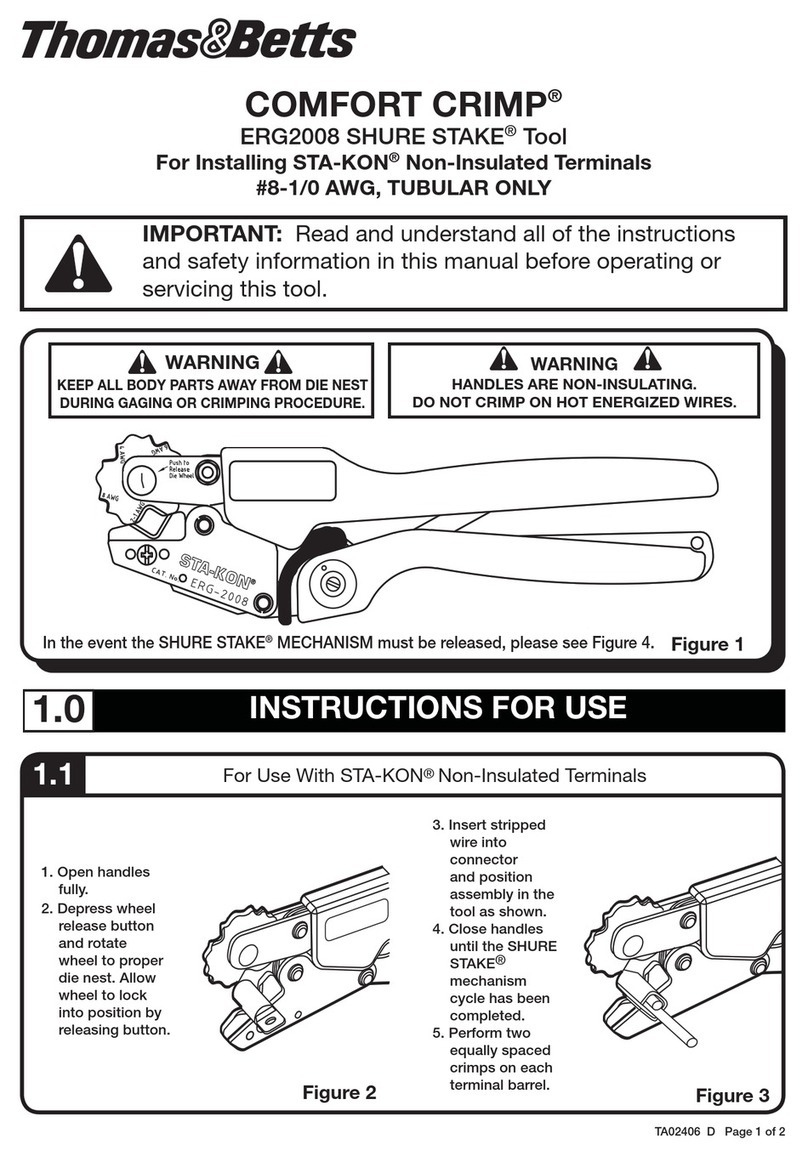

2.3 PREPARING CABLE

BAT22-6 Die Ordering Information

CAT. NO. DESCRIPTION

DIE2001 Insulated 22-10 AWG Sta-Kon

®

Terminals

DIE2002 Non-insulated 22-10 AWG Sta-Kon

®

and Spec-Kon

®

Terminals

DIE2005 Non-insulated 16-6 AWG Sta-Kon

®

and Spec-Kon

®

Terminals

DIE2007 Insulated 8-6 AWG Sta-Kon

®

Terminals

DIE2500 Insulated 22-10 AWG Spec-Kon

®

Terminals

TABLE 1

2.4

Signal Duration When it occurs What it means

a few seconds of

flashing battery insertion self check - O.K.

glowing for 20 seconds after crimp battery discharged

flashing for 20 seconds

(2 Hz) after crimp time for inspection and

preventive maintenance

20 sec. glowing and

flashing intermittently after crimp

battery discharged - time for

inspection and preventive

maintenance

CAUTION

It does not matter in which location the indentor or nest

half of the die set is installed, either crimping head or

ram. However, it is very important that the largest nest

be positioned away from the open side of the crimping

head, closest to the head itself. Failure to do so will

result in premature head failure.

