labels, company emblems, repair patches, transfers,

in short all Thermopatch materials for marking and repair are

easily and permanently pressed on all types of fabric.

1.1 Delivery

The NL-28 is mounted onto a pallet and covered with a

plywood box.

The following articles are included:

• NL-28 heat seal machine

• Power cord

• Manual on CD-ROM

• CE Declaration of Conformity in the manual on the CD

If one of these articles should be missing or faulty, please

contact your Thermopatch supplier.

1.2 Conditions of warranty

Thermopatch points to its warranty and product liability

conditions as laid down in our conditions of sales. These can

be obtained at your Thermopatch supplier.

thermopatch.com

Manual NL-28 / mn_ENG_V1.0 original

7

V. 1.0 ENG

Jan2015

2. Intended use

The NL-28 is a heat seal machine that is intended for the

application of heat seal transfers but also repair patches, heat

seal emblems and labels. In short, all Thermopatch marking

and mending materials can be applied with the NL-28.

WARNING!

Any use other than described above can be dangerous and cause damage and thus qualies

as ‘misuse’ which excludes Thermopatch bv from any liability.

thermopatch.com

Manual NL-28 / mn_ENG_V1.0 original

8

V. 1.0 ENG

Jan2015

3. Technical specications

3.1 Specifications of the NL-28

Power 2500 Watts

Power supply 230 Volt 50/60 Hz

Operating temperature 180 °C

Temperature range 0-220 °C

Press Time range 0-9 min. 30 sec.

Thermoregulator accurate up to +/- 10%

Adjustable pressure range 0-450 g/cm²

Machine height (closed) 570 mm

Machine height (open) 969 mm

Machine width 439 mm

Machine depth 830 mm

Machine depth (lower platen forward) 1020 mm

Gross weight, including packaging 75 kg

Net weight 57 kg

Size sealing pads, size 400 x 500 mm

Fuses 11.0 Ampere

A-weighted noise level <70 dB (A)

thermopatch.com

Manual NL-28 / mn_ENG_V1.0 original

9

V. 1.0 ENG

Jan2015

4. Overview of safety tips and warnings

4.1 Safety tips and warnings

CATTENTION!

Make sure you are informed about the contents of this manual before starting to work with

the NL-28. This ensures an optimal and safe use of the machine.

CATTENTION!

Always turn the power o (unplug it) when you need to carry out maintenance work or when

cleaning the machine.

CATTENTION!

Take care that there is enough space around the machine. Cables and connections must not

get pinched. Although the heat radiation of the press is low, there should be

enough space for cooling down.

CATTENTION!

Avoid contact with the the heating

element.

CATTENTION!

Pull the fabrics tight around the press pad and ensure that your hands are away from

the sealing pad before operating the machine.

WARNING!

Hot surface

WARNING!

Electric tension

thermopatch.com

Manual NL-28 / mn_ENG_V1.0 original

10

V. 1.0 ENG

Jan2015

5. Transport and storage

5.1 Transport

When the machine needs to be moved, Thermopatch advises

to use the original packaging.

• For carrying the press, ensure that the press is cold

and move the press by holding the two plates (top and

bottom) at the same time (closed press).

• Ensure that the screw designated for «Transport security»

is in place to secure the platens for carrying.

5.2 Storage

When the machine needs to be stored, Thermopatch advises

to use the original packaging. The machine should be stored

on a pallet, o the oor, in dry conditions.

Other manuals for NL-28

1

Table of contents

Other Thermopatch Kitchen Appliance manuals

Popular Kitchen Appliance manuals by other brands

Tayama

Tayama TYG-35AF instruction manual

AEG

AEG 43172V-MN user manual

REBER

REBER Professional 40 Use and maintenance

North American

North American BB12482G / TR-F-04-B-NCT-1 Assembly and operating instructions

Presto

Presto fountain popper instruction manual

Westmark

Westmark 1035 2260 operating instructions