Thytronic SME2 User manual

SME2 - Manual - 10 - 2011

SME2

DIRECTIONAL EARTH FAULT

AND SHORT-CIRCUIT DETECTOR

MANUAL

51 67

59 SME2

SME2

SME2

51

67

51 67

59

51

67

51 67

59

51

67

2SME2 - Manual - 10 - 2011

1 G E N E R A L

1 GENERAL

General info

SME2 fault detection systems are designed in conformity with the ENEL DY 1059 (RGDAT) specifica-

tion; they are installed in remote-controlled Secondary Stations in order to provide local and remote

signalling of short circuit and earth faults that may occur in MV distribution networks. SME quickly

locate the line section affected by the fault thus reducing power outage.

The SME2 device uses the signal provided by the capacitive voltage dividers fitted on MV panels

both for the directional earth function and for the voltage failure detection function; the phase volt-

age values V4, V8 and V12 are processed so as to eliminate the capacitive divider measurement

errors by means of a self calibration algorithm.

The current measure is taken by three open core current transformers supplied in the kit.

The SME2 device detects faults between phases producing a current exceeding the threshold and

earth failures both on insulated neutral networks and on compensated neutral networks, without

any need of changing the settings between different configurations and regardless of the feeding

direction.

The device detects faults lasting more than 80 ms and is not sensitive to self-restoring faults lasting

up to 40 ms.

The correct detection of the fault direction also occurs in the presence of intermittent faults.

The SME2 device checks the voltage of the three phases of the MT line and indicates whether it is

ON or OFF; a current converter is also available with an impressed current output of 4...20 mA for

sending the phase current measurement to the remote control terminal.

The device is provided with a self-calibration function capable of correcting errors and drifts (ageing

or thermal) of capacitive transducers used to detect phase voltages.

The following output relays are provided:

TS51A relay; it signals the short circuit function tripping for phase faults (between phases or dou-

ble-phase to earth),

TS67AV relay; it signals the directional earth function tripping in case of line faults (with reverse

direction disabled),

TSPRESV relay; it signals the dead line function tripping.

The following LEDs are provided:

three green-coloured LEDs indicating the voltage presence on V4, V8, V12 phases,

a white-coloured LED indicating the activation of the reverse direction for the directional earth

protection,

an orange-coloured latched LED indicating trip of the multiphase or double-phase to earth protec-

tion,

a red-coloured latched LED indicating the trip of the earth fault protection ,

a red-coloured LED indicating the calibration in progress,

a red-coloured LED indicating the self test function (blinking).

A logical input allows enabling the reversal command for earth fault directional protection (67).

Protective functions

51 Phase overcurrent

67 Directional ground fault overcurrent

59 Voltage presence

•

•

•

•

•

•

•

•

•

•

•

•

3

SME2 - Manual - 10 - 2011

2

2

MAIN FEATURES

MAIN FEATURES

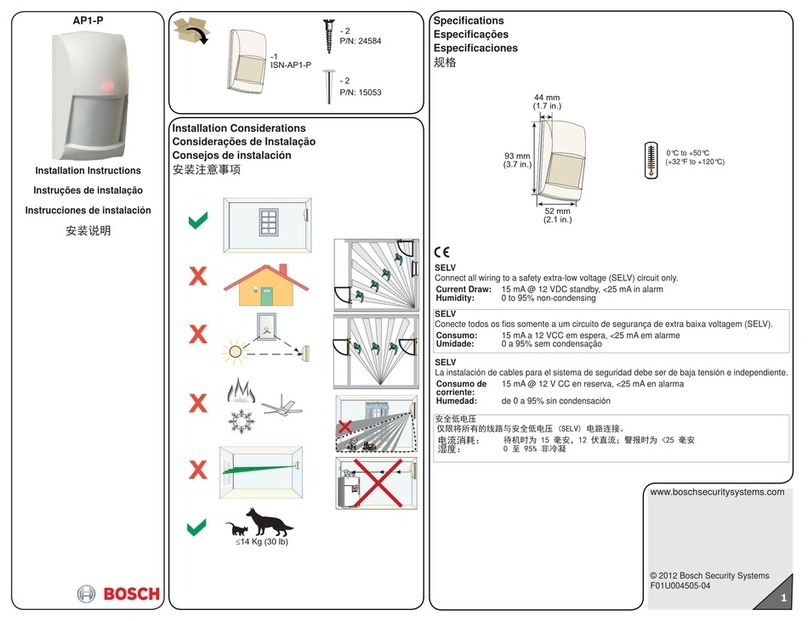

SME panel

The SME2 panel is suitable for projecting assembly.

