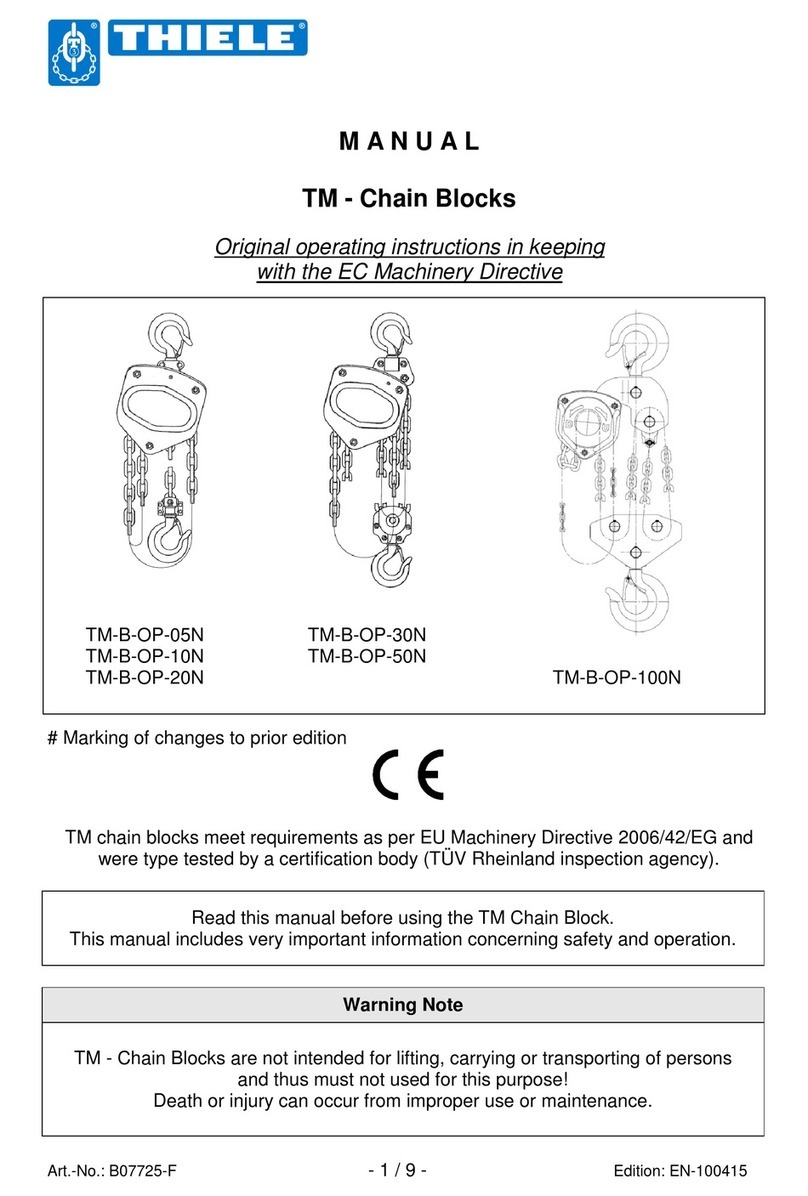

Thiele TWN 0121/1 User manual

OPERATING INSTRUCTIONS

LIFTING POINTS, SCREW TYPE

THIELE GmbH & Co. KG # Change indicator

www.thiele.de | info@thiele.de B07905-M replaces B07905-L

© All rights reserved EN 07.2021 1 | 6

Original in compliance with 2006/42/EC

TWN 0121/1

TWN 0122

TWN 0123

TWN 0127

TWN 1120

TWN 1830

TWN 1884

TWN 1890

1DESCRIPTIONAND INTENDED USE

THIELE lifting points screw-type are intended for attachment to steel, aluminum or

non-ferrous metal structures and components.

Sling chains according to EN 818-4 or lashing chains according to EN 12195 may be

used.

These Operating Instructions show the safety use of THIELE lifting points of the

following executions:

•TWN 0121/1 Lifting points, rotabable, with slide bearing

•TWN 0122 Lifting points

•TWN 0123 Lifting points

•TWN 0127 Lifting points MDB

•TWN 1120 TITAN Lifting points, rotabable, with slide bearing

•TWN 1830 X-TREME Lifting points, rotabable, with ball bearing

•TWN 1884 KE-Eyebolt, rotabable, with ball bearing

•TWN 1890 Lifting points XS-Point, rotabable

(TWN = THIELE workshop standard)

THIELE lifting points meet EG Machinery Directive 2006/42/EG requirements and

feature a safety factor of at least 4 based on the Working Load Limit (WLL).

THIELE lifting points are signed with the CE symbol.

They are also signed with the Working Load Limit (WLL) in tons or the chain size,

manufacturers mark (stamp ’H4’) and identification number.

TWN 1830 are additionally marked with the date of manufacture in the form "mm.yy"

(mm = month, yy = year). Example: "1220" = production in December 2020

THIELE lifting points are designed to withstand 20 000 dynamic load changes under

maximum load conditions. In the event of higher loads (e.g. multi-shift/automatic

operation, magnetic spreaders) the Working Load Limit must be reduced.

Lifting points must exclusively be used

•within the limits of their permissible working load limit,

•within the temperature limits prescribed,

•with suitable screws (see screw data) and fitted directly to the component.

The Working Load Limit of different modes of assembly can be seen in the load table.

THIELE lifting points are normally not intended for passenger transportation.

Turning and rotating loads

•TWN 0121/1 Turning allowed, rotating not allowed.

•TWN 0122 Turning allowed, rotating not allowed.

•TWN 0123 No turning and/or rotating allowed.

•TWN 0127 Turning allowed, rotating not allowed.

•TWN 1120 Turning allowed, rotating not allowed.

•TWN 1830 Turning and rotating allowed.

•TWN 1884 Turning allowed, rotating not allowed.

•TWN 1890 Turning allowed, rotating not allowed.

This classification relates to occasionally turning or rotating loads.

Continous or long-term turning or rotating is not allowed.

Using the lifting points exclusively for lashing the Lashing Capacity is calculated by

doubling the Working Load Limit.

An alternating use for lifting and lashing is not allowed.

2SAFETY NOTES

Risk of Injury!

Never walk or stay under lifted loads!

Make sure to use hoisting/ attach me n t

means free from defects.

•Operators, fitters, and maintenance personnel must in particular observe the

Operating Instructions also from the used sling chain assemblies, documentations

DGUV V 1, DGUV R 100-500 Chapter 2.8 and DGUV I 209-013 issued by the German

Employers’ Liability Insurance Association, as well as the Operating Instructions of

the loads concerning advise for lifting.

