5 6 71 2 4 4

Ni-MH

3

3

8

11

600

24

27

2

13

See 3.1

(Fig. 4)

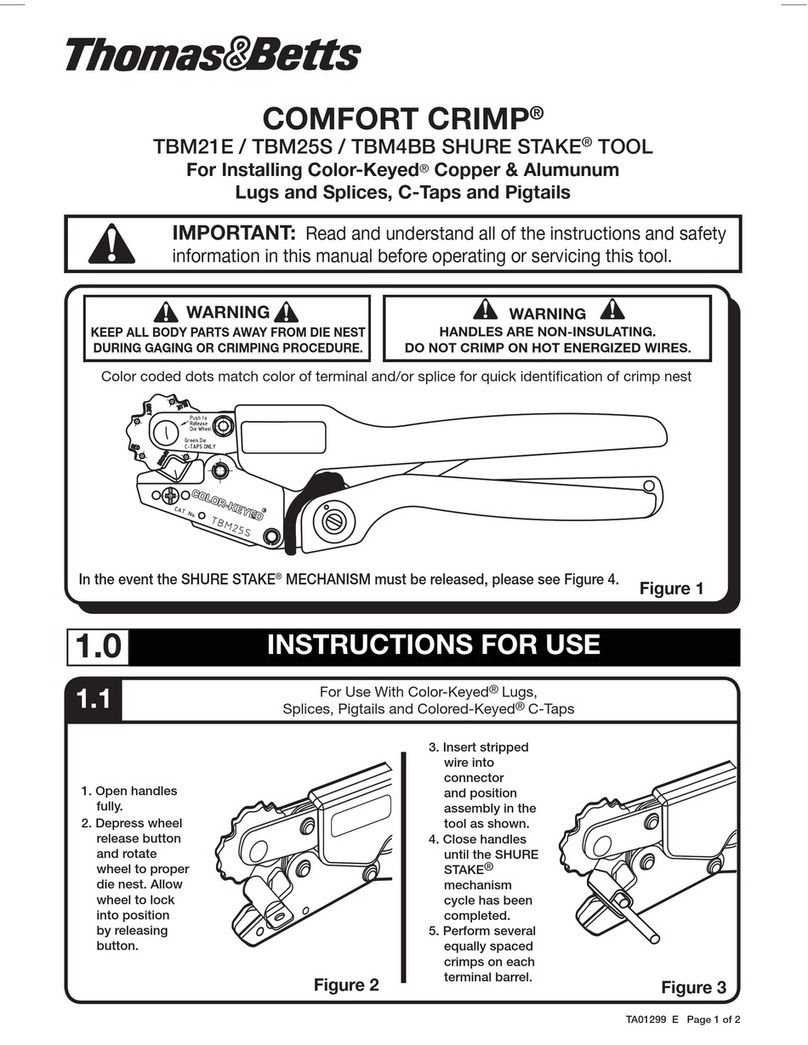

1.0 GENERAL CHARACTERISTICS

BATTERY OPERATED

HYDRAULIC CRIMPING TOOL

This “BPI42CR” hydraulic tool is powered by 9.6 V DC

Ni-MH battery. The tool is well balanced for optimum

control, quiet operation, very little vibration and

lightweight construction enabling the operator to hold the

tool in one hand while positioning the connector with the

other hand. It is equipped with an automatic system that

opens the dies once the crimping operation is completed.

The residual battery capacity level is automatically

displayed after every cycle

.

BPI42CR includes the following:

• Battery • Wrist Strap • Spare Battery

• Battery Charger • Carrying Case

BPI42300CR includes the following:

• Battery • Wrist Strap • Spare Battery

• Battery Charger • Carrying Case • Die Set

Suitable for installing electric compression connectors

for conductors from 8 AWG up to 300 Cu, 4/0 AL.