2.0

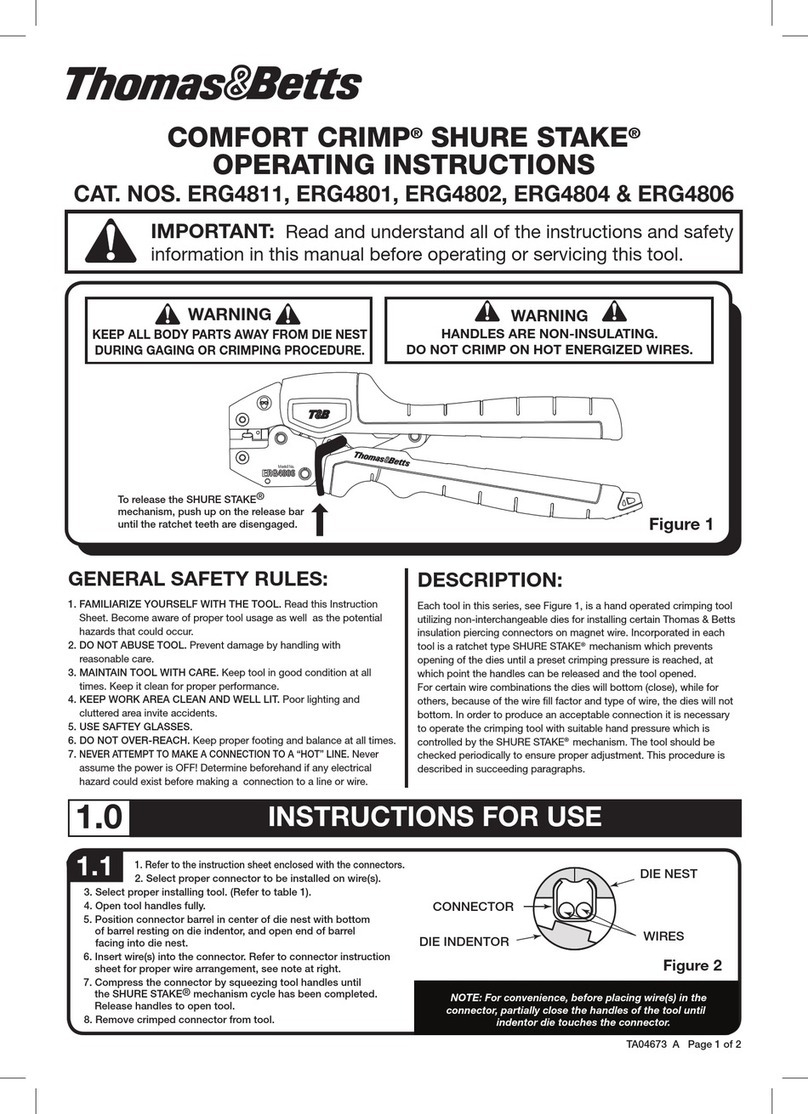

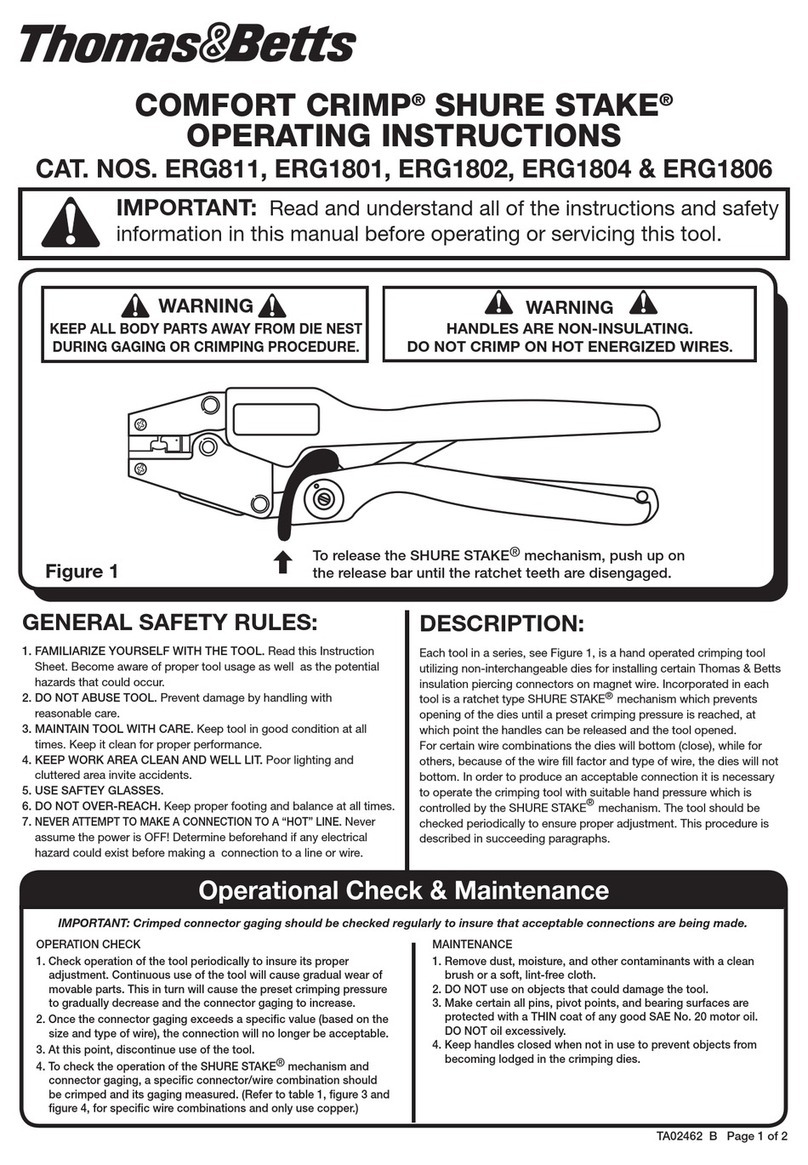

WARNING

2.1 CHARGING THE BATTERY

Read all instructions supplied with the battery charger.

OPERATION

TA02712 G

Page 3 of 8

Follow the lug manufacturer’s instructions for

appropriate cable strip length.

ELECTRIC SHOCK HAzARD: This tool is not

insulated. When using this unit near energized

electrical lines, use proper personal protective

equipment. Failure to observe this warning could

result in severe injury or death.

PINCH POINTS: Keep hands away from the crimping

head when crimping. Failure to observe this warning

could result in severe injury.

EYE PROTECTION: Wear eye protection when

operating or servicing this tool. Failure to wear eye

protection could result in serious eye injury from flying

debris or hydraulic oil.