•In the Federal Republic of Germany, the Operational Safety Ordinance (BetrSichV)

has to be implemented and the Technical Rule for Industrial Safety TRBS 1201, in

particular Annex 1, Chapter 2 "Special regulations for the use of working

equipment for lifting loads" must be observed.

•Outside the Federal Republic of Germany the specific provisions issued locally in

the country where the items are used must also be observed.

•The directions given in these Operating Instructions and specified documentations

relating to safety, assembly, operation, inspection, and maintenance must be

made available to the respective persons.

•Make sure these Operating Instructions are available in a place near the product

during the time the equipment is used.

•Please contact the manufacturer if replacements are needed.

•When performing work make sure to wear your personal protective equipment!

•Improper assembly and use may cause personal injury and/or damage to

property.

•Assembly and removal as well as inspection and maintenance must exclusively be

carried out by skilled and authorized persons.

•Structural changes are impermissible (e.g. welding, bending).

•Operators must carry out a visual inspection and, if necessary, a functional test

of the safety equipment before each use.

•Never use worn-out, bent or damaged lifting points.

•Only lift loads the mass of which is less than or equal to the working load limit of

the lifting points.

•Do not use force when mounting/positioning the lifting points.

•Only lift loads that are freely movable and not attached or fastened.

•Do not bend the ring or suspension link.

•Do not start lifting before you have made sure the load has been correctly

attached.

•Make sure no one including you (operator) is in the way of the moving load (hazard

area).

•During lifting/hoisting make sure your hands or other body parts do not come into

contact with hoisting means. Only remove hoisting means manually (use your

hands).

•Avoid impacts, e.g. due to abruptly lifting loads with chain in slack condition.

•Never move a suspended load over persons.

•Never cause suspended loads to swing.

•Always monitor a suspended load.

•Put the load only down in places/sites where it can be safely deposited.

•Put the load only down in flat places/sites where it can be safely deposited.

•Take care for sufficient place for the personnel to move when choosing the route

of transportation and storage location. Danger to life and risk of injury by crushing

hazards!

•In the event of doubts about the use, inspection, maintenance or similar things

contact your safety officer or the manufacturer!

THIELE will not be responsible for damage caused through non-observance of the

instructions, rules, standards and notes indicated!

Working under the influence of drugs, medications impairing the sense and/or

alcohol is strictly forbidden!

