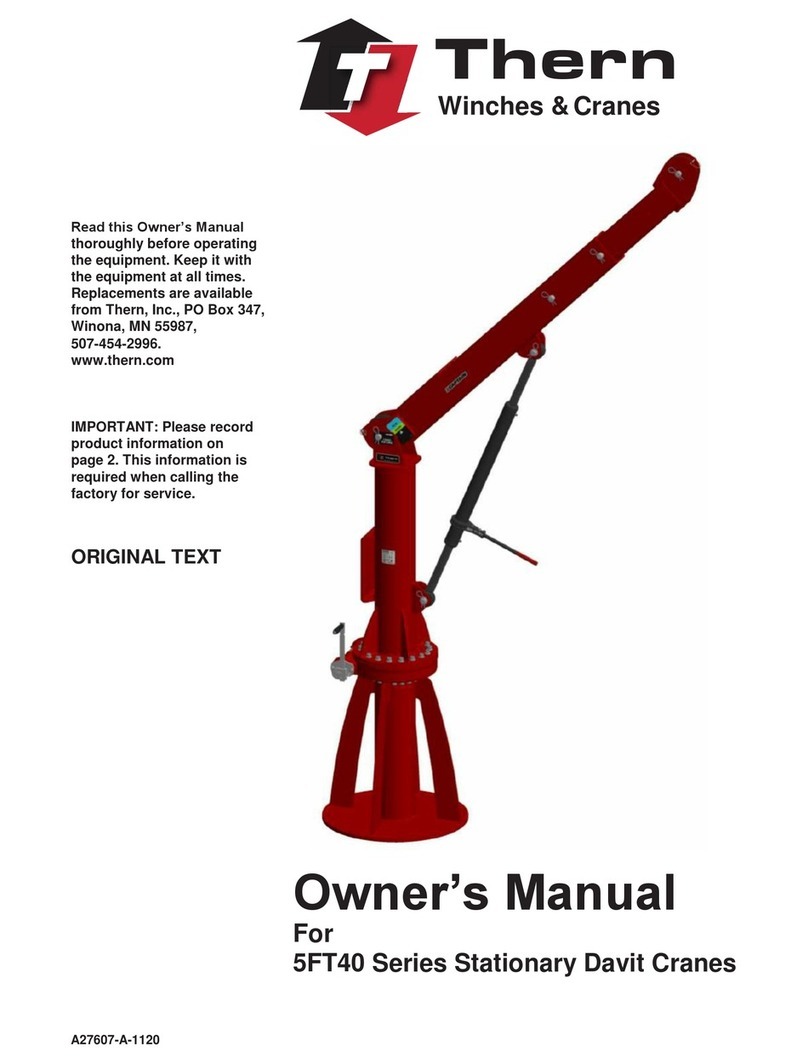

Thern 5BH5 User manual

Owner's Manual

For

5BH5 Hitch Mounted Crane Base

IMPORTANT: Please record

product information on

page 2. This information is

required when calling the

factory for service.

A28390-A-0921

ORIGINAL TEXT

Read this Owner’s Manual

thoroughly before operating

the equipment. Keep it with

the equipment at all times.

Replacements are available

from Thern, Inc., PO Box 347,

Winona, MN 55987,

507-454-2996.

www.thern.com

Thern

Winches & Cranes

Owners Manual for the 5BH5 Hitch Mount Base for Davit Cranespage 2

A28390-A-0921

Two-Year Limited Warranty

Thern, Inc. warrants its products against defects in material or workmanship for two years from the date of purchase

by the original using buyer, or if this date cannot be established, the date the product was sold by Thern, Inc. to the

dealer. To make a claim under this warranty, contact the factory for an RGA number. The product must be returned,

prepaid, directly to Thern, Inc., 5712 Industrial Park Road, Winona, Minnesota 55987. The following information

must accompany the product: the RGA number, the date of purchase, the description of the claimed defect, and a

complete explanation of the circumstances involved. If the product is found to be defective, it will be repaired or

replaced free of charge, and Thern, Inc. will reimburse the shipping cost within the contiguous USA.

This warranty does not cover any damage due to accident, misuse, abuse, or negligence. Any alteration, repair or

modication of the product outside the Thern, Inc. factory shall void this warranty. This warranty does not cover any

costs for removal of our product, downtime, or any other incidental or consequential costs or damages resulting from

the claimed defects. This warranty does not cover brake discs, wire rope or other wear components, as their life is

subject to use conditions which vary between applications.FACTORY AUTHORIZED REPAIR OR REPLACEMENT

AS PROVIDED UNDER THIS WARRANTY IS THE EXCLUSIVE REMEDY TO THE CONSUMER. THERN,

INC. SHALL NOT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES FOR BREACH OF

ANY EXPRESS OR IMPLIED WARRANTY ON THIS PRODUCT. EXCEPT TO THE EXTENT PROHIBITED

BY APPLICABLE LAW, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE ON THIS PRODUCT IS LIMITED IN DURATION TO THE DURATION OF THIS

WARRANTY. Some states do not allow the exclusion or limitation of incidental or consequential damages, or allow

limitations on how long an implied warranty lasts, so the above limitation or exclusion may not apply to you. This

warranty gives you specic legal rights, and you may also have other rights which vary from state to state.

Note: Thern, Inc. reserves the right to change the design or discontinue the production of any product without

prior notice.

