The Specialist In Drum Handling Equipment

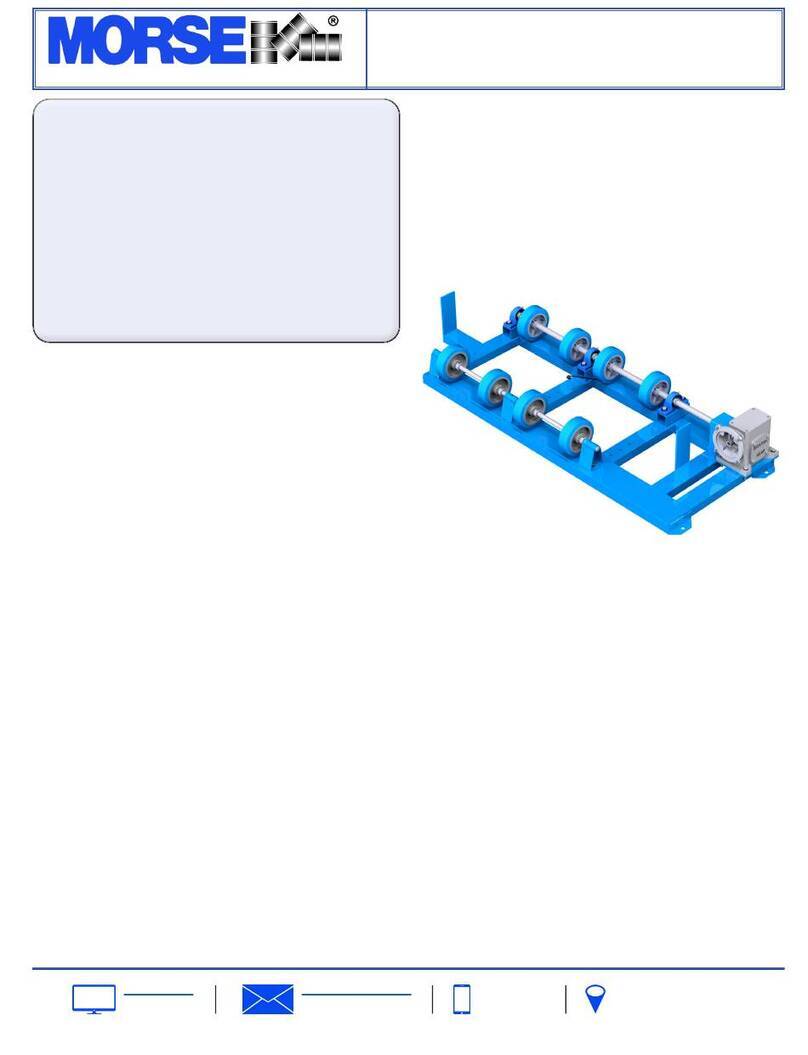

305 Series

Can Tumblers

Operator’s Manual for Morse Can Tumblers 305 Series

Serial Number 289777 to ______

morsedrum.com

Copyright 2019 - Morse Mfg. Co., Inc. Form OM305 (289777 to ______) (Updated 17 Jun, 2019) 3

