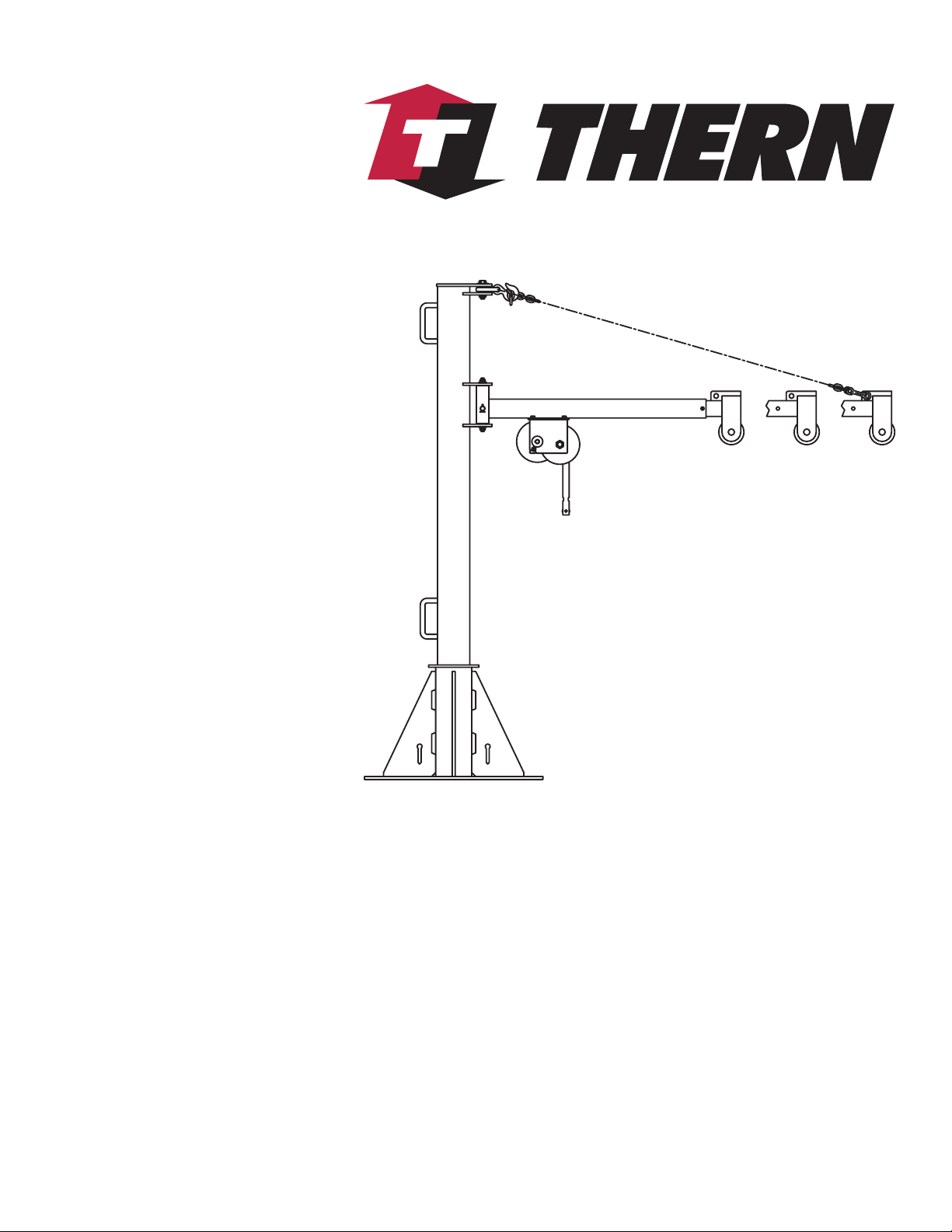

Thern 5334 Series User manual

Read this Owner’s Manual

thoroughly before operating

the equipment. Keep it with

the equipment at all times.

Replacements are available

from Thern, Inc., PO Box 347,

Winona, MN 55987,

507-454-2996.

www.thern.com

Owner’s Manual

For

Series 5334

Portable Davit Crane

IMPORTANT: Please record

product information on

page 2. This information is

required when calling the

factory for service.

A6111A-0405

Owner's Manual for Thern Series 5334 Portable Davit Cranepage 2

A6111A-0405

Owner's Manual for Thern Series 5334 Portable Davit Crane page 3

A6111A-0405

Two-Year Limited Warranty

Thern, Inc. warrants its products against defects in material or workmanship for two years from the date of purchase

by the original using buyer, or if this date cannot be established, the date the product was sold by Thern, Inc. to the

dealer. To make a claim under this warranty, contact the factory for an RGA number. The product must be returned,

prepaid, directly to Thern, Inc., 5712 Industrial Park Road, Winona, Minnesota 55987. The following information

must accompany the product: the RGA number, the date of purchase, the description of the claimed defect, and a com-

plete explanation of the circumstances involved. If the product is found to be defective, it will be repaired or replaced

free of charge, and Thern, Inc. will reimburse the shipping cost within the contiguous USA.

