TA03269 B

Page 4 of 7

The tool is shipped fully assembled (less dies).

1. Remove tool assembly from shipping container.

2. Position the tool on a workbench or table.

3. Connect air supply line to the inlet at the rear of

the tool.

NOTE: Do not add airline extensions between

the foot pedal and lter/regulator/lubricator

assembly. This will prevent line pressure drops.

NOTE: Cylinder and pneumatic components are

designed to operate without lubrication.

If you choose to lubricate use a quality grade,

non-detergent, SAE #10 parafn base oil.

Rate of lubrication should not exceed one drop

per 100 crimping cycles.

SET UP TOOL3.1

1. Disconnect air supply

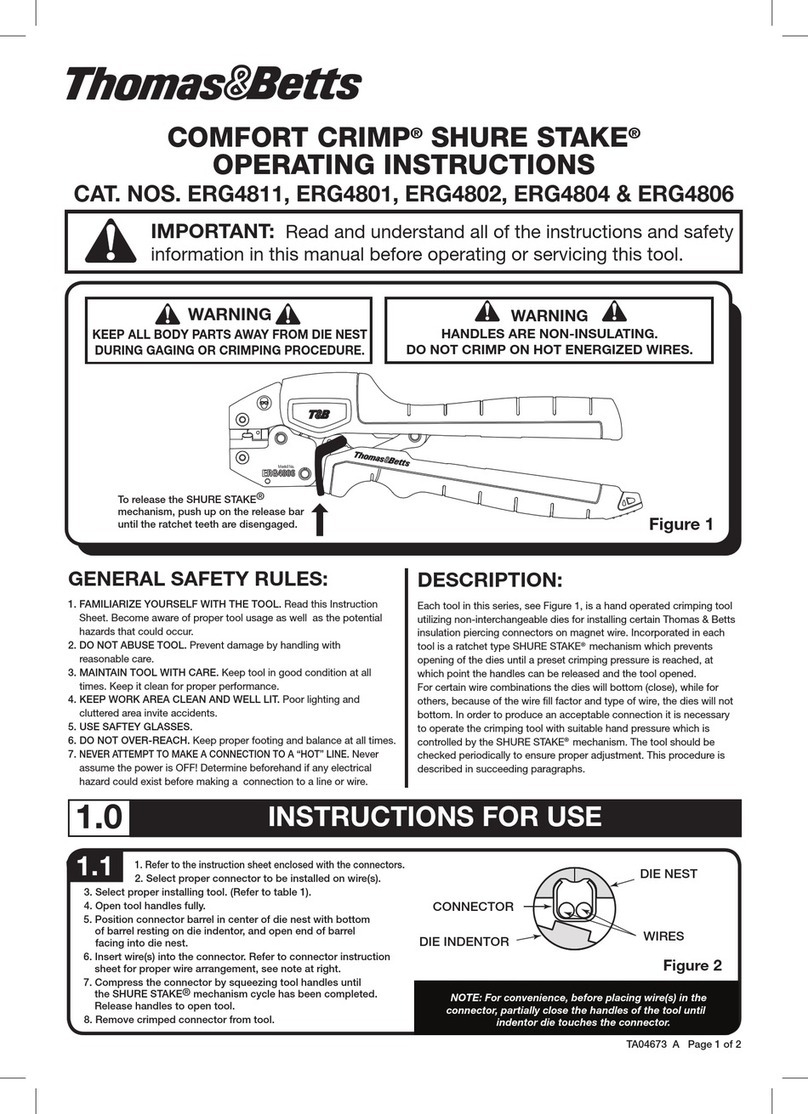

2. Install die nest into spring loaded support and die

indentor into yoke using screws provided. Screws

should be lightly hand tightened at this time.

3. Ensure that the die nest and indentor are engaged

and aligned. Securely tighten screws so that dies

will not move within support blocks.

NOTE: Some dies require use of special headed

pins combined with the screws (See Figure 2).

4. Connect air supply

.

DIE INSTALLATION3.2

Wear eye protection when

operating or servicing this tool.

Failure to wear eye protection

could result in serious eye injury

from ying debris or hydraulic oil.

