Tidal Engineering Synergy Series User manual

Synergy Controller Technical Manual, Revision H

Nano, Micro 2, and Quattro

For One to Four Channel Systems

Tidal Engineering Corporation

2 Emery Ave

Randolph, NJ 07869

www.tidaleng.com

Document Number TE1813, Revision H: October 18, 2016

Synergy Controller Technical Manual, Revision H

Page 2

Revision History

Rev.

Date

Revision

C

June 16,2005

First Release

D5

June 27, 2006

Added revision page

Updated chapter numbering for sections 8.1.1, 9.7, 11.4

E

October 17, 2006

Updated for Synergy Controller application version 2.0.8.

Added for Synergy Micro 2 Controller configuration.

Updated Overlay and Web Touch Graphics.

Revised Software Upgrade instructions in section 7.

Added LCD Backlight CCFT Lamp Replacement instructions in section 7.

Updated command set Appendix C to 2.0.8 and added examples.

Add section on Macro capability and Bar Code Scanner application.

Added replacement parts list, Section 20 Appendix C.

General document review and edit.

Corrected error in “Analog Retransmit Connections Table”

Revised Output Mapping tables in section 6.10

Revised Synergy Controller Compact Interface Panel Layout figures

F

January 10, 2008

Updated for Synergy Controller application version 2.6.10.

Added UUT Module Mechanical Drawing

Added new section for User Programmable Alarm System.

Added 4-20 mA sensor wiring section.

Added Space and Altitude section

Added Altitude section in L Values for Altitude and Space Chamber Configuration.

Added LabVIEW driver section.

Added Deviation Alarm feature.

Added PID tuning guidelines

Added touch screen calibration for Micro unit

Simplified Olympic board schematic

Added Block Diagram

Added High and Low Res Event Screens

Added Input Calibration section

Added Retro Temperature Only Configuration

Add Safety section

Added USB Bar Code reader setup for Micro applications

Added Installation Section

Added bookmark hyperlinks to document

G

October 5, 2015

Updated for Synergy Controller application software version 3.0.7 Build 893.

Upgraded figures to show Synergy Micro 2 configuration.

Reorganized into 22 sections including 6 Appendices.

Added new section for e-mail features.

Added new section for network printing features.

Updated Space and Altitude section

Added Alarm feature enhancements.

Added touch screen calibration for Micro 2 unit

Simplified Olympic board schematic

Replaced CCFT Lamp replacement with LED upgrade procedure.

H

October 18, 2016

Unified Technical Manual Covers Synergy Controller Software and programming for all

three models: Synergy Micro 2, Synergy Quattro, Synergy Nano

Synergy Controller Technical Manual, Revision H

Page 3

Table of Contents

1.0 INTRODUCTION........................................................................................................................................7

1.1 What’s New.................................................................................................................................................8

1.2 Controller Configurations............................................................................................................................9

1.3 Company Information and Assistance......................................................................................................13

2.0 SPECIFICATIONS....................................................................................................................................14

2.1 Data Sheet................................................................................................................................................14

2.2 Block Diagrams.........................................................................................................................................15

2.1.1 Process Inputs.......................................................................................................................................17

2.1.2 Input Calibration and Scaling.................................................................................................................17

2.1.3 Channel Calibration...............................................................................................................................17

2.1.4 Channel PIDs.........................................................................................................................................17

2.1.5 Channel Primitives.................................................................................................................................17

2.1.6 Channel Setpoints .................................................................................................................................18

2.1.7 User Programmable Alarm System.......................................................................................................18

2.1.8 Logging System.....................................................................................................................................18

2.1.9 Analog Retransmit Outputs ...................................................................................................................18

3.0 APPLICATIONS........................................................................................................................................19

3.1 Environmental Test Chambers.................................................................................................................19

3.2 Process Ovens .........................................................................................................................................19

3.3 Thermal Platforms ....................................................................................................................................19

3.4 Chillers......................................................................................................................................................19

3.5 Other Equipment.......................................................................................................................................19

4.0 EQUIPMENT SAFETY AND CONTROLLER ALARMS...........................................................................20

4.1 Standard Alarm Limits ..............................................................................................................................20

4.2 User Programmable Alarm Limits.............................................................................................................20

4.3 Secondary Controller Alarms....................................................................................................................20

4.4 Alarm System Testing...............................................................................................................................20

4.5 Alarm Notifications....................................................................................................................................21

