Operating manual Table of Contents

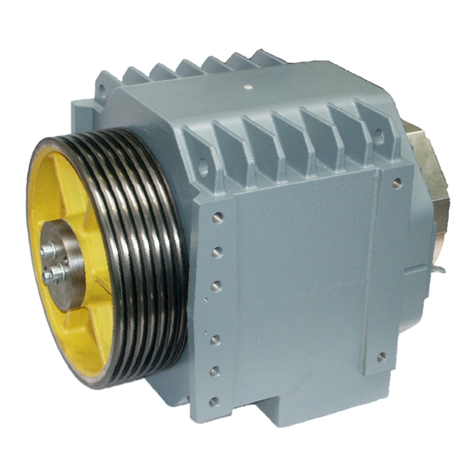

TW63B drive

thyssenkrupp Aufzugswerke Version 05/2016

Table of Contents

1About these instructions...................................................5

1.1 Guide to layout................................................................................ 5

2Safety..................................................................................6

2.1 Warning notes................................................................................. 6

2.2 Safety requirements........................................................................ 7

2.3 Warranty and liability....................................................................... 8

2.4 Dangers in handling the product ..................................................... 9

2.5 International occupational health and safety regulations................10

2.6 Personal protective equipment.......................................................11

3Product Description.........................................................12

3.1 Standards and legal requirements..................................................12

3.2 Description .....................................................................................12

3.3 Functional description ....................................................................17

4Technology.......................................................................20

4.1 Technical data................................................................................20

4.2 Dimensions of machine..................................................................21

4.3 Machine base frame.......................................................................25

4.4 Machine base frame dimension sheets..........................................29

4.5 Encoder..........................................................................................38

4.6 Brake..............................................................................................39

5Transportation and storage............................................40

5.1 Packaging ......................................................................................40

5.2 Transport........................................................................................41

5.3 Checking the delivery.....................................................................43

5.4 Packaging materials.......................................................................44

5.5 Ambient conditions.........................................................................44

5.6 Standstill maintenance...................................................................44

6Installation........................................................................45

6.1 Setting up the machine base frame................................................45

6.2 Installing and aligning the machine ................................................46

6.3 Mounting the rope guard................................................................48

6.4 Connecting motors.........................................................................49