BNP® 6012P and 7212P PRESSURE BLAST CABINETS Page 2

© 2019 CLEMCO INDUSTRIES CORP. www.clemcoindustries.com Manual No. 27724, Rev. B, 04/19

FIELD INSTALLED ACCESSORIES ........................ 3.0

Aluminum Oxide (aggressive media) Kit ................... 3.1

Cabinet Curtains Installation ...................................... 3.2

Manometer ................................................................. 3.3

Armrest ...................................................................... 3.4

Turntable with Workcar and Track ............................. 3.5

OPERATION ............................................................. 4.0

Media Loading ........................................................... 4.1

Media Unloading ........................................................ 4.2

Loading and Unloading Parts .................................... 4.3

Blasting Operation ..................................................... 4.4

Operation and Function of the Choke Valve .............. 4.5

Blasting Technique .................................................... 4.6

Stop Blasting .............................................................. 4.7

Shutdown ................................................................... 4.8

ADJUSTMENTS ........................................................ 5.0

Blasting Pressure (pilot regulator) ............................. 5.1

Media Metering (media flow) ..................................... 5.2

Reclaimer Static Pressure ......................................... 5.3

Optional Externally Adjustable Vortex Cylinder ......... 5.4

Door Interlocks ........................................................... 5.5

Cabinet Air-Inlet Damper ........................................... 5.6

Optional Manometer .................................................. 5.7

PREVENTIVE MAINTENANCE ................................ 6.0

Daily Inspection and Maintenance Before Blasting .... 6.1

Check media level ............................................... 6.1.1

Inspect reclaimer debris screen and door gasket .. 6.1.2

Compressed-air filter ........................................... 6.1.3

Inspect couplings .................................................. 6.1.4

Inspect dust container ......................................... 6.1.5

Daily Inspection During Blasting ................................. 6.2

Inspect blast hose couplings and nozzle holder ... 6.2.1

Inspect blast machine .......................................... 6.2.2

Check cabinet for dust leaks ............................... 6.2.3

Check dust-collector exhaust air for dust ............ 6.2.4

Drain pulse reservoir ........................................... 6.2.5

Cartridge pulsing ................................................. 6.2.6

Weekly Inspection and Maintenance Before Blasting .. 6.3

Inspect view-window cover lens .......................... 6.3.1

Inspect gloves ...................................................... 6.3.2

Inspect blast hose ................................................ 6.3.3

Inspect nozzle ..................................................... 6.3.4

Inspect outlet valve .............................................. 6.3.5

Weekly Inspection During Blasting ............................ 6.4

Inspect blast machine plumbing .......................... 6.4.1

Inspect flex hoses ................................................ 6.4.2

Monthly Inspection and Maintenance ......................... 6.5

Inspect reclaimer wear plate or liners .................. 6.5.1

Inspect pop-up valve ............................................. 6.5.2

Inspect pop-up seal .............................................. 6.5.3

Dust Collector ............................................................. 6.6

SERVICE MAINTENANCE ........................................ 7.0

Gloves ......................................................................... 7.1

Blast Hose and Nozzle ............................................... 7.2

View-Window Cover Lens .......................................... 7.3

View-Window Replacement ........................................ 7.4

Window-Gasket Replacement .................................... 7 . 5

Window-Frame Removal ............................................ 7.6

LED Light Assembly .................................................... 7.7

Replacing Pop-Up Valve ............................................. 7.8

Replacing Pop-Up Valve Seal .................................... 7.9

Replacing Reclaimer Wear Plate .............................. 7.10

Replacing or Installing Rubber Reclaimer Liners ....... 7.11

Removing or Replacing Reclaimer Inlet Baffle .......... 7.12

Sentinel Metering Valve ............................................ 7.13

Reverse-Pulse Dust Collector ................................... 7.14

TROUBLESHOOTING ............................................... 8.0

Poor visibility ............................................................... 8.1

Abnormally high media consumption .......................... 8.2

Reduction in blast cleaning rate .................................. 8.3

Plugged nozzle ............................................................ 8.4

Media bridging ............................................................. 8.5

Media surge ................................................................ 8.6

Air only (no media) comes out the nozzle ................... 8.7

Neither media nor air comes out the nozzle ................ 8.8

Blast machine does not pressurize .............................. 8.9

Blast machine does not depressurize ....................... 8.10

Heavy media flow ...................................................... 8.11

Media buildup in cabinet hopper ............................... 8.12

Static shocks ............................................................. 8.13

Dust leaking from cabinet ......................................... 8.14

Dust leaking from dust collector ................................ 8.15

ACCESSORIES AND REPLACEMENT PARTS ....... 9.0

Optional Accessories .................................................. 9.1

Cabinet Replacement Parts ........................................ 9.2

View Window .............................................................. 9.3

LED Light Assembly .................................................... 9.4

Foot Pedal ................................................................... 9.5

1" Diaphragm Outlet Valve ......................................... 9.6

Plumbing and Cabinet Controls .................................. 9.7

Blast Machine ............................................................. 9.8

Sentinel Valve Replacement Parts ............................. 9 . 9

Flex Hose and Wye Pipe, and Adaptors ................... 9.10

Replacement Reclaimer Assemblies ........................ 9.11

900 cfm Reclaimer, for 16" Dia. Blast Machine ......... 9.12

1200 cfm Reclaimer, for 16" Dia. Blast Machine ....... 9.13

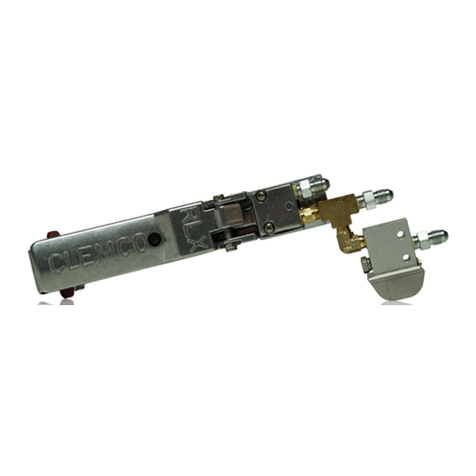

1.4 General Description

1.4.1 BNP blast cabinets enclose the blasting

environment to provide efficient blasting while

maintaining a clean surrounding work area. Production

rates are influenced by size of nozzle, compressor

output, working pressure, type and size of media, angle

and distance of the nozzle from the blast surface. BNP

pressure cabinets consist of four major components:

Cabinet Enclosure

Reclaimer

Blast Machine

Dust Collector