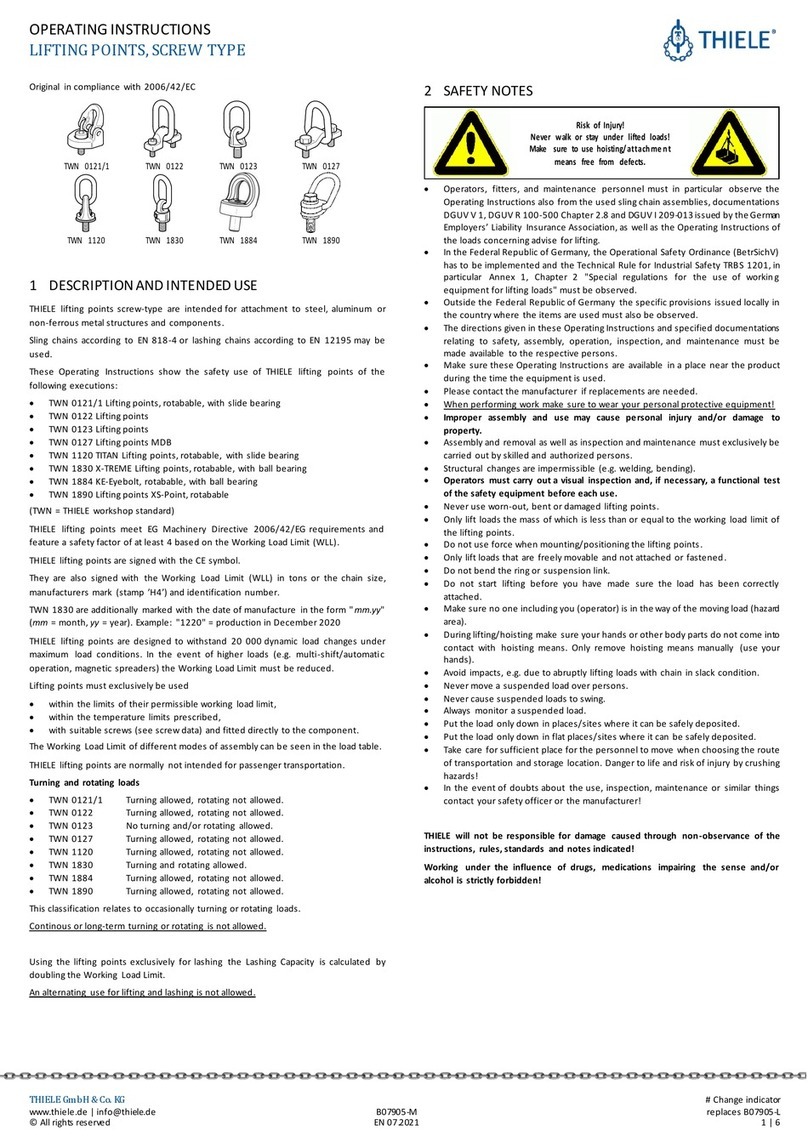

Thiele TWN 1884 User manual

OPERATING INSTRUCTIONS

LIFTING POINTS “XKE-POINTS”

TWN 1884

THIELE GmbH & Co. KG # change indicator

www.thiele.de | info@thiele.de 12243-A replaces -

© All rights reserved US 03.2023 1 | 6

The following operating instructions must always be

followed to avoid the risk of personal injury or property

damage.

Do not use a lifting point “XKE Point” before reading these

operating instructions.

1. A OUT THIS INSTRUCTION

These operating instructions describe in particular how screw

type lifting points “XKE-Points” according to TWN 1884 (TWN =

THIELE Shop Standard) are to be safely used for lifting purposes.

To comply with these instructions is essential to help avoiding

hazards and increases the reliability and service life of the lifting

points.

DANGER! Indicates a hazardous

situation, which, if not avoided, will

result in death or serious injury.

WARNING! Indicates a hazardous

situation, which, if not avoided, could

result in death or serious injury.

CAUTION! Indicates a hazardous

situation, which, if not avoided, could

result in minor or moderate injury.

NOTICE! Is used to address practices

not related to physical injury.

SAFETY INSTRUCTIONS signs indicate

specific safety-related instructions or

procedures.

Definitions

Working Load Limit (WLL)

The maximum load, which a lifting point is designed to support.

Read ASME B30.9 for sling inspection criteria.