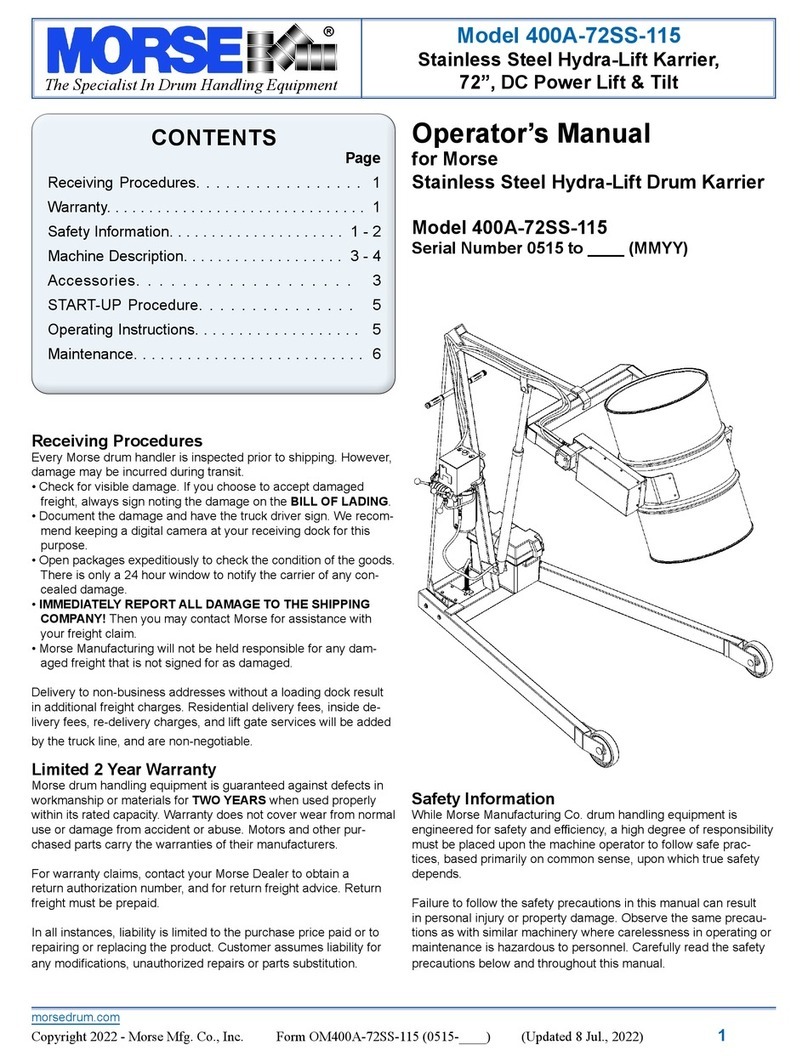

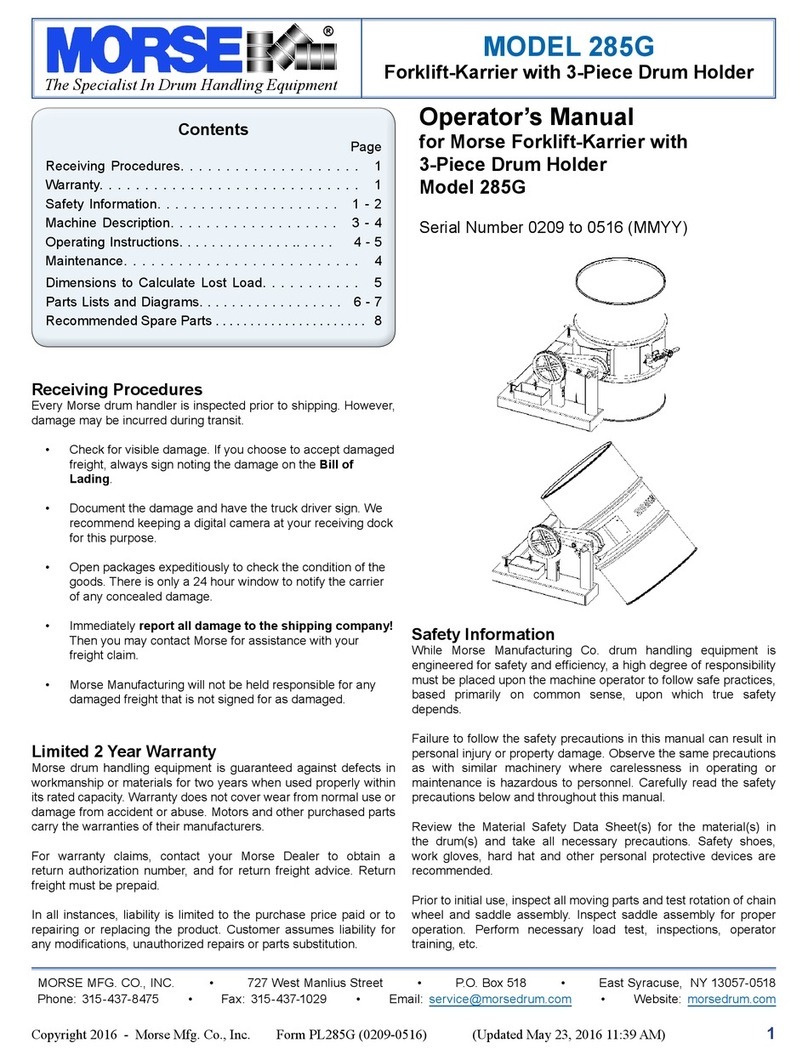

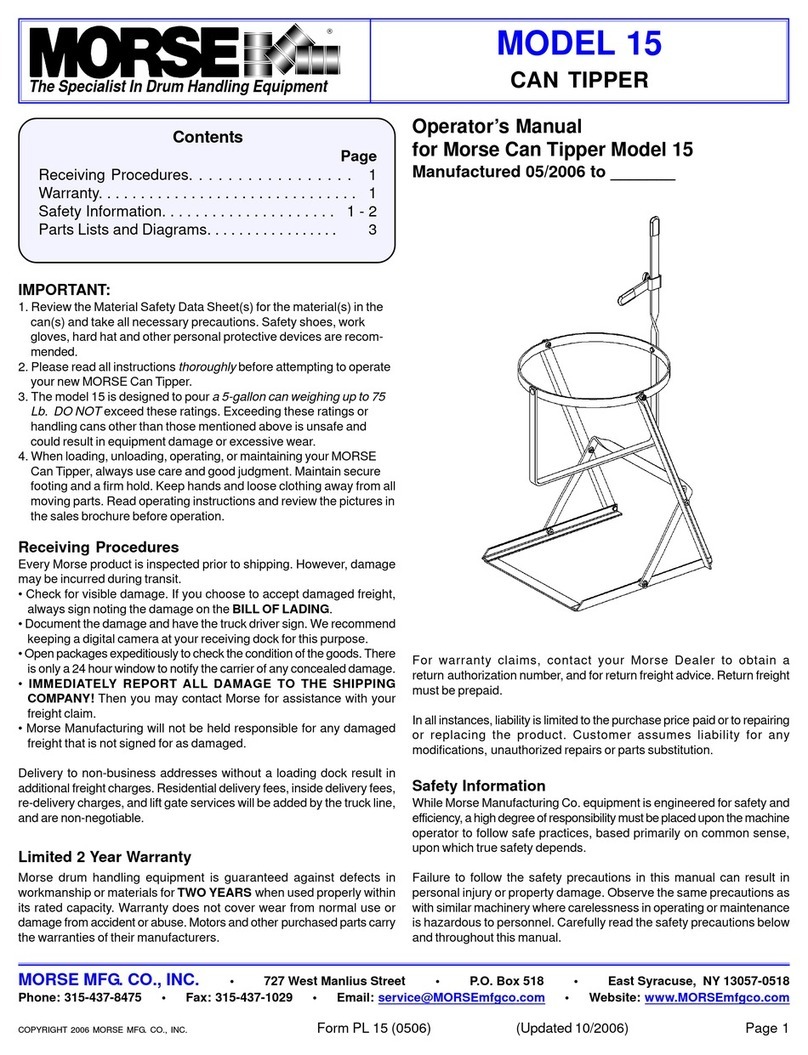

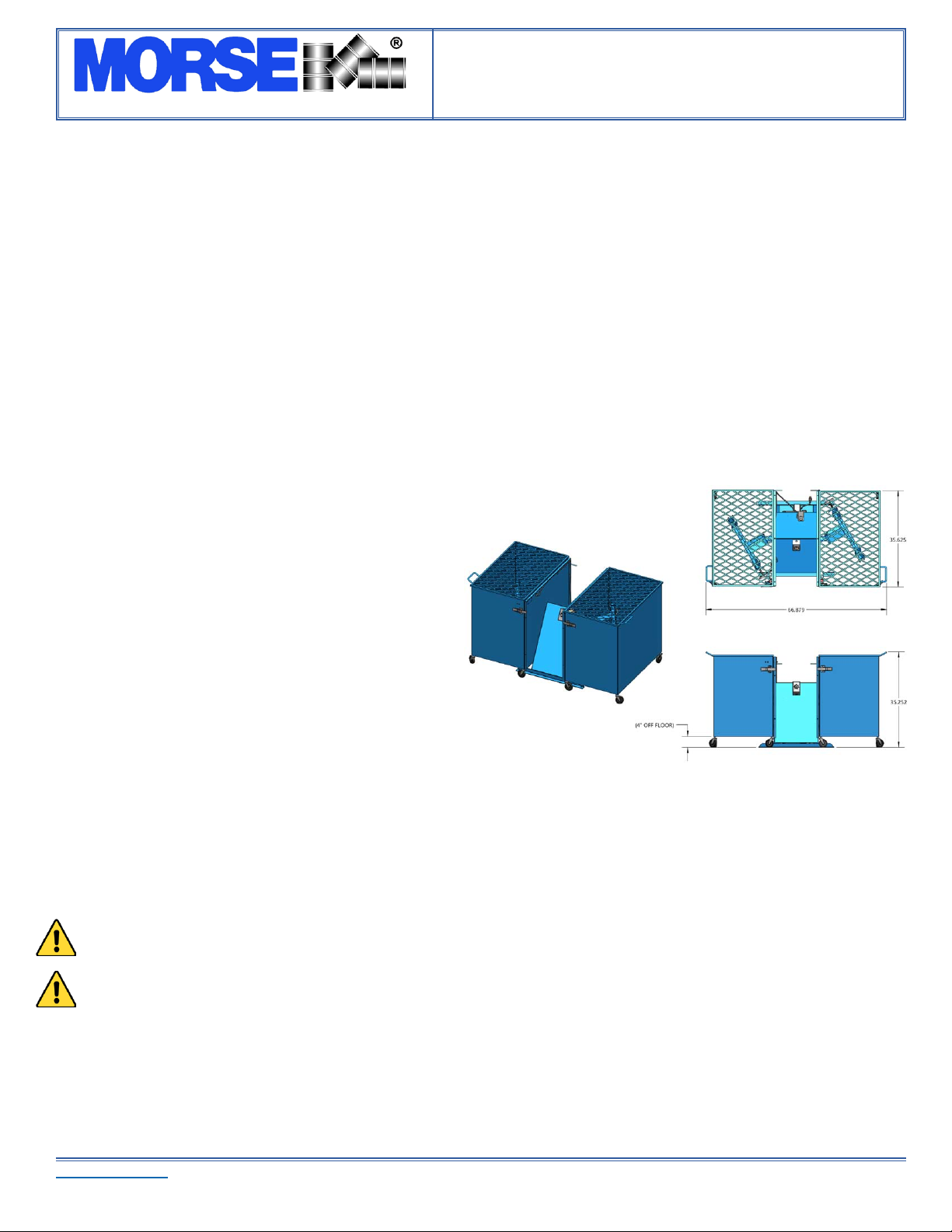

Machine Description

Morse Can Tumblers have a maximum capacity rating of 100 Lb. (45.5 kg) per can holder and are designed to rotate a can at an angle

resulting in a “corner over corner” mixing action. The can holder will accept cans 4.5” to 16.5” (12 to 42 cm) tall, and up to 12.5” (31 cm)

diameter. DO NOT exceed these ratings. Exceeding these ratings or handling cans other than those mentioned above is unsafe and

could result in equipment damage, excessive wear or awkward handling. Tumbling speed is 23 RPM (19 RPM on 50Hz models).

Assembly Instructions

Remove the following items from the cardboard box: 305 base and can holder complete.1.

Slide can holder complete onto drive shaft and attach with provided roll pin.2.

Installation Instructions

The305baseshouldbeboltedtotheoorusingthe4holesprovidedinthebaseframe.1.

Thebasehasfourholesspaced26”(66cm)widex26-5/8”(67.6cm)long.Morserecommendstherotatorsbesecuredtotheoor2.

using 3/8” (.95 cm) diameter x 3” (7.62 cm) long lag bolts. Customer is responsible for choosing proper size and type to best suit

their needs.