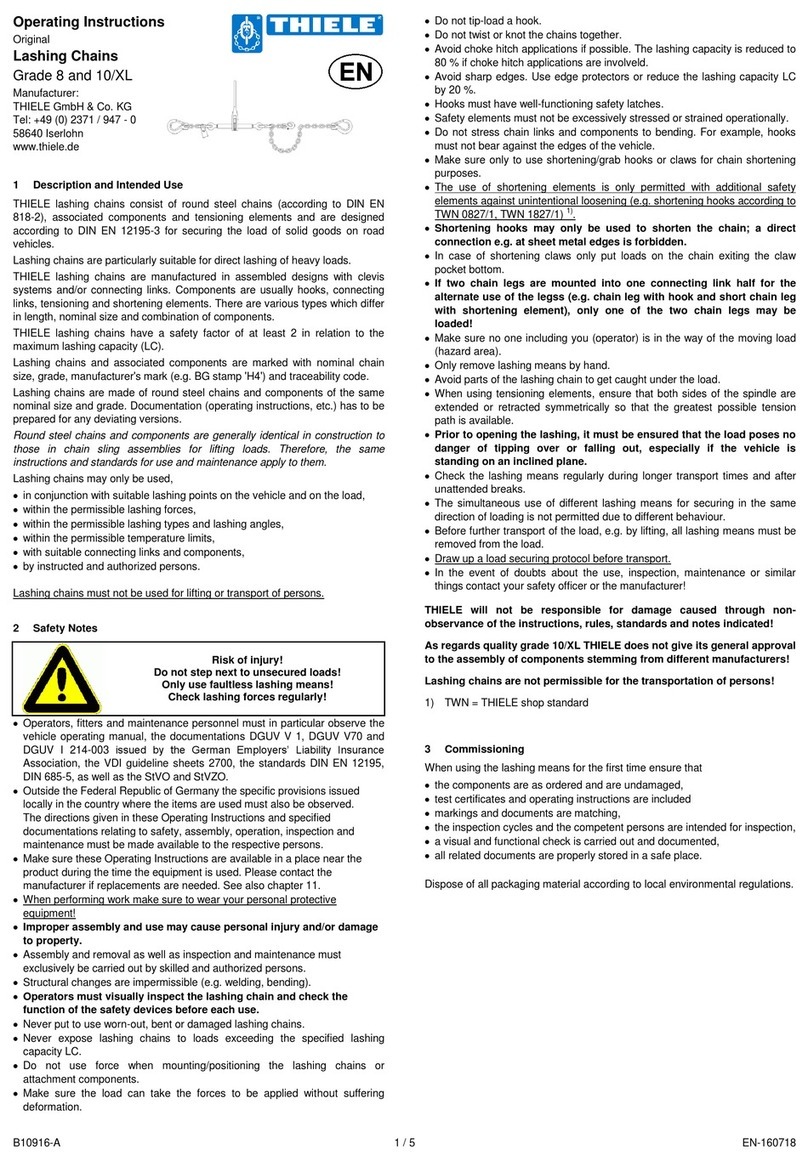

OPERATING INSTRUCTIONS

LIFTING POINTS, SCREW TYPE

THIELE GmbH & Co. KG # Change indicator

www.thiele.de | info@thiele.de B07905-M replaces B07905-L

© All rights reserved EN 07.2021 2 | 6

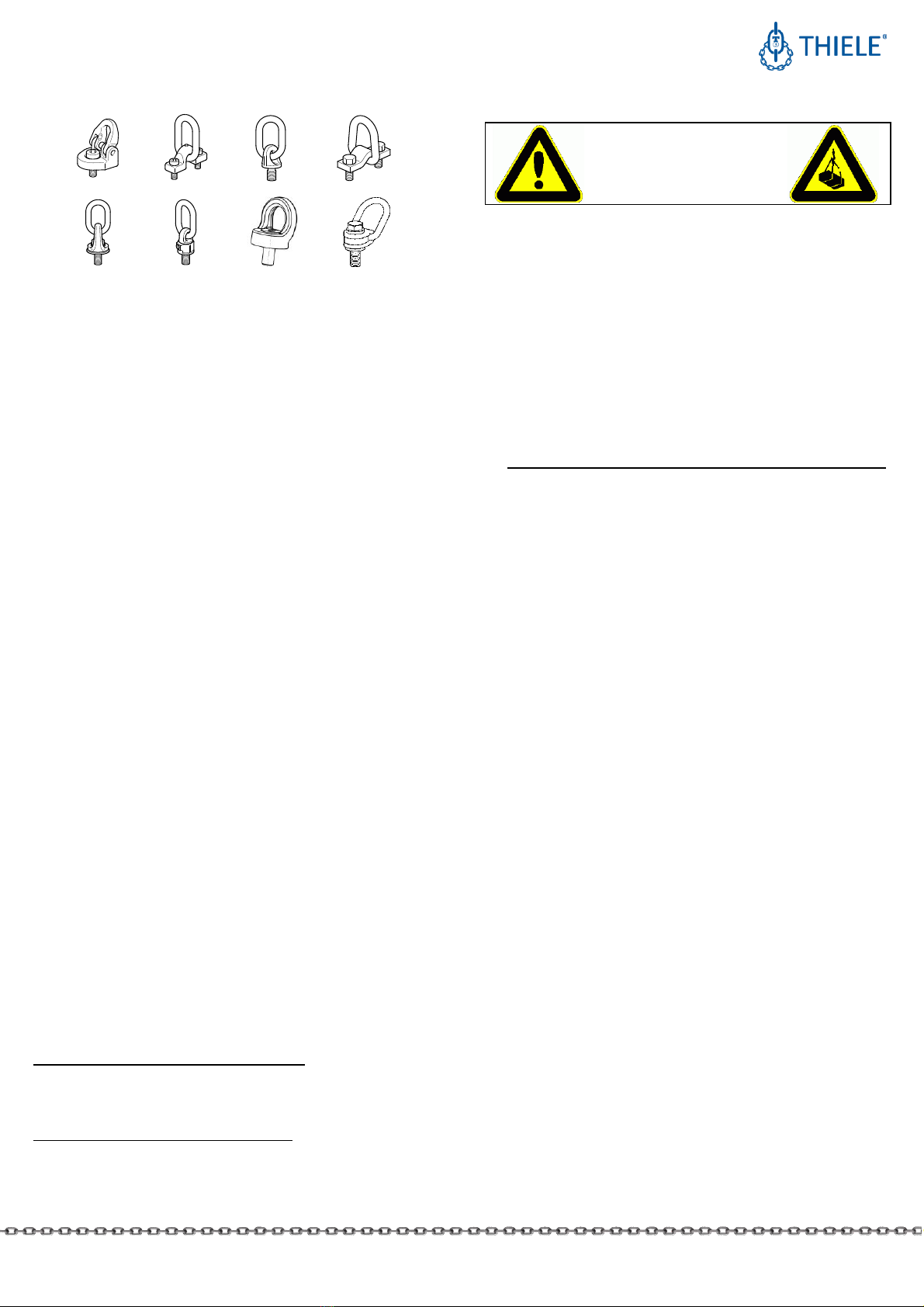

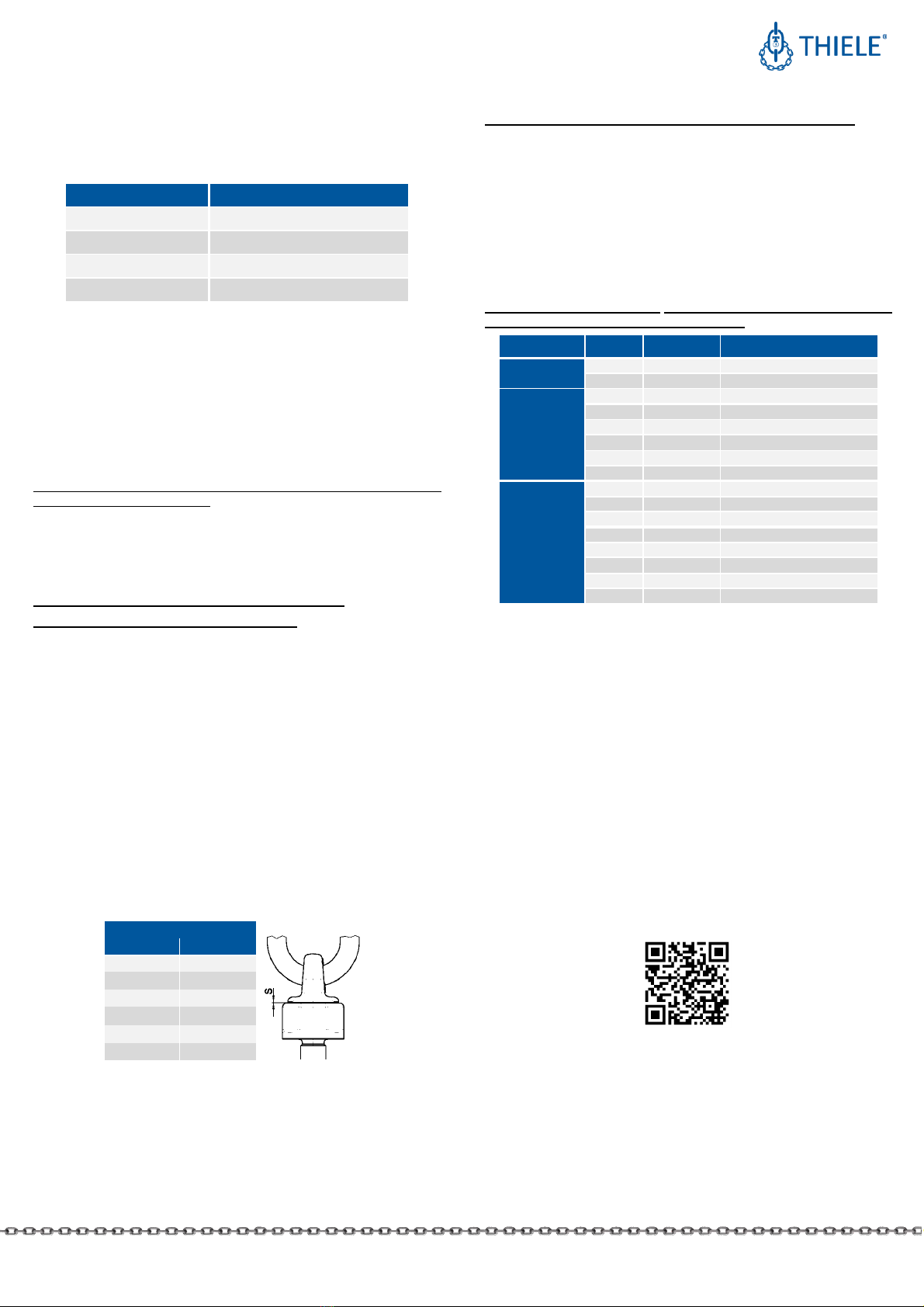

3TECHNICAL DATA

3.1 All types without TWN 1830

Load Table [t]

TWN

Article

No.