Read ASME B30.26 “Rigging Hardware”,

Chapters 26 0, 26 1, 26 4.

2. ASIC SAFETY REQUIREMENTS

To prevent the risk of injury never walk or stay under lifted

loads!

The working load limit must not be exceeded!

Lifting points as well as lifting and attachment means to be

used must be free from defects!

Working under the influence of drugs, medications

impairing the sense and/or alcohol is strictly forbidden!

•Operators, fitters and maintenance personnel must in

particular observe the operating instructions of the used sling

assembly. The operating instructions for the load, if it

contains instructions for lifting, must also be observed.

•The specific safety and operating regulations and standards

issued locally in the country where the items are used must

be observed.

•The directions given in these operating instructions and

specified documentations relating to safety, assembly,

operation, inspection, and maintenance must be made

available to persons operating and using the lifting points.

•These operating instructions must be available in a place near

the product during the time the equipment is used. Please

contact the manufacturer if replacements are needed. See

also chapter 12.

•During operation work, wear your personal protective

equipment!

•Improper assembly and use may cause personal injury

and/or damage to property.

•Assembly and removal as well as inspections and

maintenance must exclusively be carried out by skilled,

qualified, trained and authorized persons only.

•Before each use, check that the upper parts of the lifting

points can be turned easily and that the turning movement

does not occur in the screw connection!

•Operators must carry out a visual inspection and, if

necessary, a functional test of the safety equipment before

each use.

OPERATING INSTRUCTIONS

LIFTING POINTS “XKE-POINTS”

TWN 1884

THIELE GmbH & Co. KG # change indicator

www.thiele.de | info@thiele.de 12243-A replaces -

© All rights reserved US 03.2023 2 | 6

•Never install more than one connecting component to a ring.

•Structural changes are impermissible (e.g. welding, bending).

•Never use worn-out, bent or damaged lifting points.

•Only lift loads that do not exceed the working load limit of the

lifting points.

•In case of using a 3- or 4-leg chain sling, never allow for

inclination angles of less than 30° and in excess of 75°.

•Do not use force when mounting/positioning the attachment

components.

•Only lift loads that are freely movable and not attached or

fastened.

•Do not start lifting before you have made sure the load has

been correctly attached and balanced.

•No one including you (operator) must be in the way of the

moving load (hazard area).

•During lifting your hands or other body parts must not come

into contact with lifting means. Only remove lifting means

manually (use your hands).

•Avoid impacts, e.g. due to abruptly lifting loads with chain in

slack condition.

•Never move a suspended load over persons.

•Never cause suspended loads to swing.

•Always monitor a suspended load.

•Put the load only down in flat places/sites where it can be

safely deposited.

•Assume for sufficient place for the personnel to move when

choosing the route of transportation and storage location.

Danger to life and risk of injury by crushing hazards!

•In the event of doubts or concerns about the proper and safe

use, inspection, maintenance or similar things contact your

safety officer or the manufacturer.

THIELE is not responsible for damage caused by non observance

of the instructions, rules, standards and notes indicated!

As a rule, lifting points are not permitted for the transportation

of persons.

3. DESCRIPTION AND INTENDED USE

THIELE lifting points “XKE-Points” are intended to securely

connect components/loads with slings, e.g. with chain slings

according to ASTM A 906/A 906 M.

They are intended for installation to steel, aluminum or non-

errous metal component structures.

THIELE lifting points “XKE-Points” meet EC Machinery Directive

2006/42/EC requirements and feature a safety factor of at least

4 based on working load limit.

They are signed with the working load limit in tons, the thread

size, manufacturer’s mark “H4” and traceability code.

THIELE lifting points “XKE-Point” are designed to withstand

20 000 dynamic load changes under maximum load conditions.

In the event of higher loads (e.g. multi-shift/automatic operation)

the working load limit must be reduced.

The “XKE-Points” must exclusively be used

•within the limits of their permissible working load limit,

•within the temperature limits prescribed,

•with suitable screws and fitted directly to the component.

The working load limits depending on the number of legs and

inclination angles are shown in the table in chapter 5.2.

Using the lifting points exclusively for lashing, the lashing capacity

(LC) is calculated by doubling the working load limit.

The occasional turning and rotating of loads is permitted.

The permanent turning and rotating of loads is not permitted.

An alternating use for lifting and lashing is not allowed.