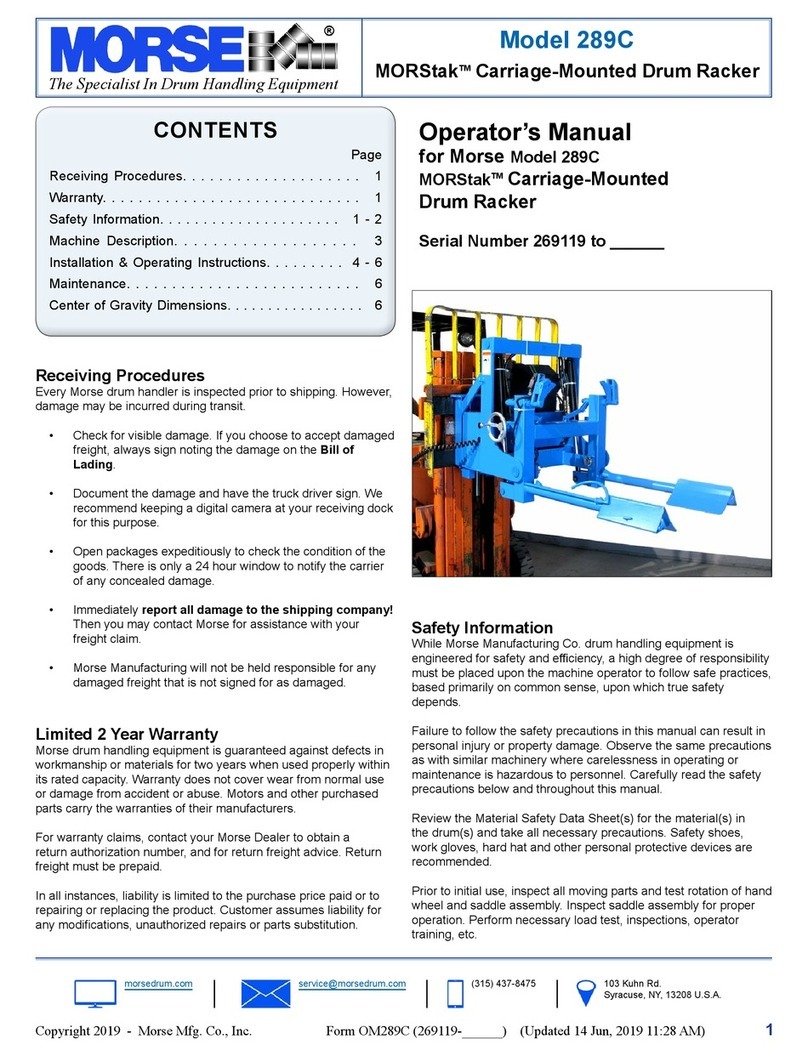

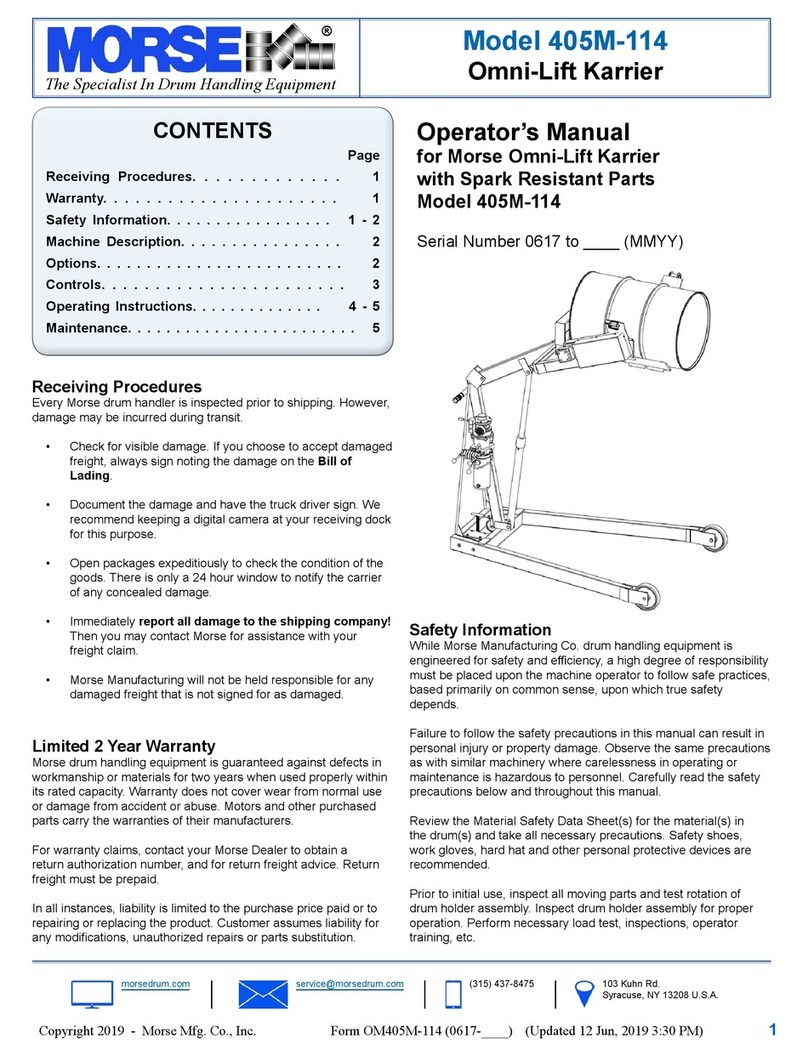

Install all Morse Rotators in accordance with OSHA requirements for enclosure and safety interlock, etc. so the rotator automatically3.