5.0 FRONT PANEL AND CONTROLS...........................................................................................................22

5.1 Front Panel Layout ...................................................................................................................................22

5.2 User Interface...........................................................................................................................................23

5.2.1 LCD Screen Touch Screen....................................................................................................................24

5.2.2 Function Keys........................................................................................................................................25

5.2.3 Keypads.................................................................................................................................................26

5.2.4 Screen Navigation Keys........................................................................................................................27

5.2.5 Navigating to a Screen Folder Path.......................................................................................................27

5.3 Screen Overview ........................................................................................................................................28

5.3.1 Setup Screen...........................................................................................................................................28

5.3.2 Maintenance Screen................................................................................................................................29

5.3.3 Comm Screen..........................................................................................................................................30

5.3.4 Program Screen.......................................................................................................................................31

5.3.5 Run Screen..............................................................................................................................................32

5.3.6 Events Screen .........................................................................................................................................33

5.3.7 Graph Screen ..........................................................................................................................................34

5.3.8 Main Screen.............................................................................................................................................35

6.0 SETUP SCREEN......................................................................................................................................37

6.1 Setup Folder Root Menu...........................................................................................................................37

6.2 Calibration.................................................................................................................................................38

6.2.1 Channel Calibration...............................................................................................................................38

6.2.2 Altitude Value.........................................................................................................................................41

Synergy Controller Technical Manual, Revision H

Page 4

6.2.3 Guaranteed Soak...................................................................................................................................41

6.2.4 Input Calibration.....................................................................................................................................41

6.2.5 Virtual Sensors ......................................................................................................................................44

6.3 PID Settings..............................................................................................................................................47

6.3.1 Heat and Cool........................................................................................................................................47

6.3.2 Cascade Control....................................................................................................................................48

6.4 Special Functions .....................................................................................................................................50

6.5 Settings List..............................................................................................................................................55

6.6 L – Values.................................................................................................................................................57

6.7 Logging.....................................................................................................................................................60

6.8 Chamber Setup.........................................................................................................................................67

6.9 Graph Settings..........................................................................................................................................69

6.10 LCD Settings...........................................................................................................................................69

6.11 Panel Lock..............................................................................................................................................69

6.12 Languages..............................................................................................................................................75

6.13 User Programmable Alarm System........................................................................................................75

6.14 Resume Behavior...................................................................................................................................90

6.15 Main Screen Setup.................................................................................................................................90

6.15.1 Channel Displays.................................................................................................................................90

6.15.2 Sensor Displays...................................................................................................................................92

6.15.3 Chamber Light.....................................................................................................................................93

6.16 Event Screen Setup................................................................................................................................94

7.0 MAINT SCREEN.......................................................................................................................................95

7.1 Operator Interface.....................................................................................................................................95

7.2 Alarm Functions........................................................................................................................................96

7.3 Channel PIDs..........................................................................................................................................101

7.4 About Screen..........................................................................................................................................102

7.5 File Utilities .............................................................................................................................................102

7.5.1 Software Upgrade Procedures............................................................................................................103

7.5.2 Export Screenshots .............................................................................................................................116

7.5.3 Logging................................................................................................................................................116

7.6 Date and Time........................................................................................................................................117

7.7 Restart ....................................................................................................................................................117

8.0 COMM SCREEN ....................................................................................................................................118

8.1 Communications Folder..........................................................................................................................118

8.2 RS-232....................................................................................................................................................118

8.3 RS-485....................................................................................................................................................119

8.4 IEEE 488 / GPIB.....................................................................................................................................119

8.5 Ethernet Network....................................................................................................................................119

8.5.1 Ethernet\IP Settings.............................................................................................................................120

8.5.2 WebTouch Remote ™.........................................................................................................................120

8.5.3 FTP Server ..........................................................................................................................................120

8.5.4 TCP/IP Server......................................................................................................................................121

8.5.5 E-Mail...................................................................................................................................................121

8.5.5.1 Ethernet Network\E-Mail\Setup........................................................................................................121

8.5.5.2 Ethernet Network\E-Mail\Addresses.................................................................................................122

8.5.6 Printer Setup........................................................................................................................................122

9.0 PROG SCREEN.....................................................................................................................................126

9.1 Loading a File from Storage Card or USB Hard Disk.............................................................................126

9.2 Creating a New Program........................................................................................................................127

9.3 Step Type Descriptions...........................................................................................................................130