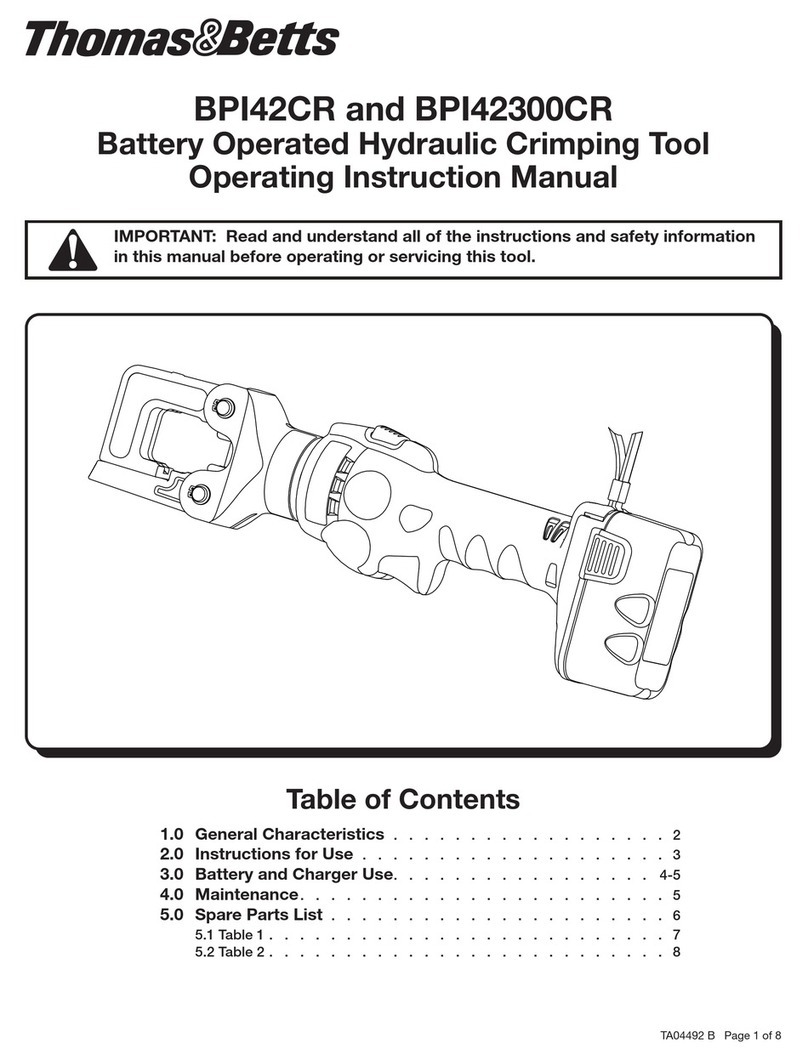

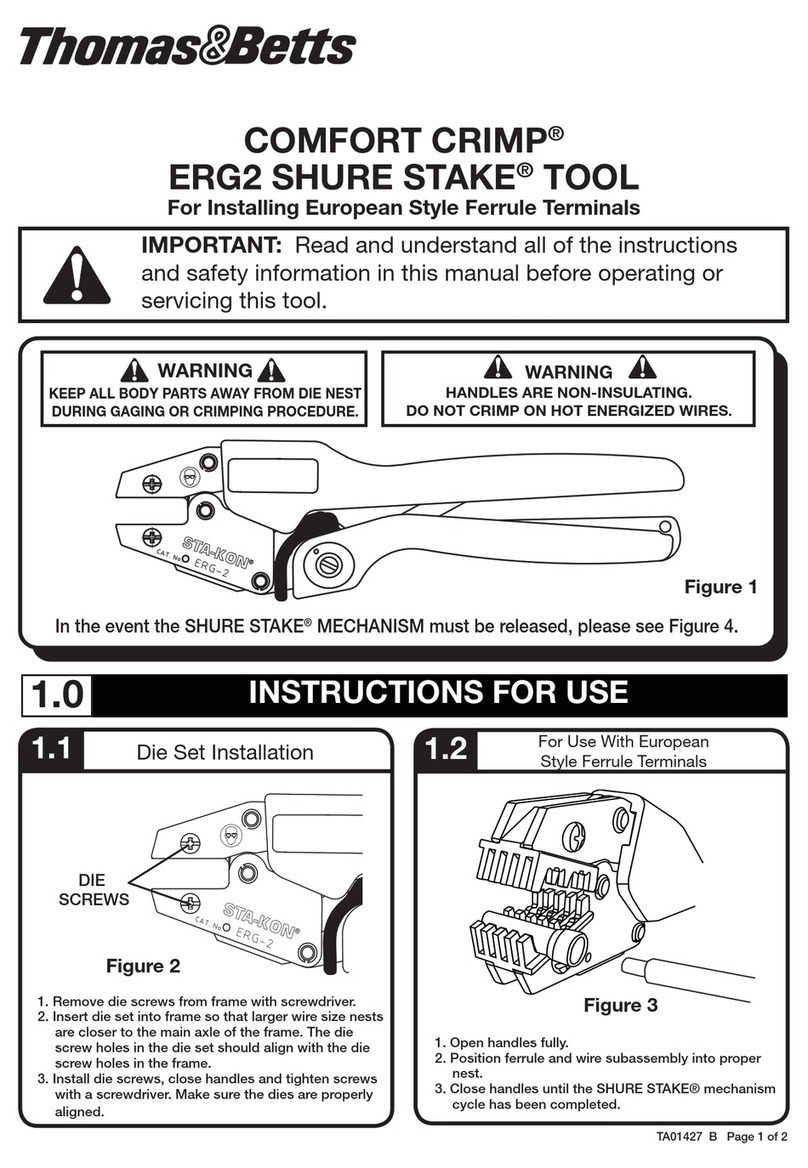

INSTALLING DIES

1. Select the proper die set for the intended crimping

operation, see Table 1.

2. Remove screw, washer, and die mounting pins from the

crimping head.

3. Extend the ram partially by momentarily pulling the

trigger to access the screw, washer, and pins in the ram,

and remove.

4. Insert one die half into the partially extended ram.

Install the 13 mm pins**, screw and washer through the

ram mounting holes and the die half. Tighten screw

snugly. Retract ram fully by depressing retract button.

5. Insert remaining die half into the crimping head, and

install with 18 mm pins**, screw and washer. Tighten

screw snugly.

