Thiele TWN 0861 User manual

MOUNTING INSTRUCTIONS

CHAIN COUPLING SHACKLES

GRADES 80 AND 100

THIELE GmbH & Co. KG # change indicator

www.thiele.de | info@thiele.de B11 91-B replaces B11 91-A

© All rights reserved US 3.2 22 1 | 5

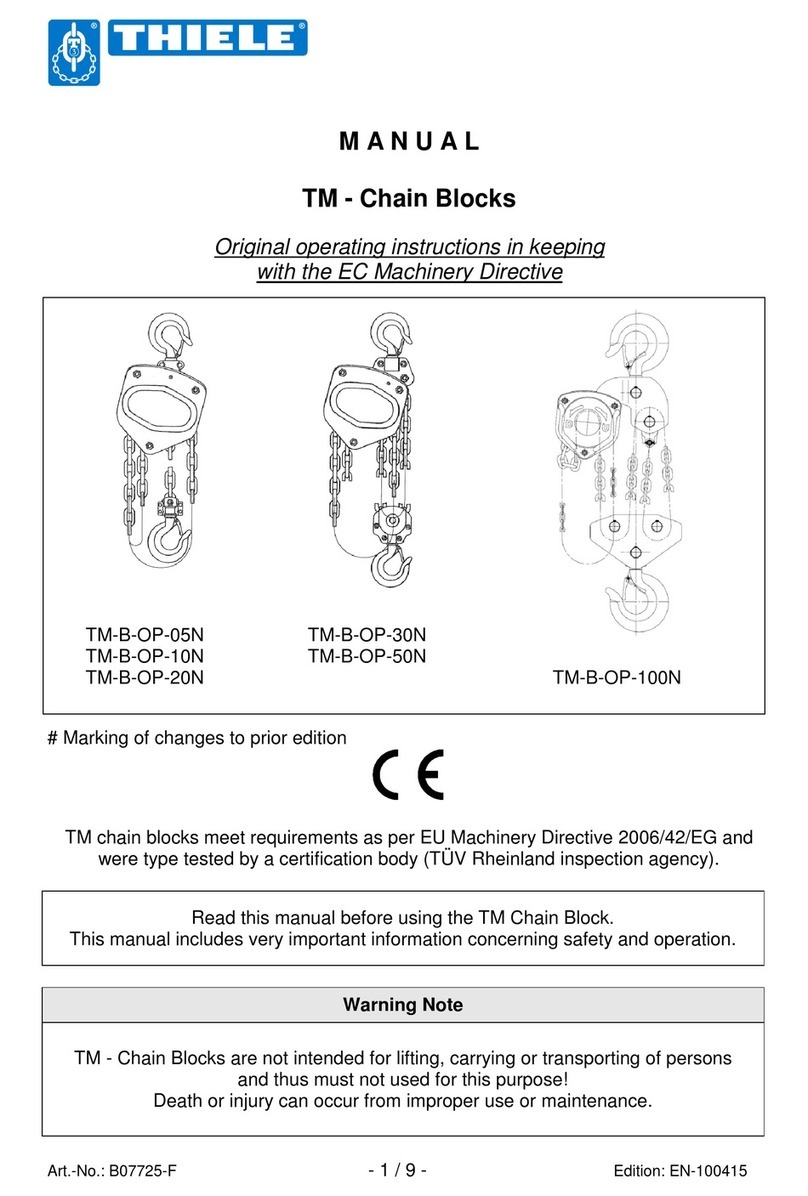

Clevis chain

coupling shackles

TWN 0861

Clevis chain coupling

bolt shackles

TWN 0862

Clevis special

shackles

TWN 0897

The following mounting inst uctions must always be

followed to avoid the isk of pe sonal inju y o p ope ty

damage.

Do not use a chain coupling shackles befo e eading these

mounting inst uctions.