This warranty does not cover any damage due to accident, misuse, abuse, or negligence. Any alteration, repair or

modication of the product outside the Thern, Inc. factory shall void this warranty. This warranty does not cover any

costs for removal of our product, downtime, or any other incidental or consequential costs or damages resulting from

the claimed defects. This warranty does not cover brake discs, wire rope or other wear components, as their life is

subject to use conditions which vary between applications.

FACTORY AUTHORIZED REPAIR OR REPLACEMENT AS PROVIDED UNDER THIS WARRANTY IS THE

EXCLUSIVE REMEDY TO THE CONSUMER. THERN, INC. SHALL NOT BE LIABLE FOR ANY INCIDENTAL

OR CONSEQUENTIAL DAMAGES FOR BREACH OF ANY EXPRESS OR IMPLIED WARRANTY ON THIS

PRODUCT. EXCEPT TO THE EXTENT PROHIBITED BY APPLICABLE LAW, ANY IMPLIED WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ON THIS PRODUCT IS LIMITED IN

DURATION TO THE DURATION OF THIS WARRANTY.

Some states do not allow the exclusion or limitation of incidental or consequential damages, or allow limitations on

how long an implied warranty lasts, so the above limitation or exclusion may not apply to you. This warranty gives

you specic legal rights, and you may also have other rights which vary from state to state.

Note: Thern, Inc. reserves the right to change the design or discontinue the production of any product without

prior notice.

About This Manual

The Occupational Safety and Health Act of 1970 states that it is the employer’s

responsibility to provide a workplace free of hazard. To this end, all equipment

should be installed, operated, and maintained in compliance with applicable trade,

industrial, federal, state, and local regulations. It is the equipment owner's respon-

sibility to obtain copies of these regulations and to determine the suitability of the

equipment to its intended use.

This Owner’s Manual, and warning labels attached to the equipment, are to serve

as guidelines for hazard-free installation, operation, and maintenance. They

should not be understood to prepare you for every possible situation.

The information contained in this manual is applicable only to the Thern Model

5334M1 Portable Davit Crane. Do not use this manual as a source of information

for any other equipment.

The following symbols are used for emphasis throughout this manual:

Failure to follow ‘WARNING!’ instructions may result in equipment damage,

property damage, and/or serious personal injury.

Failure to follow ‘CAUTION!’ instructions may result in equipment damage,

property damage, and/or minor personal injury.

Important!

Failure to follow ‘important!’ instructions may result in poor performance of

the equipment.

Please record the following:

Date Purchased:

Crane Model No.:

Crane Serial No.:

If sold with a winch:

Winch Model No.:

Winch Serial No.:

This information is required when

calling the factory for service.

Owner's Manual for Thern Series 5334 Portable Davit Cranepage 2

A6111A-0405

Owner's Manual for Thern Series 5334 Portable Davit Crane page 3

A6111A-0405

Suggestions for Safe Operation

DO the following:

Read and comply with the guidelines set forth in this Owner’s Manual. Keep

this manual, and all labels attached to the crane, readable and with the equip-

ment at all times. Contact Thern, Inc. for replacements.

Check lubrication before use.

Install the wire rope securely to the winch drum.

Keep at least 4 wraps of wire rope wound on the drum at all times, to serve as

anchor wraps. With less than 4 wraps on the drum the wire rope could come

loose, causing the load to fall.

Keep hands away from sheaves, gears, wire rope, and other moving parts of

the equipment.

Disconnect the power before servicing the equipment.

Keep all unnecessary personnel away from the crane while in operation. Keep

out of the path of the load, and out of the path of a broken wire rope that

might snap back and cause injury.

DO NOT do the following:

Do not lift people, or things over people. Do not walk or work under a load or

in the line of force of any load.

Do not exceed the load rating of the crane or any other component in

the system. To do so could result in failure of the equipment.

Do not use more than one crane to move a load that exceeds the load rating of

a single crane. A shift in load weight could overload the equipment.

Do not use damaged or malfunctioning equipment. To do so could result in

failure of the equipment.

Do not modify the equipment in any way. To do so could cause

equipment failure.

Do not wrap the wire rope around the load. This damages the wire rope and

could cause the load to fall. Use a sling or other approved lifting device.

Do not operate the crane with guards removed or improperly installed.

Do not divert your attention from the operation. Stay alert to the possibility of

accidents, and try to prevent them from happening.

Do not jerk or swing the load. Avoid shock loads by starting and stopping the

load smoothly. Shock loads overload the equipment and may cause damage.

Do not remove the winch or other components from the crane, and do not use

these components for any use other than for their original intended function.

Do not use the crane to drag or pull loads. This will create side pulls which

could damage the equipment or cause the load to tip.