About This Manual

The Occupational Safety and Health Act of 1970 states that it is the employer’s

responsibility to provide a workplace free of hazard. To this end, all equipment

should be installed, operated, and maintained in compliance with applicable

trade, industrial, federal, state, and local regulations. It is the equipment owner's

responsibility to obtain copies of these regulations and to determine the suitability

of the equipment to its intended use.

This Owner’s Manual, and warning labels attached to the equipment, are to serve

as guidelines for hazard-free installation, operation, and maintenance. They should

not be understood to prepare you for every possible situation.

The information contained in this manual is applicable only to the Thern 5BH5

Hitch Mounted Crane Base. Do not use this manual as a source of information for

any other equipment.

The following symbols are used for emphasis throughout this manual:

Failure to follow ‘WARNING!’ instructions may result in equipment damage,

property damage, and/or serious personal injury.

Failure to follow ‘CAUTION!’ instructions may result in equipment damage,

property damage, and/or minor personal injury.

Important!

Failure to follow ‘important!’ instructions may result in poor performance of

the equipment.

Please record the following:

Date Purchased:

Crane Model No.:

Crane Serial No.:

If sold with a winch:

Winch Model No.:

Winch Serial No.:

This information is required when

calling the factory for service.

page 3

A28390-A-0921

Owners Manual for the 5BH5 Hitch Mount Base for Davit Cranes

Suggestions for Safe Operation

DO the following:

Read and comply with the guidelines set forth in this Owner’s Manual. Keep

this manual, and all labels attached to the crane, readable and with the

equipment at all times. Contact Thern, Inc. for replacements.

Follow all suggestions in the “Suggestions for Safe Operation” section of the

Owner’s Manual supplied for the respective davit crane designed for use with

this hitch mounted base.

Position the hitch mounted crane base on rm ground such that the crane is

level. An uneven base may cause the boom to rotate in the direction the mast

is leaning.

Attach the hitch mounted crane base only to a 2 inch x 2 inch Class III or

better receiver hitch. The receiver hitch must be properly installed by a

qualied service technician.

Use the equipment in a clear location that is away from oncoming trac or

other hazards.

When done working, always remove the hitch mount from the vehicle.

DO NOT do the following:

Do not lift people, or things over people. Do not walk or work under a load or

in the line of force of any load.

Do not exceed the load rating of the crane or any other component in the

system. To do so could result in failure of the equipment.

Do not install non-standard davit cranes onto the hitch mounted base without

authorization from Thern, Inc.

Do not operate or apply loads without all pins securely in place.

Do not adjust support leg positions while the crane is loaded.

Do not use the hitch mount crane base with lightweight or otherwise unstable

vehicles that may move during operation.

Do not move the vehicle with the hitch mount attached.