turnsowhenenclosuredoorisopened.Onewayto

accomplish this is with a Morse enclosure with safety

interlock.

For OSHA compliance, see OSHA subpart O.1910.212(a)

(4) “Barrels, containers, and drums. Revolving drums,

barrels, and containers shall be guarded by an enclosure

which is interlocked with the drive mechanism, so that the

barrel, drum, or container cannot revolve unless the guard

enclosure is in place.”

Power connections and motor controls must comply with4.

applicable codes.

Operating Instructions

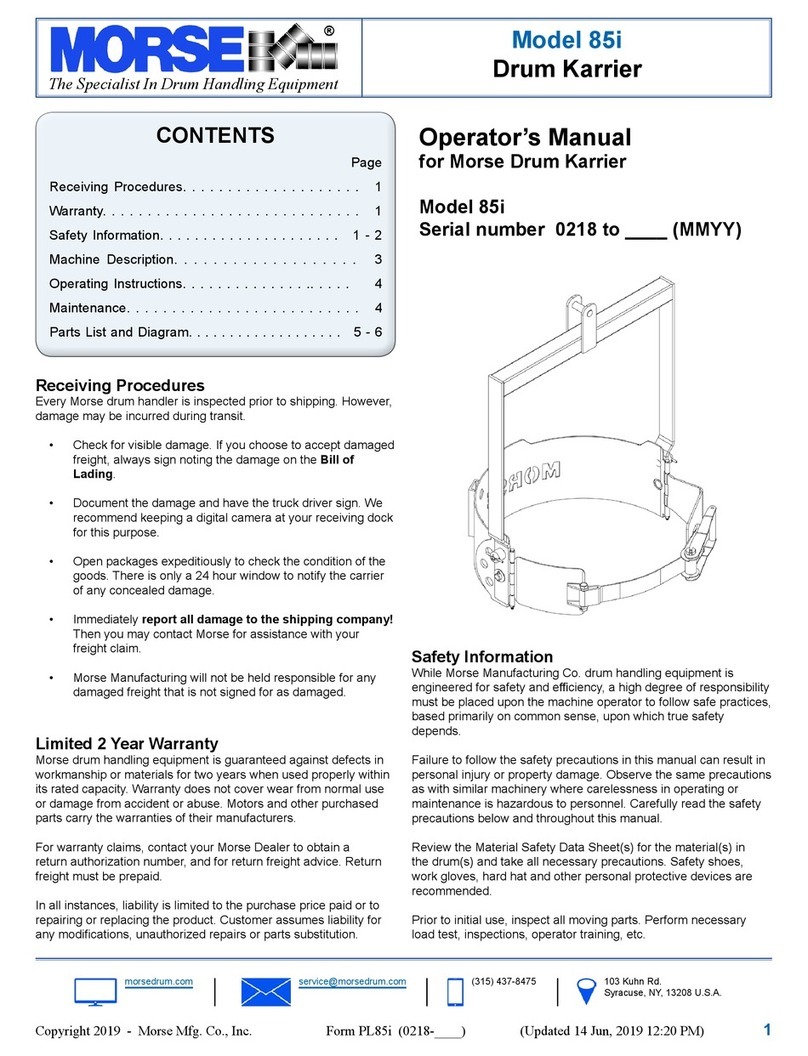

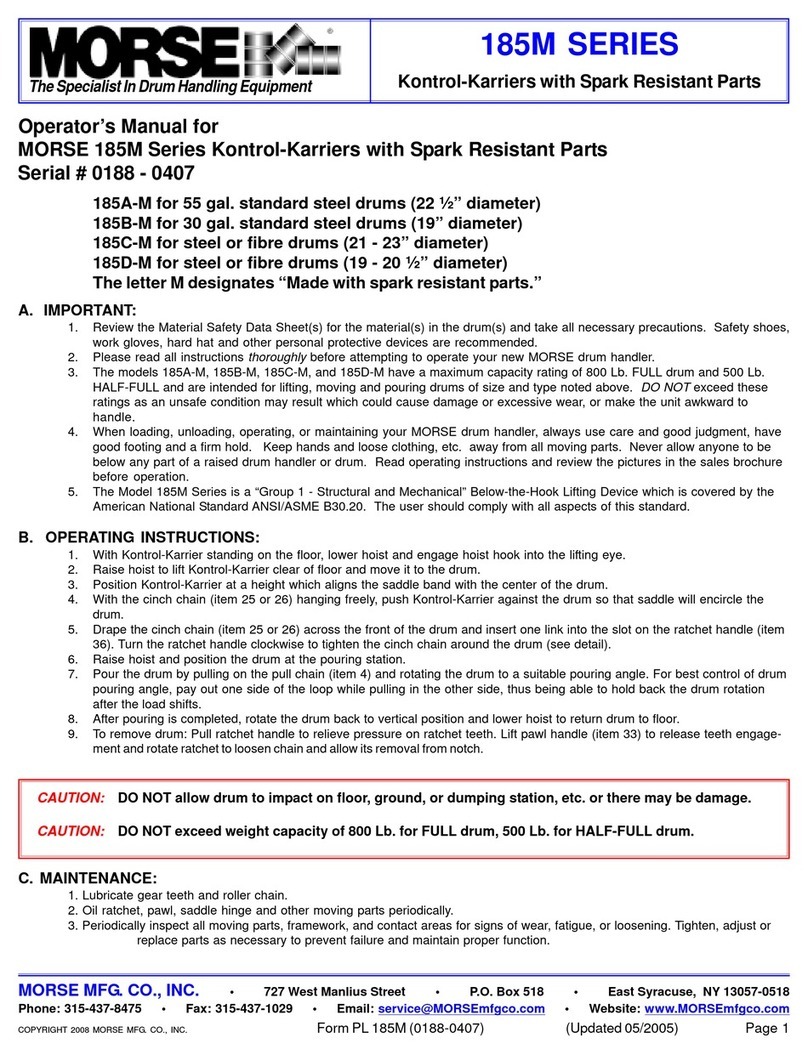

Place can in can holder so that the weight is centered in1.

the can holder. This can be done by adjusting the bottom

cross bar using the holes and 2 adjusting pins provided.

Clamp down on can with top cross bar by turning2.

handwheel until bar secures the can. Turn screw lock

down until its tight against the 5/8-8 acme nut mounted on the top channel. The can is now secure for rotating.

The 305 with the single phase tefc motor comes with a cord, plug and timer. The timer allows operator to select running time up to 603.

minuteswithautomaticshut-o.Thismodelcanbepluggedintothewallpowersupplyandstartedwiththetimer.Whenstartingthe

unit be careful to stand clear of the can holder as it will begin to rotate.

The 305 with the three phase tefc motor and explosion proof motor (1ph or 3ph) does not come with a cord or starter. The customer4.

is responsible for wiring up these motors in accordance with the electrical codes in their state.

The305withtheairmotorcomeswith3/8”pushlockhoseanda1/4”tting.Thecustomershouldconnecttheirairsupplytotheunit5.

according to the air motor manufacturer’s instructions. MORSE recommends 40 psi of air pressure to run unit properly.

WARNING: DO NOT stand near can holder when starting unit or when unit is in operation.

CAUTION: DO NOT exceed weight capacity of 100 Lb. (45.4 kg) per can.

Maintenance

Pillowblockbearingsareequippedwithgreasettingandshouldbelubricatedperiodically.Highpressuregreasegunsarenot1.

recommended, as their force may damage seals.

Greaserollerchainperiodicallywithanysucientgradeofanti-slinggrease(e.g.Whitmorelubes“surtac2000”).2.

Motors have permanently lubricated ball bearings.3.

Periodically inspect all moving parts, framework, and contact areas for signs of wear or loosening. Tighten, adjust, or replace parts4.

as necessary to prevent failure and maintain proper function.

Guard Enclosure Kit Sold Separately