Thiele TM Series User manual

Art.-No.: B07725-F - 1 / 9 - Edition: EN-100415

M A N U A L

TM - Chain Blocks

Original operating instructions in keeping

with the EC Machinery Directive

TM-B-OP-05N TM-B-OP-30N

TM-B-OP-10N TM-B-OP-50N

TM-B-OP-20N TM-B-OP-100N

# Marking of changes to prior edition

TM chain blocks meet requirements as per EU Machinery Directive 2006/42/EG and

were type tested by a certification body (TÜV Rheinland inspection agency).

Read this manual before using the TM Chain Block.

This manual includes very important information concerning safety and operation.

Warning Note

TM - Chain Blocks are not intended for lifting, carrying or transporting of persons

and thus must not used for this purpose!

Death or injury can occur from improper use or maintenance.

Art.-No.: B07725-F - 2 / 9 - Edition: EN-100415

1 General features

TM chain blocks are inter alia employed in the construction industry, in mining opera-

tions, marine applications and other sectors of industry.

Significant characteristics are:

Overload protection

Automatic, double-pawl braking system

Stainless steel load chain to EN 818-7, type T, electrogalvanized

2 Safety Notes

The subsequent safety information provides an overview of the general methods of ac-

tion in order to safely operate TM manual chain blocks. Disregard of these safety notes

may result in death, severe injury or damage to property. Instructions hereunder are not

to be considered exhaustive and are thus not limited to the following.

1. Only persons who received safety instructions and have been trained in the opera-

tion of the equipment are allowed to use the chain block.

2. In addition to the operating instructions, operators must be aware of and have

been appropriately trained with regard to the relevant accident prevention regula-

tions "Load-carrying devices used with lifting equipment", BGR 500. Only author-

ised persons in accordance with BGR 500, Chapter 2.8 may be assigned to per-

form assembly and dismantling work.

3. Check whether the suspension points are able to assume the forces to be applied.

4. Structural modifications, attachments or conversions are not permitted.

5. Do not operate or use chain blocks showing wear, damage or improperly function-

ing hook safety latches.

6. Inspect and check the chain block at regular intervals.

7. Replace worn and/or damaged parts.

8. Lubricate movable parts and the chain at regular intervals. Make sure to remove

lubricants and dirt from the braking surfaces inside the block housing.

9. Never connect the chain ends in an inadmissible manner.

10. Do not lift loads of a weight higher than what has been prescribed as load capacity

for the chain block (see section “Technical Details” in this respect).

11. If simultaneously lifting a load by means of two chain blocks, the load capacity of

each of the two blocks must at least be equal to the weight of the load.

12. Loads must be attached in accordance with BGI 556 –"Government safety asso-

ciation information for load attachment personnel".

13. The chain must not wrap around the load or other components.

14. Position the chain block vertically above the load’s center of gravity. Never ‘drag’

or ‘pull’ the load sideways.

15. The operational rotation of the load in the hook or the rotation of the chain block in

the suspension hook is not permitted.

16. Never operate a hoist the chain of which is twisted, has kinks, is elongated or oth-

erwise damaged.

17. Make sure the load is fully supported by and has contact with the hook bed and the

safety latch has engaged.

18. Do not support any load with the tip of the hook.

19. Do not run the chain over edges.

20. During hoisting operation always observe the load.

21. Always make sure no one including you (operator) is in the range of the moving

load (hazard area) and do not lift any load over people.

Art.-No.: B07725-F - 3 / 9 - Edition: EN-100415

22. Do not lift any load over people.

23. When lifting a load start with tightening the chain slowly.

24. Do not lift the load jerkily.

25. Never cause a suspended load to swing.

26. Never leave a suspended load unattended.

27. Welding or cutting work must not be performed on a lifted load.

28. Never use a hoist chain in connection with welding work.

29. Stop operation of the chain block when unusual noise is heard, or if chain jumping

or jamming occurs.

30. Only operate the chain block manually.

31. After use or in the event the chain block is inoperative make sure it has been se-

cured to prevent unauthorized or inadmissible use.

32. Do not remove or cover warning labels located on the device.

33. Do not clean chain blocks with water or with a high-pressure cleaner.

34. Do not use chain blocks to lift dangerous goods such as molten or radioactive ma-

terials.

35. Operating temperature range is between -10 °C and +50 °C.

36. The brake must be examined for icing in the event of operating temperatures be-

low 3 °C.