The front includes signalling LEDs and communication port.

Phase Current Sensor

Two open core ring type current transformers are designed so as to be mounted directly on the

medium voltage insulated cables.

Residual current sensor

The IE> sensor is an open core ring type current transformer.

The sensor is installed on insulated cables so as the earth connection of the cable armour must pass

through the transformer.

Since the core embeds the three line phases, the residual current is detected.

Current sensors connections

Current sensors connections are implemented through a harness conforming with the ENEL DY1059

specification; they must be connected to the MA terminal board located inside the SME2 panel.

Voltage sensors connection

(Capacitive dividers)

Voltage sensors connection is implemented through screened cable between the fixed outlet on the

MV panel and the SME2 device through hexapolar plug conforming with the ENEL DY811 specifica-

tion.

Remote control unit

Remote control unit connections are implemented according with ENEL DY1059 specification; they

are abutted to the terminal board MB at the factory according to the connection diagram into the

device cover.

RS232 communication

The device provides a serial interface to allow a PC connection for installation, configuration, moni-

toring and diagnostic.

The firmware upgrade is provided.

To connect to the PC an adapter may be provided on request (SOC003 converter).

3

3

FUNCTION CHARACTERISTICS

FUNCTION CHARACTERISTICS

The SME2 device performs its fault detection functions based on measure of line currents and phase

voltages; two phase currents, three phase voltages and the residual current are detected.

The following features are provided.

Earth single-phase fault

directional detection function

The function detects the occurrence of earth faults both on insulated neutral networks and on com-

pensated neutral networks, without any need of changing settings when changing type of network.

The algorithm is based on the numerical analysis of signals (FFT) through fast sampling (64 samples

per period) and phase locking algorithm (PLL); in this way the quantities are correctly measured in

Through external signal from the remote control system, it is possible to control the reversal of the

reference direction in case of line feeding from the opposed side (secondary station bar tripping

directionality); the reversal signal is provided by the remote control system through the closing of a

contact connected to terminals 8 and 9 of the MB terminal board.

The fault signal (TS67AV) is provided to the remote control unit by the closing of a contact connected

to terminal 5 of the MB terminal board.

The sensitivity of the earth directional function depends on the extension of the line and on the neu-

tral status (insulated or with Petersen coil).

The setting is based on the adjusting of a U0residual voltage[1] threshold adjustable in the 1...16% Un

range and a I0zero sequence current [2] adjustable in the 1...9 A range.

The protective element detects the directional earth fault if all the following conditions occur:

Residual voltage exceeds the U0> threshold ,

Residual current exceeds the IED> threshold IED>,

Residual current - residual voltage displacement between 60 ° and 255 ° (IED lags behind to U0with

reversed direction disabled),

All the above conditions were met for almost 80 ms.

Note 1 - The residual voltage U0is the vector sum of the three phase voltages divided by three.

Note 2 - The residual current IE is the vector sum of the three phase currents.

Double earth single-phase

or phase-phase (short circuit)

fault detection function

The L4 and L12 phase currents are measured and fault indication is provided when current in at

least one phase exceeds the set threshold a:

500 A for multi-phase faults

150 A for double earth-phase faults).

The fault signal (TS51A) is provided to the remote control unit by the closing of a contact connected

to terminal 2 of the MB terminal board.

•

•

•

•

•

•

•

•

•

4SME2 - Manual - 10 - 2011

Voltage presence

The three phases voltages are measured; when at least one voltage value is higher than 80% of the

rated voltage the information (TSV) is provided to the remote control unit by the closing of a contact

connected to terminal 3 of the MB terminal board.

Current converter

The SME2 device is provided with an impressed current analogue output for sending the phase cur-

rent measure to the remote control unit. Signal 4...20 mA is available for transfer to the remote control

unit on terminals 4 (M1 connected to the positive auxiliary power) and 7 (M2 of terminal board MB).

The rated primary current is adjustable inside the 100...500 A range with 100 A step.

Calibration

The calibration procedure aims to adjust the SME2 device voltage inputs to the capacitive dividers

mounted on secondary switchgears; it should be carried out without faults on the network.

The self calibration The phase voltages and acquired and the voltage parameters are normalized.

The automatic calibration process is started with PC command.

The computed parameters are stored to a nonvolatile memory and maintained when auxiliary power

is goes down.

Output relay commissioning

The output relays TS51A and TS 67AV trip as for faults causing the switch to open, as for transient

faults. Relays are energised for the fault time, and in any case for a minimum of 150 ms.