1. ABOUT THIS INSTRUCTION

These mounting instructions describe in particular how chain

coupling shackles according to TWN 861, TWN 862 and

TWN 897 (TWN = THIELE works standard) are to be safely

used for lifting purposes.

The instructions apply analogously to components of identical

design.

To comply with these mounting instructions is essential to help

avoid hazards and increases the reliability and service life of

the chain coupling shackles.

DANGER! Indicates a hazardous

situation, which, if not avoided, will

result in death or serious injury.

WARNING! Indicates a hazardous

situation, which, if not avoided, could

result in death or serious injury.

CAUTION! Indicates a hazardous

situation, which, if not avoided, could

result in minor or moderate injury.

NOTICE! Is used to address practices not

related to physical injury.

SAFETY INSTRUCTIONS signs indicate

specific safety-related instructions or

procedures.

Chains and accesso ies ma ked with the Ame ican nominal

size 7/32” al eady co esponded to Eu opean nominal size

6 mm. In o de to achieve a bette match, the p evious

nominal size 7/32" is now conve ted to the new nominal size

1/4”

#

. The wo king load limits have now also been adjusted.

#

DEFINITIONS

Clevis

A U-shaped fitting with pin.

Working Load Limit (WLL)

The maximum load which a chain coupling shackle is designed

to support.

Read ASME B30.26 “Rigging Ha dwa e”,

Chapte s 26-0, 26-1, 26-4.

2. BASIC SAFETY REQUIREMENTS

To p event the isk of inju y neve walk o stay unde lifted

loads!

The wo king load limit must not be exceeded!

Chain coupling shackles as well as lifting and attachment

means to be used must be f ee f om defects!

Wo king unde the influence of d ugs, medications

impai ing the sense and/o alcohol is st ictly fo bidden!

•Operators, fitters and maintenance personnel must in

particular observe the operating and mounting instructions

as well as standards ASTM A 9 6/A 9 6 M (Standard

Specification for Grade 8 and Grade 1 Alloy Steel Chain

Slings for Overhead Lifting), ASTM A 952/A 952 M (Standard

Specification for Forged Grade 8 and Grade 1 Steel

Lifting Components and Welded Attachment Links),

ISO 56 (Non-calibrated round steel link lifting chain and

chain slings; Use and maintenance), ISO 7593 (Chain slings

assembled by methods other than welding; Grade T(8)) and

ISO 4778 (Round steel short link chains for lifting purposes –

Chains slings of welded construction – Grade 8).

•The specific safety and operating regulations and standards

issued locally in the country where the items are used must

be observed.

•The directions given in these mounting instructions and

specified documentations relating to safety, assembly,

operation, inspection, and maintenance must be made

available to persons operating and using the chain coupling

shackles.

MOUNTING INSTRUCTIONS

CHAIN COUPLING SHACKLES

GRADES 80 AND 100

THIELE GmbH & Co. KG # change indicator

www.thiele.de | info@thiele.de B11 91-B replaces B11 91-A

© All rights reserved US 3.2 22 2 | 5

•These mounting instructions must be available in a place

near the product during the time the equipment is used.

Please contact the manufacturer if replacements are

needed. See also chapter 11.

•During operation work, wear your personal protective

equipment!

•Imp ope assembly and use may cause pe sonal inju y

and/o damage to p ope ty.

•Assembly and removal as well as inspection and

maintenance must exclusively be carried out by skilled and

authorized persons.

•Structural changes are impermissible (e.g. welding,

bending).

•Never attempt to make the shackle opening smaller by

bending or welding in intermediate elements.

•Ope ato s must ca y out a visual inspection and, if

necessa y, a functional test of the safety equipment

befo e each use.

•Usage without safety devices (nuts, dowels pins) is not

permitted.

•Never put to use worn-out, bent or damaged shackles.

•Never expose shackles to loads exceeding the specified

working load limits.

•Do not use force when mounting/positioning shackles.

•Make sure the load can take the forces to be applied

without suffering deformation.