37. The brake pads may overheat when constantly lowering when dealing with long

hook paths (> 3m). Ensure that cooling pauses are taken.

38. Storage temperature range is between 0 °C and +40 °C.

39. Observe national regulations that may not be stated here.

3 Pre –installation inspections

Prior to commissioning (first use) the user should observe any applicable local or other

provisions relating to the specific operation of the chain block.

Before using the chain block for the first time read this operating manual as well as any

labels supplied with or attached to the hoist to rule out the equipment is operated im-

properly. Further points to be observed:

Before using it, visually inspect the chain block carefully to detect transportation

damage, if any.

Ensure that a functional and visual inspection is performed by an expert.

In case of a used chain block check the equipment’s service history and any doc-

umentation provided.

Lubricate the load chain of the hoist prior to commissioning.

Ensure that testing intervals and the next testing date is determined. A notification

regarding the next test must be attached to the manual chain block.

Dispose packing in accordance to local regulations.

After hanging the chain block, position the lower end of the hand chain at a height of

500-1000 mm from the floor. In order to complete this task, you may have to shorten the

hand chain by laterally bending the non-welded connecting link open, shortening the

hand chain respectively and bending the connecting link closed.

Normal chain links are not suitable for use as a connecting link.

4 Operating instructions

Check the load brake for proper functioning by first raising the load and keeping it in that

position. Position the chain block between the load to be lifted and the suspension point

Art.-No.: B07725-F - 4 / 9 - Edition: EN-100415

in the load’s center of gravity. Ensure hooks are seated correctly and the safety latches

are engaged.

Also make sure that chains and hooks are not twisted, knotted or have cracks.

Lifting the load:

Ensure that there are no people or obstructions in the immediate area of the moving

load. Begin lifting by slowly pulling the hand chain in „U“(up) direction.

Lowering the load:

Ensure that there are no people or obstructions in the immediate area of the moving

load. Lower the load by pulling the hand chain in „D“ (down) direction. For releasing the

brake disk a little more force may be needed.

After use:

Remove any foreign objects and dirt from the chain and hoist. Inspect chains, hooks and

the safety latches to ensure they are operational. When unused, store the chain block in

a dry and clean location.

Slip clutch:

The slip clutch is set to approx. 1.6 x WLL at the factory and exclusively serves to pro-

vide the chain block an overload protection. It may not be operationally used or actuat-

ed. The slip clutch must exclusively be adjusted/set by manufacturer or authorized com-

petent persons. Repeated checks of the slip clutch setting at short intervals (e.g. after it

has been hired out) are not permissible.

5 Load chain mounting

1. Clean the chain that is to be assembled as well as the parts of the chain block that

come into contact with the chain.

2. Insert the first chain link in an upright position (vertical to the sprocket) between

the chain guide and the sprocket. Ensure that the welding seams of the follow-

ing vertical chain links point outwards in a radial manner. Rotate the hand

wheel so that the second chain link can be horizontally assumed by the following

pocket of the sprocket.

3. Continue with the rotary movements until sufficient chain links protrude from the

other side of the housing in order to perform the further steps.

4. Pay attention to the correct positioning of both chain strands in terms of the chain

guide rollers. During operation, the housing orients itself according to the

load. Neither of the chain strands may then come into contact with the hous-

ing bolts under load. The chain may not run above the guide roller under any

circumstances.

5. When dealing with a single-strand design, insert the chain end of the load strand

into the console of the hook attachment and fasten it with the chain bolt. Secure

chain bolt with new self-locking nuts.

6. When dealing with a twin-strand design, insert the chain end of the load strand

above the bottom block sprocket. In doing so, pay attention to the correct align-

ment of the inlet to the chain drive sprocket so that the chain strand is not twisted.

7. When dealing with the TM-B-OP-100, insert the chain end of the of the load strand

via the sprockets of the bottom and top block according to the reeving diagram il-

lustrated on the next page. In doing so, pay attention to the correct alignment of

the inlets to the chain drive sprocket so that the chain strands are not twisted.

8. Fasten the loose chain to the chain end fitting fixed to the housing. In the event of

a twin-strand reeving the loose chain end coming out of the bottom block will be

Art.-No.: B07725-F - 5 / 9 - Edition: EN-100415

fixed by a bolt to the upper hook suspension. Pay attention that the chain strands

are not twisted. If necessary, shorten the chain by removing a link. Secure the

chain bolt with a new splint.