The following cases are covered:

single-phase ground fault with residual current IE≤ 150 A: the directional protection trips (67) if the

direction is correct,

single-phase ground fault with current IE> 150 A: the short circuit (51) protection trips,

double single-phase earth fault with current IE≤ 150 A (on the same line or on different lines): the

67 trips if the direction is correct,

double single-phase earth fault with current exceeding 150 A (on the same line or on different

lines): the 51 protection trips,

multi-phase fault with residual current IE> 500 A: the 51 protection trips.

voltage presence indication: the TSV relay remains energised as long as the three phase voltages

remain below the voltage off threshold (20% Un).

The operation of directional earth fault protection (67) is masked by the trip of the phase overcurrent

protection (51) according to the logic shown in Figure below.

Voltage presence

Two thresholds are provided:

80% of rated voltage for trip (4% accuracy),

20% of rated voltage for reset (4% accuracy).

The transition between the states of presence / absence voltage is described:

Starting from the no voltage condition (Voltage Presence OFF), the logic state of supply voltage is

detected when, for at least 250 ms the following condition is true:

(V4>80%Vn) OR (V8>80%Vn) OR (V12>80%Vn)

Starting from the condition of Voltage Presence ON, the logic state is no longer recognized if the

following condition is true:

(V4<20%Vn) AND (V8<20%Vn) AND (V12<20%Vn) without intentional delay.

In case of fall and recovery of 24 VDC power supply, the logic state starts no voltage condition (Volt-

age Presence OFF) and only if the following condition is true:

(V4>80%Vn) OR (V8>80%Vn) OR (V12>80%Vn) the voltage presence is recognized

•

•

•

•

•

•

•

•

•

•

•

0.15 s

t

67 trip

51 trip

Operating logic for masking the 67 trip implemented through

the trip of the 51 protection

5

SME2 - Manual - 10 - 2011

The voltage presence logic is shown

Led indicators management

The SME2 device is provided with 8 indicator LEDs:

three green LEDs indicating that V4, V8, V12 phase voltages are ON,

a white LED indicating the direction reversal for the directional earth protection,

an orange LED indicating the multiphase or double single-phase function tripping,

a red LED indicating the earth fault function tripping downstream of the device,

a green LED indicating the calibration in progress condition,

a red LED indicating the self-test function tripping.

The fault indicator LEDs light up when a fault occurs which causes the opening of the switch, and

they remain open until the three phase voltages return and remain for at least one second at a value

of more than 80% the rated phase voltage.

The V4, V8, V12 LEDs, light up if the voltage of the relative phase is greater than 0.8 Vn and go OFF

when the voltage is less than 0.2 Vn.

Glossary/definitions

50/51 Phase overcurrent ANSI code

59 Voltage presence ANSI code

67 Directional ground fault ANSI code

Vn Rated voltage

In Rated current (500A)

V4, V8, V12 Phase voltages

I> Phase overcurrent threshold (51)

t> Operate time (51)

IED> Directional ground fault threshold (67)

U0> Residual voltage threshold (67)

tED> Operate time (67)

U> Voltage presence threshold (59)

•

•

•

•

•

•

0.2 Un

0.8 Un

Voltage presence (59)

Voltage presence status (59)

Voltage presence LED (59)

V4, V8, V12

t

V4, V8,V12

0.25s

6SME2 - Manual - 10 - 2011

4 T E C H N I C A L D A T A

4 TECHNICAL DATA

4.1 GENERAL

Insulation

Reference standards EN 60255-5 IEC 60255-5

High voltage test (50 Hz 60 s)

Auxiliary power supply 1 kV

Input circuits 1 kV

Output circuits 1 kV

Output circuits (between open contacts) 1 kV

Impulse voltage withstand test (1.2/50 μs):

Auxiliary power supply 2 kV

Input circuits 2 kV

Output circuits 2 kV

Output circuits (between open contacts) 2kV

Insulation resistance >100 MΩ

EMC tests for interference immunity

Reference standards

Product standard for measuring relays EN 50263

Generic standards immunity for industrial environments EN 61000-6-2

Apparati di automazione e controllo per centrali e stazioni elettriche (ENEL utility standard)

- Compatibilità elettromagnetica - Immunità ENEL REMC 02

- funzione del rivelatore di guasto protezione

- ambiente di installazione stazione MT

- porta di segnale collegamenti locali

Climatic tests

Reference standards IEC 60068-x ENEL R CLI 01 CEI 50

Ambient temperature -10...+55 °C

Storage temperature -40...+85 °C

Relative humidity 10...95 %

Atmospheric pressure 70...110 kPa

Mechanical tests

Reference standards

- Normativa di compatibilità elettromeccanica

per apparati e sistemi (ENEL utility standard) ENEL REMC 01

Reference standards

Rivelatore di guasto direzionale (RGDAT) (ENEL utility standard) ENEL DY 859

Prescrizioni per la costruzione ed il collaudo ENEL DY 1059 Ed.02-2004

Other applicable standards

Electric relays EN61810-1 (ex CEI 41-1) IEC 60255

Protection degree (IP code) EN60529, EN60529/A1

EMC Directive 89/336/EEC

Low Voltage Directive 73/23/EEC

Technical data

Mounting:

Phase current transformer on isolated cable

Residual current transformer on isolated cable

SME2 device Projecting

Protection degree IP31

SME2 mounting position vertical

Mass:

Phase current transformer 0.3 kg

Residual current transformer 0.7 kg

SME2 device 0.9 kg

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

7

SME2 - Manual - 10 - 2011

4.3 Input circuits

Auxiliary power supply Uaux

Rated voltage 24 V-

Nominal value (range) 19...29 V-

Max alternating component 10%

Maximum time at power ON 0.10 s

Power consumption at rest condition 2.5 W

Max power consumption 4 W

Phase current transformer

Inside diameter 50 mm

Rated current In500 A

Permanent overload 4 In

Thermal overload (1 s) 100 In

Dynamic overload (10 ms) 250 In

Frequency:

Rated frequency fn50 Hz

Operative range 0.95...1.05 fn

Connection to SME2

type unipolar wires

section 1 mm2

length 3.5 m

Residual current transformer

Inside diameter 150 mm

Permanent overload 1 kA

Thermal overload (1 s) 12.5 kA

Dynamic overload (10 ms) 31.5 kA

Frequency:

Rated frequency fn50 Hz

Operative range 0.95...1.05 fn

Connection to SME2

type unipolar wires

section 1 mm2

length 3.5 m

Phase voltage input circuits

Voltage plug DY811

MV rated voltage 15, 20, 23 kV

Transformation ratio 200...1800

Capacitive reactance (MTV side) 100...700 MΩ

Connection to SME2

type shielded wires

section 0.5 mm2

length 3.5 m

Binary input

Quantity 1

Type optocoupler

Operative range rated Uaux

Max consumption, energized 3 mA

4.4 Output circuits

Relays

Quantity 3

Type of contacts make (SPST-NO, type A)

Nominal current 2 A

Nominal voltage 250 V

Breaking capacity (24 V, L/R = 40 ms) 0.2 A

Minimum switching load 300 mW (5 V/5 mA)

Current converter

Operating range 0...500 A

Output current 4...20 mA

Accuracy 10%

Max load 750 Ω

Maximum response time 300 ms

•

•

•

•

•

•

•

•

•

•

•

•

•

8SME2 - Manual - 10 - 2011

4.5 LEDs

Signalling LEDs

Voltage presence (V4) green LED

Voltage presence (V8) green LED

Voltage presence (V12) green LED

Trip direction IED> (INV 67) white LED

Trip I> (51A) orange LED

Tripe IED> (67AV) red LED

Calibration in progress (CALIBRATION) red LED

Self test red LED

Connection to the remote control unit

Type 9 wires multipolar cable

Section 1 mm2

Length 8 m

4.6 COMMUNICATION INTERFACE

Local port

Connection RJ45

RS232-copper adapter SOC003

Rate 9600 Bps

Parity None

Protocol ModBus RTU®

4.7 PROTECTION AND CONTROL FUNCTIONS

Overcurrent (51)

I> threshold (1) 500 A

Operate time (definite time characteristic) 0.12 s

Dropout ratio > 0.95

Reset delay 0.02 s

Duration of the fault not detected 0.04 s

Duration of the fault detected 0.08 s

Reference values rest: 0

trip: 1.2 I>

Threshold accuracy ±10%

Operate time accuracy ±3% ± 20 ms

Note 1: For multi-phase faults the operating threshold is 500 A, for single-phase or multi-phase double earth fault the operating threshold is 150 A

Voltage presence (59)

U> threshold 0.80 Vn (1)

Operate time (definite time characteristic) 0.25 s

Dropout ratio 0.25

Reset delay 0.04 s

Reference values rest: 0

trip: 1.0 Vn

Threshold accuracy ±4%

Operate time accuracy ±3% ± 20 ms

Note: The 59 protection trips when the value of at least one phase voltage is greater than 0.8 Vnand is reset when the voltage of all three phases is

less than 0.2 Vn.