•Lateral loads bending the shackles are not permissible.

Shackles must be capable of aligning themselves in loading

direction.

•Do not start lifting before you have made sure the load has

been correctly attached.

•No one including you (ope ato ) must be in the way of the

moving load (haza d a ea).

•During lifting make sure your hands or other body parts do

not come into contact with lifting means. Only remove

lifting means manually (use your hands).

•Avoid impacts, e.g. due to abruptly lifting loads with lifting

means in slack condition.

•Applications where the bolt may become threaded out, e.g.

by a rope or load, shall be avoided. If such applications

cannot be avoided bolts with safety pins shall be used.

•If shackles are expected to perform under continuous

service conditions (multi-shift, automatic operations or the

like) contact the manufacturer first to reduce the working

load limit as necessary.

•Never move a suspended load over persons.

•Never cause suspended loads to swing.

•Always monitor a suspended load.

•Put the load only down in flat places/sites where it can be

safely deposited.

•Avoid shackles to get caught under the load.

•In the event of doubts or concerns about the proper and

safe use, inspection, maintenance or similar things contact

your safety officer or the manufacturer.

THIELE is not esponsible fo damage caused by non-

obse vance of the inst uctions, ules, standa ds and notes

indicated!

As a ule, chain coupling shackles a e not pe mitted fo the

t anspo tation of pe sons.

3. DESCRIPTION AND INTENDED USE

THIELE Chain coupling shackles are intended as end fittings of

chain sling assemblies. The chain strands are to be fitted

directly to the clevis. Shackles of TWN 861 are intended to be

mounted once to be left on the load permanently.

Shackles must only be used

•within the limits of their permissible working load limit,

•for permissible attachment methods and sling angles,

•within the temperature limits prescribed,

•with their original bolts and dowel pins of appropriate size,

•by trained and authorized persons.

Failure to do so may cause serious injury or property damage.

THIELE-Chain coupling shackles meet EG Machinery Directive

2 6/42/EG requirements and feature a safety factor of at

least 4 based on working load limit (WLL).

THIELE shackles are designed to withstand 2 dynamic load

changes under maximum load conditions. In the event of

higher loads (e.g. multi-shift/automatic operation, magnetic

spreaders) the working load limit must be reduced.

Generally, they are marked with the associated chain size and

grade, manufacturer’s symbol and traceability code.

Shackles must only be used with a single loaded chain leg.

Shackles can also be used within lashing chain assemblies.

When used within a lashing system the maximum lashing

capacity (LC) is obtained by doubling the working load limit.

Any alternating use for lifting and lashing purposes is

impermissible!

MOUNTING INSTRUCTIONS

CHAIN COUPLING SHACKLES

GRADES 80 AND 100

THIELE GmbH & Co. KG # change indicator

www.thiele.de | info@thiele.de B11 91-B replaces B11 91-A

© All rights reserved US 3.2 22 3 | 5

4. COMMISSIONING

Prior to using the components for the first time assure that

•the shackles comply with the order and have not been

damaged,

•test certificates and mounting instructions are at hand,

•markings correspond with what is specified in the

documentation,

•inspection deadlines and the qualified persons for

examinations are determined,

•visibility and functional testings are carried out and

documented,

•documentation is safely kept in an orderly manner.

Dispose of the packing in an environmentally compatible way

according to local rules.

5. TECHNICAL DATA

Tables include only article numbers of standard and not

customized parts.