Owners Manual for the 5BH5 Hitch Mount Base for Davit Cranespage 4

A28390-A-0921

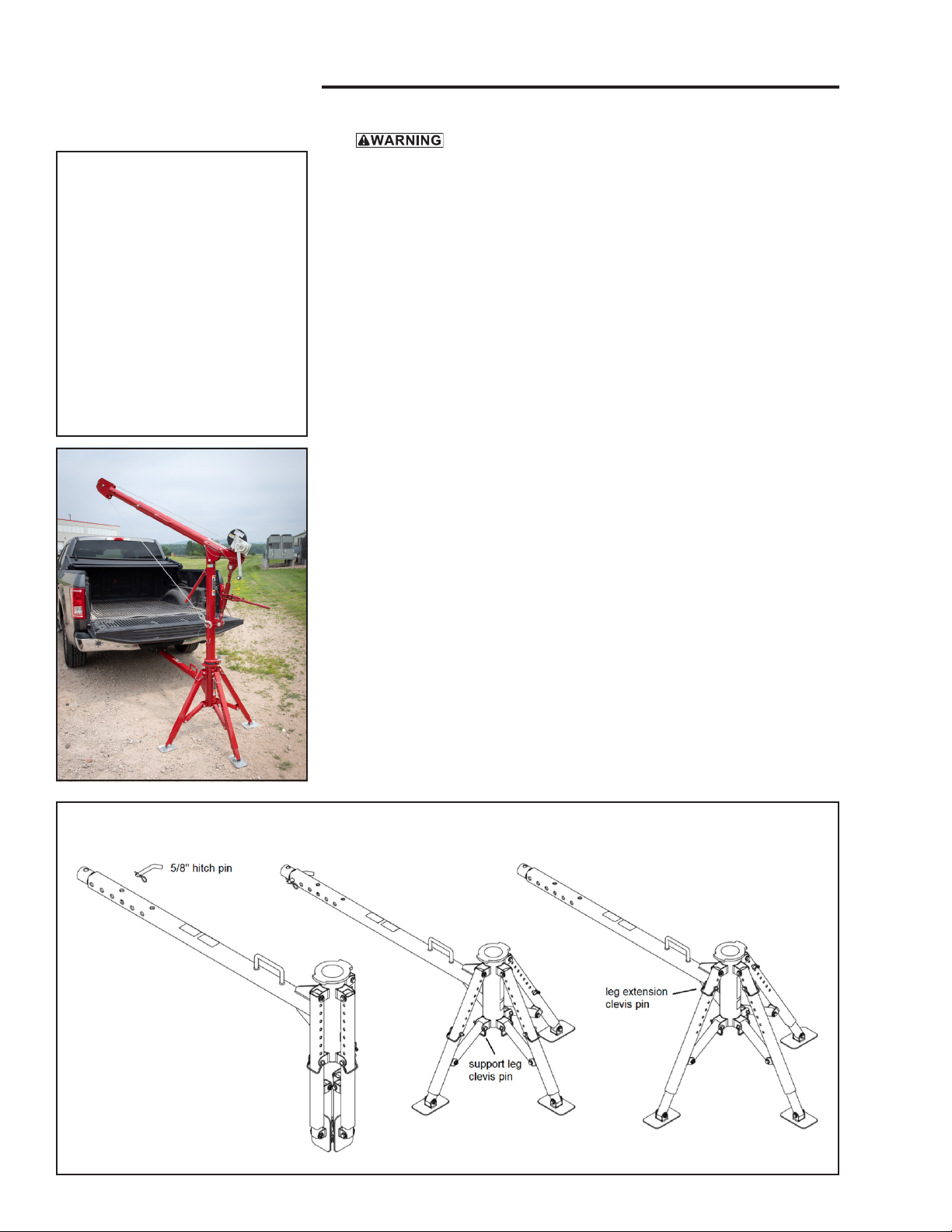

1.1 Installing the Hitch Mounted Base

Position the hitch mounted crane base on rm ground such that the crane is

level. An uneven base may cause the boom to rotate in the direction the mast

is leaning.

Attach the hitch mounted crane base only to a 2 inch x 2 inch Class III or

better receiver hitch. The receiver hitch must be properly installed by a

qualied service technician.

Use the equipment in a clear location that is away from oncoming trac or

other hazards.

Do not use the hitch mount crane base with lightweight or otherwise unstable

vehicles that may move during operation.

1.1.1 STUDY PARTS DRAWINGS to understand how the hitch mounted base is

assembled. See page 8.

1.1.2 LOCATE THE EQUIPMENT in an area clear of trac and obstacles that

could interfere with operation. Set the vehicle’s parking brake.

1.1.3 ASSEMBLE THE BASE for the crane to be located directly behind the

vehicle. See Figure 1. Skip to section 1.1.4 if you want the crane positioned

to the left or right of the vehicle.

a INSERT THE BASE PIPE assembly into the receiver hitch. Secure in place

with the provided 5/8” hitch pin.

b REMOVE THE CLEVIS PINS to spread the support legs. Reinstall the

clevis pins to secure this position.

c REMOVE THE CLEVIS PINS to extend the support legs. There are various

support leg height positions to accommodate dierent truck sizes and uneven

ground. Reinstall the clevis pins to secure the support legs at the desired

height. Make sure the base is level. The support legs should be able to

extend if necessary during operation.

Important!

• Inspect the hitch mounted base

during assembly. This will give

you a record of the condition of

the base with which to compare

future inspections.

• Save all packaging that the base

was shipped in, to re-use if you

need to repackage the base.

• Contact the factory immediately

if any parts are missing or dam-

aged.

Figure 1 - Crane located behind the vehicle

page 5

A28390-A-0921

Owners Manual for the 5BH5 Hitch Mount Base for Davit Cranes

1.1.4 ASSEMBLE THE BASE for the crane to be located to the left or right of

the vehicle. See Figure 2.

a INSERT THE BASE HITCH “T” assembly into the receiver hitch. Secure

in place with the provided 5/8” hitch pin.

b INSERT THE BASE PIPE assembly into the hitch “T”. Secure in place with

the provided 5/8” hitch pin and then tighten thumb screws.

c REMOVE THE CLEVIS PINS to spread the support legs. Reinstall the

clevis pins to secure this position.

d REMOVE THE CLEVIS PINS to extend the support legs. There are various

support leg height positions to accommodate dierent truck sizes and uneven

ground. Reinstall the clevis pins to secure the support legs at the desired

height. Make sure the base is level. The support legs should be able to

extend if necessary during operation.

e ATTACH THE SUPPORT JACK and secure with the clevis pin supplied

with the jack. Rotate the handle to extend the leg to the ground. Check

again to make sure the base is level.

f TO USE THE PULLEY TO CHANGE ROPE DIRECTION, remove the

sheave from the base hitch “T”. Position the winch rope in the sheave’s

groove and reinstall the sheave onto the base hitch “T”. Loads can be pulled

horizontally at angles up to 45 degrees left or right. See Figure 3.

1.2 Installing the Crane into Hitch Base

1.2.1 ASSEMBLE THE CRANE using the Owner’s Manual provided with the

respective Thern crane purchased for this hitch mounted base.

1.2.2 ASSEMBLE THE ROTATION STOP assembly provided with the hitch

base to the crane using a 7/16” wrench and 5/32” hex key.

Figure 3 – Pully

(Top View)

Figure 2 - Crane located left or right of the vehicle

Owners Manual for the 5BH5 Hitch Mount Base for Davit Cranespage 6

A28390-A-0921

2.2 Preparing for Operation

Do not operate or apply loads without all pins securely in place.

Do not adjust support leg positions while the crane is loaded.

Do not use the hitch mount crane base with lightweight or otherwise unstable

vehicles that may move during operation.

2.2.1 CONSIDER THE OPERATION. Do not begin until you are sure you can

perform the entire operation without hazard.

2.2.2 SECURE THE VEHICLE. Make sure the vehicle’s engine is OFF with

automatic transmission in PARK or manual transmission in 1st gear. Engage

the parking brake and chock wheels for added safety.

