THOR RIDGE User manual

RIDGE

User Guide

Document reference: RIDGE User Guide 22v8

Distribution date: August 15, 2022

© 2018 THOR AV. All rights reserved.

No part of this publication may be reproduced or

transmitted in any form or by any means without the

express written consent of the publisher.

www.THORav.us | sales@thorav.us | (763) 999-4253

™ & ® 2018 THOR AV. © 2022 THOR AV.

ii

TO REDUCE THE RISK OF ELECTRIC SHOCK, DO NOT REMOVE COVER. NO USER SERVICEABLE PARTS

INSIDE.

The lightning ash with arrowhead symbol, within an equilateral triangle, is intended to alert

the user to the presence of un-insulated and/or potentially dangerous voltage within the

products enclosure that may be of sufcient magnitude to constitute a risk of electric shock to

persons.

The exclamation point within an equilateral triangle is intended to alert the user to the

presence of important operating and maintenance (servicing) instructions in the literature

accompanying the appliance.

IMPORTANT SAFETY INSTRUCTIONS

1. Intended use for the RIDGE series is for indoor applications.

2. Inspect all products and perform safety related checks before deployment.

3. Read and understand this entire manual.

4. Keep this manual available for reference.

5. Heed all warnings and precautions in this manual and notices marked on the product.

6. Do not use this product near water or damp environments.

7. Do not block any ventilation openings. Install in accordance with the manufacturer’s instructions.

8. Provide for proper airow around product. Do not install near products that produce high levels

of heat. Do not expose the unit to direct sun light or heating units as the internal components’

temperature may rise and shorten the life of the components.

9. Do not defeat the safety purpose of the polarized or grounding-type plug. A polarized plug has two

blades with one wider than the other. A grounding type plug has two blades and a third grounding

prong.

10. Protect the power cord from being walked on or pinched particularly at plugs, convenience

receptacles, and the point where they connect to the product. Do not use the unit if the electrical

power cord is frayed or broken.

11. THOR AV products must be used in accordance with local, state, federal and industry regulations.

The responsibility to evaluate the reliability of any rigging or mounting method for their application

is solely the user’s responsibility. Rigging is to be carried out by experienced professionals.

12. Abide by the Working Load Limit (WLL) of third party equipment for suspension points, chain hoists

and additional rigging hardware.

13. Verify structural integrity meets engineering requirements for ying, ground stacking and wall

mounting applications.

14. THOR AV is not responsible for any rigging, attachments and accessories provided by third party

manufacturers.

15. Utilize safety measures at all times, including safety slings and cables.

16. Unplug this product during lightning storms or when unused for long periods of time.

17. Refer all servicing to qualied service personnel. There are no user serviceable components inside

the product.

18. The product shall not be exposed to moisture. Do not touch the unit with wet hands. Do not handle

the unit or power cord when your hands are wet or damp.

19. The product should be connected to a power supply only of the type described in the operating

instructions or as marked on the product.

CARE

• From time to time you should wipe off the front and side panels and the cabinet with a dry soft

cloth. Do not use rough material, thinners, alcohol or other chemical solvents or cloths since this may

damage the nish or remove the panel lettering.

• The manufacturer cannot be held responsible for damages caused to persons, personal possessions,

or data due to an improper or missing ground connection.

RIDGE LED PANEL INSTRUCTIONS

www.THORav.us | sales@thorav.us | (763) 999-4253

™ & ® 2018 THOR AV. © 2022 THOR AV. iii

All THOR AV LED products are warranted to the original purchaser to be free of defects in materials and

workmanship for a period of two years from date of purchase. During this period, THOR AV will, at its

discretion, repair the defective unit or replace it with a new or rebuilt one.

The warranty does NOT cover:

• Damages caused by abuse, accident, improper use, improper handling, improper operation,

improper installation/disassembly of the display or any other customer misconduct.

• Damages due to installation of any unauthorized hardware, accessories, consumable parts or

components.

• Defects, malfunctions or damages caused during transportation.

• Units on which the product serial number has been removed or altered.

• Units that have been serviced by unauthorized personnel.

All implied warranties, including warranties on merchantability and tness, are limited in time to the length

of this warranty. Some states do not allow time limitations on implied warranties, so this limitation may not

apply to you. THOR AV’s liability is limited to the repair or replacement of its product. THOR AV shall in no

way be held liable for incidental or consequential damages resulting from the use of their product or its

software, including, without limitation, damages from loss of business prots, business interruption, loss

of business information or other pecuniary loss. Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation or exclusion may not apply to you.

REPAIR POLICY

Please contact support@thorav.us to obtain an RMA number prior to returning your product to THOR AV.

Do not return the product to the place of purchase. Write the RMA number on the outside of the shipping

carton. Any product sent to us without a valid RMA number will be refused.

Shipping Address:

THOR AV

Attn: RMA Number

8821 Zealand Ave. N, Ste. B

Brooklyn Park, MN 55445 USA

Include the following with the product: a brief description of the problem, your name, return shipping

address, phone number and the RMA number. Do not include any accessories. THOR AV is not

responsible for any damage to or loss of the product during transit. We recommend that customers obtain

a receipt and tracking number for all packages shipped to us. Turnaround time on repairs is generally ten

business days. If you live outside of the United States, please contact your local distributor for warranty

service.

WARRANTY SERVICE

You will be responsible for shipping charges to THOR AV and the product will be returned by THOR AV.

We reserve the right to inspect any product that may be the subject of any warranty claim before repair is

carried out. To qualify for warranty service, documentation showing the date of purchase may be required.

Final determination of warranty coverage lies solely with THOR AV.

NON-WARRANTY SERVICE

If it is determined that the product does not meet the terms of our warranty, you will be billed for labor,

materials, return shipping and insurance. There is a $100 USD minimum charge for materials and labor.

Appropriate shipping charges will be applied. We require payment in advance of repair by credit card;

we accept Visa and Master Card. In the event the charges are over the minimum charge, THOR AV will

contact you and inform you of the cost of the repair before any work is completed.

THOR LIMITED WARRANTY

www.THORav.us | sales@thorav.us | (763) 999-4253

™ & ® 2018 THOR AV. © 2022 THOR AV.

iv

TABLE OF CONTENTS

SAFETY INSTRUCTIONS

RIDGE LED PANEL INSTRUCTIONS II

WARRANTY

THOR LIMITED WARRANTY III

OVERVIEW

RIDGE LED PANEL 1

SPECIFICATIONS 2

ANATOMY 3

Front View 3

Rear View 4

Power Data Box 5

Parts 6

Dimensions 8

INSTALLATION REQUIREMENTS

MECHANICAL 9

ELECTRICAL 9

VIDEO SYSTEM 9

INSTALL APPLICATION

IMPORTANT SAFETY CONSIDERATIONS 10

FLOWN LED WALL 11

Using Flybar 11

Using Ground/Flybar 13

GROUND STACKED LED WALL 14

WALL MOUNTED LED WALL 19

CONNECTION GUIDE

POWER CONNECTION 23

DATA CONNECTION 24

PROCESSORS

BROMPTON TECHNOLOGY 25

NOVASTAR 25

www.THORav.us | sales@thorav.us | (763) 999-4253

™ & ® 2018 THOR AV. © 2022 THOR AV. 1

RIDGE LED wall panels offers outstanding

performance with exible install options. RIDGE

can be installed in ground stack, own, or wall

mounted congurations. This LED panel series is

ideal for House of Worship, Fixed Installations,

Virtual Production, and Signage.

• 1.8mm, 2.5mm, and 3.7mm pixel pitches

• Brompton and NovaStar processing options

• Easy servicing from front or back

• Best-in-class on-camera performance

• Easily visible in all levels of ambient light

• Ideal for churches, stages, corporate board

rooms and lobbies, and VR/XR studio

production.

INDOOR LED WALL PANEL

RIDGE LED PANEL

www.THORav.us | sales@thorav.us | (763) 999-4253

™ & ® 2018 THOR AV. © 2022 THOR AV.

LISTED

E498026

2

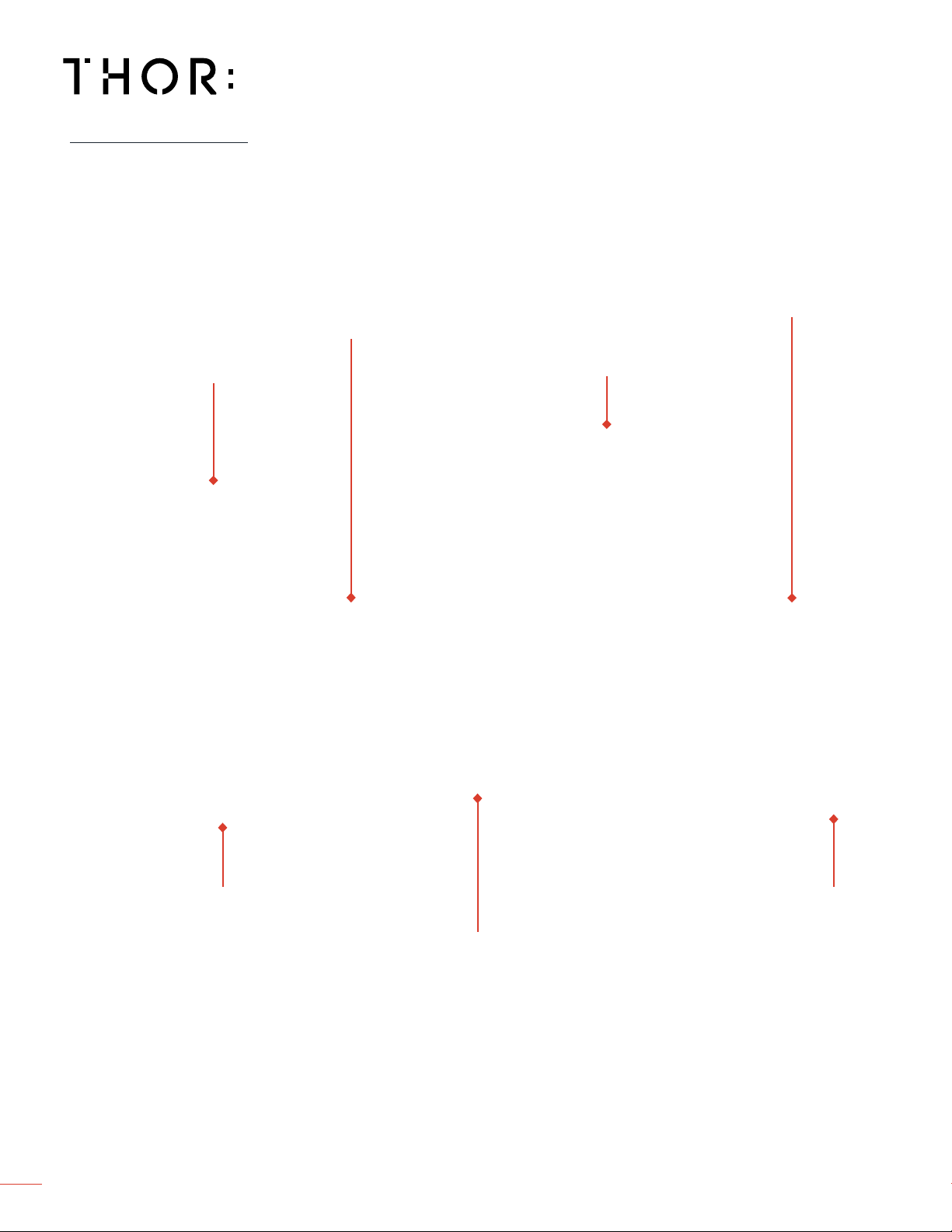

1.8 Brompton 2.5 Brompton

2.5i NovaStar

3.7 Brompton

3.7i NovaStar

Pixel Pitch 1.8mm 2.5mm 3.7mm

Calibrated Brightness 1175 nits 1200 nits 1250 nits

Viewing Angle 140° x 140° 140° x 140° 140° x 140°

Closest Viewer 7 FT / 2.1M 10 FT / 3M 18 FT / 5M

LED Module SMD 1010 gold wire SMD 2121 gold wire SMD 2121 gold wire

Driving IC Module MBI IC Drivers with S-PWM MBI IC Drivers with S-PWM MBI IC Drivers with S-PWM

Serviceability Front / Rear Front / Rear Front / Rear

Panel Dimensions 600 x 337.5 x 58mm

(23.62” x 13.29” x 2.29”)

600 x 337.5 x 58mm

(23.62” x 13.29” x 2.29”)

600 x 337.5 x 58mm

(23.62” x 13.29” x 2.29”)

Hardware Options Fly, Ground Stack, & Wall Mount Fly, Ground Stack, & Wall Mount Fly, Ground Stack, & Wall Mount

Processor Platform/Receiving

Card*

Brompton Brompton R2 Brompton R2 Brompton R2

NovaStar N/A NovaStar A5s Series NovaStar A5s Series

Driving Method 1/15 scan 1/15 scan 1/15 scan

Gray Scale 16 bit 16 bit 16 bit

Refresh Rate 3,840+ Hz 3,840+ Hz 3,840+ Hz

Brightness Control

Brompton 1175 steps 1200 steps 1250 steps

NovaStar N/A 256 steps 256 steps

Pixel Conguration 320 x 180 (w x h) 57,600 240 x 135 (w x h) 32,400 160 x 90 (w x h) 14,400

Module Conguration 2 x 1 2 x 1 2 x 1

Chassis - Straight Standard Standard Standard

Operating Temperature -30° to 50° C -30° to 50° C -30° to 50° C

Operating Humidity Up to 90% Up to 90% Up to 90%

Power Input 120/240 Volt at 50/60 Hz 120/240 Volt at 50/60 Hz 120/240 Volt at 50/60 Hz

Power Consumption 150W max. 50W avg. 120W max. 40W avg. 120W max. 40W avg.

BTU/hr 437 max. 137 avg. 437 max. 137 avg. 437 max. 137 avg.

Electrical Circuits 120V/20A 24 panels 24 panels 24 panels

Flown Maximum Rigging

Height 8M (26.25’) 8M (26.25’) 8M (26.25’)

Ground Stacked Maximum

Height 5M (16.4’) 5M (16.4’) 5M (16.4’)

Chassis Material Die Cast Aluminum Die Cast Aluminum Die Cast Aluminum

Weight 8.5 kg (18.6 lbs) 8.5 kg (18.6 lbs) 8.5 kg (18.6 lbs)

IP Rating IP31 IP31 IP31

Certications FCC, ETL, EMC, UL FCC, ETL, EMC, UL FCC, ETL, EMC, UL

Life Span 100,000+ Hours 100,000+ Hours 100,000+ Hours

Limited Warranty 2 years 2 years 2 years

SPECIFICATIONS

www.THORav.us | sales@thorav.us | (763) 999-4253

™ & ® 2018 THOR AV. © 2022 THOR AV. 3

LED MODULES

MODULE GUIDE POSTS

MODULES

CONNECTOR

MODULES

HANDLE

FRONT VIEW

www.THORav.us | sales@thorav.us | (763) 999-4253

™ & ® 2018 THOR AV. © 2022 THOR AV.