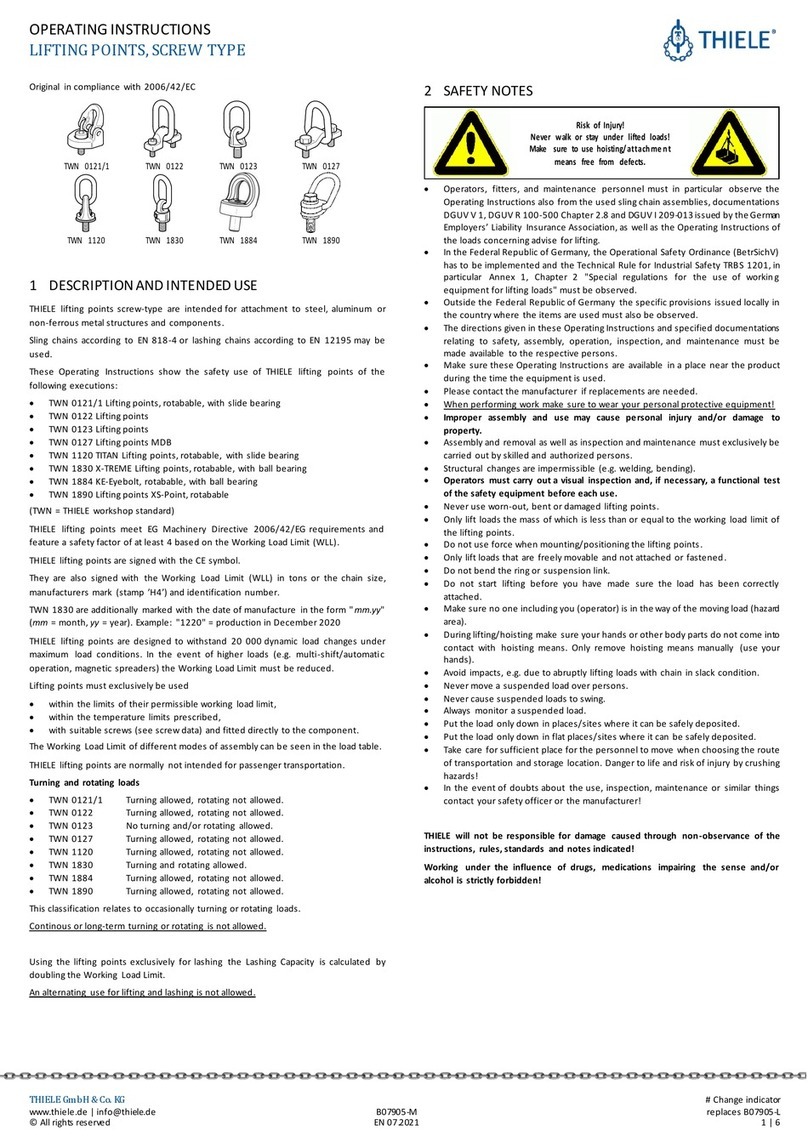

5.1 Specia chain coup ing shack es, TWN 0861,

Grade 80

Nominal

size A ticle no.

WLL

[lbs]

Dimensions [mm]

Mass

[lbs]

E D

C

F B

1

B

2

3/8 F3 6 1 7 1 64 16 32 36 21 47 1.34

1/2 F3 611 12 83 2 4 49 27 61 2.73

5/8 F3 621 18 1 99 24 48 56 33 75 4.63

5.2 Chain coup ing shack es, TWN 0862, Grade 80

Nominal

size A ticle no.

WLL

[lbs]

Dimensions [mm] Mass

[lbs]

E D

C

F B

1

B

2

3/8 F3 6 7 1 64 16 32 36 21 47 1.48

1/2 F3 61 12 83 2 4 49 27 61 3. 2

5/8 F3 62 18 1 99 24 48 56 33 75 5. 3

5.3 Specia coup ing shack es, TWN 0897,

Grade 80

Nominal

size A ticle no.

WLL

[lbs]

Dimensions [mm] Mass

[lbs]

E D

C

F B

1

B

2

1/4

#

F3 586 2 5 7 2 39 46 35 65 1. 4

5/16 F3 596 4 5 7 2 39 46 35 65 1.19

6. ASSEMBLY AND REMOVAL

6.1 Genera

All components to be installed or used must be in perfect

condition and the relevant Working Load Limits of all parts

must accommodate the respective load to be handled.