WLL

[t]

Usable

thread

length

[mm]

Screw data / Suspension link

[dimensions in mm]

Tightenin g

torque

[Nm]

1-leg

2-leg

1-leg

2-leg

2-leg

2-leg

3-/4-leg

3-/4--leg

0°

0°

90°

90°

0°- 45°

45°- 60°

dissym.

3)

0°- 45°

45°- 60°

dissym.

3)

TWN 0121/1

F35000

1,12

M16 x 25

M16 x 40 DIN 7984 8.8

170

1)

1,12

2,24

1,12

2,24

1,6

1,12

1,12

2,4

1,7

1,12

F35010

2,0

M20 x 30

M20 x 50 DIN 7984 8.8

350

1)

2,0

4,0

2,0

4,0

2,8

2,0

2,0

4,2

3,0

2,0

F35020

3,15

M24 x 36

M24 x 60 DIN 7984 8.8

600

1)

3,15

6,3

3,15

6,3

4,5

3,15

3,15

6,7

4,7

3,15

F35030

5,3

M30 x 50

M30 x 80 DIN 6912 10.9

1 200

1)

5,3

10,6

5,3

10,6

7,5

5,3

5,3

11,2

8,0

5,3

TWN 0122

F35070

3,15

M16 x 25

M16 x 45 DIN 7984 10.9

2)

170

1)

3,15

6,3

3,15

6,3

4,5

3,15

3,15

6,7

4,7

3,15

F35075

5,3

M20 x 36

M20 x 60 DIN 7984 10.9

2)

350

1)

5,3

10,6

5,3

10,6

7,5

5,3

5,3

11,2

8,0

5,3

F35080

8,0

M30 x 50

M30 x 80 DIN 6912 10.9

2)

950

1)

8,0

16

8,0

16

11,3

8,0

8,0

17

12

8,0

F35095

15

M36 x 53

M36 x 90 DIN 6912 10.9

2)

1 900

1)

15

30

15

30

21,2

15

15

31,8

22,5

15

F35098

21,2

M42 x 67

M42 x 100 sim.DIN7984 10.9 Sp.

2)

2 100

1)

21,2

42,4

21,2

42,4

30

21,2

21,2

45

31,8

21,2

F35101

25

M45 x 67

M45 x 110 sim.DIN7984 10.9 Sp.

2)

2 400

1)

25

50

25

50

35,4

25

25

53

37,5

25

F35102

31,5

M56 x 88

M56 x 135 sim.DIN7984 10.9 Sp.

2)

3 200

1)

31,5

63

31,5

63

44,5

31,5

31,5

66,8

47,3

31,5

F35285

36

M56 x 88

M56 x 135 sim.DIN7984 10.9 Sp.

2)

3 200

1)

36

72

36

72

50,9

36

36

76,4

54

36

TWN 0123

F34110

1,12

M16 x 30

B16 x 70 x 35

hand-

screwed

1,12

2,24

1,12

2,24

1,6

1,12

1,12

2,4

1,7

1,12

F34115

1,12

M16 x 30

A16 x 110 x 60

1,12

2,24

1,12

2,24

1,6

1,12

1,12

2,4

1,7

1,12

F34120

2,0

M20 x 38

B16 x 70 x 35

2,0

4,0

2,0

4,0

2,8

2,0

2,0

4,2

3,0

2,0

F34121

2,0

M20 x 38

A16 x 110 x 60

2,0

4,0

2,0

4,0

2,8

2,0

2,0

4,2

3,0

2,0

F34130

3,15

M24 x 35

B18 x 85 x 40

3,15

6,3

3,15

6,3

4,5

3,15

3,15

6,7

4,7

3,15

F34131

3,15

M24 x 45

A18 x 110 x 60

3,15

6,3

3,15

6,3

4,5

3,15

3,15

6,7

4,7

3,15

TWN 0127

F35157

3,15

M20 x 38

M20 x 50 ISO 4017 10.9

2)

350

3,15

6,3

3,15

6,3

4,5

3,15

3,15

6,7

4,7

3,15

F35158

5,3

M24 x 35

M24 x 50 ISO 4017 10.9

2)