9.4 Synergy Controller Program Sheet.........................................................................................................132

9.5 Copying, Editing and Deleting a Step.....................................................................................................133

9.6 Saving a Program...................................................................................................................................133

Synergy Controller Technical Manual, Revision H

Page 5

10.0 RUN SCREEN......................................................................................................................................134

10.1 Loading a Program...............................................................................................................................134

10.2 Program Control ...................................................................................................................................134

11.0 EVENTS SCREEN ...............................................................................................................................136

11.1 Event Outputs.......................................................................................................................................136

11.1.1 Event Outputs Setup..........................................................................................................................137

11.1.2 Humidity Channel Event Outputs ......................................................................................................137

11.1.3 Event Output Board Options..............................................................................................................138

11.1.4 Event Output Board Connections......................................................................................................139

11.2 UUT Temperatures...............................................................................................................................143

11.3 Digital Outputs......................................................................................................................................143

11.4 Digital Inputs.........................................................................................................................................144

11.5 High Resolution Analog Inputs.............................................................................................................145

11.6 Low Resolution Analog Inputs..............................................................................................................145

12.0 GRAPH SCREEN.................................................................................................................................146

12.1 Temperature / Humidity / Air Temperature...........................................................................................146

13.0 MAIN SCREEN.....................................................................................................................................147

13.1 Steady State Operation ........................................................................................................................147

13.1.1 Entering a set point............................................................................................................................147

13.1.2 Turn the chamber On..........................................................................................................................148

13.2 Main Screen Setup...............................................................................................................................148

13.2.1 Main Screen Graph Setup.................................................................................................................148

13.2.2 Chamber Light...................................................................................................................................149

13.2.3 Channel Text .....................................................................................................................................149

13.2.3 Sensor Displays.................................................................................................................................150

14.0 DATA ACQUISITION AND LOGGING.................................................................................................151

14.1 Data Logging Setup..............................................................................................................................151

14.1.1 “Deliver Test Results” Automatic Test Data Delivery..........................................................................154

14.1.2 Profile Logging.....................................................................................................................................158

14.1.3 Logging Commands.............................................................................................................................159

14.2 Logging Applications.............................................................................................................................160

14.2.1 Controller Tuning and Troubleshooting...............................................................................................160

14.3 Log File Format......................................................................................................................................163

14.4 UUT Thermocouple Data Acquisition Module Option...........................................................................167

14.4.1 Setup Procedure................................................................................................................................169

14.5 Alarm Logging........................................................................................................................................172

15.0 INSTALLATION AND TROUBLESHOOTING......................................................................................173

15.1 Installation Check List...........................................................................................................................173

15.2 Chamber Configuration Selection.........................................................................................................173

15.3 Controller Setup....................................................................................................................................173

15.4 Generic Chamber Types ......................................................................................................................174

15.4.1 Generic Temperature Only................................................................................................................175

15.4.2 Generic Temperature/Temperature, Dual Thermal Shock................................................................177

15.4.3 Generic Temperature/Humidity .........................................................................................................179

15.4.4 Generic Temperature/Humidity Single Stage....................................................................................181

15.4.5 Generic Temperature/Pressure, Altitude and Space.........................................................................183

15.4.6 Generic Temperature/Humidity/Pressure, Altitude............................................................................190

15.4.7 Generic Temperature/Vibration.........................................................................................................192

15.4.8 Retro Temperature Only....................................................................................................................194

15.5 Device Primitives and Logic Flow Charts.............................................................................................196

15.8 Alarm System Test ...............................................................................................................................209

15.9 Control System Verification..................................................................................................................209

Synergy Controller Technical Manual, Revision H

Page 6

15.10 Controller Splash Screen....................................................................................................................209

16.0 CONTROLLER TUNING AND CALIBRATION.....................................................................................210

16.1 PID Tuning............................................................................................................................................210

16.2 Cascade (Part) Temperature Control...................................................................................................214

16.2.1 Cascade Control Setup ......................................................................................................................215

16.2.2 Configuring Cascade Software...........................................................................................................216

16.2.3 Using Cascade Mode........................................................................................................................221

16.3 Two-Point Calibration ...........................................................................................................................224

16.4 End to End Calibration..........................................................................................................................225

16.5 Touch Screen Calibration.....................................................................................................................226

17.0 APPENDIX A COMMUNICATIONS ...................................................................................................228