Allways assemble/remove shackles or parts in load-free

condition.

To prevent unilateral loads and misalignment spacers may be

arranged to center the load application point on the bolt.

Disassemble the parts in reverse order.

Use a suitable drift punch to drive the dowel pins out.

Suitable drift punches are available by article no. Z 33 3.

Dowel pins and cotter pins must only be installed once.

6.2 C evis fastening system

The clevis fastening system only

permits attachment of the nominal

chain size that suits the attachment

component.

6.2.1 ASSEMBLY

•If necessary, remove dowel pin

and pin.

•(A) Place end of chain leg

between the lateral clevis

elements.

•(B) Push pin from the side fully

into the clevis and through the last chain link of the leg.

•(C) Drive dowel pin fully in (must not project) to secure the

pin. The slot must face away from the pin.

Check whether the chain runs smoothly.

The dowel pins must only be installed once.

MOUNTING INSTRUCTIONS

CHAIN COUPLING SHACKLES

GRADES 80 AND 100

THIELE GmbH & Co. KG # change indicator

www.thiele.de | info@thiele.de B11 91-B replaces B11 91-A

© All rights reserved US 3.2 22 4 | 5

Only connect pins and attachment components of identical

grades. Starting with Ø ½” the pins are marked on the front

end.

6.2.2 DISASSEMBLY

•Slacken the respective chain leg.

•(A) Drive dowel pin out using

hammer and drift punch

1)

.

•(B) Push pin out using a drift

punch.

•(C) Remove the chain.

Suitable drift punches are available by article no. Z 33 3.

6.3 Bo t assemb y TWN 0861

A) Move the bolt (1) through both

holes in the shackle ends and see

to it that the two grooves in the

bolt are positioned concentrically

with the dowel pin holes in the

shackle body.

B) Insert the dowel pins (2). Make

sure the slot faces away from the

bolt towards the shackle bow.

6.4 Bo t assemb y TWN 0862 and TWN 0897

A) Fully insert the bolt (1) through both

shackle boreholes.

B) Retain the bolt with a suitable nut

(2) and tighten the nut so as to be

hand-tight using an appropriate tool.

Make sure bolt and nut are evenly

seated against the shackle body.

C) Finally, insert the cotter pin (3) in

the respective hole in the bolt

to secure the connection.

7. CONDITIONS OF USE

7.1 Norma use

Shackles must not be exposed to bending loads; make sure

eccentric loads are avoided.

Shackles must be able to move freely. Supporting of shackles

on other parts is not permitted.

Take care that

•incorrect arrangements are avoided, e.g. eccentric loads,

•damage of lifting or lashing accessories, e.g. by sharp edges,

is not possible,

•the shackles can be reached easily for fitting/unhinging

lifting or lashing accessories.

wrong correct correct

7.2 Inf uence of temperature

The respective temperature range limits must be considered

for all components used.

Using chain coupling shackles in high temperatures will cause

the working load limit to be reduced as indicated below.

Tempe atu e ange Remaining WLL

-4 °C ≤ t ≤ 2 5 °C

-4 °F ≤ t ≤ 4 °F 1 %

2 5 °C < t ≤ 3 °C

4 °F < t ≤ 572 °F 9 %

3 °C < t ≤ 4 °C

572 °F < t ≤ 752 °F 75 %

If a shackle has been exposed to tempe atu es exceeding

the maximum values specified, it must not be used

fu the mo e.

7.3 Environmenta inf uence

Chain Coupling Shackles must not be used in environments

where acids, aggressive or corrosive chemicals or their fumes

are present.

Hot-dip galvanizing or a galvanic treatment is prohibited as

well. Chain coupling shackles are not intended for applications

in abrasive blasting environments.

7.4 Especia y hazardous conditions

The degree of danger when used for the lifting of hazardous

loads, such as for example liquid metal or similar, risk

potentials must be assessed by a competent person in the form

of a risk analysis. Any additional rules and directives must be

followed in this case.