4

LATCH LOCKS

LOCKING CLAMP

SOCKET

WALL MOUNT

SCREW HOLE

GUIDE PIN LATCH

LED MODULE

SAFETY SCREWS

CHASSIS HANDLE

REMOVABLE

POWER & DATA BOX

REAR VIEW

www.THORav.us | sales@thorav.us | (763) 999-4253

™ & ® 2018 THOR AV. © 2022 THOR AV. 5

DATA IN/OUT DATA IN/OUT

PowerCON IN PowerCON OUT

POWER & TEST

PATTERN BUTTON

POWER SUPPLY

THUMB SCREWS

POWER DATA BOX

www.THORav.us | sales@thorav.us | (763) 999-4253

™ & ® 2018 THOR AV. © 2022 THOR AV.

6

600mm x 66.67mm x 4.69mm

23 ⅝” x 2 ⅝” x 4

1111

//

1616

”

4.5 kg / 9.92 lbs

1200mm x 66.67mm x 119mm

47 ¼” x 2 ⅝” x 4

1111

//

1616

”

8.5 kg / 18.74 lbs

98mm x 75mm x 10mm

3 ⅞” x 2

1515

//

1616

” x .39”

.18 kg / .34 lbs

75mm x 48mm x 10mm

2

1515

//

1616

” x 1 ⅞” x ⅜”

.09 kg / .12 lbs

1800mm x 38.1mm x 25.4mm

70 ⅞” x 1 ½” x 1”

2.45 kg / 5.4 lbs

2400mm x 38.1mm x 25.4mm

94 ½” x 1 ½” x 1”

1.8 kg / 4 lbs

114.3mm x 63.5mm x 38.1mm

4 ½” x 2 ½” x 1 ½”

.36 kg / .8 lbs

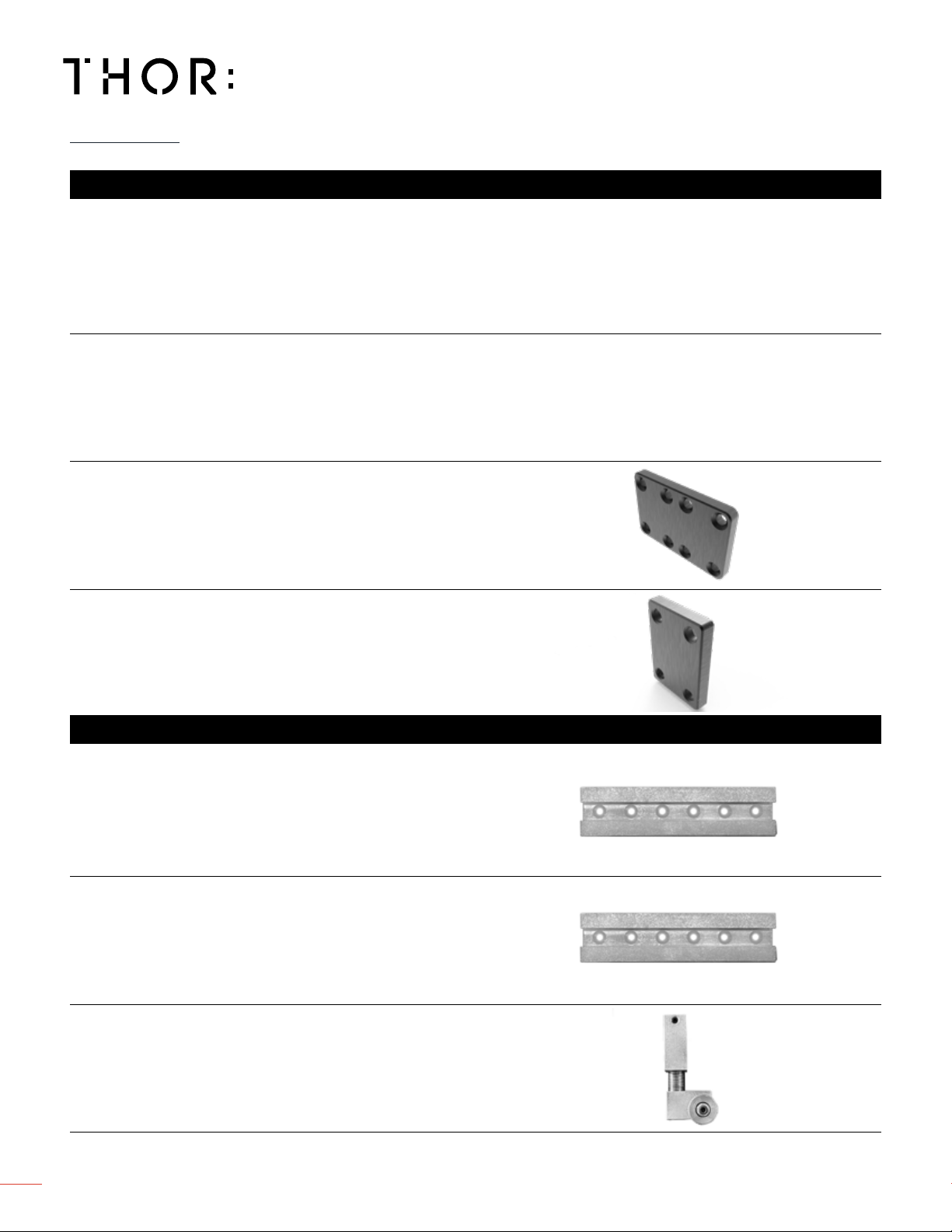

Flybar 600mm

Wall Mount 1800mm Track

Flybar 1200mm

Wall Mount 2400mm Track

Flybar Bracket

Wall XYZ Mount

Flybar Endcap

Flown Install

Wall Mount Install

PARTS

www.THORav.us | sales@thorav.us | (763) 999-4253

™ & ® 2018 THOR AV. © 2022 THOR AV. 7

600mm x 80mm x100mm

23 ⅝” x 3 ⅛” x 3

1515

//

1616

”

4.63 kg / 10.1 lbs

1200mm x 80mm x 100mm

47 ¼” x 3 ⅛” x 3

1515

//

1616

”

9.53 kg / 21 lbs

850mm x 160mm x 105mm

33

77

//

1616

” x 6

55

//

1616

” x 4 ⅛”

3.76 kg / 8.3 lbs

675mm 240mm x 50mm

26

99

//

1616

”x 9

77

//

1616

” x 1

1515

//

1616

”

2.5 kg / 5.5 lbs

1010mm x 240mm x 50mm

39 ¾” x 9

77

//

1616

” x 1

1515

//

1616

”

3.18 kg / 7 lbs

240mm x 105mm x 116mm

9

77

//

1616

” x 4 ⅛” x 4

99

//

1616

”

.64 kg / 1.4 lbs

1200mm x 50mm x 30mm

47 ¼” x 1

1515

//

1616

” x 1

33

//

1616

”

1.81 kg / 4 lbs

Ground/Flybar 600mm

Ground/Flybar 1200mm

Ladder Truss 1010mm

Locking Clamp

Rear Drawbar 1200mm

Ground Stack Install

Rear Ground Truss 850mm

Ladder Truss 765mm

Ground and Flown Install

Ground and Flown Install

PARTS

www.THORav.us | sales@thorav.us | (763) 999-4253

™ & ® 2018 THOR AV. © 2022 THOR AV.

8

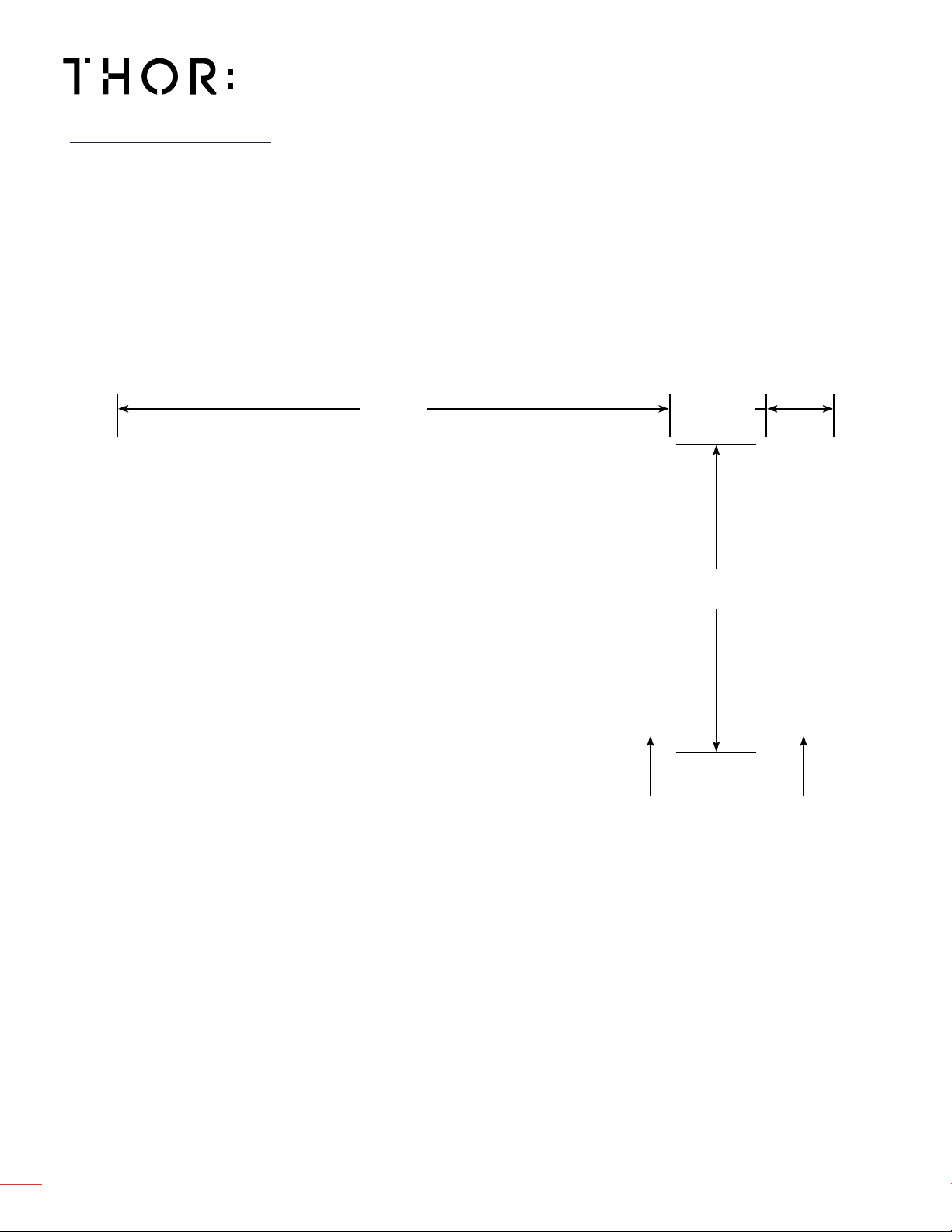

DIMENSIONS

23 ⅝”

600mm

255

//

1616

”

58mm

13 55

//

1616

”

337.5mm

M5 M3

www.THORav.us | sales@thorav.us | (763) 999-4253

™ & ® 2018 THOR AV. © 2022 THOR AV. 9

MECHANICAL

VIDEO SYSTEM

THOR LED Panels are available with Brompton and NovaStar processing. Contact THOR for specics.

Pixel capacity per port may vary based on LED wall mapping conguration and pixel pitch.

PROCESSING

LED PANELS PER PROCESSOR PORT

RIDGE 1.8 RIDGE 2.5 RIDGE 3.7

60Hz 120Hz 180Hz 240Hz 60Hz 120Hz 180Hz 240Hz 60Hz 120Hz 180Hz 240Hz

8 bit

Panel Qty 9 4 3 2 16 8 5 4 36 18 12 9

10 bit

Panel Qty 7 3 2 1 12 6 4 3 29 14 9 7

12 bit

Panel Qty 6 3 2 1 10 5 3 2 24 12 8 6

Structural integrity for all types of LED wall installation applications (Flown and Ground Stack) is required

for each site and veried by a structural engineer.

See Important Safety Considerations on page 10.

STRUCTURAL

ELECTRICAL

Ground Stack LED walls require ballasting a percentage of the total weight. Ballast the LED wall by

distributing evenly on the Rear Ground Bars.

Ballast Weight Calculator

Wall Height, 1-3 meters — 50% of wall weight

Wall Height, 4 meters — 75% of wall weight

Wall Height, 5 meters — 100% of wall weight

Wall Height, 6 meters — 100%* of wall weight

If a wall weighs 3,300lbs., then the total ballasting weight is 1650lbs. If there are 12 Rear Ground Bars for

this LED wall, 137.5lbs. is needed for each Rear Ground Bar.

*At 6 meters we recommend adding another row of Rear Ground Bar and another set of Rear Ground

Truss.

Verify the mounting structure load capacity (truss, purlins, schedule 80 pipe, unistrut, etc). Determine

adequate amount of pick points for stabilizing LED wall.

BALLASTING

RIGGING

EDGE Panels require 110-240 VAC, 50-60 Hz and should be 16A or less. Proper grounding is required.

POWER

www.THORav.us | sales@thorav.us | (763) 999-4253

™ & ® 2018 THOR AV. © 2022 THOR AV.

10

THOR AV products must be used in accordance with local, state, federal and industry regulations. In

addition to this, THOR AV is not responsible for any rigging, attachments and accessories provided by

third party manufacturers.

INTENDED USE

The RIDGE series LED panels are for indoor applications only. Installations require professionally trained

personnel.

Do not use this product near water or damp environments. Do not expose the unit to direct sun light or

heating units as the internal components’ temperature may rise and shorten the life of the components.

Provide for proper airow around product. Do not install near products that produce high levels of heat.

INSPECT PRODUCT

Inspect all products and perform safety related checks before deployment. Heed all warnings and

precautions in this manual and notices marked on the product.

Protect the power cord from being walked on or pinched particularly at plugs, convenience receptacles,

and the point where they connect to the product. Do not use the unit if the electrical power cord is frayed

or broken.

INSTALLATION GUIDELINES

The responsibility to evaluate the reliability of any rigging or mounting method for their application is

solely the user’s responsibility. Rigging is to be carried out by experienced professionals. Abide by the

Working Load Limit (WLL) of third party equipment for suspension points, chain hoists and additional

rigging hardware.

Verify structural integrity meets engineering requirements for ying, ground stacking and wall mounting

applications. Utilize safety measures at all times, including safety slings and cables.