9. Perform a functional test using a low load. Check that the chain strands are not

twisted, that the chain is not touching the housing bolts and that it flawlessly glides

into the chain guide.

Reeving of Load Chain - TM-B-OP-100N:

For chain mounting make sure that the welds of the upright chain links in the

sprockets of the drive module and top block face outwardly!

For design reasons, at the bottom block this can only be achieved by a deflector roll.

The load chain must not be twisted between its two attachment ends.

6 Inspection and tests

Prior to use the operating personnel or maintenance staff must visually check the chain

block for damage or incorrect functioning.

Operation:

Watch out for damage or abnormal noise that may be the result of potential problems.

Do not use the chain block when the load chain cannot run freely through the blocks.

Listen for clicking and pay attention to any blocking or malfunction. The clicking sound of

the pawl of the ratchet is normal when a load is lifted. If a chain jams, jumps or in case

excessive noise can be heard check the chain carefully.

Make sure the hand chain moves freely without jamming and is not damaged.

If any problem is permanent return the chain block to one of the service addresses for

inspection and/or repair.

Do not operate the chain block until all problems are solved.

Drive module

Top block

Bottom block

Hand chain

Art.-No.: B07725-F - 6 / 9 - Edition: EN-100415

Diameter

Welded area

Wear in these

areas

Load chain:

Check all chain links for bending, cracks, and notch-

es, pitting, and wear.

The chain should be taken out of service if the pitch

has increased by more than 3 % or the average wire

diameter reduced by more than 10 %.

Check for correct chain lubrication and re-lubricate if

necessary. If the chain is dirty and unlubricated, this

can lead to premature wear and subsequent chain

failure. Lubricate the chain, e.g. with a mineral oil in

accordance with DIN 51502 CLP 220 or with a dry lubricant, e.g. Unimoly C 220 Spray

in the event of a dusty or dirty environment.

Hooks:

Check hooks for wear and damage. Take hooks out of service if the hook opening has

widened by more than 10 % or the shank height in the hook bed reduced by more than

5 % compared to a new hook. In the event a safety latch does not correctly engage with

the hook tip this is due to overloading and the respective hoist must be replaced. Check

whether the hooks swivel smoothly. Check the safety latch for proper functioning.

Slipping clutch:

If the device is used as intended, the slipping clutch is not set or adjusted. It can only be

replaced as a complete unit and must be subsequently examined by expert staff once

installed.

Transmission:

The transmission is maintenance-free.

Tests and maintenance work must be arranged by the user.

The chain block shall be checked by an authorized repair center at least once a year.

An inspection documentation must be prepared for each hoist and all inspection activi-

ties must be included in that service history.

The chain block must be recertified after 4 years of operation at the latest. Such a recer-

tification must also be performed after the chain block has been repaired with such a

repair to be carried out by an authorized repair center. In this case contact one of the

service addresses listed in this manual.

7 Maintenance and repair

The repair of a chain block must exclusively be performed by a service workshop au-

thorized by THIELE. In this case please refer to one of the service addresses.

Replacing the chain:

Relieve the chain block of load and loosen the chain bolt on the hook tackle or suspen-

sion console in the event of a twin-strand reeving as well as on the chain end fitting. Al-

low the used chain to run through the chain block in the lifting or lowering device and, if

necessary, pull the chain through the top and bottom block. Assemble the new chain

according to the information provided in Chapter 5.

Replacing the load hook / hook tackle (single-strand):

Art.-No.: B07725-F - 7 / 9 - Edition: EN-100415

The hook tackle can only be replaced as a unit. Relieve the chain block of load and

open the nut belonging to the chain bolt. Pull the chain bolt out of the hook tackle con-

sole. Insert the chain end into the console of the new hook tackle and push a new chain

bolt into the drill hole of the console and through the last chain link. Secure the chain

bolt with a new self-locking nut.

Replacing the load hook / bottom block (twin-strand):

Relieve the chain block of load and open the screw belonging to the bottom block con-

sole. Open one half of the bottom block console and remove the hook. Correctly insert

the new hook complete with its retainer into the bottom block console. Close the bottom

block console with its half. In doing so, ensure that the hook retainer and the sprocket

bolts are located in the intended retainers.