4. COMMISSIONING

Prior to using the components for the first time assure that

•the components comply with the order and have not been

damaged,

•test certificates and operating instructions are at hand,

•markings correspond with what is specified in the

documentation,

•inspection deadlines and the qualified persons for

examinations are determined,

•visibility and functional testings are carried out and

documented,

•documentation is safely kept in an orderly manner.

Dispose of the packing in an environmentally compatible way

according to local rule.

OPERATING INSTRUCTIONS

LIFTING POINTS “XKE-POINTS”

TWN 1884

THIELE GmbH & Co. KG # change indicator

www.thiele.de | info@thiele.de 12243-A replaces -

© All rights reserved US 03.2023 3 | 6

5. TECHNICAL DATA

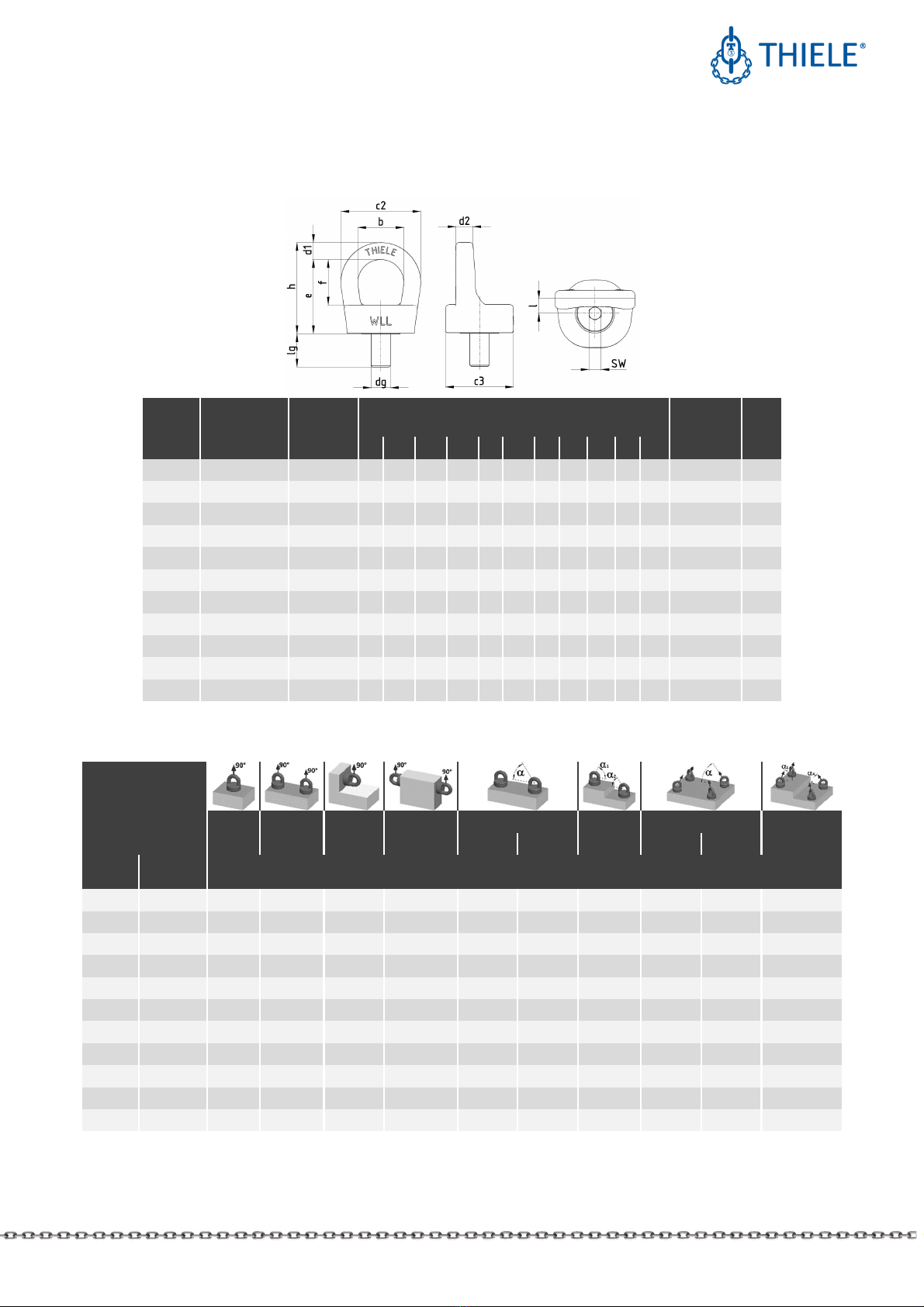

5.1 Dime sio s

Thread

size

Working load

limit (WLL) Article no.

