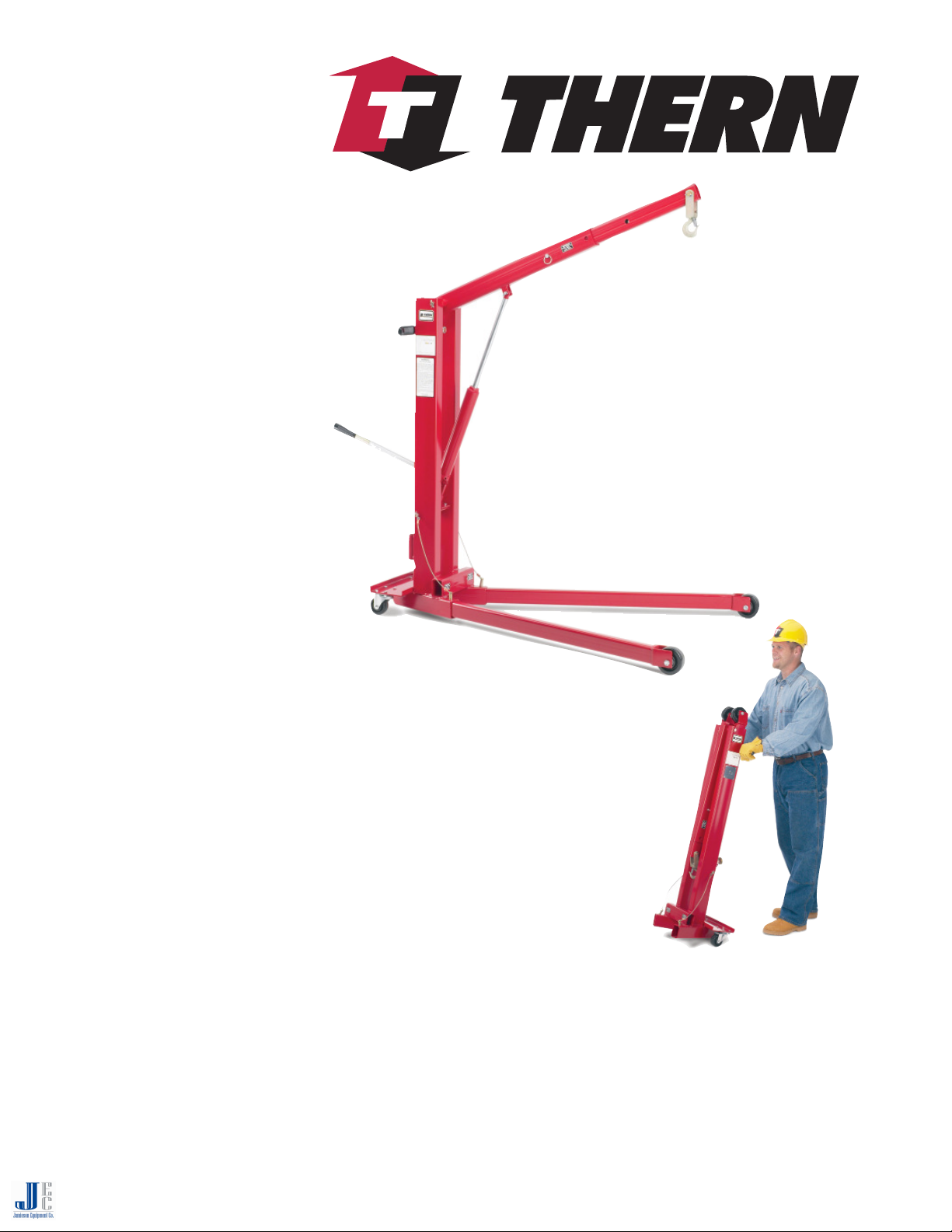

Owner's Manual for Thern Model 548 Floor Cranepage 2

A6759C-0912

Two-Year Limited Warranty

Thern, Inc. warrants its products against defects in material or workmanship for two years from the date of purchase

by the original using buyer, or if this date cannot be established, the date the product was sold by Thern, Inc. to the

dealer. To make a claim under this warranty, contact the factory for an RGA number. The product must be returned,

prepaid, directly to Thern, Inc., 5712 Industrial Park Road, Winona, Minnesota 55987. The following information

must accompany the product: the RGA number, the date of purchase, the description of the claimed defect, and a com-

plete explanation of the circumstances involved. If the product is found to be defective, it will be repaired or replaced

free of charge, and Thern, Inc. will reimburse the shipping cost within the contiguous USA.

This warranty does not cover any damage due to accident, misuse, abuse, or negligence. Any alteration, repair or

modification of the product outside the Thern, Inc. factory shall void this warranty. This warranty does not cover any

costs for removal of our product, downtime, or any other incidental or consequential costs or damages resulting from

the claimed defects. This warranty does not cover brake discs, wire rope or other wear components, as their life is

subject to use conditions which vary between applications.

FACTORY AUTHORIZED REPAIR OR REPLACEMENT AS PROVIDED UNDER THIS WARRANTY IS THE

EXCLUSIVE REMEDY TO THE CONSUMER. THERN, INC. SHALL NOT BE LIABLE FOR ANY INCIDENTAL

OR CONSEQUENTIAL DAMAGES FOR BREACH OF ANY EXPRESS OR IMPLIED WARRANTY ON THIS

PRODUCT. EXCEPT TO THE EXTENT PROHIBITED BY APPLICABLE LAW, ANY IMPLIED WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ON THIS PRODUCT IS LIMITED IN

DURATION TO THE DURATION OF THIS WARRANTY.

Some states do not allow the exclusion or limitation of incidental or consequential damages, or allow limitations on

how long an implied warranty lasts, so the above limitation or exclusion may not apply to you. This warranty gives

you specific legal rights, and you may also have other rights which vary from state to state.

Note: Thern, Inc. reserves the right to change the design or discontinue the production of any product without

prior notice.

About This Manual

The Occupational Safety and Health Act of 1970 states that it is the employer’s

responsibility to provide a workplace free of hazard. To this end, all equipment

should be installed, operated, and maintained in compliance with applicable trade,

industrial, federal, state, and local regulations. It is the equipment owner's respon-

sibility to obtain copies of these regulations and to determine the suitability of the

equipment to its intended use.

This Owner’s Manual, and warning labels attached to the equipment, are to serve

as guidelines for hazard-free installation, operation, and maintenance. They

should not be understood to prepare you for every possible situation.

The information contained in this manual is applicable only to the Thern Model

548 Floor Crane. Do not use this manual as a source of information for any other

equipment.

The following symbols are used for emphasis throughout this manual:

Failure to follow ‘WARNING!’ instructions may result in equipment damage,

property damage, and/or serious personal injury.

Failure to follow ‘CAUTION!’ instructions may result in equipment damage,

property damage, and/or minor personal injury.

Important!

Failure to follow ‘important!’ instructions may result in poor performance of

the equipment.

Please record the following:

Date Purchased:

Crane Model No.:

Crane Serial No.:

This information is required when

calling the factory for service.