** DIE2001, DIE2500 do not use die mounting pins.

When installing the dies, proceed as described above but

do not tighten screws fully. After die set is in place, ensure

dies are properly aligned and extend the ram until the dies

engage under some pressure.

Tighten screws snugly.

CAUTION

• Donotoperatethetoolwithoutdies.Damagetotheramorcrimpingheadcanresult.

• Donotoperatewiththecrimpingheadopen.Damagetotheramorsealscanresult.

• Thistoolisnotdesignedforcontinuoususe.After100crimpingcycles,allowthecrimpingtooltocoolfor15minutes.

•Donotplacethetoolinavise.Thecrimpingtoolisdesignedforhand-heldoperation.

• Thistoolmaybeusedindamporwetenvironments;however,werecommendair-dryingthetoolbeforeuseifitbecomessoaked.

• Usethistoolformanufacturer’sintendedpurposeonly.

FAILURE TO OBSERVE THESE PRECAUTIONS MAY RESULT IN INJURY OR PROPERTY DAMAGE.

WARNING

An incomplete crimp can cause a fire.

•Useproperdie,connector,andcablecombinations.

Improper combinations can result in an incomplete

crimp.

•Thereliefvalvewillsoundtoindicateacompletedcrimp.

Ifyoudonothearthesoundofthereliefvalve,thecrimp

is not complete.

FAILURE TO OBSERVE THESE WARNINGS COULD

RESULT IN SEVERE INJURY OR DEATH.

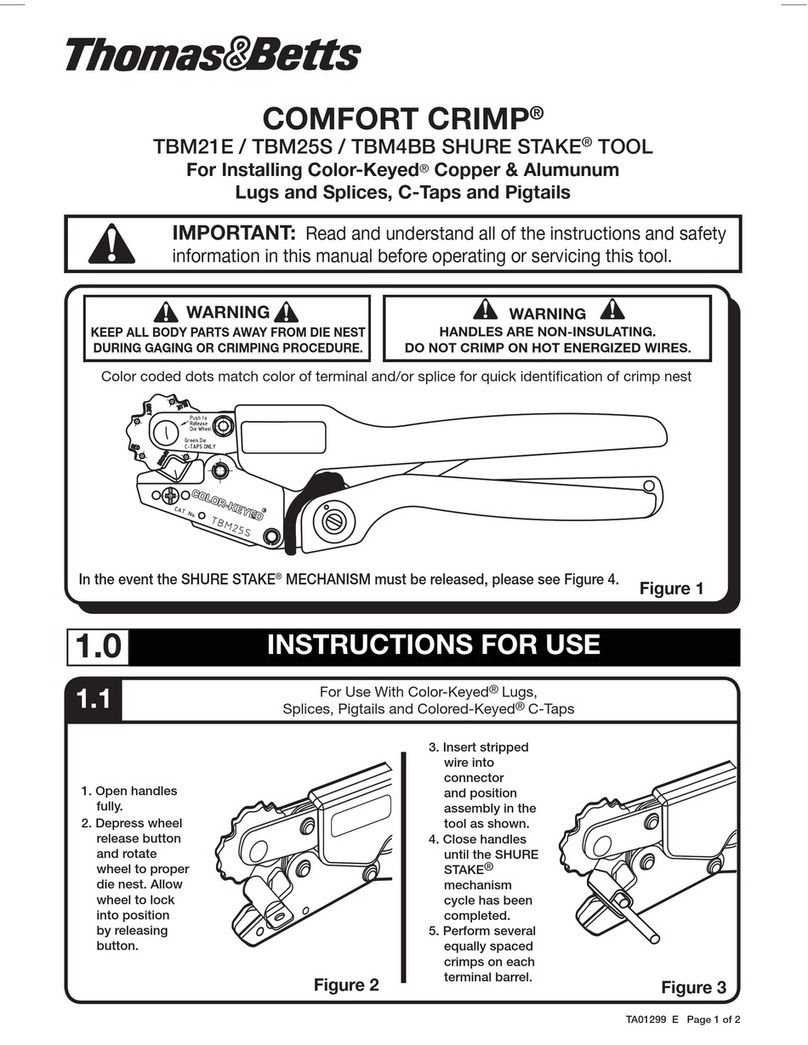

LED DISPLAY

2.2

This tool is equiped with a special circuit board incorporating

several important features to inform the user about the current

status of the unit. The LED signals in the following cases: