Thern 5FT40 Series User manual

A27607-A-1120

Thern

Winches &Cranes

Read this Owner’s Manual

thoroughly before operating

the equipment. Keep it with

the equipment at all times.

Replacements are available

from Thern, Inc., PO Box 347,

Winona, MN 55987,

507-454-2996.

www.thern.com

IMPORTANT: Please record

product information on

page 2. This information is

required when calling the

factory for service.

ORIGINAL TEXT

Owner’s Manual

For

5FT40 Series Stationary Davit Cranes

A27607-A-1120

page 2

Owner's Manual for Thern 5FT40 Captain Series Stationary Davit Cranes

Please record the following:

Date Purchased:

Crane Model No.:

Crane Serial No.:

If sold with a winch:

Winch Model No.:

Winch Serial No.:

This information is required when

calling the factory for service.

Two-Year Limited Warranty

Thern, Inc. warrants its products against defects in material or workmanship for two years from the date of purchase

by the original using buyer, or if this date cannot be established, the date the product was sold by Thern, Inc. to the

dealer. To make a claim under this warranty, contact the factory for an RGA number. The product must be returned,

prepaid, directly to Thern, Inc., 5712 Industrial Park Road, Winona, Minnesota 55987. The following information

must accompany the product: the RGA number, the date of purchase, the description of the claimed defect, and a

complete explanation of the circumstances involved. If the product is found to be defective, it will be repaired or

replaced free of charge, and Thern, Inc. will reimburse the shipping cost within the contiguous USA.

This warranty does not cover any damage due to accident, misuse, abuse, or negligence. Any alteration, repair or

modification of the product outside the Thern, Inc. factory shall void this warranty. This warranty does not cover any

costs for removal of our product, downtime, or any other incidental or consequential costs or damages resulting from

the claimed defects. This warranty does not cover brake discs, wire rope or other wear components, as their life is

subject to use conditions which vary between applications.

FACTORY AUTHORIZED REPAIR OR REPLACEMENT AS PROVIDED UNDER THIS WARRANTY IS THE

EXCLUSIVE REMEDY TO THE CONSUMER. THERN, INC. SHALL NOT BE LIABLE FOR ANY

INCIDENTAL OR CONSEQUENTIAL DAMAGES FOR BREACH OF ANY EXPRESS OR IMPLIED

WARRANTY ON THIS PRODUCT. EXCEPT TO THE EXTENT PROHIBITED BY APPLICABLE LAW, ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ON THIS

PRODUCT IS LIMITED IN DURATION TO THE DURATION OF THIS WARRANTY.

Some states do not allow the exclusion or limitation of incidental or consequential damages, or allow limitations on how

long an implied warranty lasts, so the above limitation or exclusion may not apply to you. This warranty gives you

specific legal rights, and you may also have other rights which vary from state to state.

Note: Thern, Inc. reserves the right to change the design or discontinue the production of any product without

prior notice.

About This Manual

The Occupational Safety and Health Act of 1970 states that it is the employer’s

responsibility to provide a workplace free of hazard. To this end, all equipment

should be installed, operated, and maintained in compliance with applicable trade,

industrial, federal, state, and local regulations. It is the equipment owner's

responsibility to obtain copies of these regulations and to determine the suitability

of the equipment to its intended use.

This Owner’s Manual, and warning labels attached to the equipment, are to serve

as guidelines for hazard-free installation, operation, and maintenance. They should

not be understood to prepare you for every possible situation.

Theinformationcontained inthis manualis applicableonlytothe Thern Captain

Series Model 5FT40 Stationary Davit Cranes. Do not use this manual as a source

of information for any other equipment.

The following symbols are used for emphasis throughout this manual:

Failure to follow ‘WARNING!’ instructions may result in equipment damage,

property damage, and/or serious personal injury.

Failure to follow ‘CAUTION!’ instructions may result in equipment damage,

property damage, and/or minor personal injury.

Important!

Failure to follow ‘important!’ instructions may result in poor performance of

the equipment.

A27607-A-1120

Owner's Manual for Thern 5FT40 Captain Series Stationary Davit Cranes

page 3

Suggestions for Safe Operation

DO the following:

Read and comply with the guidelines set forth in this Owner’s Manual. Keep

this manual, and all labels attached to the crane, readable and with the

equipment at all times. Contact Thern, Inc. for replacements.

