8 ILM for rothe erde®slew drives 9

If possible, the slew drive should be installed in the vertical

rotation axis.

The mounting surface must be free of anti-corrosion agents.

An alkaline cleaning agent can be used to clean the contact

surface.

Note:

The preservative can easily be removed with, for example, a

biodegradable alkaline cleaning agent.

Warning:

Do not let the cleaning agent touch the sealing or raceway!

Do not paint the sealing!

The slew drive must be installed on a level,

oil/grease-free surface of bare metal.

When connecting the slew drive to the connecting structure, check

that the fastening holes (slew drive/connecting structure) match.

If the fastening holes do not match, the slew drive may warp when

the bolts are tightened. In the installation process, first connect the

housing mounting surface to the connecting structure.

The slew drive’s fastening bolts must be of strength grade

10.9 and hand tightened. Please use the specified number and

diameter of bolts. Carefully tighten the bolts diagonally using

a suitable tool (see Figure 1).

Warning:

Do not allow peaks to form in small sectors, i.e. from 0°–180° the

curve should only rise and fall once evenly.

Hardness gap: The unhardened areas – “hardness gap”

(stamped “S”) – of the ball slewing bearing must be arranged

in the load-neutral area.

Table 3: Permitted deviation from levelness of contact surfaces

under DIN EN ISO 1101

Table 4: Preload forces and tightening torques from VDI 2230

Figure 1: Correct order for tightening fastening bolts

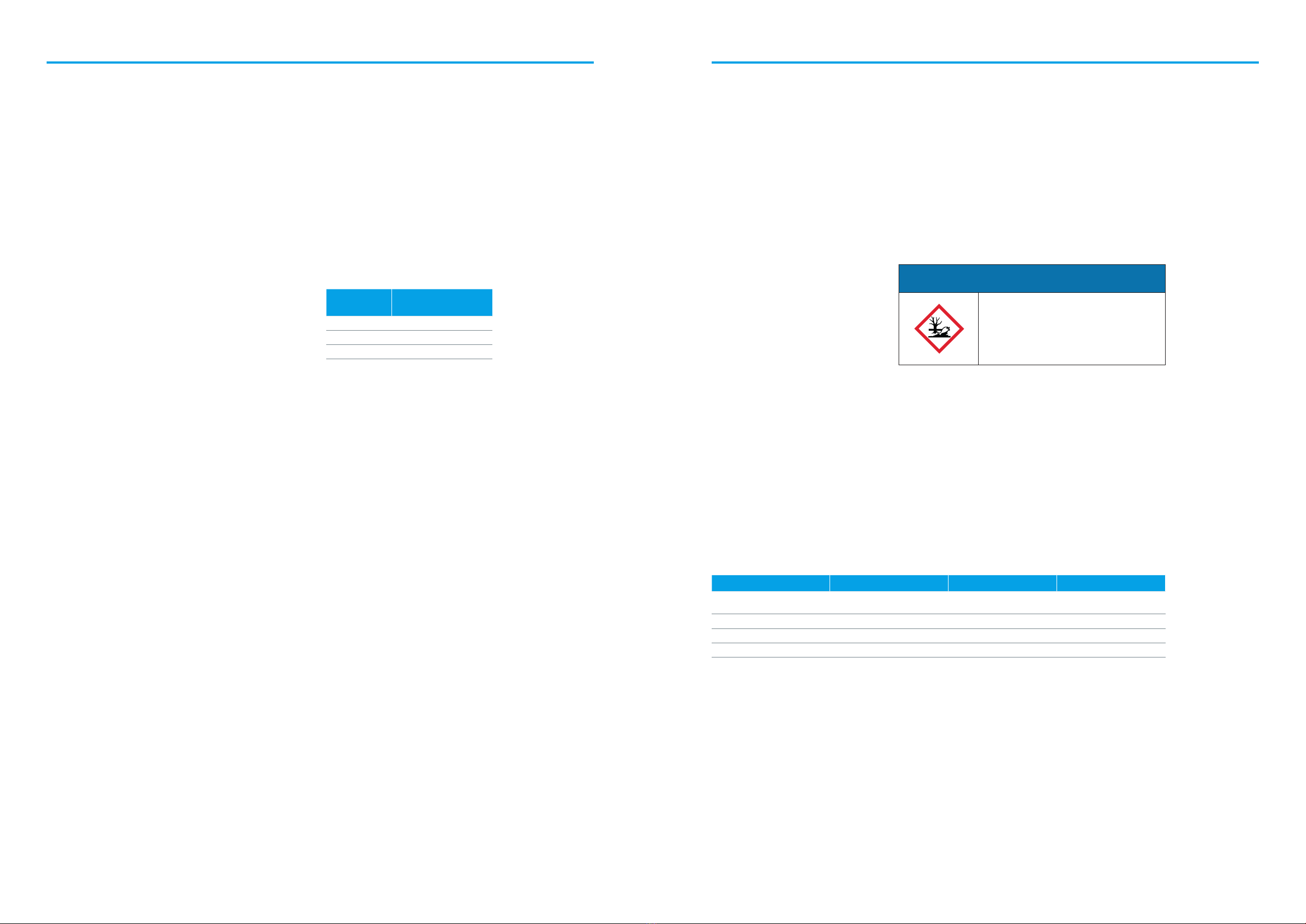

WARNING

Preservatives may

cause skin irritation

• Wear gloves when removing

• Please follow the manufacturer’s

instructions

Ball track Ø Deviation from levelness under

DIN EN ISO 1101

up to 500 mm 0.10 mm

up to 1000 mm 0.15 mm Bolts

10.9

Preload force

[kN]

Tightening torque

M16 115.7 338

M20 181 661

DANGER

Danger of crushing when depositing the

load

• Inspect the site before depositing

• Be aware of co-workers

Please check that the contact surfaces for the slew drive are level.

The maximum permitted deviation from levelness under DIN EN

ISO 1101 is given in Table 3.

Ball track Ø can be found in the model specifications.

For example: SE 0244-L => ball track Ø 244mm

After the first 20% of the bolts are tightened diagonally, all bolts

must be tightened. As tightening the bolts affects the neighboring

bolts, this should be done in at least two passes.

Warning:

Please check the bolt length in advance. At least 6 free thread

turns must be available in the part of the bolt that is loaded (thread

seat) to guarantee the minimum bolt penetration.

The interface pressure under the bolt head/nut may not exceed the

permitted limits. If the interface pressure limit is exceeded, wash-

ers of suitable size and hardness must be used (see section

“Bolts” in the rothe erde®Large Diameter Slewing Bearing catalog

or download it at https://www.thyssenkrupp-rotheerde.com/en/

downloads/brochures-and-catalogues)

The above tightening torque assumes threads and nuts/head con-

tact surfaces have been lightly oiled and that bolts and nuts do not

have treated surfaces (total µ ges. = 0.140).

1.3.3 Operating

temperature

The temperature range for the slew drive extends from -20°C to

60°C, assuming an even temperature distribution. If temperatures

fall outside the permitted temperature range, steps must be taken

to stay within it.

Please contact thyssenkrupp rothe erde Germany GmbH.

1.3.4 Duty cycle

Slew drives are designed for short-lasting loads. Overly long duty

cycles lead to temperature increases and premature breakdown of

the slew drive. A full load duty cycle of 10% of a minute must be

followed by an appropriate cool-down period.

1.3.5 Start-up

The slew drive must be fully bolted together when started up.

Please ensure that the slew drive cannot be damaged by current

flow or equalization of potential during installation and operation.

1.3 Installation

1.3.1 Preparation 1.3.2 Bolts