IMPORTANT SAFETY CONSIDERATIONS

www.THORav.us | sales@thorav.us | (763) 999-4253

™ & ® 2018 THOR AV. © 2022 THOR AV. 11

1

3

2

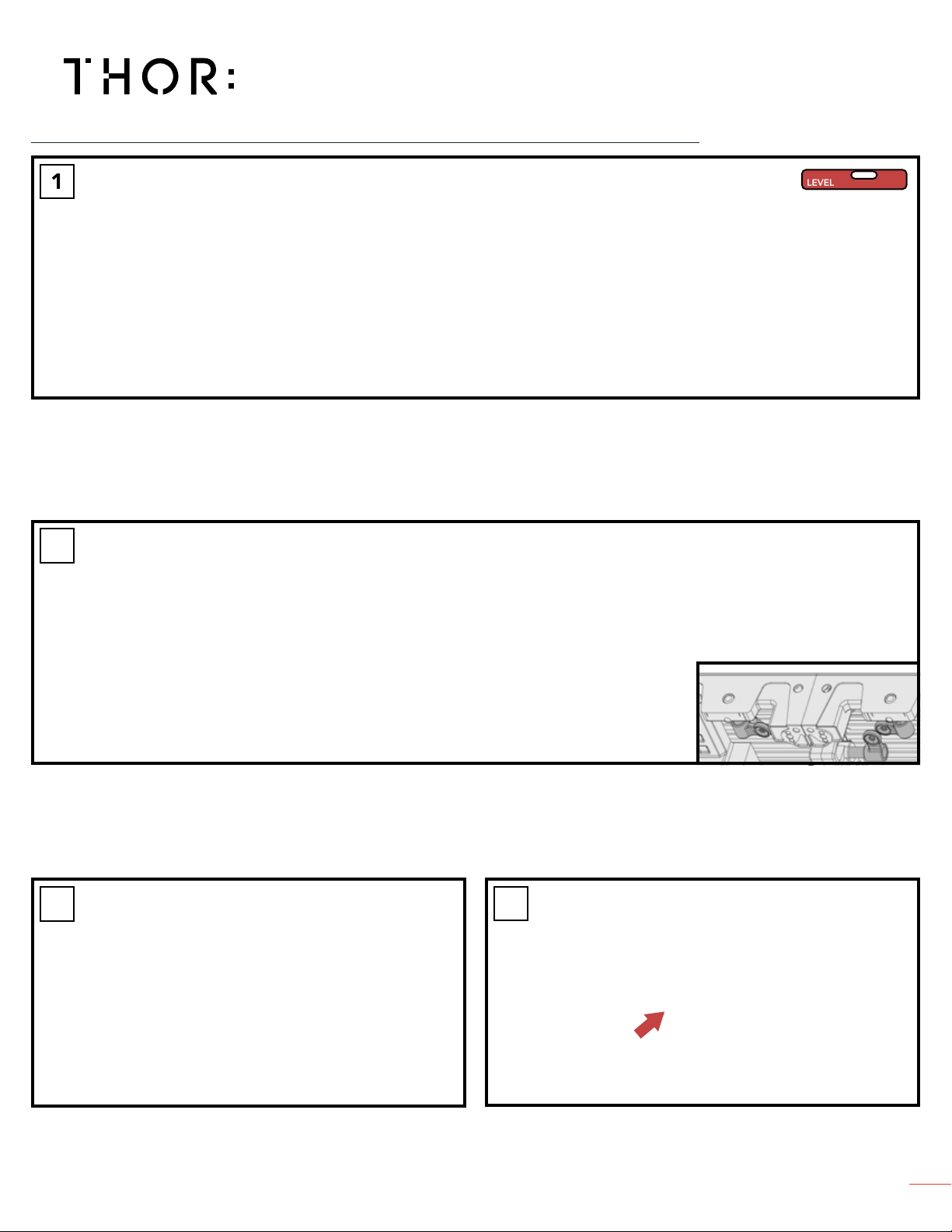

Secure and level Flybars to weight bearing structure using Eyebolt. Eyebolts are removable. Use a thin wall 1-5

/

32” socket on under side of Flybar.

LEVEL

1 ¾ in

(4.5 cm)

Loosely secure Flybars together with Flybar Bracket. Use large Phillips screwdriver and spare screws on Flybar.

Attach aesthetic End Cap to either end of Flybar assembly.

FLOWN APPLICATION - USING FLYBAR

www.THORav.us | sales@thorav.us | (763) 999-4253

™ & ® 2018 THOR AV. © 2022 THOR AV.