600

5,3

10,6

5,3

10,6

7,5

5,3

5,3

11,2

8,0

5,3

TWN 1120

F34405

0,3

M8 x 18

M8 x 35 12.9

hand-

screwed by

open-ended

spanner

0,3

0,6

0,3

0,6

0,42

0,3

0,3

0,64

0,45

0,3

F34390

0,45

M10 x 18

M10 x 35 12.9

0,45

0,9

0,45

0,9

0,64

0,45

0,45

0,95

0,68

0,45

F34395

0,6

M12 x 23

M12 x 40 12.9

0,6

1,2

0,6

1,2

0,85

0,6

0,6

1,3

0,9

0,6

F34400

1,4

M16 x 28

M16 x 45 10.9

2,1

4,2

1,4

2,8

2,0

1,4

1,4

3,0

2,1

1,4

F34410

2,5

M20 x 32

M20 x 50 10.9

3,0

6,0

2,5

5,0

3,5

2,5

2,5

5,3

3,8

2,5

F34420

3,5

M24 x 40

M24 x 60 10.9

6,0

12

3,5

7,0

4,9

3,5

3,5

7,4

5,3

3,5

F34430

6,7

M30 x 52

M30 x 80 12.9

7,1

14,2

6,7

13,4

9,5

6,7

6,7

14,2

10

6,7

F34440

8,0

M36 x 66

M36 x 100 12.9

12,5

25

8,0

16

11,3

8,0

8,0

17

12

8,0

TWN 1884

F38005

0,5

M8 x 16

DIN 7991 M8 x 30 10.9

hand-

screwed by

allen key

0,5

1,0

0,5

1,0

0,7

0,5

0,5

1,0

0,75

0,5

F38006

0,75

M10 x 16

DIN 7991 M10 x 30 10.9

0,75

1,5

0,75

1,5

1,0

0,75

0,75

1,5

1,1

0,75

F38007

1,0

M12 x 18

DIN 7991 M12 x 35 10.9

1,0

2,0

1,0

2,0

1,4

1,0

1,0

2,1

1,5

1,0

F38010

1,7

M16 x 27

DIN 7991 M16 x 50 10.9

1,7

3,4

1,7

3,4

2,4

1,7

1,7

3,6

2,5

1,7

F38020

2,6

M20 x 33

DIN 7991 M20 x 60 10.9

2,6

5,2

2,6

5,2

3,6

2,6

2,6

5,5

3,9

2,6

F38030

3,2

M24 x 39

DIN 7991 M24 x 70 10.9

3,5

7,0

3,5

7,0

4,9

3,5

3,5

7,0

5,2

3,5

TWN 1890

F35243

0,63

M10 x 17

M10 x 45 ISO 4017 12.9

80

0,63

1,26

0,63

1,26

0,89

0,63

0,63

1,3

0,95

0,63

F35244

1,0

M12 x 22

M12 x 50 ISO 4017 12.9

130

1,0

2,0

1,0

2,0

1,4

1,0

1,0

2,1

1,5

1,0

F35245

1,7

M16 x 30

M16 x 70 ISO 4017 10.9

180

1,7

3,4

1,7

3,4

2,4

1,7

1,7

3,6

2,6

1,7

F35246

2,5

M20 x 38

M20 x 80 ISO 4017 10.9

350

2,5

5,0

2,5

5,0

3,5

2,5

2,5

5,3

3,8

2,5

F35247

4,0

M24 x 40

M24 x 90 ISO 4017 12.9

500

4,0

8,0

4,0

8,0

5,7

4,0

4,0

8,5

6,0

4,0

F35249

6,0

M30 x 44

M30 x 100 ISO 4017 10.9

500

6,0

12

6,0

12

8,5

6,0

6,0

12,7

9,0

6,0

F35250

8,0

M36 x 64

M36 x 120 ISO 4017 12.9

750

8,0

16

8,0

16

11,3

8,0

8,0

17

12

8,0

F35251

10

M42 x 74

M42 x 140 ISO 4017 10.9

950

10

20

10

20

14,1

10

10

21,2

15

10

1) For tapped holes in steel

2) Additional technical THIELE-specification must be observed

3) Reduced WLL according to DIN 685-5

OPERATING INSTRUCTIONS

LIFTING POINTS, SCREW TYPE

THIELE GmbH & Co. KG # Change indicator

www.thiele.de | info@thiele.de B07905-M replaces B07905-L

© All rights reserved EN 07.2021 3 | 6

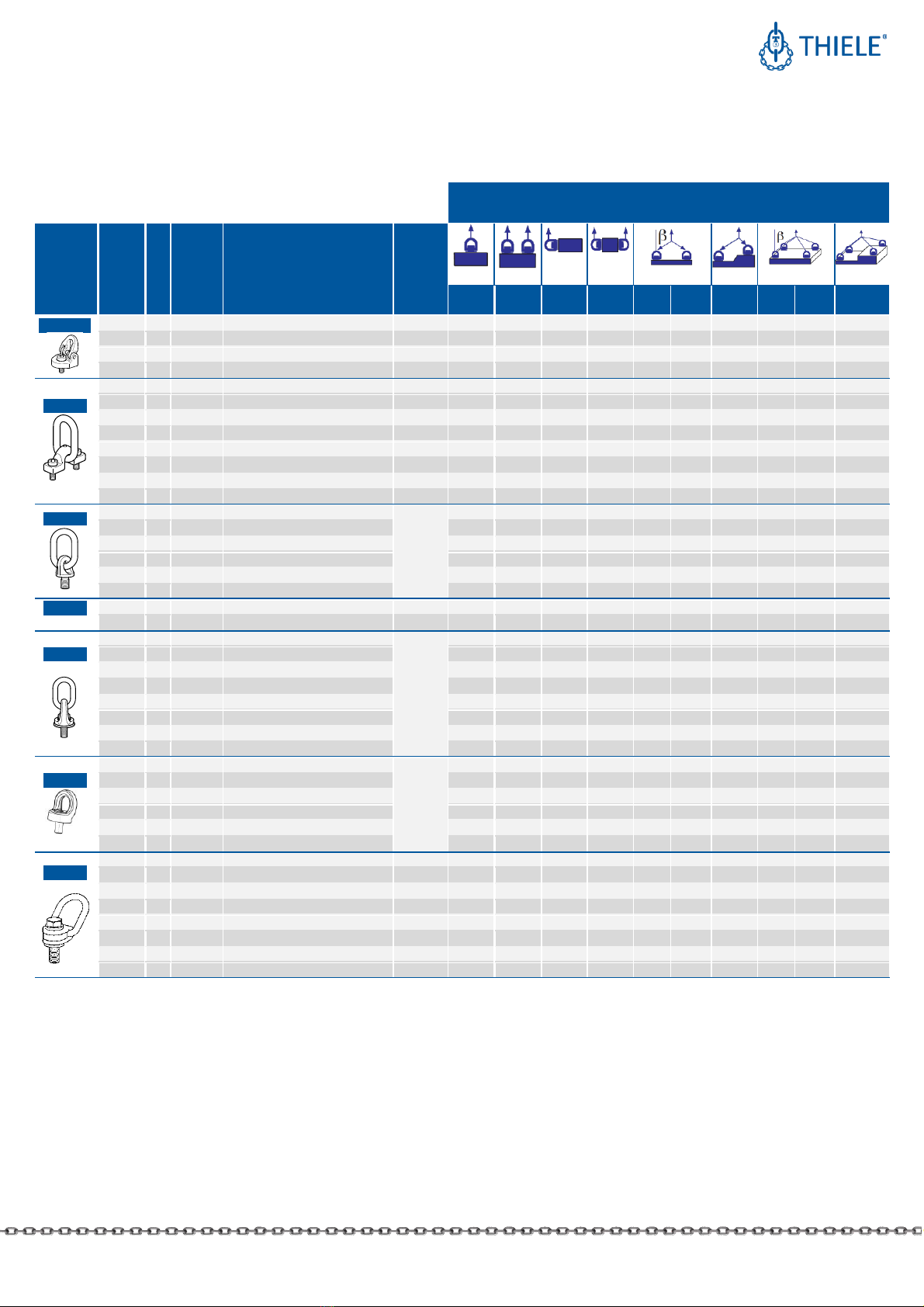

3.2 Technical data for TWN 1830

Nominal WLL

[t]

Article-

No.