•

500 A I

t>

I>

t

TRIP

General operation time characteristic for the phase overcurrent element - 50/51

500 A I

t>

I>

t

TRIP

General operation time characteristic for the phase overcurrent element - 50/51

9

SME2 - Manual - 10 - 2011

Directional earth fault overcurrent (67)

IED> threshold (1) 1.0...9.0 A (step 0.5 A)

U0> threshold 0.01...0.16 Vn(step 0.01 Vn)

Operate tED>(definite time characteristic) 0.15 s

Dropout ratio > 0.95

Reset delay 0.03 s

Duration of the fault not detected 0.04 s

Duration of the fault detected 0.08 s

Reference values rest: 0 V, 0 A

trip: 2IED>,2U0>

Threshold accuracy ±15%

Operate time accuracy ±3% ± 20 ms

Angular sector accuracy (U0=1...120%; IE=1...150 A) ±2°

Hysteresis on the sector output ≤ 3°

Note (1) The directional earth fault function operate whenever the set residual voltage threshold U0> is exceeded with a residual current IE>

higher than threshold with a defined phase relation.

The masking time as voltage is restored is 0.15 s.

The operation of the directional earth fault protection is masked by the overcurrent trip according to

the logic function described below:

t

Uo

Uo>

IE>

Uo

IE

IE

tED>

TRIP

General operation time characteristic for the 67 element

TRIP

t

Uo

Uo>

IE>

Uo

IE

IE

tED>

TRIP

General operation time characteristic for the 67 element

TRIP

U

0

I

E

IE>

IE>

60˚

90˚ 90˚

NO TRIP

NO TRIP

TRIP

TRIP

157.5˚

180˚

255˚ 240˚

270˚

U

0

I

E

75˚

157.5˚

180˚

270˚

Polar tripping characteristic (67) with reversing direction OFF Polar tripping characteristic (67) with reversing direction ON

Operating logic for masking trip of the 67 protection with trip of the 51 protection

0.15 s

t

67 trip

51 trip

10 SME2 - Manual - 10 - 2011

5 I N S T A L L A T I O N

5 INSTALLATION

SME2 device For fixing you must:

remove the cover by unscrewing the fastening screws;

fix the SME panel fitting the four M5 screws supplied into the holes on the case bottom; the opera-

tion is made easier by the presence of the slotted holes.

Current sensors

Since current shorting connectors are not provided for the secondary CT’s, the current sensors must

be installed at the same time with the SME device and connected at once. In case of replacing

and/or maintenance operation of amperometric circuits, it is indispensable that the circuit breaker

is OFF.

Since the earth fault detection function is directional, the toroid fitting direction must be complied

with, or the device could fail to operate.

The assembly of the current sensors must be performed in the same way for feeders or incoming

lines (operation according to the output direction from the switchgear).

Phase current sensors

For fixing you must:

split the two core parts removing the metal clamp fastening screw;

fit the core to the phase conductor by properly coupling the two parts forming the sensor and

make attention that the earth connection of the cable shield don’t pass through the sensor. The

two phase current sensors supplied into each package have a different colour with respect to the

container for an easier coupling; in particular, the two half-cores should be aligned properly so

that references “P1” on the same cores are matching. For mechanical stability reasons, the sensor

fitting direction should be such as to have said references arranged towards the upper side of the

MT switchgear.

apply the metal clamp and tighten the fastening screw;

anchor the core to the phase conductor using the insulating clamps supplied.

Residual current sensor

Note: for use on MV grid the installation on insulated cables is required!

Before fitting, make sure that there are no earth connections of the screens upstream of the sensor;

in particular, for unified unipolar terminal ends, insulate support brackets from earth using the com-

ponents supplied in the kit to the MT switchgear. Fig. 5, illustrating the assembly drawing of the entire

compartment, shows the layout with plates, screws and insulating bolts. For different applications,

refer to the MV panel manufacturer’s instructions.

For a perfect sensor fitting, the three earth connection screens should be collected into a single

bundle to be anchored to the central cable so as to implement an ordered fitting (fig.5); proceed as

follows:

split the two core parts removing the metal clamp fastening screw;

fit the toroid so as to embrace the three cables, making sure that also the screening braiding earth

connection is included;

apply the metal clamp and tighten the fastening screw; align the two half cores properly so that

references “P1” on the same cores are matching.

The sensor fitting direction should be such as to have said references arranged towards the upper

side of the MV compartment (line outgoing side downstream of switch).

fasten the core using the insulating clamps supplied.