2.2.3 INSPECT ALL COMPONENTS of the system.

a INSPECT THE CRANE and other equipment according to the Instructions

for Frequent Inspection.

b INSPECT THE WINCH according to the instructions in the Winch Owner’s

Manual.

c OPERATORS must be in good health, alert, thoroughly trained in operating

the equipment, and properly clothed (hard hat, safety shoes and safety

glasses, no loose clothing).

d THE LOAD must be clear of other objects and free to move. Make sure the

load will not tip, spin, roll away, or in any way move uncontrollably.

2.2.4 KNOW YOUR LOAD and make sure you do not exceed the load rating of

the crane or any other equipment in the system.

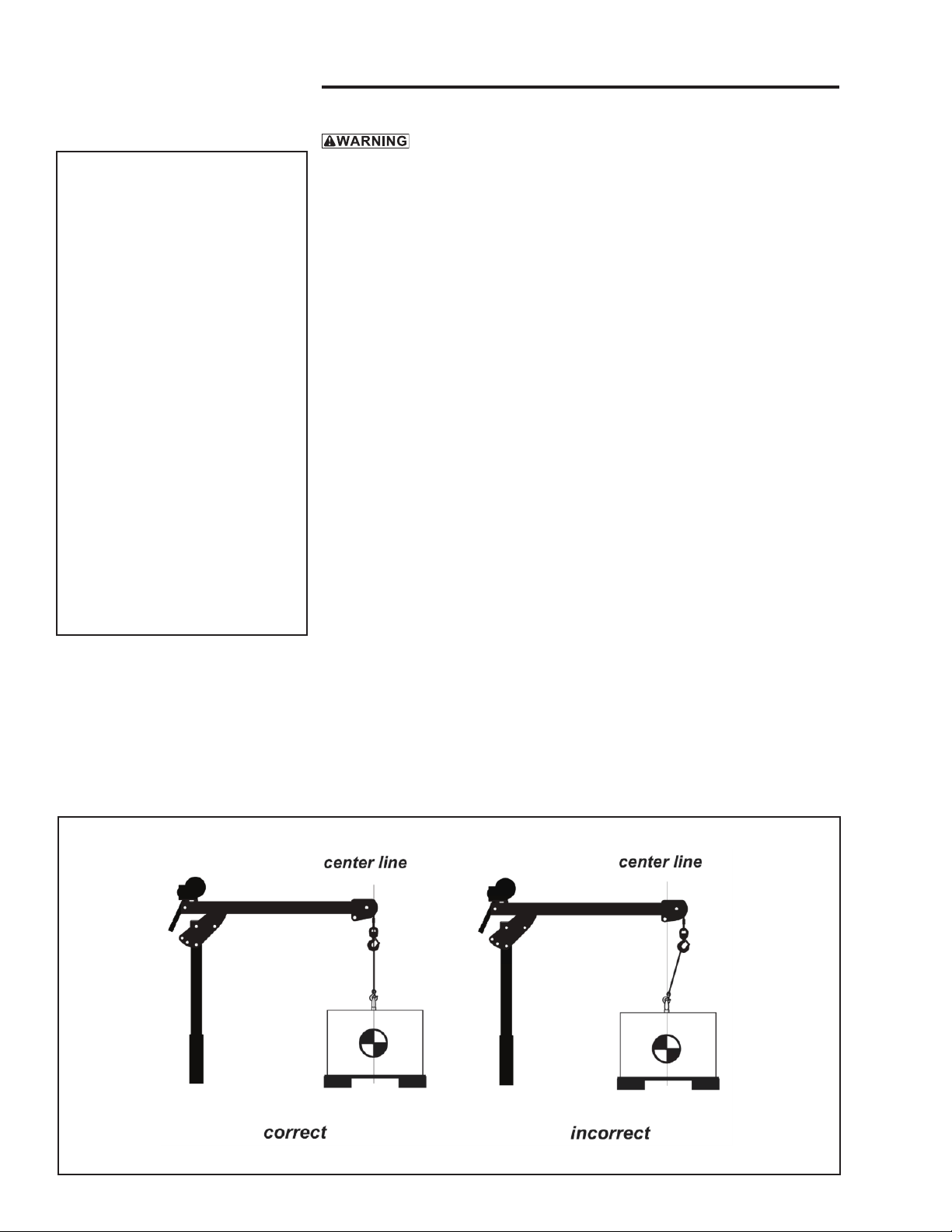

2.2.5 POSITION THE BOOM so the load hook is centered over the load.

Avoid side pulls which could damage the crane or cause the load to tip.

See Figure 4.

Important!

• When determining whether the

load will exceed the load rating,

consider the total force required

to move the load.

• Obey a stop signal from anyone.

• Maintain tension on the wire

rope to keep it tightly and evenly

wound on the drum.

• If the crane and load are

not visible during the entire

operation, get help from another

person.

• Appoint a supervisor if more

than one person is involved in

the operation. This will reduce

confusion and increase safety.

• When lifting a load, use a tag line

to keep the load from swinging or

twisting, while keeping yourself

away from the load.