MOUNTING INSTRUCTIONS

CHAIN COUPLING SHACKLES

GRADES 80 AND 100

THIELE GmbH & Co. KG # change indicator

www.thiele.de | info@thiele.de B11 91-B replaces B11 91-A

© All rights reserved US 3.2 22 5 | 5

8. INSPECTION, MAINTENANCE, DISPOSAL

Inspections and maintenance must be arranged by the owner!

Inspection intervals shall be determined by the owner!

Visual inspections must be regularly carried out and

documented by competent and trained persons, at least once a

year or more frequently if the shackles are in heavy duty

service. After three years at the latest they must additionally

be examined for cracks. A load test is not a substitute for this

examination.

The results of the inspection shall be kept in a file that has to

be set up for each shackle before first used. The register will

show characteristic data of the shackles as well as identity

details.

Immediately stop using chain coupling shackles that show the

following defects:

•missing or illegible identification/marking,

•deformation, elongation or fractures,

•cuts, notches, cracks, incipient cracks, pinching,

•damaged threads,

•heating beyond permissible limit,

•severe corrosion,

•impaired or missing safety systems,

•wear in excess of 1 %, e.g. in the receiving area of the pin

diameter,

•missing or damaged pin locks or removal preventing guards.

Cleaning (e.g. prior to inspections) must not take place by using

flames or methods that might cause hydrogen embrittlement

(e.g. pickling or immersion in acidic solutions).

8.1 Inspection service

THIELE offers inspection, maintenance and repair services by

trained and competent personnel.

8.2 Maintenance

Maintenance and epai wo k must only be pe fo med by

competent and t ained pe sons.

Minor notches and cracks may be eliminated by careful

grinding observing the maximum cross section reduction

requirement of 1 % and avoid making more severe cuts or

scores. All maintenance and repair activities must be

documented properly.

8.3 Disposa

All components and accessories of steel taken out of service

must be scrapped in accordance with local regulations and

provisions.

9. SPARE PARTS

Use only original spare parts.

9.1 Spare part sets for c evis fastening system

Sets consist of pin and dowel pin.

Size A ticle no.

1/4

#

F48694

5/16

F48352

3/8 F48355

1/2 F48358

5/8 F48361

9.2 Pin sets for TWN 0861

Sets consist of pin and dowel pins.

Size

A ticle no.

3/8

F48 36

1/2

F48 39

5/8

F48 42

9.3 Pin sets for TWN 0862

Sets consist of pin, nut and cotter pin.

Size

A ticle no.

3/8

F3 451

1/2

F3 461

5/8

F3 471

1 . STORAGE

Shackles must be stored properly sorted and in dry conditions

at temperatures between 32 °F and 1 4 °F.

Do not store in a manner that cause mechanical damage.

11. THIELE OPERATING AND MOUNTING

INSTRUCTIONS

Current mounting and operating instructions

are available as a PDF download on the THIELE-

website www.thiele.de.

12. PUBLISHING INFORMATION

#

Company KWS Inc. THIELE GmbH & Co. KG

(Distributor) (Manufacturer)

Postal

address

P.O. Box 47 487

Tulsa, OK 74147

USA

Werkstrasse 3

5864 Iserlohn

Germany

Phone

number +1 (539) 367 2274 +49 2371/947-

Fax number +1 (539) 367 2278 +49 2371/947-241

This manual suits for next models

10

Table of contents

Other Thiele Lifting System manuals

Popular Lifting System manuals by other brands

Harbor Freight Tools

Harbor Freight Tools PITTSBURGH 56617 Owner's manual & safety instructions

morse

morse 400A-72-115 Operator's manual

Wabtec

Wabtec Ricon S Series Service manual

Phoenix Mecano

Phoenix Mecano Rose+Krieger RKPowerlift M Memory Assembly instructions

probst

probst EL-SDH operating instructions

Molift

Molift Rail System Handbook