•

•

•

•

•

•

•

•

•

•

•

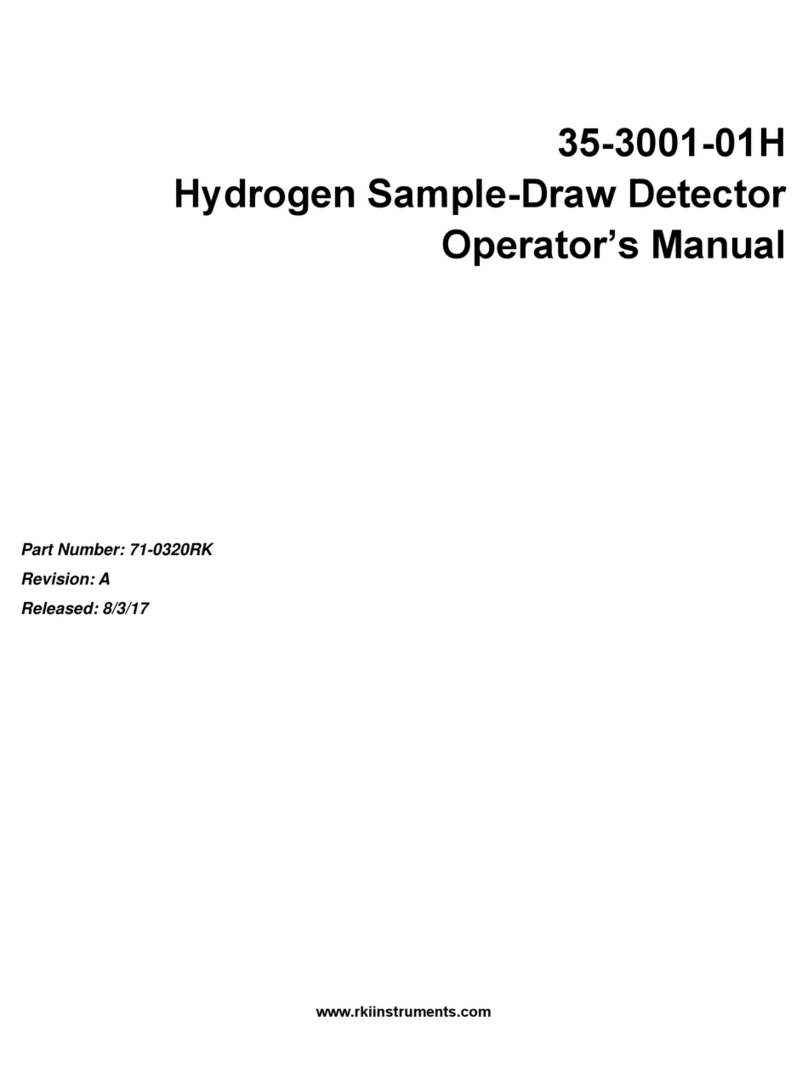

Mounting on unshielded cables Mounting on shielded cables

Isolated cables

11

SME2 - Manual - 10 - 2011

In order to ensure a linear response from the sensor, the cables must be positioned in the centre

of the transformer so that the magnetic effect of the three cables is perfectly compensated in the

absence of residual current (Correct installation).

Hence, the assembly indicated in the drawing (Improper installation), in which phase L3 causes local

magnetic saturation whereby the vectorial sum of the three currents would be non-null, should be

avoided.

The same considerations also apply when the sensor is positioned near bends in the cabling.

It is recommended that the transformer be placed away from bends in the conductors).

Electrical connections

Electrical connections must comply with the connection diagram shown on the inside of the SME2

panel cover; they include:

1) connection to the current sensors;

2) connection to the remote control unit;

3) connection to the capacitive dividers;

4) connections to the earth terminal.

1) Fit the connection cables to the Ct’s through the fair lead provided in the lower side of the case for

a minimum length of 20 cm. Connect the cables to MA terminal board; the operations are made easier

by the marks on the conductors and by the signatures print on the PCB.

2) As regards the connection to the remote control unit, the cable is supplied already abutted to the

MB terminal board.

3) The connection cable to voltage sensors (capacitive dividers) is supplied already abutted to the

MA terminal board, so you only have to connect the hexapolar plug to the relevant outlet (voltage

on lights).

4) Connect the case to earth and implement the earth node between current sensor return conduc-

tors (CT).

Final operations

After wiring, make sure that no bare parts off the components come in contact with the circuit. As

further precaution it is advisable to mechanically secure connection cables to the sensors, to ca-

pacitive dividers and to the remote control unit outside the SME2 panel, so as to prevent the cables

from exerting any stress on the terminals.