Suspension link

[mm]

Thread

d x G

[mm]

Tightenin g

torque

[Nm]

Working Load Limit for each lifting point

depending on alignment and inclination angle

= ± 5°

5° < ≤105°

5° < ≤45°

P R E F E R E D

to avoid

[t]

[t]

[t]

0,45

F34306

B13 x 55 x 33

M10 x 15

hand-

screwed

0,9

0,6

0,45

0,6

F34307

B13 x 55 x 33

M12 x 18

1,2

0,75

0,6

1,4

F34300

B13 x 55 x 33

M16 x 20

2,8

1,7

1,4

2,5

F34310

B16 x 70 x 35

M20 x 25

5,3

2,8

2,5

3,5

F34320

B18 x 85 x 40

M24 x 30

7,0

4,0

3,5

5,3

F34330

B22 x 100 x 50

M30 x 40

10

6,3

5,3

8,0

F34340

B22 x 100 x 50

M36 x 50

15

9,5 1)

10 2)

8,0

10

F34350

B32 x 140 x 70

M42 x 60

18

13

10

12,5

F34353

B32 x 140 x 70

M45 x 65

20

15

12,5

12,5

F34355

B32 x 140 x 70

M48 x 68

20

16

12,5

12,5

F34361#

B32 x 140 x 70

M52 x 78 #

20

16

12,5

17

F34360

B32 x 140 x 70

M56 x 78

28

22

17

17

F34363

B32 x 140 x 70

M64 x 96

28

22 1)

25 2)

17

31,5

F34380

B45 x 220 x 110

M72 x 108

50

40

31,5

35

F34383

B45 x 220 x 110

M80 x 120

50

48

35

40 t

F34385

B45 x 220 x 110

M90 x 135

50

50

40

40 t

F34388

B45 x 220 x 110

M100 x 150

50

50

40

1) until date of manufacture „1220“ (December 2020)

2) from date of manufacture „0121“ (January 2021)

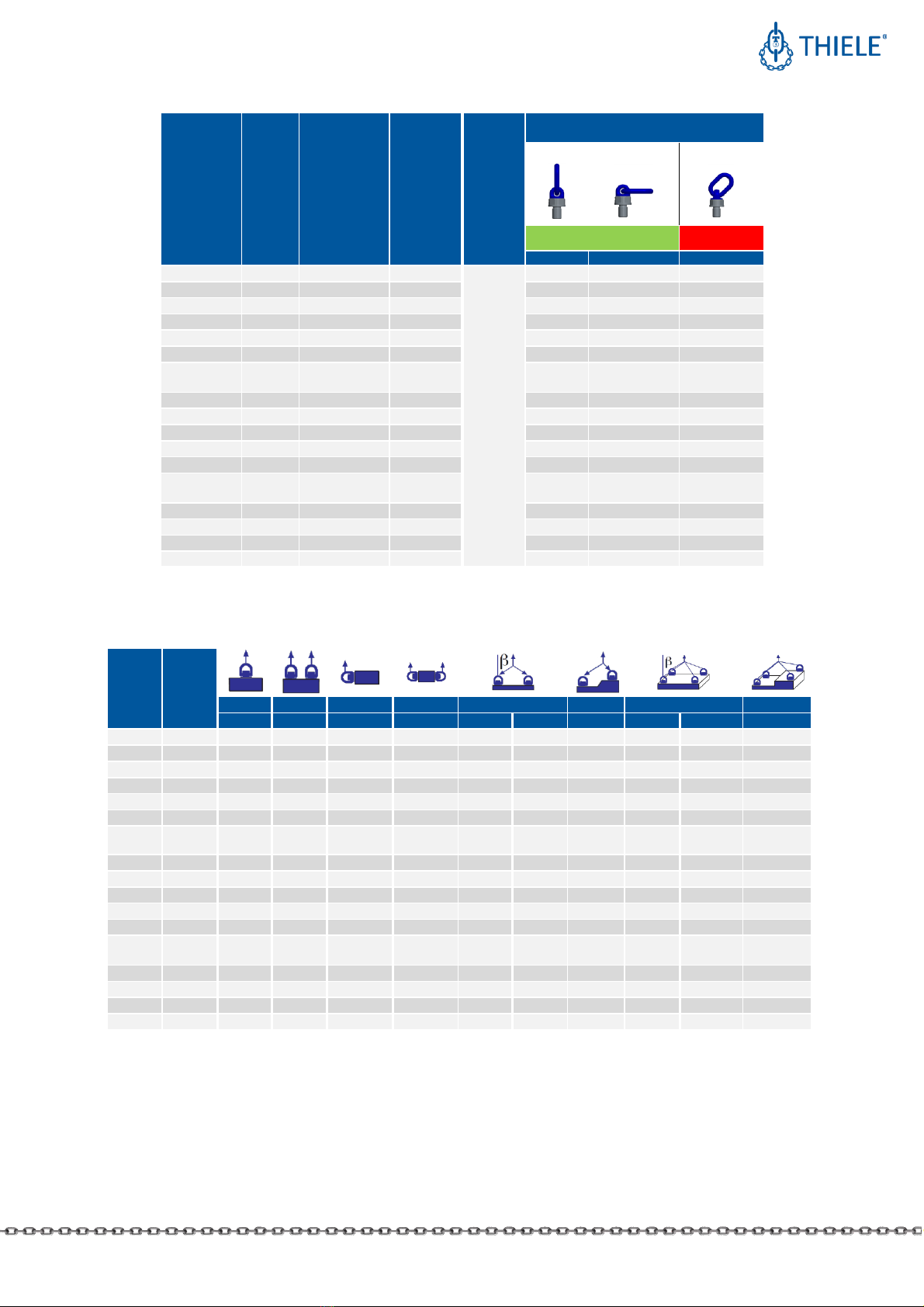

Working Load Limit (WLL) depending on number of legs and inclination angle in t

Nominal

WLL

[t]

Thread

[mm]

1-leg

2- leg

1- leg

2- leg

2- leg 5)

2- leg 5)

3-/4- leg5)

3-/4- leg5)

± 5°

± 5°

75- 105°

75- 105°

0°- 45°

45°- 60°

dissym.6)

0°- 45°

45°- 60°

dissym.6)

0,45

M10

0,9

1,8

0,6

1,2

0,85

0,6

0,6

1,3

0,9

0,6

0,6

M12

1,2

2,4

0,75

1,5

1,0

0,75

0,75

1,57

1,12

0,75

1,4

M16

2,8

5,6

1,7

3,4

2,4

1,7

1,7

3,6

2,6

1,7

2,5

M20

5,3

10,6

2,8

5,6

4,0

2,8

2,8

5,9

4,2

2,8

3,5

M24

7,0

14

4,0

8,0

5,7

4,0

4,0

8,5

6,0

4,0

5,3

M30

10

20

6,3

12,6

8,9

6,3

6,3

13,4

9,5

6,3

8,0

M36

15

30

9,5 3)

104)

193)

204)

13,4 3)

14,1 4)

9,5 3)

104)

9,5 3)

104)

20,2 3)

21,2 4)

14,3 3)

154)

9,5 3)

104)