Dimensions [mm] Tightening

torque

1)

Mass

dg [mm]

[t] b c2 c3

e

f

h lg

d1

d2

l SW

[Nm] [kg]

M 8 0,3 F38005 26

45 37 40 26

50 16

9,5

9,5

8 6 13 0,18

M 10 0,5 F38006 26

45 37 40 26

50 16

9,5

9,5

8 6 25 0,18

M 12 1,0 F38007 30

51 43 47 30

57 18

11

11

10

8 40 0,29

M 16 1,7 F38010 38

66 56 62 38

76 27

14

14

13

10 90 0,66

M 20 2,6 F38020 42

74 61 70 42

86 33

16

16

15

12 170 0,99

M 24 3,5 F38030 51

85 65 82 51

99 39

17

18

16

14 280 1,34

M 30 6,0 F38040 62

104

82 97 62

118

45

21

22

20

19 550 2,29

M 36 8,0 F38050 75

131

92 116

75

144

55

28

28

25

19 900 4,18

M 42 12,5

F38060 95

173

122

142

95

181

64

39

39

33

22 1 400 8,89

M 45 15,0

F38070 95

173

122

142

95

181

74

39

39

33

24 1 600 9,12

M 48 17,0

F38080 95

173

122

142

95

181

74

39

39

33

27 1 900 9,21

1) See chapter 5.2

5.2 Worki g load limit (WLL) depe di g o umber of legs (lifti g poi ts) a d i cli atio a gle

Attachment type

Number of legs 1 Leg 2 Legs 1 Leg 2 Legs 2 Legs 2 Legs 3 /4 Legs 3 /4 Legs

Inclination angle α

90°

±5°

90°

±5°

90°

±5°

90°

±5°

45° 90°

30° 45° asym.

2)

45° 90°

30° 45° asym.

2)

WLL

[t]

Thread

[mm] MAXIMUM TOTAL LOAD [t]

3)

0,3 M 8 0,3 0,6 0,3 0,6 0,4 0,3 0,3 0,6 0,45 0,3

0,5 M 10 0,5 1,0 0,5 1,0 0,7 0,5 0,5 1,0 0,75 0,5

1,0 M 12 1,0 2,0 1,0

2,0

1,4 1,0

1,0

2,1 1,5 1,0

1,7 M 16 1,7 3,4 1,7 3,4 2,4 1,7 1,7 3,6 2,5 1,7

2,6 M 20 2,6 5,2 2,6 5,2 3,6 2,6 2,6 5,5 3,9 2,6

3,5 M 24 3,5 7,0 3,5 7,0 4,9 3,5 3,5 7,4 5,2 3,5

6,0 M 30 6,0 12,0 6,0 12,0 8,4 6,0 6,0 12,7 9,0 6,0

8,0 M 36 8,0 16,0 8,0 16,0 11,3 8,0 8,0 16,9 12,0 8,0

11,5 M 42 11,5 23,0 11,5 23,0 16,2 11,5 11,5 24,3 17,2 11,5

13,0 M 45 13,0 26,0 13,0 26,0 18,3 13,0 13,0 27,5 19,5 13,0

14,5 M 48 14,5 29,0 14,5 29,0 20,5 14,5 14,5 30,7 21,7 14,5

2) Reduced working load limits according to DIN 685-5

3) Without consideration of further slings

OPERATING INSTRUCTIONS

LIFTING POINTS “XKE-POINTS”

TWN 1884

THIELE GmbH & Co. KG # change indicator

www.thiele.de | info@thiele.de 12243-A replaces -

© All rights reserved US 03.2023 4 | 6

6. ASSEM LY AND REMOVAL

6.1 Preparatio s

All components to be installed or used must be in perfect

condition and the relevant working load limits of all parts must

accommodate the respective load to be handled.