L1

L2 L3

L1

L2 L3

>3 D

Diameter D

CORRECT INSTALLATION IMPROPER INSTALLATION

L1

L2 L3

L1

L2 L3

>3 D

Diameter D

CORRECT INSTALLATION IMPROPER INSTALLATION

12 SME2 - Manual - 10 - 2011

6 COMMISSIONING

6 COMMISSIONING

For start up, apply the auxiliary power voltage fitting the connector in the remote control outlet.

Upon start up, all of the eight leds are controlled to light up for 1 s; afterwards, they turn off except

for led V4, V8, V12, if voltage on the corresponding phases is ON.

In order to check the device operation, it is possible to measure the current input of the auxiliary

power which, at rest conditions with voltage equal to the rated value of 24 V, must be within the

90 ... 130 mA range.

The settings must be made by Personal Computer with sw ThySetter

6.1 ThySetter

The ThySetter sw is a “browser” of data (setting, measure, etc..); it implements an engine that is

afford to rebuild the menu set up and the relationships to data concerning all Thytronic protective

relays by means of XML files.

Following operations are performed by means ThySetter:

Open-store of setting files;

ASCII or Excel export reports;

Open/close communication;

Send settings, read settings;

Firmware upgrades;

Session level selection and log enabling (log files);

After the device selection Thysetter allows to:

Set the relay reference data;

Read info, measures, etc... ;

Store settings.

ThySetter installation

The ThySetter sw is available free of charge; the latest version can be downloaded from site www.

thytronic.it (section PRODUCT/SOFTWARE APPLICATIONS/THY-SETTER/download area)