Re-insert the screws and secure them with new self-locking nuts.

Replacing the suspension hook:

The housing must be opened in order to replace the suspension hook. Therefore, this

work should only be performed by an authorized expert. In such a case, please contact

a service address.

Dispose:#

Nearly all parts are made of steel and should be scrapped in accordance to local regula-

tions.

THIELE GmbH & Co. KG will not assume any responsibility for failures or damage that may result from a non

appropriate use of the products or a non-observance of the product documentations.

Copyright on this documentation remains with THIELE GmbH & Co. KG. Any use not authorized by the copyright

owner (e.g. reproduction) is liable to prosecution and gives rise to damages claims.

Art.-No.: B07725-F - 8 / 9 - Edition: EN-100415

8 Spare parts

Item

Description

Item

Description

Item.

Description

1

Gearbox cover

19

Hand chain wheel

37

Ball bearing, hook

2

Housing plate, gear side

20

Hand chain

38

Hook nut

3

Housing plate, handwheel

21

Housing cover, handwheel

39

Sprocket, top/bottom block

4

Gearwheel stage

22

Hex. nut, self-locking

40

Needle bearing, sprocket

5

Sprocket, complete

23

Guide roll

41

Bracket, hook suspension

6

Suspension hook

24

Scraper

42

Bolt

7

Safety latch, complete

25

Chain

43

Hook pin

8

Hook

26

Pin

44

Sprocket pin

9

Drive shaft

27

Chain end fitting

45

Suspension plate

10

Safety ring

28

Pin, chain end fitting

46

Bracket, bottom block

11

Gearwheel

29

Cotter pin

55

Hex. nut, slip clutch

12

Pin

30

Slotted nut

56

Cup spring, slip clutch

13

Pawl spring

31

Hook, 2-strand

57

Thrust disk, slip clutch

14

Pawl

32

Sprocket, bottom block

58

Friction lining

15

Brake hub

33

Pin, bottom block

59

Hand chain whel

16

Brake lining

34

Bracket, bottom block

60

Pawl, slip clutch

17

Ratched disk

35

Hex. Bolt

61

Thrust disk, brake

18

Housing cover, inside

36

Bracket, susp. hook

62

Circlip, slip clutch

When ordering spare parts please indicate the model and serial No. of the chain block.

Art.-No.: B07725-F - 9 / 9 - Edition: EN-100415

Article-no. spare parts

Type TM-B-OP-…

Item

Description

…05N

…10N

…20N

…30N

…50N

6

Suspension hook

Z09939

Z09940

Z09941

Z09942

Z09943

7

Safety latch, complete

Z09944

Z09945

Z09946

Z09947

Z09948

8

Hook

Z09949

Z09950

Z09951

Z09952

Z09953

16

Brake lining

Z06934

Z06935

Z06936

Z06937

Z06938

17

Ratched disk

Z06928

Z06929

Z06930

Z06931

Z06932

25

Chain (sold by meter)

F09027

F09047

F09057

Please direct your inquiries to the service address for the TM-B-OP-100N spare parts.

9 Technical details

Model/Type ►

TM-B-OP-05N

TM-B-OP-10N

TM-B-OP-20N

TM-B-OP-30N

TM-B-OP-50N

TM-B-OP-100N

Capacity (WLL) [t]

0,5

1

2

3

5

10

Standard lift [m]

2,5#

2,5#

3

3

3

3

Pull force at hand chain with

full capacity [N]

230#

360#

430#

440#

470#

480#

Max. force transmission until

the activation of the over-

load protection

0,96

1,92

3,84

5,76

9,6

19,2

Min. distance between

hooks [mm]

270

317

414

465

636

798

Load chain dia. [mm]

6

6

8

8

10

10

Net weight [kg]

8,1#

10,7#

17,7#

24#

38,6#

80,4#

Packing dimensions

L x W x H [cm]

25 x 20 x 17

30 x 24 x 17

35 x 26 x 19

39 x 28 x 19

46 x 32 x 21

50x41x21

Additional weight for special

chain lengths [kg/m]

0,9

1

1,2

2,4

4,6

9,2

10 Service address

THIELE GmbH & Co. KG, Postfach 8040, 58618 Iserlohn, Tel. +49(0)2371/947-0

11 Warranty

For TM chain blocks, a one-year warranty is granted from the date of purchase for de-

fective materials or executions. Wear parts as well as parts that have been overloaded

and incorrectly used are excluded from the warranty.