17.1 Frequently Used Commands................................................................................................................228

17.2 Synergy Controller Command Set........................................................................................................229

17.3 Profile Creation and Control Commands..............................................................................................272

17.4 Software Applications and Networks....................................................................................................275

17.4.1 SimpleComm Communications Software..........................................................................................275

17.4.2 Synergy Manager, Chamber Control Software for Desktop PC........................................................285

17.4.3 Ethernet MAC Address......................................................................................................................293

18.0 APPENDIX B SETTINGS LIST ..........................................................................................................297

19.0 APPENDIX C DELIVERING RESULTS .............................................................................................304

19.1 Network Printing ...................................................................................................................................304

19.2 E-Mail Delivery......................................................................................................................................305

19.2.1 E-Mail Setup........................................................................................................................................307

19.2.2 E-mail Format......................................................................................................................................310

19.3 FTP Server Export................................................................................................................................311

19.4 USB Flash Drive Export........................................................................................................................313

19.5 Web Touch Remote™ - Synergy Controller Web Server.....................................................................314

19.6 FTP Server ...........................................................................................................................................318

19.7 LabVIEW ™ Driver ...............................................................................................................................319

19.8 SimpleComm Examples.......................................................................................................................325

20.0 APPENDIX D BAR CODE SCANNER SETUP..................................................................................328

20.1 Synergy Controller Macros...................................................................................................................328

20.2 Using a Bar Code Scanner with a Synergy Controller.........................................................................328

20.3 Bar Code Scanner Equipment...............................................................................................................328

20.4 Bar Code Scanner Installation...............................................................................................................329

20.5 Barcode Interface Specifications..........................................................................................................332

20.6 Controller Setup....................................................................................................................................332

20.7 Testing and Troubleshooting................................................................................................................335

21.0 APPENDIX E APPLICATION NOTE LIST..........................................................................................338

22.0 APPENDIX F PART NUMBERS.........................................................................................................339

22.1 Controllers ............................................................................................................................................339

22.2 Output Board Options...........................................................................................................................340

22.3 Software Options..................................................................................................................................341

22.4 Accessories ..........................................................................................................................................341

22.5 Spare Parts...........................................................................................................................................343

Synergy Controller Technical Manual, Revision H

Page 7

1.0 INTRODUCTION

Welcome to the Synergy Controller line of touch screen control systems designed and manufactured by Tidal

Engineering Corporation. Synergy Controllers incorporate the latest innovations in environmental test

chamber and process oven control and are designed to improve efficiency and simplify test programming

and documentation tasks.

The Synergy Micro 2 Controller employs features that maximize the capabilities of your test chamber. It is

designed to take complete command of the chamber’s conditioning systems with total programming of

process variables such as temperature and humidity versus time.

The Synergy Controller employs communication capabilities for the “Global Factory”, where data is gathered

from around the globe via the Internet; from around the factory floor via Ethernet; and from around the test

lab via IEEE 488, RS-485, and RS-232. In addition, these controllers feature: E-mail, FTP, HTTP (Web),

PDF plotting, and now Cloud resources.

One of the most powerful features of the Synergy Controller is the WebTouch Remote ™ Web Server which

permits control of the equipment from anywhere in the world using a standard web browser. To support

global deployment, the Synergy Controller can support multiple languages and employs built-in on-line Help

and Wizard systems.

The Synergy Controller utilizes Microsoft’s advanced Windows™ Embedded Compact operating system.

Windows Embedded Compact is a modular, state-of-the-art, multi-tasking, real-time system.It offers the

latest touch screen technology and incorporates Screen Navigation keys and a friendly and powerful user

interface.

The Synergy Controller supports USB Hard Disks for data logging, program download / upload. File format is

Windows™ compatible, and program, logging and calibration files can all be exchanged with the desktop.

File names are also Windows compatible so meaningful names can be used.

Eight Screen Navigation keys provide immediate access to all areas in the system; i.e. the controller is easily

switched between setup, programming, and diagnostic tasks. While entering information on one screen, you

can switch to another screen to view a setting or parameter, and then return to where you left off on the

previous screen. Navigation and control buttons on every screen permit easy access to chamber functions

and options. Color real-time data graphing displays important trend information and the versatility and the

simplicity built into the new Synergy Controller makes it enjoyable to operate.

