TA02982 E page 4 of 8

56

200

203

3

1

65

17

A

54

53

55

55

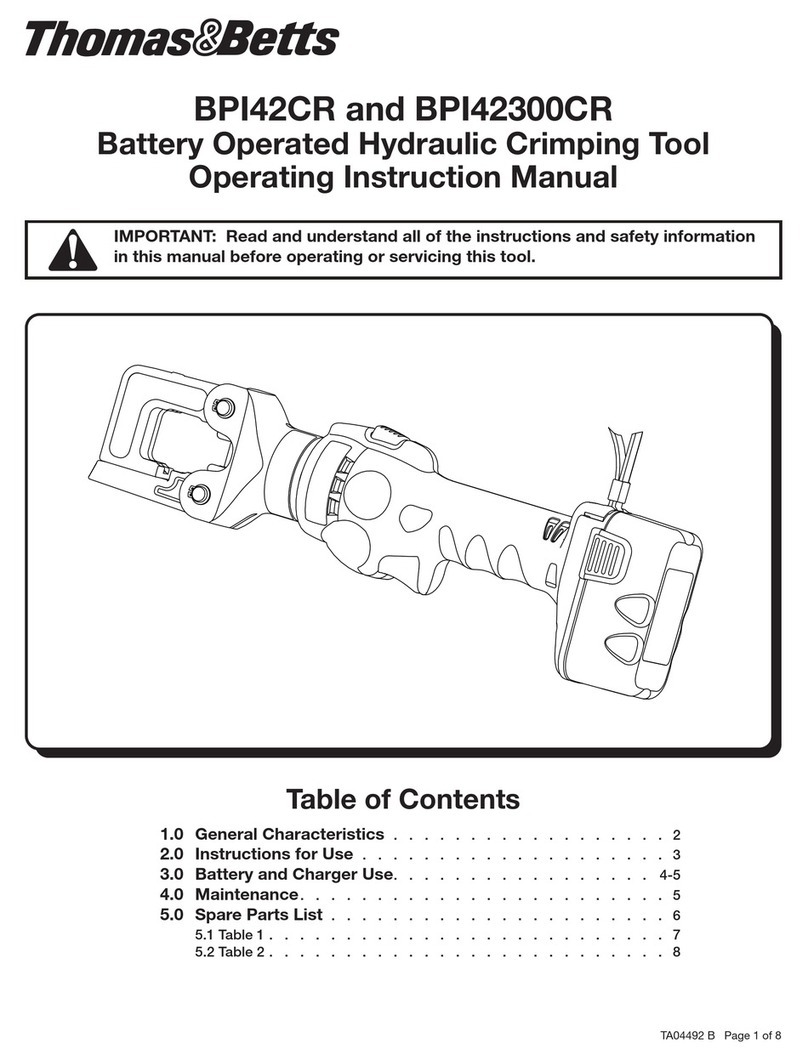

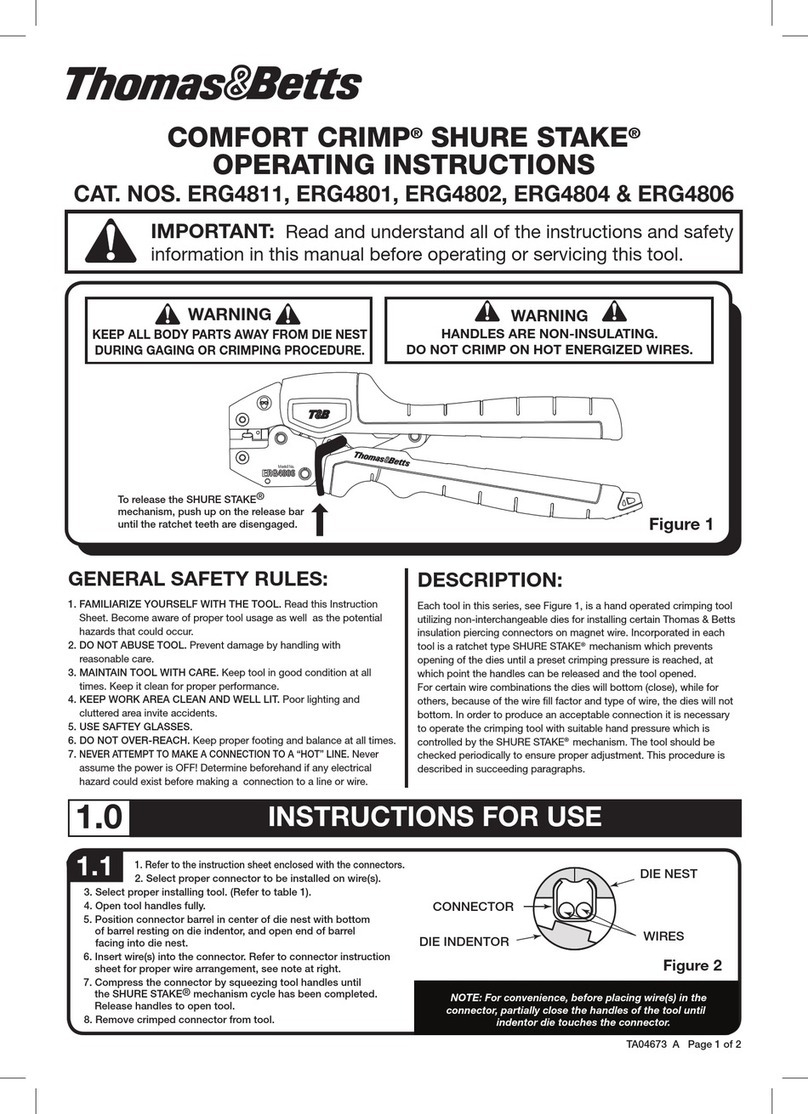

3.0 MAINTENANCE

When not in use, the tool should be put in the rest position

and placed in the plastic case for storage and transportation.