The mounting location for each lifting point has to ensure that

•the load can take the forces including safety factors safely to

be applied without suffering deformation,

•the lifting point can be assembled flush,

•no areas of danger are created (crushing point, shearing

point),

•lifting and moving is not restrained by overhang,

•used lifting means (e.g. hooks) are freely movable and will

not be bended,

•incorrect use is avoided,

•the sling cannot be damaged, for example by sharp edges,

•lifting point can be used easily.

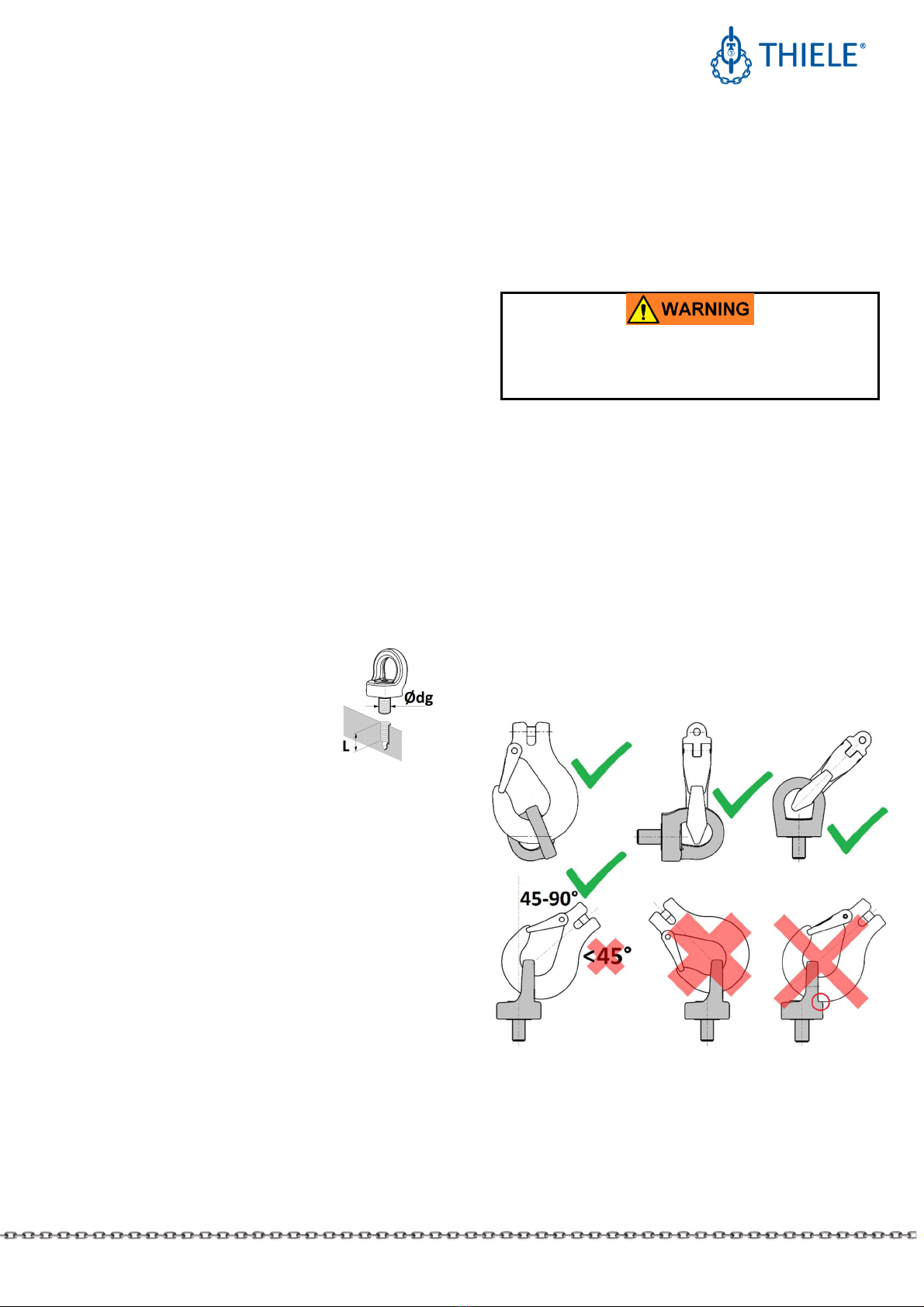

6.2 Assembly

The useful depth of the thread must enable the lifting points to

be safely screwed in. Use only the delivered screws!