The Synergy Controller software was first released in 2001 and has been steadily improved through a

continuous process. Numerous software versions have been released in an effort to improve the usability,

reliability and features of the controller. This manual refers to the features in the newest major upgrade of

the Synergy Controller application, version 3.0.7. Some of the features described in this manual were not

available in previous versions. Check the Tidal Engineering website (www.tidaleng.com) for information on

the latest version, the newest features, and upgrades.

We welcome feedback on the Synergy Controller and this document and appreciate suggestions for

improvements and new features. Thank you for choosing Tidal Engineering’s Synergy Controller.

Synergy Controller Technical Manual, Revision H

Page 8

1.1 What’s New

The latest software version, Version 3.0.7 Build 893x, offers some powerful new features and capabilities

including:

•E-mail

oAlarms

oLog Files

oPlots

•Network printing features.

oPDF plots

oPrint directly to a network printer.

•User alarms

oCustom alarms for pressure transducers, Basket jam

•Main screen layout features

oDisplay additional sensor values for user information

oChamber light switch

oToggle switch

oFont size options; Large, Medium, Small

oFTP Server

•New Output Primitive Types

oPWM – General purpose time proportioning output (Up to 8)

oON/OFF – Thermostatic Primitive. (Up to 8)

•Updated Help System

oSpanish Language

oEdited for clarity

•Graph

oImproved graph timing accuracy and resolution

oAdditional Graph Scaling features; Time Scale and Vertical Scale

•Events Screen

oNew parameter turns off Humidity events and displays 9 total User Events

oDisplay friendly event names like GN2 Purge or LN2 Enable

•Alarm Screen

oAlarm information enhanced; i.e. Alarm shows source of Digital Input DIN 1

•Improved Cascade Control Algorithm

oControl Boost Heat and Boost Cool explicitly

•Command Set

o200 new commands

•Logging Feature

oProfile Logging

oProfile log Auto-Removal

oExport file naming

oWarn when full

oStop logging or Overwrite option when full.

oAdded Header to all logs and settings that includes chamber information

oLogging PID Values, constants and variables

•Programming

oAdded Pause Step

oChange Setpoint while paused

oAdded a “Wait For Tolerance” Parameter for each channel.

oDisplay Program Name in the Title Bar of all screens

•Standard Alarms

oAdded Deviation Alarm Feature

oAdded Alarm Delay

oCustom Behavior capability

•Added Chamber Name feature to allow each chamber to be uniquely identified in chamber in logs & e-mails

•Virtual Sensors

oVirtual Pressure

oWet-Bulb/Dry Bulb

oVirtual Kft sensor for altitude chambers

•Remote Start Stop Feature controlled by assignable Digital Inputs

•Analog Programming for setpoints

•Added Resume Behavior options

•FTP Server

Appendix A, “Deliver Test Results with Synergy Controller” added to highlight the various ways the controller

can format and deliver test results.

Synergy Controller Technical Manual, Revision H

Page 9

1.2 Controller Configurations

This technical manual supports the Synergy Micro 2 and the legacy Synergy Micro and Synergy Micro V

configurations. In many cases the features of these configurations are identical.

The Synergy V and Synergy Compact configurations are supported by the prior technical manual (Rev F).

The unique features of each configuration are listed in the table below along with an icon for each. Features

that aren’t supported by all five configurations are identified in this document with the appropriate icons.