Crimping Force Nominal.............................4 Tons

Rated Operating Pressure..........................5600 psi

Dimensions:

Length..............................................................14.6”

Width..................................................................4.2”

Height.................................................................2.6”

Weight (with battery).....................................5.3 lbs

Motor...........................................................9.6V DC

Battery - direct current..........9.6 V - 2.0 Ah Ni-MH

Oil Recommended..................AGIP ARNICA 22 or

SHELL TELLUS TX22 or equivalent

Safety...............the tool is provided with a

maximum pressure relief safety valve.

(Directive 2006/42/EC, annexe 1, point 1.7.4.2 letter u)

The weighted continuous acoustic pressure level

equivalent

A at the work place LPA is equal to............66.8 dB (A

)

The maximum value of the weighted acoustic

displacement pressure

C at the work place LpCPeak is....................<130 dB (C)

The acoustic power level emitted by the machine

LWA is equal to...............................................75 dB (A)

(Directive 2006/42/EC, annexe 1, point 2.2.1.1)

Tests performed in compliance with UNI ENV 25349

and UNI EN 28663 part 1st Standards, and under

operating conditions more severe than normal,

certify that the weighted root mean square in

frequency of the acceleration the upper limbs are

exposed to for each biodynamic reference axis does

not exceed 2.5 m/sec2

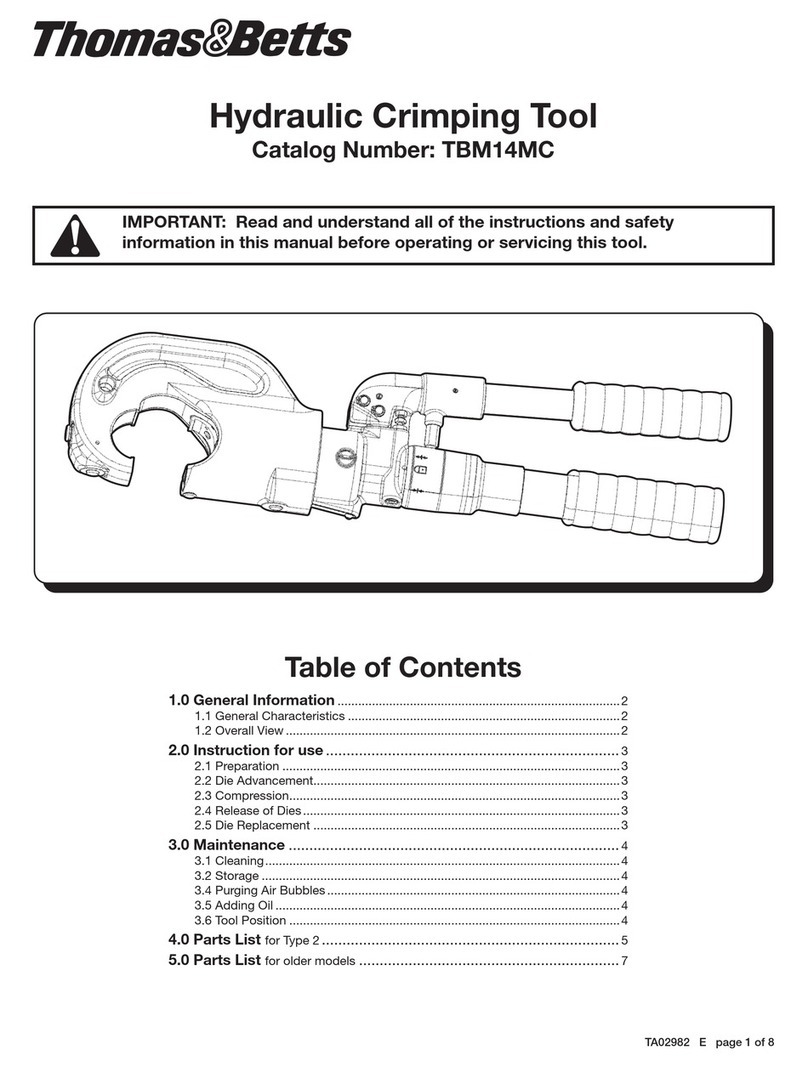

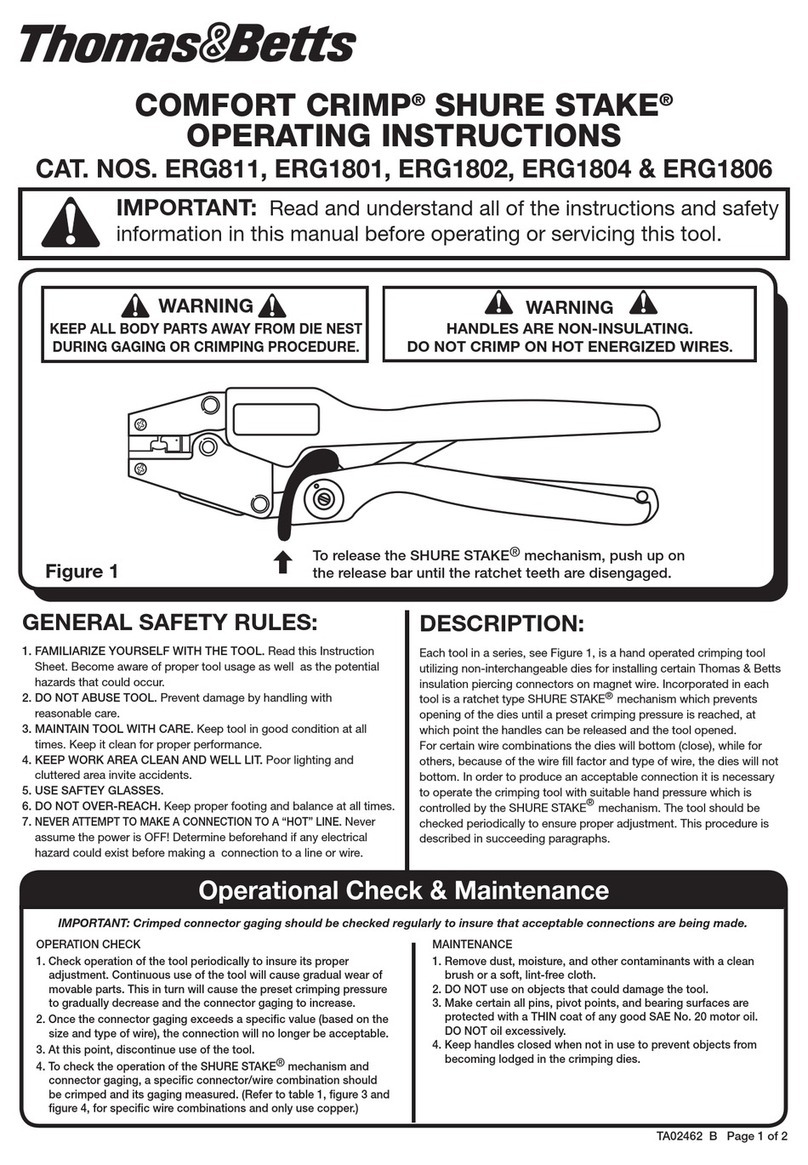

1.5 OVERALL VIEW

1.1

APPLICATION RANGE

1.2

3Operating Button 8Pressure Release Button

13 Wrist Strap 24 Upper Die Support

11 Battery Condition Display 27 Lower Die Support

2Battery 600 Head Complete

RISK DUE TO VIBRATION

ACOUSTIC NOISE

1.3

1.4

Fig. 1

TA04492 B Page 2 of 8

WARNING

1. BEFORE USING THE TOOL, CAREFULLY READ

INSTRUCTIONS IN THIS MANUAL.

2. WHEN OPERATING THE TOOL NEVER PLACE HANDS OR

OTHER BODY PARTS BETWEEN THE CRIMPING DIES.

3. DO NOT USE IN WATER OR IN THE RAIN.

4. ALWAYS ENSURE CORRECT LATCHING AND SECURITY

OF THE TOOL HEAD.

5. DO NOT SHORT CIRCUIT THE BATTERY TERMINALS.

6. ALWAYS RECYCLE THE BATTERIES.

7. DO NOT DISCARD BATTERIES INTO DOMESTIC REFUSE

OR WASTE DISPOSAL.