The threaded hole must be perpendicular to the screw-on

surface in the load. The depth of the thread "L" of the

component must be at least as follows:

L = 1.0 x d for steel (yield stress R

e

≥ 235 N/mm²)

L = 1.25 x d for castings

L = 2.0 x d for aluminum

L = 2.5 x d in aluminum-magnesium-alloys

(L = depth of thread; d = thread diameter)

•Make sure the threads of the lifting point and in the

component are clean and dry.

•For lifting points have to remain on the component a usual

fluid safety agent for screws has to be used.

•For through-boltings, the nut must be secured against

loosening.

•Single lifting operation WITHOUT turning or rotating:

Hand-tighten the screws with a suitable spanner for screws

with hexagon socket according to DIN.

It must be ensured that the screws of the lifting points

cannot loosen by themselves.

•Lifting WITH turning or rotating as well as multiple lifting

operations:

Tighten the screws to the tightening torques specified in the

technical data.

However, repeated lowering of the load to the ground

requires a new check!

Lifting points that remain on the loads should be tightened

to the tightening torques specified in the technical data.

•Chamfers on the threaded holes are not required.

6.3 Removal

Unload the lifting point and remove any lifting attachments

connected to it. Turn the screw counterclockwise and remove

the lifting point. Assure that no damage occurs during transport

and storage.

7. CONDITIONS OF USE

Continuous or long term turning or rotating is not

allowed.

An alternating use for lifting and lashing is not allowed.

7.1 Normal use

The working load limit for different applications of assembly can

be seen in the load table, chapter 5.2.

The force must be applied in the longitudinal direction of the

attached component (e.g. hook).

The attached component (e.g. hook) must always be able to

move freely. Supporting the component at the lifting point is not

permissible.

Using 4-leg chain sling assemblies may cause higher risk because

only two opposite legs may carry the load. Check the working

load limit of lifting points and chain sling assembly carefully and

chose if necessary bigger sizes.

The following illustrations show typical applications and

foreseeable misuse:

OPERATING INSTRUCTIONS

LIFTING POINTS “XKE-POINTS”

TWN 1884

THIELE GmbH & Co. KG # change indicator

www.thiele.de | info@thiele.de 12243-A replaces -

© All rights reserved US 03.2023 5 | 6

7.2 Use i through holes

If lifting points are fastened by means of nuts in holes (e.g. of

metal sheets), the following conditions must be observed:

•Turning or rotating the load is not permitted.

•The strength class of the nuts must be 10 or higher (thread

size M12: class 12).

•The chamfer at the end of the screw thread must protrude

from the nut.

•It must be ensured that the component to be lifted is suitable

to withstand the force to be applied safely and without

deformation, including the corresponding safety factors.

•Suitable action must be taken to ensure that the nut cannot

loosen unintentionally, e.g. suitable torque or threadlocker.

7.3 I flue ce of temperature

The permissible working load limit of the lifting points reduces

at elevated temperatures. The reduced working load limit

figures shown in the following tables shall only apply for short-

term use at the temperatures indicated.

Temperature range Remaining WLL

-20 °C ≤ t ≤ 100 °C

- 4 °F ≤ t ≤ 212 °F 100 %

100 °C < t ≤ 205 °C

212 °F ≤ t ≤ 400 °F 85 %

205 °C < t ≤ 250 °C

400 °F ≤ t ≤ 482 °F 80 %

250 °C < t ≤ 300 °C

482 °F ≤ t ≤ 572 °F 75 %

Take care for a loss of lubricant depending on several fitting

positions and higher temperatures. A higher wear may occur.

Shorten the inspection interval for that case.

7.4 E viro me tal i flue ce

Lifting points must not be used in environments where acids,

aggressive or corrosive chemicals or their fumes are present.

Hot-dip galvanizing or a galvanic treatment is also prohibited.

7.5 Especially hazardous co ditio s

The degree of danger when used in offshore applications, the

lifting of hazardous loads, such as for example liquid metal or

similar, risk potentials have to be assessed by a competent

person in the form of a risk analysis. Any additional rules and

directives must be followed in this case.

8. INSPECTION, MAINTENANCE, DISPOSAL

8.1 Ge eral

Inspections and maintenance must be arranged by the owner!

Inspection deadlines shall be determined by the owner!

Visual inspections must be carried out and documented by

competent and trained persons regularly but at least once a

year, or more frequently if the lifting points are in heavy-duty

service. After three years at the latest, they must additionally be

examined for cracks. A load test is not a substitute for this

examination.