Figure 4 – Positioning the Boom

page 7

A28390-A-0921

Owners Manual for the 5BH5 Hitch Mount Base for Davit Cranes

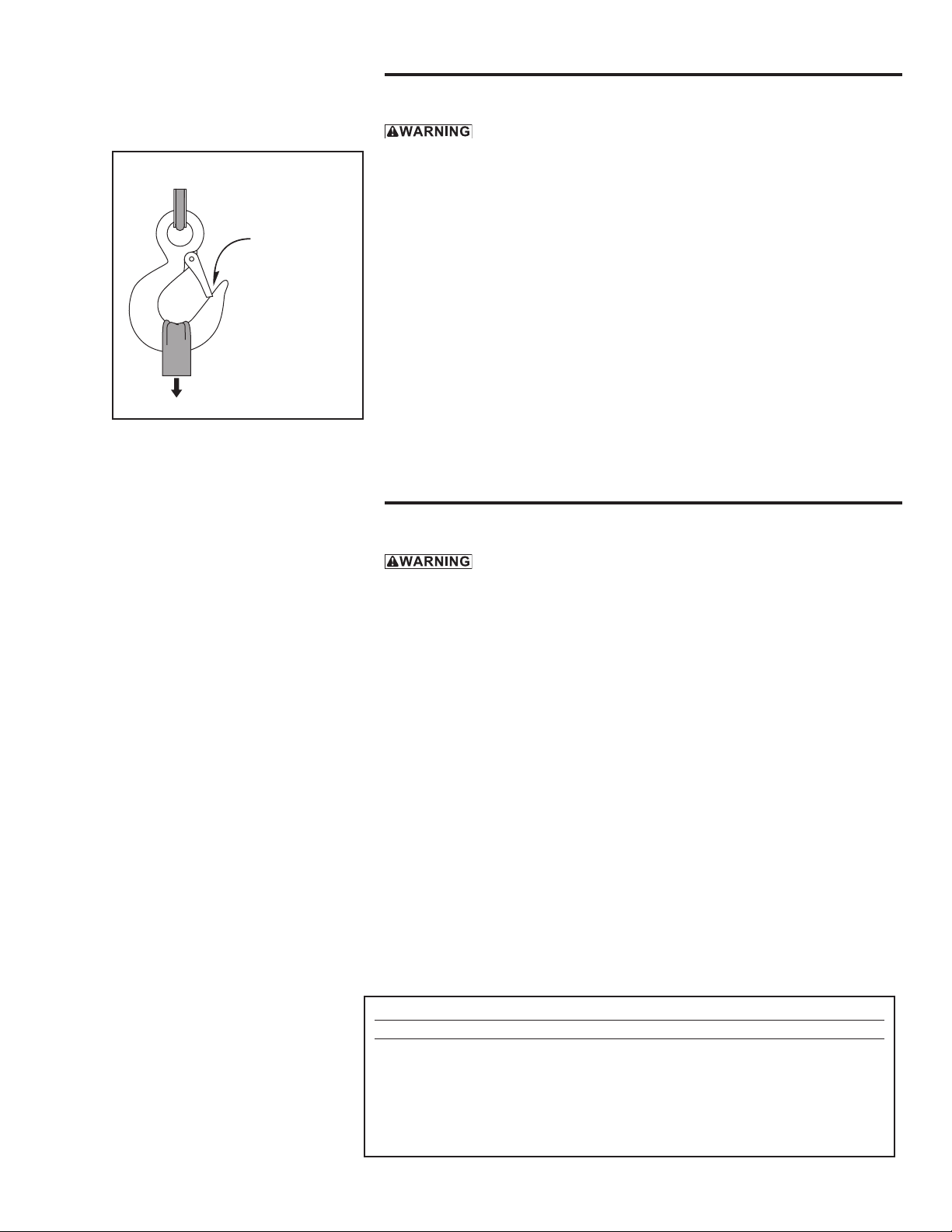

Figure 5 – Attaching Load

latch closed tight

against hook

sling seated in

saddle of hook

2.3 Attaching the Load

Do not wrap the wire rope around the load. This damages the wire rope and

could cause the load to escape. Use a sling or other approved lifting device.

2.3.1 CLEAR OBJECTS from the path of the load so you can move it freely and

observe it at all times during the operation.

2.3.2 MAKE SURE THE WIRE ROPE is not twisted. A twisted wire rope could

cause the load to spin when it is raised o the ground.

2.3.3 ATTACH THE LOAD using a nylon sling, or other approved lifting device.

Follow the recommendations of the sling manufacturer.

a SEAT THE SLING in the saddle of the hook with the hook latch completely

closed. See Figure 5.

b CENTER THE LOAD on the hook so it will remain balanced and not tip or

rotate to one side.

2.4 Moving the Load

Do not make adjustments to the crane or base while the crane is loaded.

2.4.1 MOVE THE LOAD slowly and smoothly, only a small distance at rst.

Make sure the load is balanced and securely attached before continuing.

2.4.2 OPERATE THE WINCH to raise or lower the load. Refer to the instructions

in the Winch Owner’s Manual.

2.4.3 OBSERVE THE WIRE ROPE as it winds onto the drum. If it becomes

loose, uneven, or overlapped, stop the operation and rewind the wire rope

before continuing. Continued operation with overlapped or uneven wire

rope can damage the wire rope and shorten its life.

2.4.4 ROTATE THE MAST AND BOOM to move the load side-to-side.

a ROTATE THE BOOM slowly and smoothly to avoid swinging the load or

causing shock loads. Do not jam the boom against other objects.

b CENTER THE LOAD on the hook so it will remain balanced and not tip or

rotate to one side.