Check lubrication before use.

Check for leaks before use.

Install the wire rope securely to the winch drum.

Keep at least 4 wraps of wire rope wound on the drum at all times, to serve as

anchor wraps. With less than 4 wraps on the drum the wire rope could come

loose, causing the load to escape.

Keep hands away from sheaves, gears, wire rope, and other moving parts.

Disconnect any power before servicing the equipment.

Keep all unnecessary personnel away from crane while in operation.

Keep out of the path of the load, and out of the path of a broken wire rope

that might snap back and cause injury.

Ensure that both threaded ends of the ratchet jack are threaded an equal

distance out of the jack when assembled to the crane. If threaded ends are not

equal, the crane boom will not be able to operate in its full range of motion.

A27607-A-1120

page 4

Owner's Manual for Thern 5FT40 Captain Series Stationary Davit Cranes

Suggestions for Safe Operation (cont.)

DO NOT do the following:

Do not lift people, or things over people. Do not walk or work under a load

or in the line of force of any load.

Do not exceed the load rating of the crane or any other component in the

system. To do so could result in failure of the equipment.

Do not use more than one crane to move a load that exceeds the load rating

of a single crane. A shift in load weight could overload the equipment.

Do not use damaged or malfunctioning equipment. To do so could result in

failure of the equipment.

Do not modify the equipment in any way. To do so could cause equipment

failure.

Do not wrap the wire rope around the load. This damages the wire rope and

could cause the load to escape. Use a sling or other approved lifting device.

Do not operate the crane with guards removed or improperly installed.

Do not divert your attention from the operation. Stay alert to the possibility

of accidents, and try to prevent them from happening.

Do not jerk or swing the load. Avoid shock loads by starting and stopping

the load smoothly. Shock loads overload the equipment and may cause

damage.

Do not use the crane and winch components for any use other than for their

original intended function.

Do not use the crane to drag or pull loads. This will create side pulls, which

could damage the equipment or cause the load to tip.

Do not leave a suspended load unattended. Place the load on the ground if it

must be left unattended.

Do not adjust the winch brake with the load suspended.

Do not operate or apply loads without all pins securely in place.

Do not adjust the boom extension while the crane is loaded.

Do not make adjustments to the ratchet jack while the crane is loaded. Todo

so may require the use of excessive force which could cause damage or injury.

A27607-A-1120

Owner's Manual for Thern 5FT40 Captain Series Stationary Davit Cranes

page 5

1.1 Installing the Crane

Do not install the crane in an area defined as hazardous by the National Electric

Code, unless installation in such an area has been thoroughly approved.

Do not install the crane near corrosive chemicals, flammable materials,

explosives, or other elements that may damage the crane or injure the operator.

Adequately protect the crane and the operator from such elements.

Position the crane so the operator can stand clear of the load, and out of the path

of a broken wire rope that could snap back and cause injury.

Attach the crane to a rigid and level foundation that will support the crane and

its load under all load conditions, including shock loading.

1.1.1 CONSULT APPLICABLE CODESAND REGULATIONS for specific

rules on installing the equipment.

1.1.2 LOCATE THE CRANE in an area clear of traffic and obstacles that could

interfere with operation. Make sure the crane is accessible for maintenance

and operation.

1.1.3 INSTALL THE CRANE on a level surface.

1.1.4 FASTEN THE BASE securely to the foundation to withstand applicable

overturning moments and mounting bolt reaction. See Table 1.

a FOR STANDARD PRODUCTS referred to in this manual, use coarse

thread fasteners, grade 5 or better.

Suggested Fastener Torque Values (ft-lbs)

Plain & Dry

Zinc Plated

Lubricated

(eg. Loctite)

3/4 inch grade 5

260

230

200

M20 grade 8.8

320

270

240

Refer to manufacturer's instructions for other fastener types with

specific torque or installation instructions.

b NON-STANDARD PRODUCTS that vary from the original design may

have different fastening requirements. Contact a structural engineer or

Thern, Inc. for this information.

TO COMPLY WITH LOCAL CODES, CONTACT A QUALIFIED

PROFESSIONAL TO OBTAIN PROPER STRUCTURE OR FOUNDATION

SPECIFICATIONS FOR THE MOUNTING OF THERN PRODUCTS.