The results of the inspection shall be kept in a file that has to be

set up for each lifting point before first use. The register will

show characteristic data as well as identity details.

Immediately stop using lifting points that show the following

defects:

•missing or illegible identification/marking

•deformation, elongation or fractures

•cuts, notches, cracks, incipient cracks, pinching

•limited rotatability (dry or stuck ball bearing)

•heating beyond permissible limits

•severe corrosion

•defect screw or thread

8.2 I spectio

service

THIELE offers inspection, maintenance and repair services for

lifting points performed by trained and competent personnel.

8.3 Mai te a ce

Maintenance and repair work must only be performed by

competent and trained persons.

Minor notches and cracks at suspension links may be eliminated

by careful grinding observing the maximum cross section

reduction requirement of 10 % and avoid making more severe

cuts or scores.

Regreasing of the ball bearing is not intended. Replace lifting

points with recognisably dry ball bearings.

All maintenance and repair activities are to be documented.

8.4 Disposal

All components and accessories of steel taken out of service

must be scrapped in accordance with local regulations and

provisions.

If a lifting point has been exposed to temperatures

exceeding the maximum value specified, it must not be

used furthermore.

Use below 40 °F / 40 °C is generally not permitted.

OPERATING INSTRUCTIONS

LIFTING POINTS “XKE-POINTS”

TWN 1884

THIELE GmbH & Co. KG # change indicator

www.thiele.de | info@thiele.de 12243-A replaces -

© All rights reserved US 03.2023 6 | 6

9. SPARE PARTS

Use only original spare parts.

Exclusively use original THIELE screws because these are made

to meet special requirements e.g. concerning the impact

toughness.

Thread size

Article no. Screw data

M 8 Z11727 DIN 7991 M8 x 30 10.9

M 10 Z11728 DIN 7991 M10 x 30 10.9

M 12 Z11681 DIN 7991 M12 x 35 12.9

M 16 Z10869 DIN 7991 M16 x 50 10.9

M 20 Z11200 DIN 7991 M20 x 60 10.9

M 24 Z11199 DIN 7991 M24 x 70 10.9

M 30 Z11722 DIN 7991 M30 x 80 10.9

M 36 Z11747 DIN 7991 M36 x 100 10.9

M 42 Z11804 DIN 7991 M42 x 110 10.9

M 45 Z11805 DIN 7991 M45 x 120 10.9

M 48 Z11806 DIN 7991 M48 x 120 10.9

10. USE OF THIRD-PARTY SCREWS

If local circumstances dictate that screws have to be used

different from those supplied with the installation or listed in

chapter 9, the operator must ensure that

•these fasteners conform to the specified diameter and

strength class,

•they can achieve the minimum required screw-in depth,

•they are 100 % crack tested,

•each bolt has a proven notch impact energy of min. 36 J as a

mean value of three samples tested at -4 °F or at the lowest

fitting temperature if this is below -4 °F, and that none of the

samples fall below 25 J,

•written confirmation of the crack test and impact energy

results is enclosed with the technical documentation.

11. STORAGE

Lifting points must to be properly stored in dry conditions at

temperatures between 32 °F and 104 °F.

Do not store in a manner that cause mechanical damage.

12. THIELE OPERATING AND MOUNTING

INSTRUCTIONS

Current mounting and operating instructions are available as a

PDF download on the homepage.

13. PU LISHING INFORMATION

Company KWS Inc. THIELE GmbH & Co. KG

(Distributor) (Manufacturer)

Postal

address

P.O. ox 470487

Tulsa, OK 74147

USA

Werkstrasse 3

58640 Iserlohn

Germany

Phone

number +1 (539) 367 2274 +49 2371/947-0

Fax number +1 (539) 367 2278 +49 2371/947-241

Other manuals for TWN 1884

1

Table of contents

Other Thiele Lifting System manuals

Popular Lifting System manuals by other brands

Guldmann

Guldmann GH2 installation guide

ATH-Heinl

ATH-Heinl RG 5.5 WG user manual

Harmar Mobility

Harmar Mobility Pinnacle SL600 Installation & service manual

Lehner Lifttechnik

Lehner Lifttechnik Delphin Manual and Operating Instruction

ASE

ASE 2000 owner's manual

Braun

Braun VISTA Series Installation & service manual