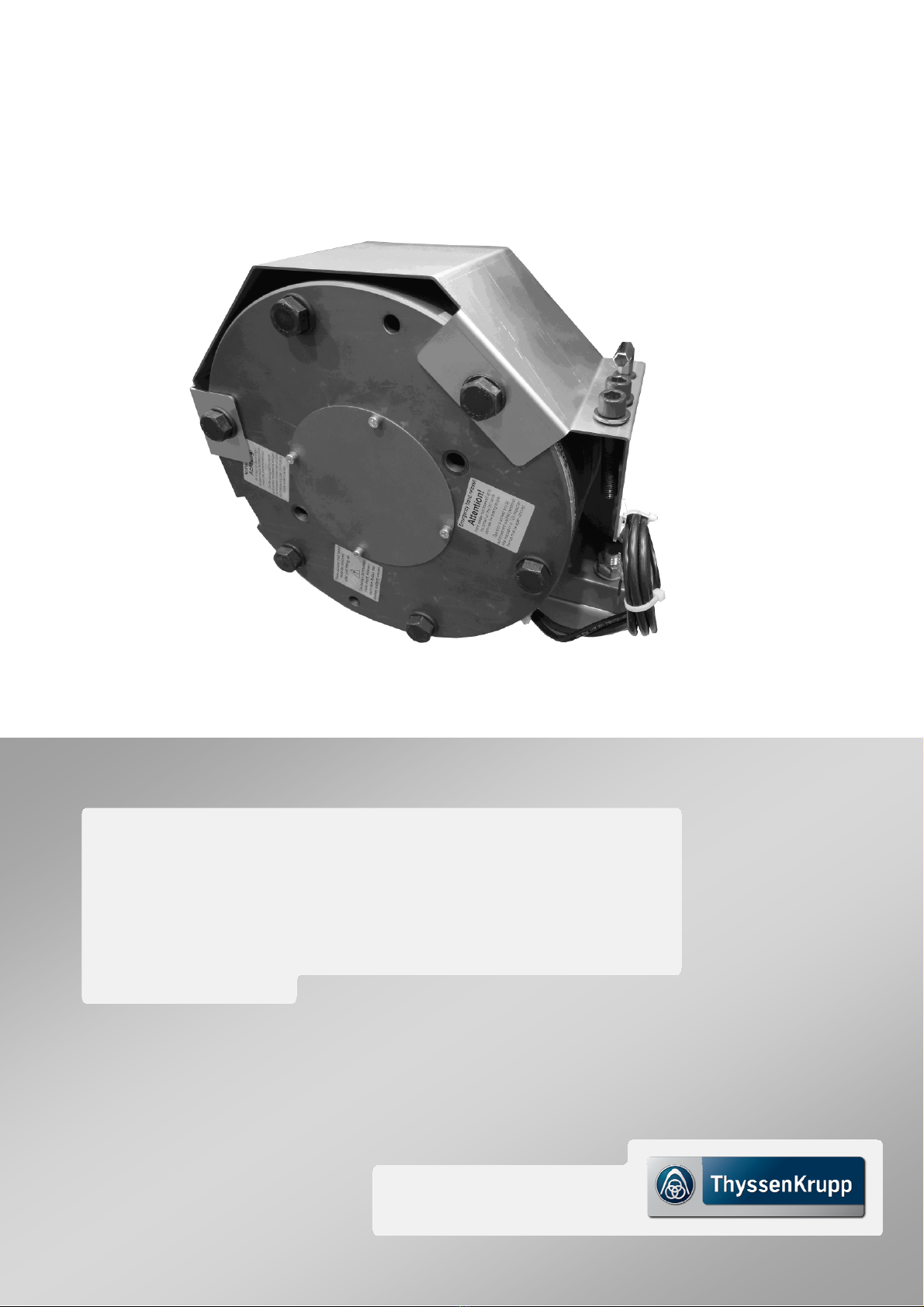

OPERATING MANUAL NBS SAFETY

ThyssenKrupp Aufzugswerke GmbH

Informal notes on the safety measures

The operating manual is to be kept permanently at the usage site of the

installation.

Complementary to the operating manual, the generally applicable and local

regulations for accident prevention and environmental protection are to be

provided and complied with.

Legally prescribed safety instructions are to be provided for the users at

clearly visible positions.

Keep all safety and hazard warnings on the installation in a legible condition.

Use in line with intended purpose

The NBS emergency brake has been constructed using state-of-the-art

technology and in line with the recognised technical safety regulations.

The NBS emergency brake may only be deployed when it is in perfect

working order with regard to safety.

The exclusive intended purpose of the NBS emergency brake is to protect

the elevator car against overspeed as it is moving upwards.

Any other or additional form of use shall be regarded as non-compliant with

the intended use. THYSSENKRUPP AUFZUGSWERKE GmbH shall not be

liable for any damage arising from such use and any damage arising due to

operator errors.

Proper use in line with the intended purpose also includes

compliance with all instructions in the operating manual and

compliance with the commissioning instructions, the installation description

as well as performance of the inspection and maintenance work.

Warranty and liability

As a general principle, the 'General Terms of Sale and Delivery' of

THYSSENKRUPP AUFZUGSWERKE GmbH apply

Warranty and liability claims in the event of personal injury and damage to

property shall be excluded if they arise due to any of the following causes:

Improper use that is not in line with the intended purpose of the NBS

emergency brake

Installation, commissioning, operation and maintenance of the NBS

emergency brake that is not in line with accepted technical principles

Operation of the NBS emergency brake with defective and/or malfunctioning

safety and protection devices

Nonobservance of the instructions in the operating manual with regard to

transport, storage, installation, commissioning, setting, operation and

maintenance of the NBS emergency brake

Customer constructional alterations to the NBS emergency brake