WARNING

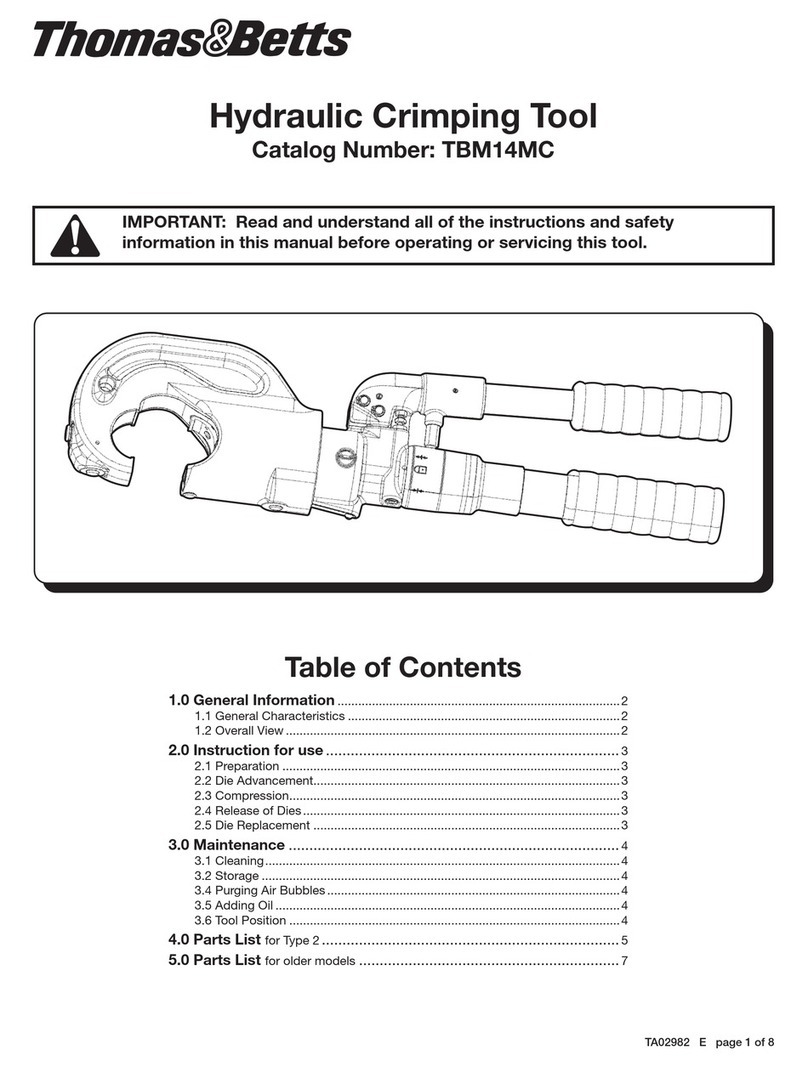

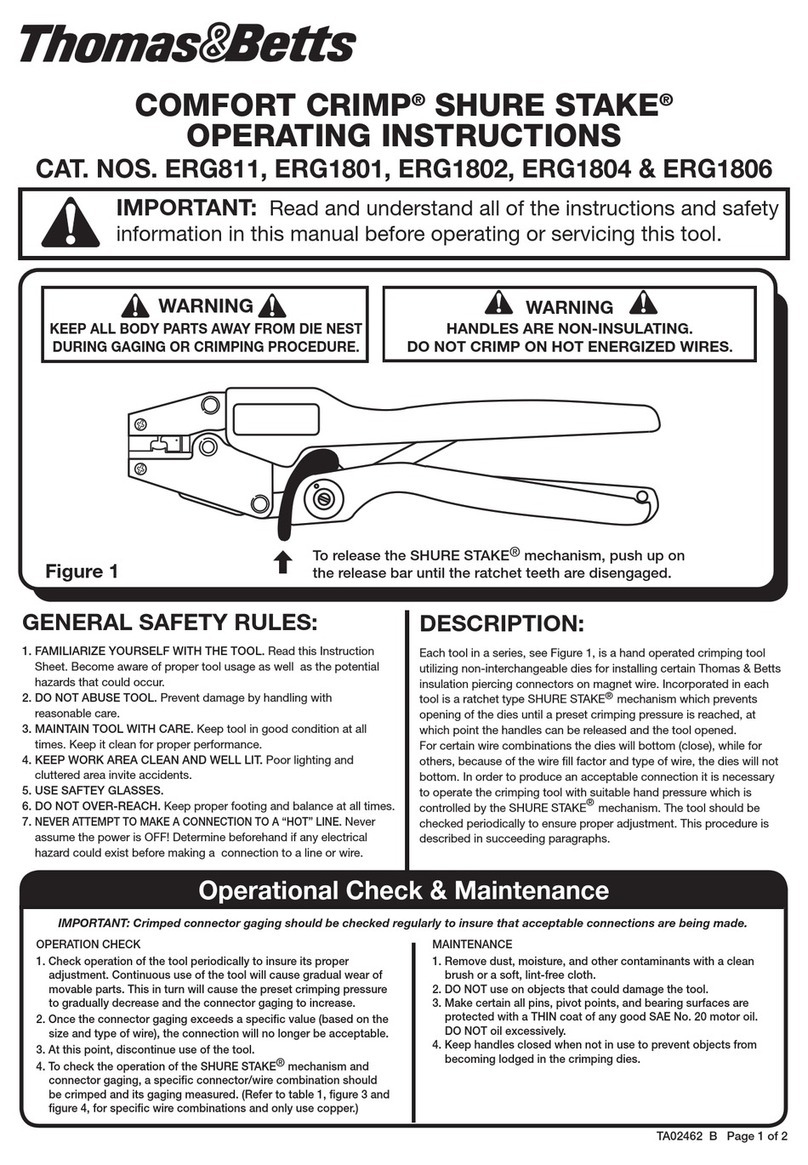

Headed Pins

FIGURE 2

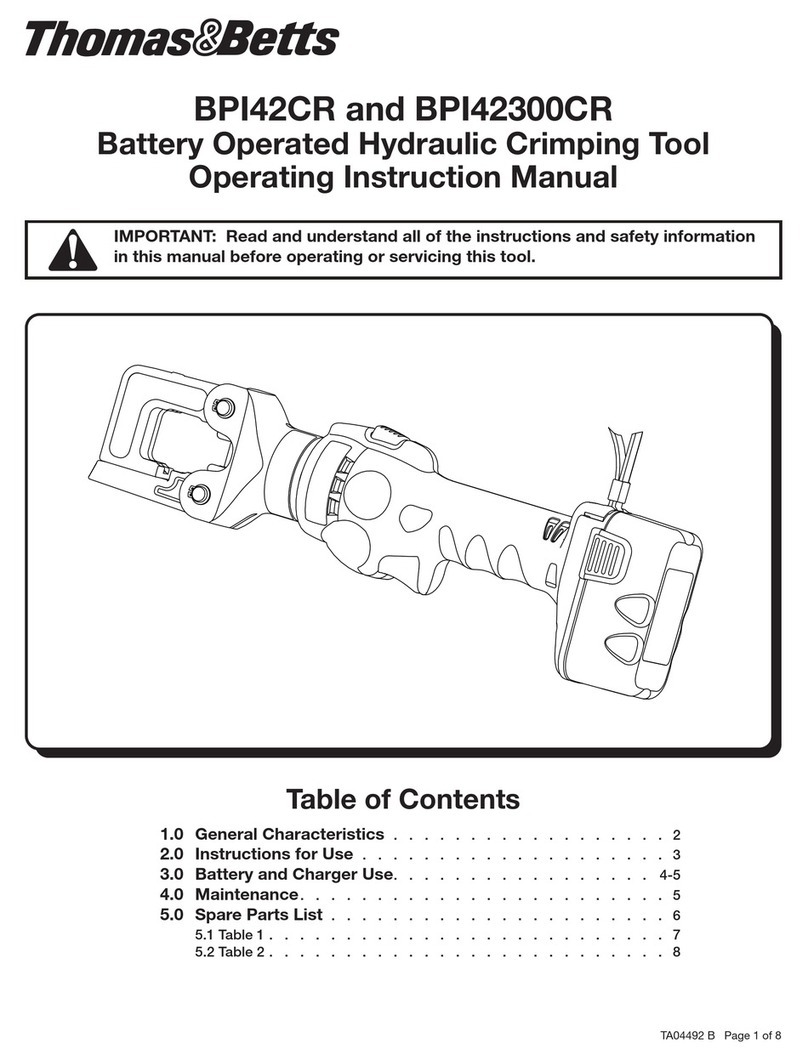

1. To operate the tool properly, it is essential to

hold the actuating handle (see Figure 1) down

until the tool cycles completely. This assures a

sustained volume of air in the cylinder at full

pressure to complete the crimp.

2. The tool is equipped with a spring loaded lower

die support to hold the terminal.

TOOL OPERATION3.3

Follow the terminal manufacturer's instructions for

appropriate cable strip length.

PREPARING CABLE3.4

• Inspect tool and dies before use. Replace any

worn or damaged parts. A damaged or

improperly assembled tool can break and strike

nearby personnel.

• Failure to observe this warning could result in

severe injury or death.

•

Do not attempt to connect the tool to an

energized air line.

• Disconnect tool from air supply when servicing

or changing dies.

WARNING

• Do not operate the tool without dies. Damage

to the ram or crimping head can result.

• Never exceed 100 psi operating pressure.

• Use this tool for manufacturer's intended

purpose only

.

Failure to observe these precautions may result in

injury or property damage.

CAUTION

CAT. NO. DESCRIPTION

DIE2001 Insulated 22-10 AWG Sta-kon®Terminals

DIE2002 Non-insulated 22-10 AWG Sta-Kon®and

Spec-Kon Terminals

DIE2005 Non-insulated 16-6 AWG Sta-Kon®and

Spec-Kon Terminals

DIE2007 Insulated 8-6 AWG Sta-Kon®Terminals

DIE2500 Insulated 22-10 AWG Spec-Kon®Terminals

STA-KON®ORDERING INFORMATION3.5

OPERATION3.0