Table 1 - Weight Chart

Base Component lbs (kg)

Main Assembly 47.6 (21.6)

Leg Extension (each) 4.8 (2.2)

Receiver “T” w/ Sheave 17.3 (7.8)

Support Jack 16.0 (7.2)

TOTAL 95.3 (43.2)

Owners Manual for the 5BH5 Hitch Mount Base for Davit Cranespage 8

A28390-A-0921

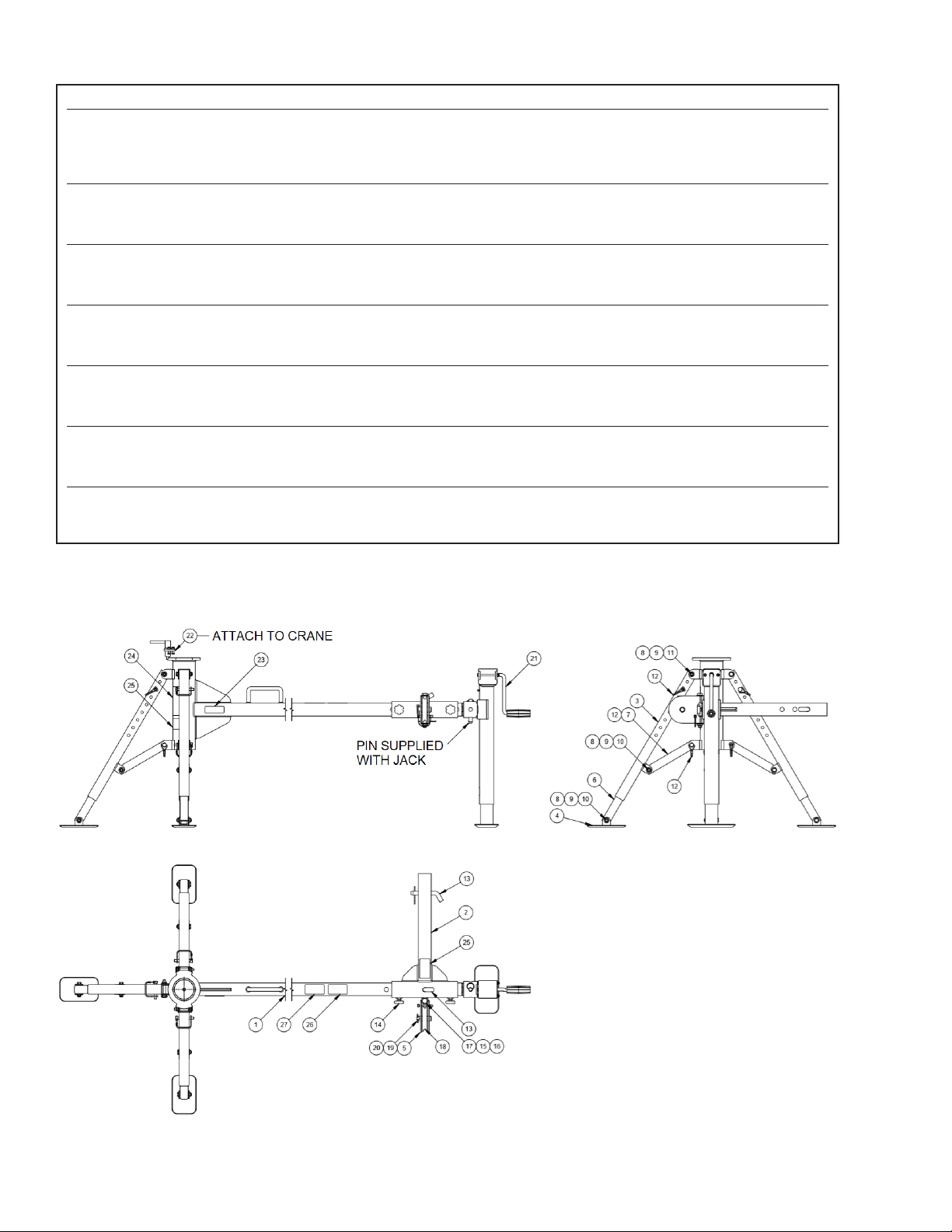

5BH5 Hitch Mount Base

item description part number qty.