12

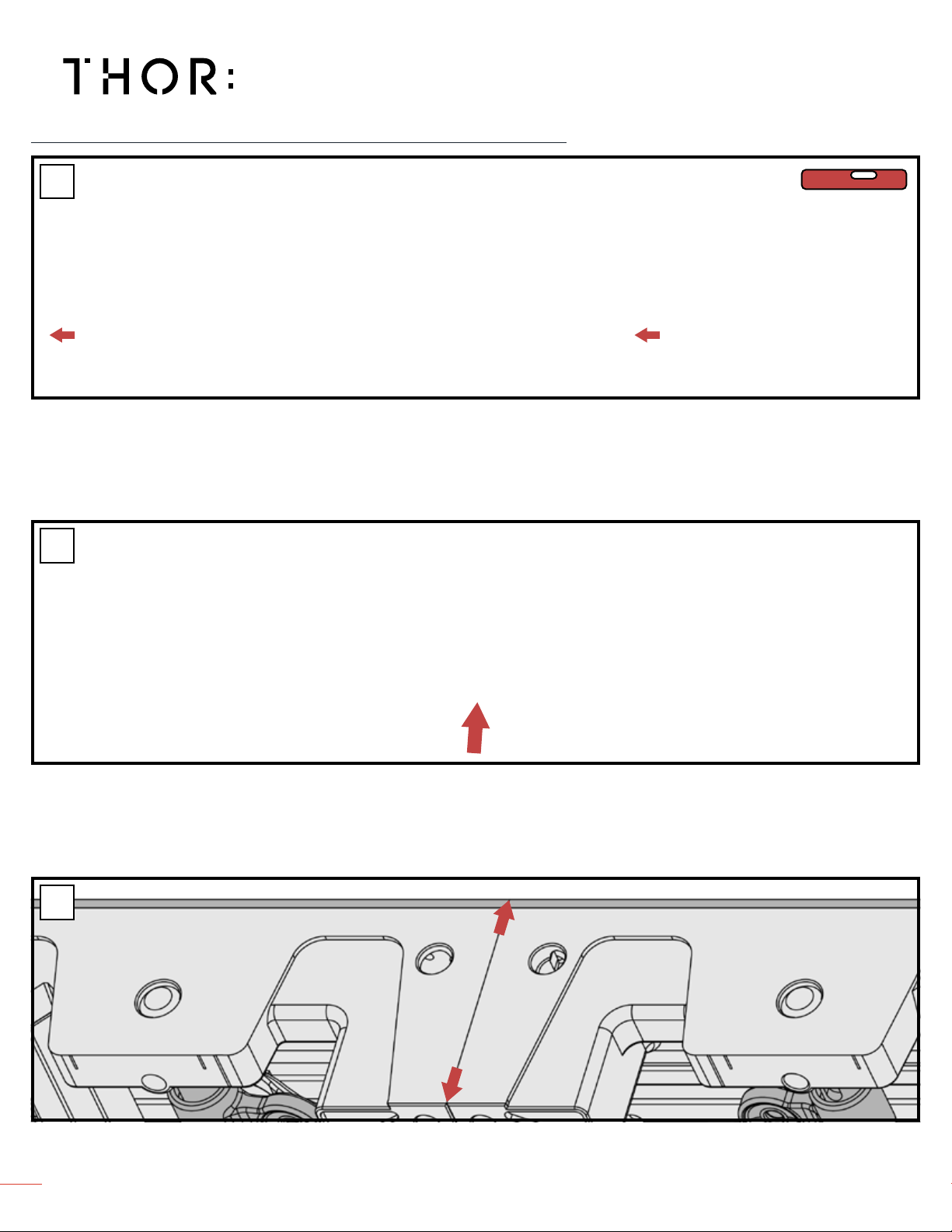

Insert Latch Guide Pins into receiving holes on Flybar and adjacent panels. Align panels and lock into position by twisting the Latch Guide Pin. Do not over

tighten. Continue until rst row is complete. For additional rows, align panels and lock into position.

Push latch lever, on Flybar or panel, to lock or release Latch Guide Pins. New Latch lever may need to be pushed in and out a few times for Latch Guide Pins

to properly secure into place.

Verify LED panels are aligned before tightening into place.

LEVEL

4

6

5

FLOWN APPLICATION - USING FLYBAR

www.THORav.us | sales@thorav.us | (763) 999-4253

™ & ® 2018 THOR AV. © 2022 THOR AV. 13

1

2

LEVEL

Secure and level Ground/Flybars to weight bearing structure using Eyebolt.

Insert Latch Guide Pins into receiving holes on Ground/Flybar and adjacent panels. Align panels and lock into position by twisting the Latch Guide Pin. Do not

over tighten. Continue until rst row is complete. For additional rows, align panels and lock into position.

Attach Ground/Flybar Locking Triangle Eyebolt to adjacent Ground/Flybar

and tighten or loosen as needed. Do not over tighten.

The receiving hole for the Latch Guide Pin locks panels into position. Push to

lock or release.

4

3

FLOWN APPLICATION - USING GROUND/FLYBAR

www.THORav.us | sales@thorav.us | (763) 999-4253

™ & ® 2018 THOR AV. © 2022 THOR AV.

14

Connect Rear Ground Truss to Ground/Flybar using truss bolt and cotter pin. Truss Bolt can only be inserted one direction. Use rubber mallet to insert truss

bolt completely before inserting Cotter Pin.

To eliminate seams in the LED wall, level Ground Stack hardware. Adjust

using 8mm hex key.

Attach Ground/Flybar Locking Triangle Eyebolt to adjacent Ground/Flybar and tighten or loosen as needed. Do not over tighten.

Level Ground/Flybars by adjusting attached feet with 8mm hex key. Extends

from 0-1 inch.

LEVEL LEVEL

1

4

3

2

36 ¾ in

(933 mm)

4 ¾ in

(120 mm)

33

1515

//

3232

in

(850 mm)

≤ 1 in (26 mm) ≤ 1 ¼ in (32 mm)

GROUND STACKED LED WALL

www.THORav.us | sales@thorav.us | (763) 999-4253

™ & ® 2018 THOR AV. © 2022 THOR AV. 15

GROUND STACKED LED WALL

Insert Latch Guide Pins into receiving holes on panel and twist to lock into place.

Place other panels next to each other and insert Latch Guide Pins into

receiving holes on panel and twist to lock into place. Verify LED panels are

aligned before tightening into place.

Insert Latch Guide Pins into adjacent panel and secure. Do not over

tighten. Continue steps 7-8 until rst row is complete. Adjust leveling feet

if necessary as more weight is added to each row. For additional rows, align

panels and lock into position.

The receiving hole on panel, locks the Ground/Flybar Guide Pins into position. Push to lock or release.

5

8

6

7

Table of contents

Other THOR Lighting Equipment manuals