The plastic case can also accommodate 14 die sets

(See Figure 3).

To put the tool in the rest position:

−

Retract the ram completely

as describe in 2.4.

− Keeping the handles

completely closed, release

the xed handle which will

rotate automatically to the

rest position . The

moveable handle will then

be locked by means of the

handle latch (49).

Every six months, check the oil level in the reservoir.

If necessary, bring the oil level up to the top lip of the

reservoir, see section 3.4 , a, b, c, e, g, h and i.

− Always use clean recommended oil, see section 1.1, pg. 2.

−

Do not use old or recycled oil.

−

Do not use hydraulic brake uid.

IMPORTANT: Ensure that disposal of used oil is in

accordance with current legislation.

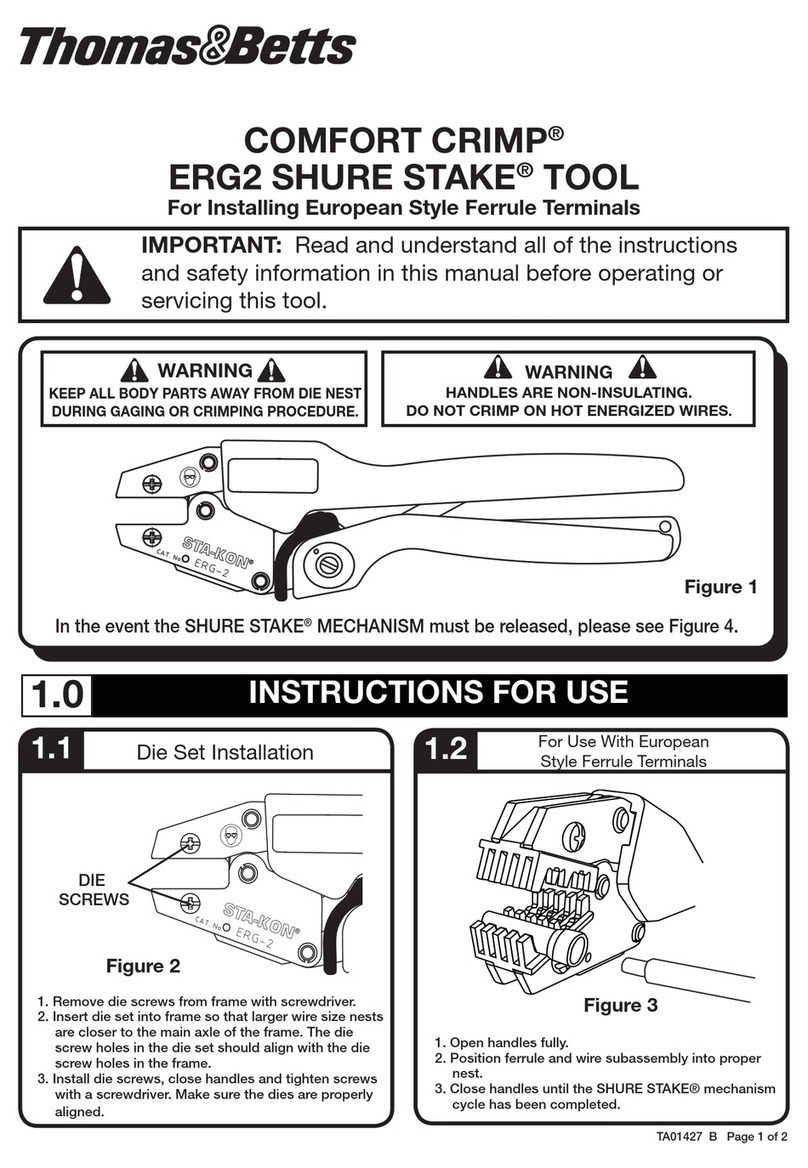

Air in the hydraulic circuit may affect the performance

of the tool (e.g. no lower die advancement; slow

advancement of lower die; lower die pulsating).

See Figures 4 and 5.

To purge air bubbles from hydraulic circuit:

a. Hold tool upright with the head in a vice and handles

open (Figure 4).

b. Using a 2,5mm allen key, remove screws (17 and

56), slide off the xed handle (200) to expose the oil

reservoir (3). Recover spring (54) and spring cover (53).

c. Remove reservoir cap (1).

d. Operate the moveable handle (203) three or four times

to advance the ram (202).

e. Depress pressure release pin (65) until ram is fully

retracted.

f. Repeat points dand eat least ve times, to ensure all

air bubbles in the hydraulic circuit are purged into the

reservoir.

g.

If the oil level is low, top off as directed in paragraph 3.5.

h. Replace the cap (1).

i. With the tool in the horizontal position, relocate spring

(54) and spring cover (53) in seat A (see detail in Fig. 4).

Reassemble the xed handle (200), insert screws (17

and 56) complete with washers (55) in their respective

positions and tighten them.

If the tool continues to malfunction, return the tool for

service/repair as detailed on page 8.

STORAGE

ADDING OIL

PURGING AIR BUBBLES

TOOL POSITION

Compliance with the following points should help to maintain the optimum performance of the tool.

Dust, sand and dirt are a danger for any hydraulic device.

Every day, after use, the tool must be cleaned with a clean

cloth, taking care to remove any residual particles, especially

close to pivots and moveable parts.

CLEANING

3.1 3.5

3.2

3.4

3.6

FIGURE 4 For Maintenance Operations

FIGURE 3