10

M42

18

36

13

26

18,2

13

13

27,3

19,5

13

12,5

M45

20

40

15

30

21,2

15

15

31,8

22,5

15

12,5

M48

20

40

16

32

22,6

16

16

33,9

24

16

12,5

M52 #

20

40

16

32

22,6

16

16

33,9

24

16

17

M56

28

56

22

44

31,1

22

22

46,7

33

22

17

M64

28

56

223)

254)

443)

504)

31,1 3)

35,3 4)

223)

254)

223)

254)

46,7 3)

534)

333)

37,5 4)

223)

254)

31,5

M72

50

100

40

80

56

40

40

85

60

40

35

M80

50

100

48

96

68

48

48

102

72

48

40

M90

50

100

50

100

71

50

50

106

75

50

40

M100

50

100

50

100

71

50

50

106

75

50

3) until date of manufacture „1220“ (December 2020)

4) from date of manufacture „0121“ (January 2021)

5) for the prefered alignment

6) Reduced WLL according to DIN 685-5

OPERATING INSTRUCTIONS

LIFTING POINTS, SCREW TYPE

THIELE GmbH & Co. KG # Change indicator

www.thiele.de | info@thiele.de B07905-M replaces B07905-L

© All rights reserved EN 07.2021 4 | 6

4COMMISSIONING

Prior to using the components for the first time make sure that

•the lifting points comply with the order and have not been damaged,

•test certificate, statement of compliance, and operating instructions are at hand,

•markings correspond with what is specified in the documentation,

•inspection deadlines and the qualified persons for examinations are determined,

•visibility and functional testing are carried out and documented,

•documentations are safely kept in an orderly manner.

Dispose of the packing in an environmentally compatible way according to local rules.

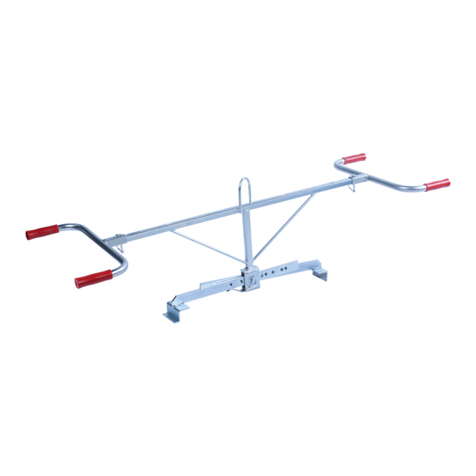

5ASSEMBLY AND REMOVAL

5.1 Preparations

The mounting location for each lifting point must ensure that

•the load can take the forces safely to be applied without suffering deformation,

•the lifting point can be assembled flush,

•no areas of danger are created (crushing point, shearing point),

•transportation is not restrained by overhang,

•deflections of sling parts are avoided,

•incorrect use is avoided,

•the suspension gear cannot be damaged, for example by sharp edges,

•the lifting point can be used easily.

5.2 Assembly

The useful depth of the thread must enable the lifting points to be safely screwed in.

Use only the delivered screws!

Make sure the tapped hole is arranged at right angle to the attachment face on the

component. The depth of the thread „L“ of the component must at least be as follows:

L = 1,0 x d for steel

L = 1,25 x d for castings

L = 2,0 x d for aluminum

L = 2,5 x d in aluminum-magnesium-alloys

(L = depth of thread; d = thread diameter)

•Make sure the threads of the lifting point and in the

component are clean and dry.

•If lifting points should remain on the component a thread

locker has to be used.

•In case of a bolted joint the nut must be secured against unintentionally loosening.

•TWN 0123, TWN 1120, TWN 1830 and TWN 1884:

Use a suitable open-ended spanner, ring spanner or allen key to fix the lifting

points hand-tight.

•TWN 0121/1, TWN 0122, TWN 0127 and TWN 1890:

Take care to tighten the screws by the right torque shown in the table. As long as

it is ensured there is no load turning for a singular use and the lifting point cannot

be loosened a hand tightening of the lifting points by a suitable open-ended

spanner or ring spanner is sufficient. An additional check is necessary in case of a

repeated load lowering.

•TWN 1830 and TWN 1884:

Take care not to exceed the tightening torque of 40 Nm for screws M10 and M12.

There must be made a chamfer on the hole for the thread:

Thread [mm]

Chamfer [mm]

M8

1,5

+0,5

x 45°

M10, M12

2,0

+0,5

x 45°

M16, M20

2,5

+0,5

x 45°

M24, M30

3,5

+0,5

x 45°

M36 - M48

4,0

+0,5

x 45°

M52

#

- M100

4,5

+0,5

x 45°

6CONDITIONSOFUSE

6.1 Normal Use

The top part of the lifting point including attachment link must always be freely

movable.

It must not rest on or be supported by other structural parts.

When attaching the components make sure the position of the lifting point always

enables forces to be exerted in longitudinal direction of the suspension link.

Make sure only the top parts of the lifting points turn into loading direction and not

the firmly secured stationary portion.

Using 4-leg chain link assemblies may cause higher risk because only 2 opposite legs

carrying the load. Check the Working Load Limit of lifting point and chain link assembly

carefully and chose if necessary bigger sizes.

The force must be applied lengthwise to the suspension link.

TWN 1830:

The lifting point must not be used for a permanent or prolonged turning of the load.

to prefer to avoid not permitted

TWN 1890:

TWN 1884:

Components connected to the eyelet must always be able to move freely.

6.2 Use in through holes #

If screwable lifting points are fastened by means of nuts in holes (e.g. of metal sheets),

the following conditions must be observed:

•Rotating or turning the load is not permitted.

•The strength class of the nuts must be 10 or higher.

•The chamfer at the end of the screw thread must protrude from the nut.

•It must be ensured that the component to be lifted is suitable to withstand the force

to be applied safely and without deformation, including the corresponding safety

factors.

•Suitable action must be taken to ensure that the nut cannot loosen unintentionally,

e.g. suitable torque or threadlocker.

OPERATING INSTRUCTIONS

LIFTING POINTS, SCREW TYPE

THIELE GmbH & Co. KG # Change indicator

www.thiele.de | info@thiele.de B07905-M replaces B07905-L

© All rights reserved EN 07.2021 5 | 6

6.3 Influence of Temperature

The permissible Working Load Limit of the lifting points reduces at elevated

temperatures.

The reduced Working Load Limit figures shown in the following tables shall only apply

for short-term use at the temperatures indicated.

Temperatu re range

1) #

Remaining Workin g Load Limit (WLL)

-20 °C ≤ t ≤ 100 °C

100 %

100 °C < t ≤ 200 °C

85 %

200 °C < t ≤ 250 °C

80 %

250 °C < t ≤ 300 °C

75 %

1)

other temperatu re ranges only after consultatio n with the manufac tu re r

If the lifting points have been exposed to temperatures exceeding the maximum values

specified, they must no longer be used.