Do not leave a suspended load unattended. Place the load on the ground if it

must be left unattended.

Do not adjust the winch brake with the load suspended.

Owner's Manual for Thern Series 5334 Portable Davit Cranepage 4

A6111A-0405

Owner's Manual for Thern Series 5334 Portable Davit Crane page 5

A6111A-0405

Important!

• A qualied professional should

inspect or design the founda-

tion to insure that it will provide

adequate support.

• Locate the crane so it will be vis-

ible during the entire operation.

1.1 Installing the Crane

Do not install the crane in an area dened as hazardous by the National Elec-

tric Code, unless installation in such an area has been thoroughly approved.

Do not install the crane near corrosive chemicals, ammable materials, ex-

plosives, or other elements that may damage the crane or injure the operator.

Adequately protect the crane and the operator from such elements.

Position the crane so the operator can stand clear of the load, and out of the

path of a broken wire rope that could snap back and cause injury.

Attach the crane to a rigid and level foundation that will support the crane

and its load under all load conditions, including shock loading.

1.1.1 CONSULT APPLICABLE CODES AND REGULATIONS for specific rules

on installing the equipment.

1.1.2 LOCATE THE CRANE in an area clear of traffic and obstacles that could

interfere with operation. Make sure the crane is accessible for maintenance

and operation.

1.1.3 INSTALL THE CRANE on a level surface. An unlevel surface may cause

the boom to rotate in the direction the mast is leaning.

1.1.4 FASTEN THE BASE securely to the foundation.

a FOR STANDARD PRODUCTS referred to in this manual, use 5/8 inch

coarse thread fasteners, grade 5 or better, torqued dry to 150 ft-lbs without

lubrication. Make sure mounting holes are secured to a solid foundation able

to support the crane and the load under all conditions with design factors

based on accepted engineering practices.

b NON-STANDARD PRODUCTS that vary from the original design may

have different fastening requirements. Contact a structural engineer or Thern,

Inc. for this information.

TO COMPLY WITH LOCAL CODES, CONTACT A QUALIFIED PROFES-

SIONAL TO OBTAIN PROPER STRUCTURE OR FOUNDATION SPECI-

FICATIONS FOR THE MOUNTING OF THERN PRODUCTS.

Owner's Manual for Thern Series 5334 Portable Davit Cranepage 4

A6111A-0405

Owner's Manual for Thern Series 5334 Portable Davit Crane page 5

A6111A-0405

Important!

• Inspect the crane during assem-

bly according to the Instructions

for Periodic Inspection. This will

give you a record of the condition

of the crane with which to com-

pare future inspections.

• Save all boxes and crates that the

crane was shipped in, use them

again if you need to repackage

the crane.

• Contact the factory immediately

if any parts are missing or dam-

aged.

• Do not overtighten fasteners, this

may strip threads or cause dam-

age to other parts.

1.2 Assembling the Crane

1.2.1 STUDY PARTS DRAWINGS to understand how the crane is assembled. See

page 17.

1.2.2 LUBRICATE PINS and other components prior to assembly. Refer to the

Lubrication Instructions.

1.2.3 INSTALL THE BASE then assemble the crane in the following order.

a INSTALL THE MAST in the base.

b INSTALL THE GRAB HOOK between the upper mast ears using the spacer

and fasteners provided. Make sure the hook opening faces up. See gure 2.

c INSTALL THE BOOM SWIVEL, see figure 2.

• PLACE THE BUSHINGS in the boom swivel and position this assembly

between the lower mast ears. Make sure the swivel is positioned correctly.

• INSERT FASTENERS and tighten until cotter pins can be inserted. Make

sure cotter pins are locked in the slots of the hex nuts.

d INSTALL THE BOOM in the boom swivel using the pin provided. Make

sure the boom is positioned correctly, and install the boom extension.

e ATTACH ONE END OF THE LOAD CHAIN to the boom extension and the

other end to the grab hook. Avoid twisting the chain and make sure it is

seated in the saddle of the hook. See gure 2.

f INSTALL THE SHEAVE using the pins provided.

g INSTALL THE WINCH using the fasteners provided. Make sure the winch

is positioned correctly.

1.2.4 COMPLETE ASSEMBLY.

a MAKE SURE ALL FASTENERS are tightened, and cotter pins properly

bent to secure them in place, see gure 1.

b LUBRICATE THE ENTIRE CRANE.

c INSTALL THE WINCH HANDLE according to the instructions in the

Winch Owner’s Manual.

d INSTALL THE WIRE ROPE according to the instructions in the Winch

Owner’s Manual.

Figure 2 – Crane Assembly

spacer hook opening

faces up

chain link

turned sideways

and seated in

saddle of hook

ange on

underside

side holes

in boom

swivel

positioned

down

boom

pin

ange between

boom swivel and

mast ear

Figure 1 – Cotter Pins

bend arms back

Table of contents

Other Thern Construction Equipment manuals