Product

Description

Designed for use with hoisting equipment, the MRPTHD-AC lifters support loads using vacuum and

manipulate loads using manual 360° rotation and powered 90° tilt motions.

Model

Number MRPTHD89AC MRPTHD1211LAC MRPTHD2011LAC

Vacuum Pads

(standard rubber1

1...... Available with other rubber compounds for special purposes (see www.wpg.com).

)

Eight 9" [23 cm] nominal

diameter (Model VPFS9)

Twelve 11" [28 cm] nominal

diameter, lipped (Model G3370)

Twenty 11" [28 cm] nominal

diameter, lipped (Model G3370)

Pad Spread2

2...... These dimensions reflect pad configurations with the Maximum Load Capacity; other configurations are possible for lighter loads.

--------------------------------to outer edges---------------------------------

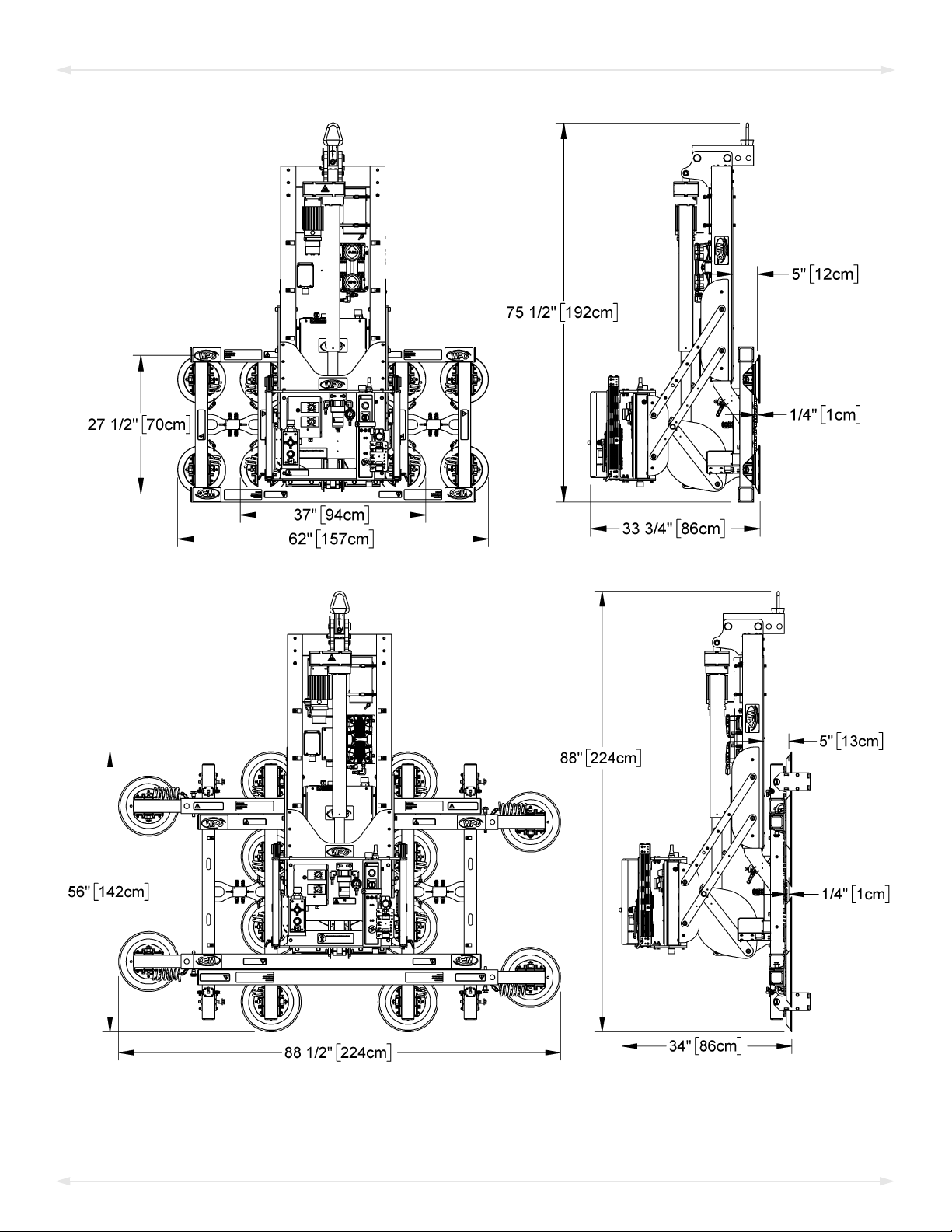

Length ‒Maximum 62" [157 cm] 140¼" [356 cm] 140½" [357 cm]