In the event of a justified complaint, the girder clamp will be repaired or replaced.

12 Documentation

TM Chain Blocks will be supplied with this manual and with an acceptance test certifi-

cate with a Declaration of Conformity.

This manual suits for next models

6

Other Thiele Lifting System manuals

Popular Lifting System manuals by other brands

VOGELS

VOGELS PPL 2500 installation manual

Tommy Gate

Tommy Gate V2 Series Owner's and operator's manual

Braun

Braun CENTURY NCL 06 Series Service manual

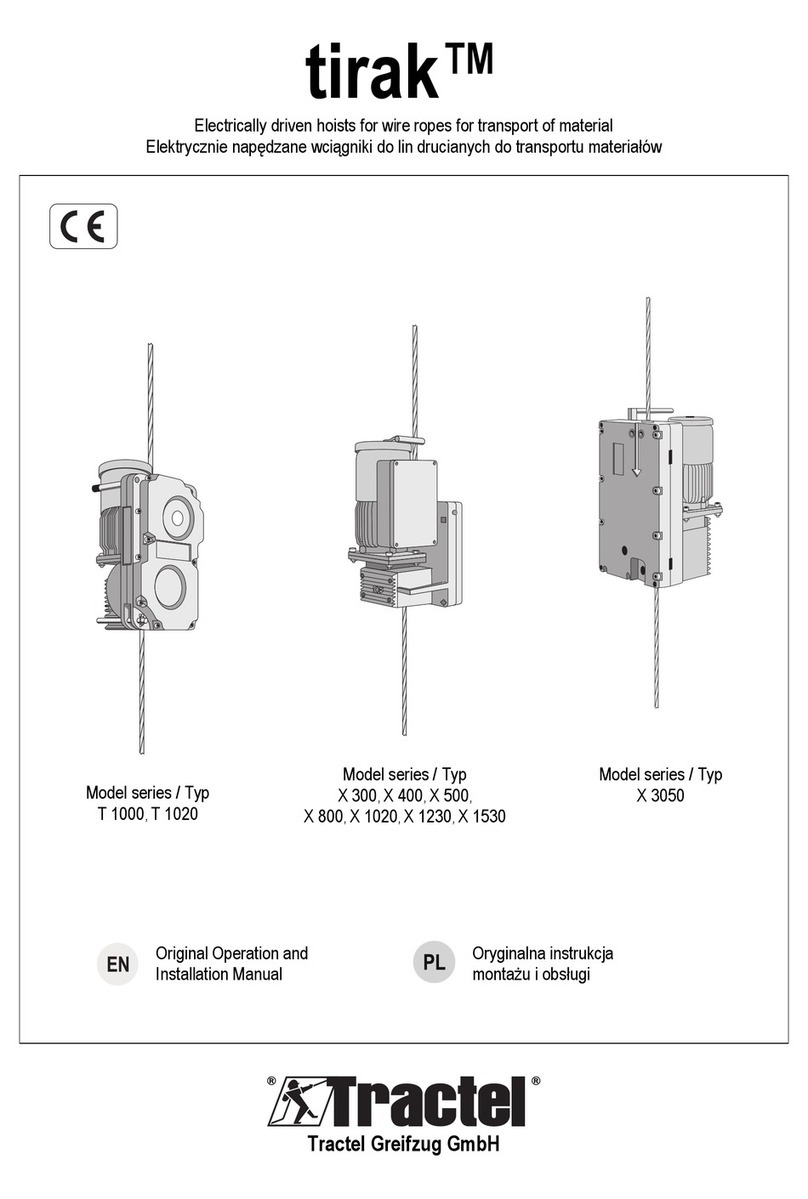

Tractel

Tractel T 1000 Original Operation and Installation Manual

Porta-Dock

Porta-Dock 1265V instructions

Vestil

Vestil SLNM Series Operation and maintenance manual

Braun

Braun NCL Century 2 Series manual

AMGO Hydraulics

AMGO Hydraulics PRO-12 Installation and service manual

Snorkel

Snorkel S39770RT Repair parts manual

Ergotron

Ergotron StyleView SV22 Assembly instructions

Ravaglioli

Ravaglioli KPN345WE Translation of the original instructions

Omega Lift

Omega Lift 23225 user manual