1 WELDMENT BASE PIPE A27732 1

2 WELDMENT BASE HITCH T A27733 1

3 WELDMENT BASE LEG A27735 3

4 WELDMENT BASE FOOTPAD A27736 3

5 WELDMENT BASE SHEAVE A27737 1

6 BASE LEG TUBE EXTENSION A27826 3

7 BASE LEG SUPPORT A27828 3

8 WASHER FLT SAE .375 X .812 X .065 ZNPL A11973 18

9 NUT HEX JAM NYLK .375-16NC ZNPL GR2 A3180 9

10 CAPSCR HEXHD .375-16NC X 2.000 ZNPL GR5 A3495 6

11 CAPSCR HEXHD .375-16NC X 2.250 ZNPL GR5 A3494 3

12 PIN LINCH D .375 X 1.875 ZNPL A27832 6

13 PIN HITCH .625 X 3.000 EFF LENGTH ZNPL A27214 2

14 SCREW THUMB .375-16NC X .750 BLK A27831 2

15 WASHER FLT SAE .500 X 1.062 X .095 ZNPL A2932 2

16 NUT HEX JAM NYLK .500-13NC ZNPL GR2 A3176 1

17 CAPSCR HEXHD .500-13NC X 5.000 ZNPL GR5 A3247 1

18 SHEAVE ASSEMBLY B2462 1

19 PIN CLEVIS .750 DIA 5PT SHEAVE SST A12314 1

20 PIN LINCH D ASSY - SEE PRINT A12414SS 1

21 JACK ROUND SCREW 2000 LB. W/FOOTPLATE A27829 1

22 ROTATION STOP ASSEMBLY 5Px B6241 1

23 LABEL THERN 1.00 X 3.20 A6889 1

24 LABEL WARNING B5790 1

25 LABEL WARNING BEFORE LOADING B6229 2

26 LABEL WARNING VEHICLE STABILITY A27271 1

27 LABEL WARNING REMOVE HITCH MOUNT A27432 1

page 9

A28390-A-0921

Owners Manual for the 5BH5 Hitch Mount Base for Davit Cranes

NOTES:

Owners Manual for the 5BH5 Hitch Mount Base for Davit Cranespage 10

A28390-A-0921

NOTES:

page 11

A28390-A-0921

Owners Manual for the 5BH5 Hitch Mount Base for Davit Cranes

NOTES:

Thern, Incorporated

5712 Industrial Park Road

Winona, MN 55987

PH 507-454-2996

FAX 507-454-5282

EMAIL: [email protected]

www.thern.com

Thern Europe

Bedrijvenpark Twente 454e

7602 KM Almelo

Netherlands

PH +31-546-898-380

EMAIL: [email protected]