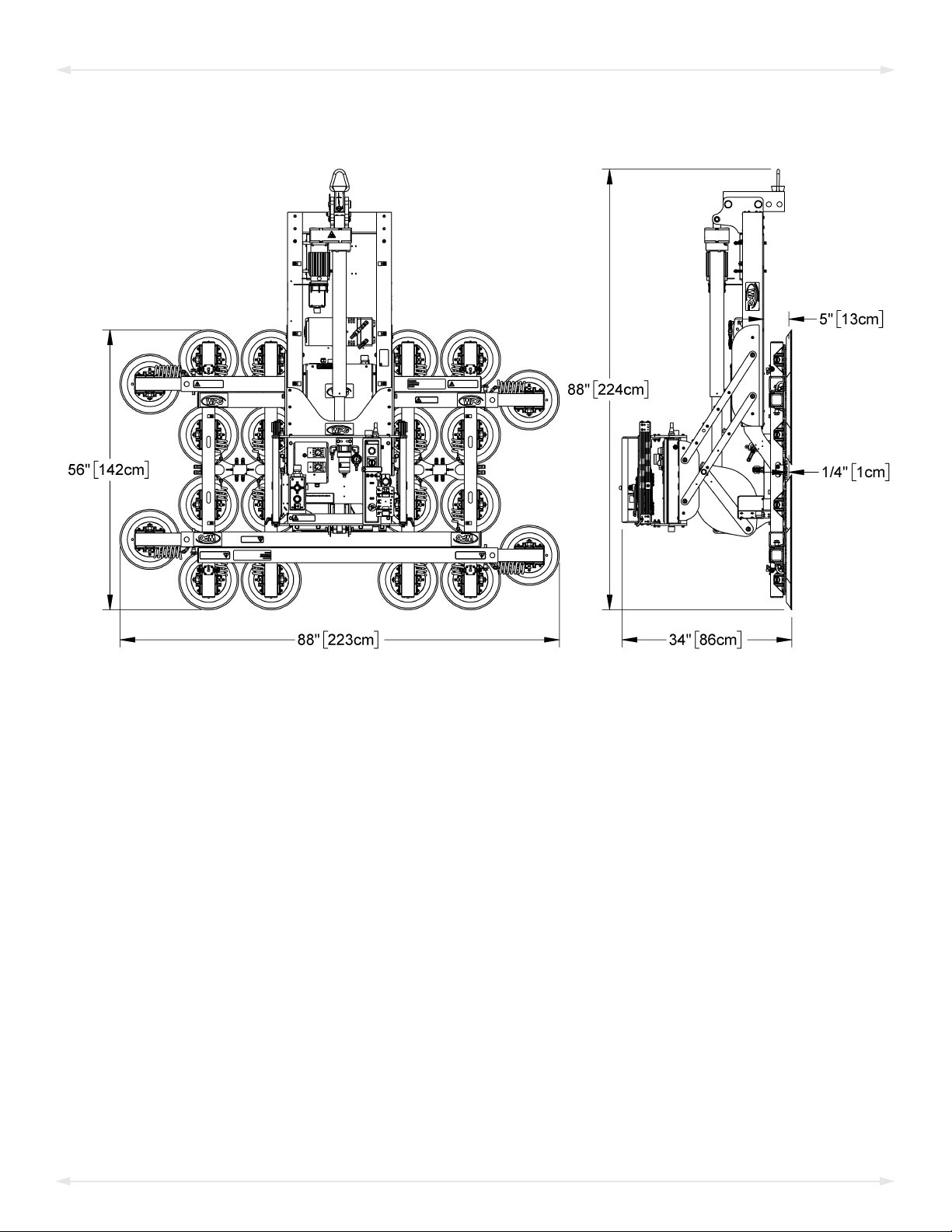

Length ‒Minimum 62" [157 cm] 64½" [164 cm] 88" [223 cm]

Width ‒Maximum 27½" [70cm] 56" [142 cm] 56" [142 cm]

Width ‒Minimum 27½" [70cm] 46¼" [117 cm] 56" [142 cm]

Maximum

Load Capacity3

3...... The Maximum Load Capacity is rated at a vacuum of 16" Hg [-54 kPa] on clean, smooth, nonporous flat surfaces with a friction coefficient of 1. Pad

compound, load rigidity, strength, surface conditions, overhang, angle, center of gravity and temperature can also affect the lifting capacity. A “qualified

person” should evaluate the effective lifting capacity for each use (see definition under “Rated Load Test” on page 28).

Per pad: 125 lbs [57 kg]

Total: 1,000 lbs [455 kg]

Per pad: 167 lbs [75.5 kg]

Total: 2,000 lbs [905 kg]

Per pad: 150 lbs [68 kg]

Total: 3,000 lbs [1,360 kg]

Lifter

Weight 565 lbs [257 kg] 700 lbs [318 kg] 740 lbs [336 kg]

Power

Source See serial label for specific AC voltage, frequency and amperage.

Rotation

Capability Manual, 360°, with latching at every 18° of revolution (when required)

Tilt

Capability4

4...... Specifications shown for 120V AC lifters;characteristics may vary for other voltages.

Powered, 90°, with adjustable electronic speed controller; Maximum speed = approx 20 seconds per tilt

travel in one direction; Maximum duty = 50 tilts per hour

Product

Options See separate instructions about options.

Operating

Elevation Up to 6,000' [1,828 m]

Operating

Temperatures 32° — 104° F [0° — 40° C]

Service

Life 20,000 lifting cycles, when used and maintained as intended5

5...... Vacuum pads, filter elements and other wear-out items are excluded.

ASME Standard

BTH-1 Design Category "B", Service Class "0" (see www.wpg.com for more information)

Rev 1.0/2-21 MRPTHD-AC: #350663

!!–CE–!! This symbol appears only when a CE Standard is different from other applicable standards. CE requirements are mandatory

in the European Union, but may be optional elsewhere.

SPECIFICATIONS