•

•

•

•

•

•

•

•

13

SME2 - Manual - 10 - 2011

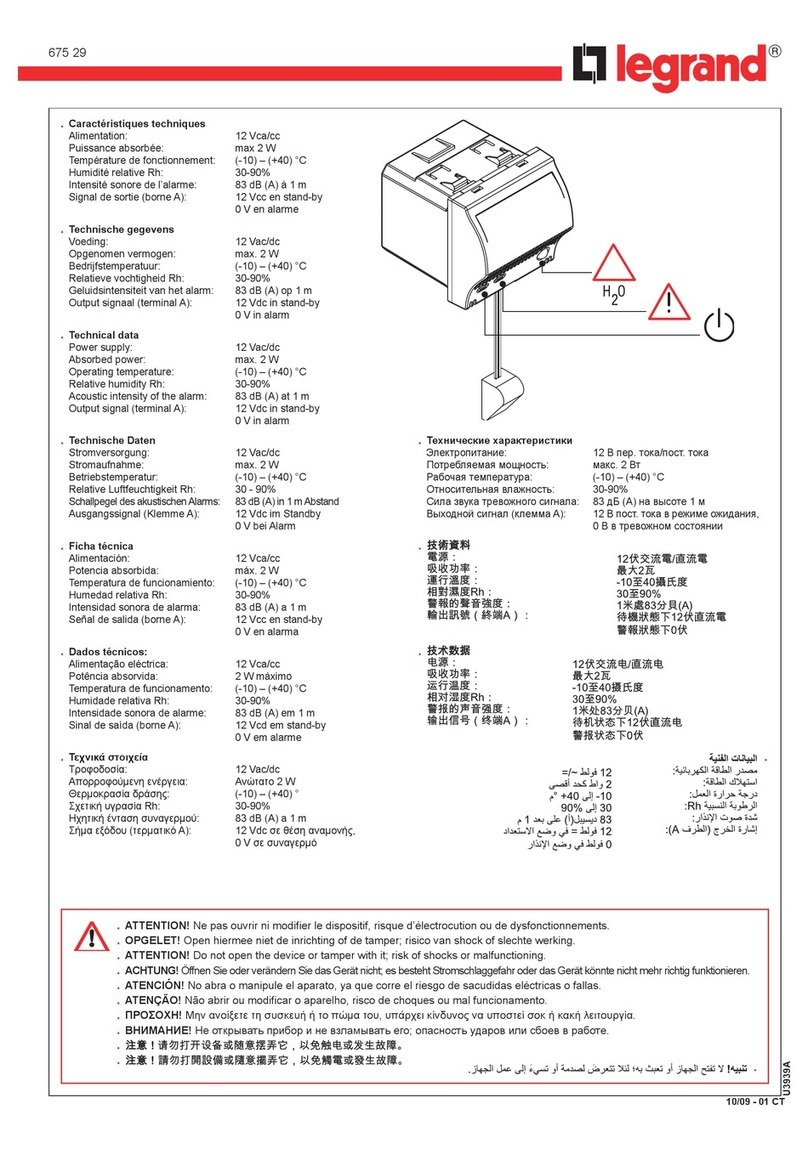

6.2 CONNECTION DIAGRAM

6.3 SME2 DEVICE

MB terminal block

to remote control unit

I> current sensor

I> current sensor

IE> current sensor

TRIP

capacitive

divider

normal direction

of power

MA terminal block

SME2

14 SME2 - Manual - 10 - 2011

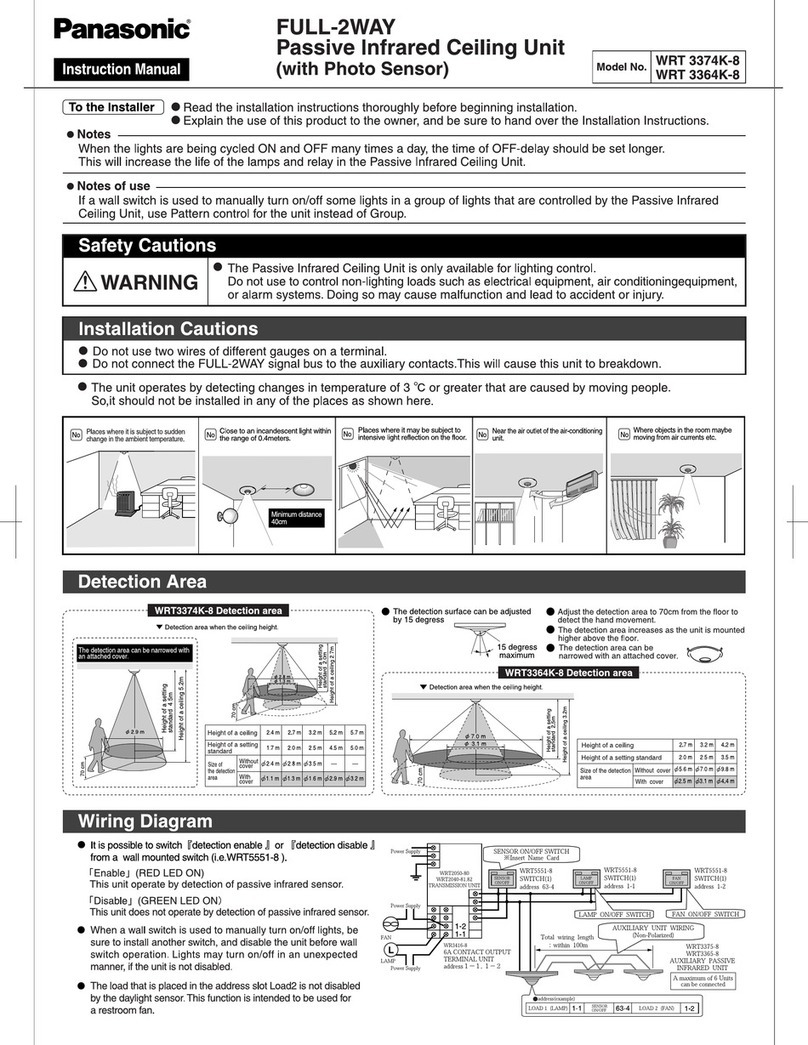

6.4 CURRENT SENSORS

188

86

83

Ø 150

Ø51

150

Ø5.5 Ø5.5

Ø5.5 Ø5.5

100

6.5 CUTOUT

Headquarters: 20139 Milano - Piazza Mistral, 7 - Tel. +39 02 574 957 01 ra - Fax +39 02 574 037 63

Factory: 35127 Padova - Z.I. Sud - Via dell’Artigianato, 48 - Tel. +39 049 894 770 1 ra - Fax +39 049 870 139 0

www.thytronic.it www.thytronic.com thytronic@thytronic.it

7 MAINTENANCE

7 MAINTENANCE

The SME2 relays do not require any particular maintenance; all circuits use high quality static com-

ponents, the subassembly products undergo dynamic checks on their functioning before the final

assembling of the complete equipment. The dedicated circuits and the firmware for the self-test

function continuously check the relay operation; the continuously operating auto-zeroing function

dynamically corrects the measuring errors due to offset, heat dependent drifts, aging of compo-

nents, etc.

The microprocessor is equipped with a watch-dog circuit which restores the correct operation of

the firmware in case of fault.

8 S T O R A G E

8 STORAGE

The SME2 devices must be stored within the required temperature limits; the relative humidity should

not cause condensation or formation of frost.

It is recommended that the devices are stored in their packaging; in the case of long storage, espe-

cially in extreme climatic conditions, it is recommended that the device is supplied with power for

some hours before the commissioning, in order to bring the circuits to the rating conditions and to

stabilize the operation of the components.

Table of contents

Other Thytronic Security Sensor manuals