Thern

Winches & Cranes

Table of contents

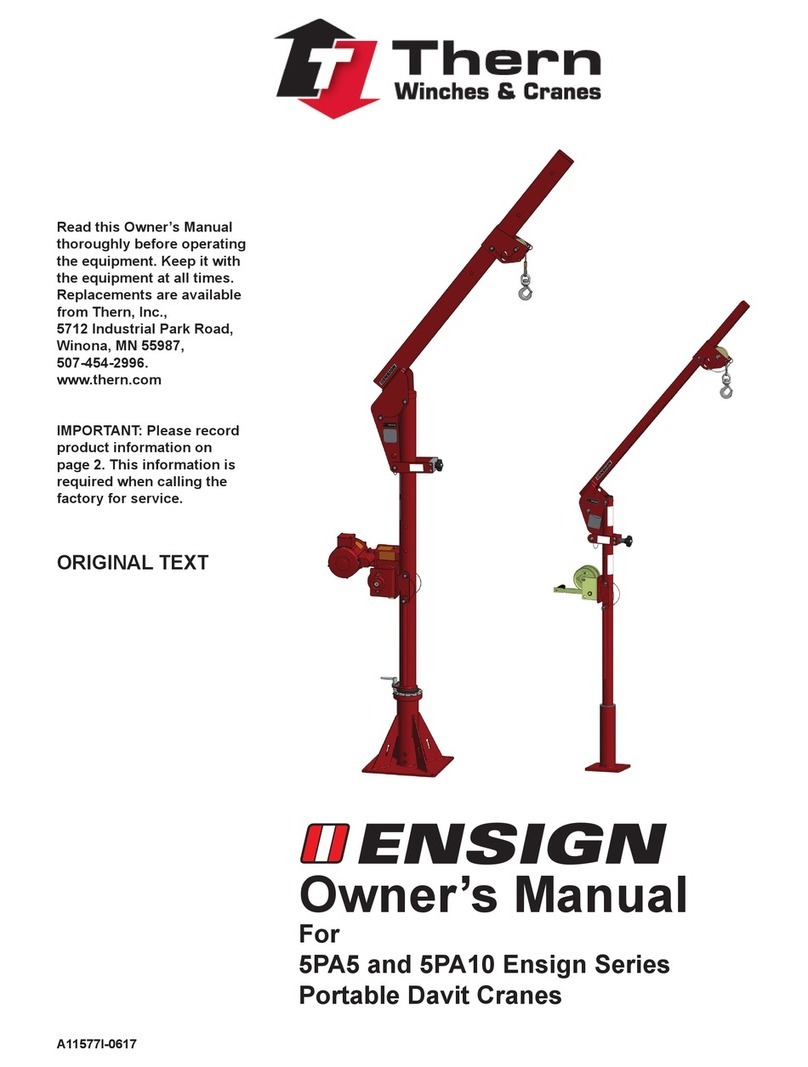

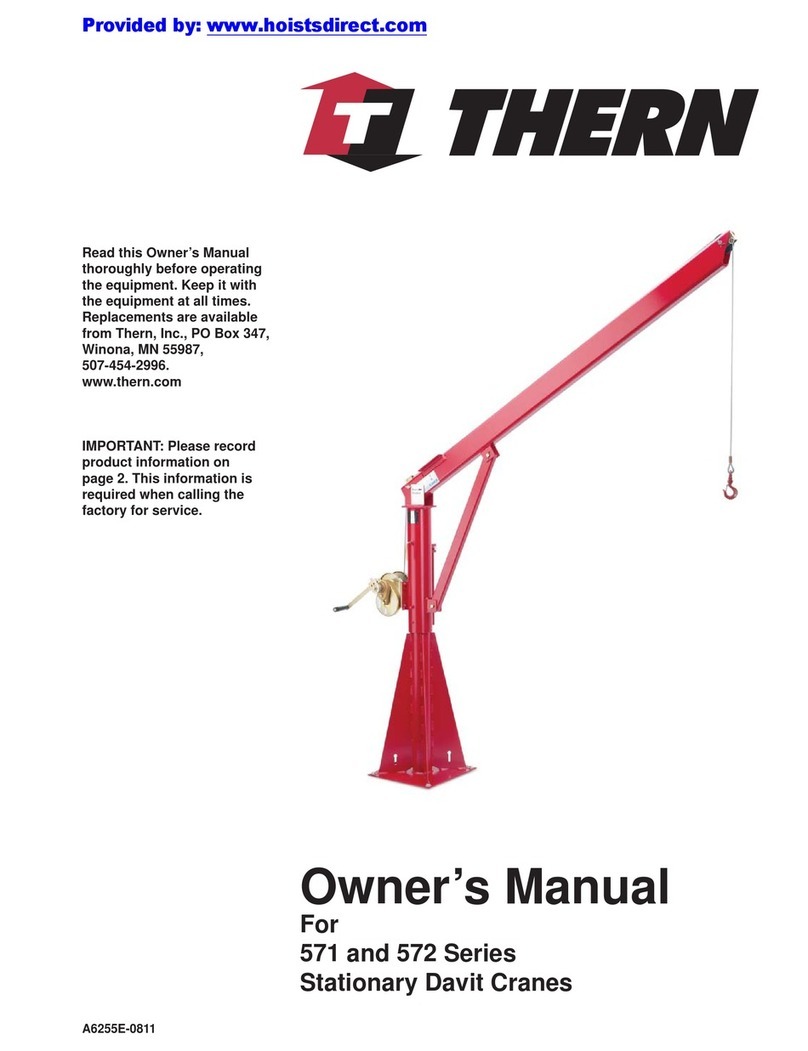

Other Thern Construction Equipment manuals

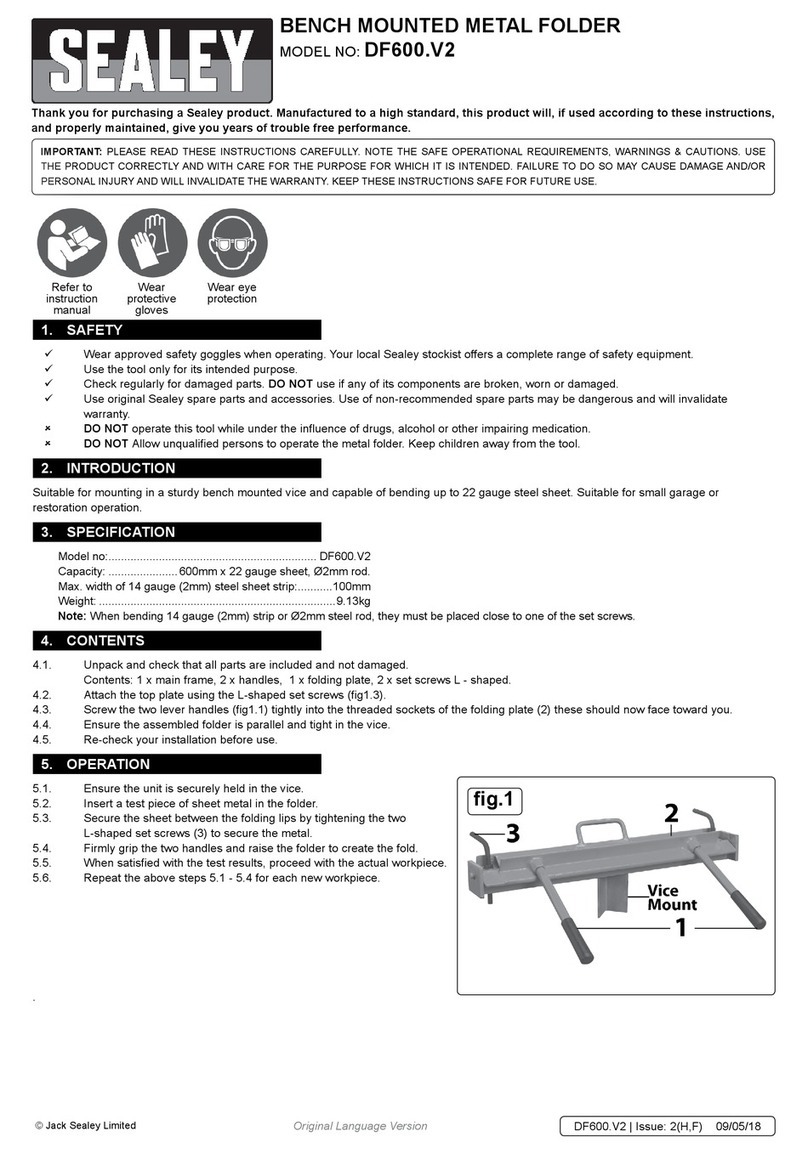

Popular Construction Equipment manuals by other brands

Southwire

Southwire MAXIS Xtreme Bender MXB2000 operating instructions

Allied

Allied AR Series Safety, operation and maintenance

HIAB

HIAB 435K HiPro CD Operator's manual

MKT

MKT V-2Esc Service, Operating, Maintenance and Parts Manual

Falcon

Falcon RME Series OPERATION, PARTS AND REPAIR MANUAL

Fayat

Fayat Dynapac F80W operating manual