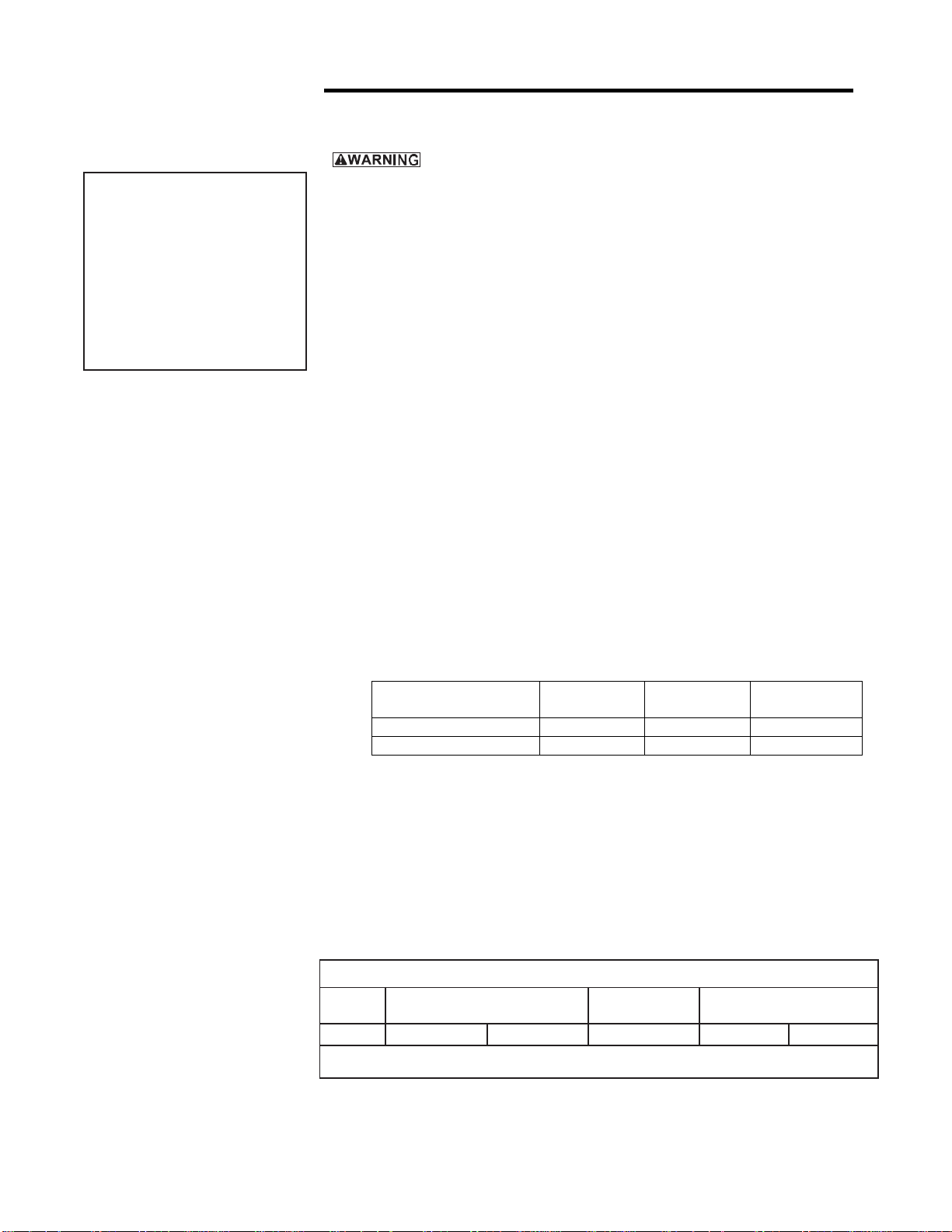

Table 1 –Crane Reactions

Crane

Model

Mast

Moment

Suggested

Bolt Size

Force per

Bolt (tension)

5FT40

398,100 in-lbs

44,982 N-m

3/4 inch (M20)

6,470 lbs

28,782 N

This information may change without prior notice. It is the responsibility of the installer and/or

end user to ensure the most current information is used.

Important!

•

A qualified professional

should inspect or design the

foundation to insure that it

will provide adequate support.

•

Locate the crane so it will be

visible during the entire

operation.

Table of contents

Other Thern Construction Equipment manuals