TWN 1830 and TWN 1884:

Take care for a loss of lubricant depending on several fitting positions and higher

temperatures. A higher wear may occur.

Shorten the inspection interval for that case.

6.4 Environmental Influence

Lifting points must not be used in environments where acids, aggressive or corrosive

chemicals or their fumes are present.

Hot-dip galvanizing or a galvanic treatment is prohibited as well.

7INSPECTIONS, MAINTENANCE AND DISPOSAL

7.1 General

Inspections and maintenance must be arranged for by the owner!

Inspection deadlines shall be determined by the owner!

Inspections must be carried out and documented by competent persons regularly but

at least once a year, or more frequently if the lifting points are in heavy-duty service.

After three years at the latest they must additionally be examined for cracks. A load

test shall never be considered a substitute for this examination.

The results of the inspection shall be entered into a register (DGUV I 209-062 or DGUV

I 209-063) to be prepared when the lifting point is firstly used. The register will show

characteristic data of the lifting points and other components as well as identity details.

Immediately stop using lifting points that show the following defects:

•missing or illegible identification/marking,

•deformation, elongation or fractures,

•cuts, notches, cracks, incipient cracks, pinching,

•no freely rotating or turning possible,

•heating beyond permissible limits,

•severe corrosion,

•wear exceeding 10 %, for example in the suspension link diameter area,

•defect screws,

•TWN 1830: gap size „s“ exceeds figures in table below:

Max. gap size „s“ for TWN 1830

Thread

s [mm]

M10 –M20

1.5

M24

2.0

M30

2.5

M36

3.0

M42 –M64

3.5

M72 –M100

4,0

Inspection Service

THIELE offers inspection, maintenance and repair services for lifting points performed

by trained and competent personnel.

7.2 Maintenance

Maintenance and repair work must only be performed by competent persons.

Minor notches and cracks at suspension links may be eliminated by careful grinding

observing the maximum cross section reduction requirement of 10 % and avoid making

more severe cuts or scores.

All maintenance and repair activities are to be documented.

7.3 Disposal

All components and accessories of steel taken out of service are to be scrapped in line

with local regulations and provisions.

8SPARE PARTS

Only use original THIELE-spare parts. Exclusively use original THIELE screws and bolts

because these are made to meet special requirements.

Type

WLL

Article No.

Screw data

TWN 0127

3,15

Z07742

M20 x 50 ISO 4017 10.9

5,3

Z09017

M24 x 50 ISO 4017 10.9

TWN 1884

0,5

Z11727

DIN 7991 M8 x 30 10.9

0,75

Z11728

DIN 7991 M10 x 30 10.9

1,0

Z11363

DIN 7991 M12 x 35 12.9

1,7

Z10869

DIN 7991 M16 x 50 10.9

2,6

Z11200

DIN 7991 M20 x 60 10.9

3,5

Z11199

DIN 7991 M24 x 70 10.9

TWN 1890

0,63

Z10836

M10 x 45 ISO 4017 12.9

1,0

Z10795

M12 x 50 ISO 4017 12.9

1,7

Z09544

M16 x 70 ISO 4017 10.9

2,5

Z08692

M20 x 80 ISO 4017 10.9

4,0

Z09809

M24 x 90 ISO 4017 12.9

6,0

Z07810

M30 x 100 ISO 4017 12.9

8,0

Z07828

M36 x 120 ISO 4017 12.9

10

Z10136

M42 x 140 ISO 4017 10.9

9USE OF DIFFERENT SCREWS

If local circumstances dictate that different screws must be used from those supplied

with the installation, or listed in Section 8, the operator must ensure that

•these fasteners conform to the specified diameter and strength class ,

•they can achieve the minimum required screw-in depth,

•they are 100 % crack tested,

•each bolt has a proven notched impact energy of min. 36 J as a mean value of

three samples tested at -20 °C or at the lowest fitting temperature, if this is below

-20 °C, and that none of the samples fall below 25 J,

•written confirmation of the crack test and impact energy results is enclosed with

the technical documentation.

10 STORAGE

Lifting points have to be stored in dry locations at temperatures ranging between 0 °C

and +40 °C.

11 THIELE OPERATING AND MOUNTING INSTRUCTIONS

Current operating and installation instructions are available as a PDF download on the

homepage.

12 PUBLISHING INFORMATION

THIELE GmbH & Co. KG, Werkstraße 3, 58640 Iserlohn, Germany

Tel.: +49(0)2371/947-0

Email: info@thiele.de

OPERATING INSTRUCTIONS

LIFTING POINTS, SCREW TYPE

THIELE GmbH & Co. KG # Change indicator

www.thiele.de | info@thiele.de B07905-M replaces B07905-L

© All rights reserved EN 07.2021 6 | 6

EU DECLARATION OF CONFORMITY

acc. to Machinery Directive 2006/42/EG, Annex II A for a machine

THIELE GmbH & Co. KG herewith declares as manufacturer that

•TWN 0121/1 Lifting points, rotatable, with slide bearing

•TWN 0122 Lifting points

•TWN 0123 Lifting points

•TWN 0127 Lifting points MDB

•TWN 1120 TITAN Lifting points, rotatable, with slide bearing

•TWN 1830 X-TREME Lifting points, rotatable, with ball bearing

•TWN 1884 KE-Eyebolts

•TWN 1890 Lifting points XS-Point, rotatable

are placed on the market in the form of a complete machine by THIELE together with

the relevant test certificate and are in compliance with the applicable provisions of the

EU Machinery Directive 2006/42/EG.

The following harmonized standards have been observed:

•DIN EN ISO 12100

•DIN EN 1677-1

•DIN EN 1677-4

Other standards and specifications have also been observed as follows:

•DIN 685-5

•DIN 5688-3

This declaration/statement is not meant to warrant any product properties.

Safety notes and instructions pertinent to the products must be observed.

Responsible for the documentation: Iserlohn, 27th July 2021

Rene Völz Dr. Michael Hartmann

(Head of QA and EP) (Managing Director)

Tel.: +49(0)2371/947-541

Other manuals for TWN 0121/1

3

This manual suits for next models

7

Table of contents

Other Thiele Lifting System manuals

Popular Lifting System manuals by other brands

Meganex

Meganex MEG16 instruction manual

JLG

JLG DVL Series Operation and safety manual

ATH-Heinl

ATH-Heinl Flex Lift 30 operating instructions

Safelift

Safelift PushAround PA35 Original instructions

Telpro

Telpro PARAGON PRO TROLL 112 manual

Snorkel

Snorkel MHP 13/35 Mark II Maintenance and repair parts manual