Type

Synergy Micro 2

Synergy Micro

Synergy Micro V

Synergy V

Synergy Compact

Icon

P/Ns

TE2174-3

TE1704-3

TE1704-5

TE1364

TE1530, TE1666

Processor

ARM

ARM

ARM

x86

x86

Floppy Drive

No

No

No

Yes

Yes

OS

5.0.E1

5.0

5.0

2.11 and 4.2

2.11 and 4.2

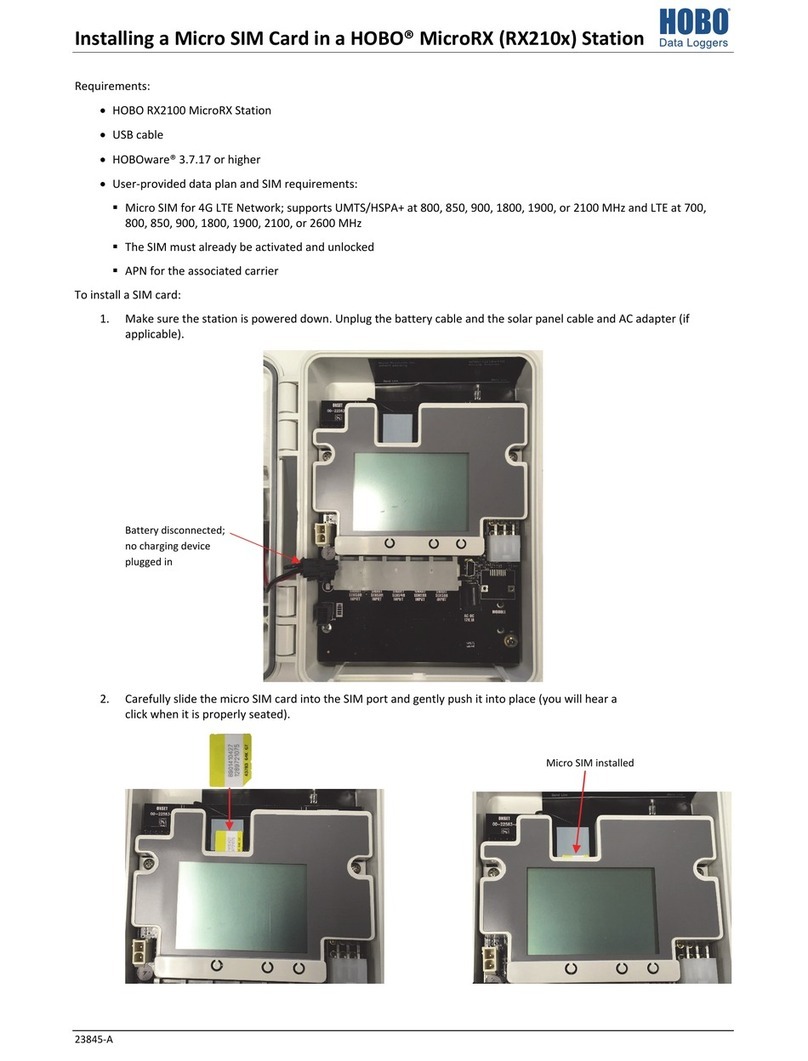

The following table shows each of the above configurations with the corresponding image.

Synergy Micro 2

P/N TE2174-3

Processor ARM

Floppy Drive: No

OS: P/N TE2144

Synergy Micro

P/N TE1704-3

Processor ARM

Floppy Drive: No

OS: P/N TE1860

Synergy Controller Technical Manual, Revision H

Page 10

The Synergy V and Synergy Compact configurations below are supported by prior technical manuals; Rev F.

Synergy Compact

P/N TE1666, TE1530

Processor: X86

Floppy Drive: Yes

OS: P/N TE1360

Synergy V

P/N TE1364

Processor: x86

Floppy Drive: Yes

OS: P/N TE1360

Synergy Micro 2 V

P/N TE2174-5

Processor Arm

Floppy Drive: No

OS: P/N TE2144

Synergy Controller Technical Manual, Revision H

Page 11

In addition to the full-sized Synergy Micro and Micro 2 Controllers, Tidal Engineering offers the more

economical Synergy Quattro and the compact ¼ DIN Synergy Nano.

The Synergy Nano is available in four different configurations.

Type

Synergy Nano 1

Synergy Nano 2

Synergy Nano 3

Synergy Nano +

Icon

P/Ns

TE1858-1

TE1858-2

TE1858-3

TE1858-4

Processor

ARM

ARM

ARM

ARM

Main Outputs

(6) Open Collector

(6) Electro-

Mechanical Relays

(6) SSRs

Solid State Relays

Expanded

Olympic Board

Aux Outputs

(6) Open Collector

(6) Open Collector

(6) Open Collector

Expanded

Olympic Board

Event Outputs

(6) Open Collector

(6) Open Collector

(6) Open Collector

Expanded

Olympic Board

Ethernet

10/100 BaseT

10/100 BaseT

10/100 BaseT

10/100 BaseT

OS

5.0

5.0

5.0

5.0

Synergy Quattro

P/N TE1961-3

Processor: ARM

Floppy Drive: No

OS: P/N TE2162

Synergy Controller Technical Manual, Revision H

Page 12

Chamber Type Applications

The Synergy Controller supports many different test chamber types including one, two, three and four

channel systems. These standard configurations are as follows:

♦Generic Temperature Only

♦Generic Temperature/Temperature (Thermal Shock Chambers)

♦Generic Temperature/Humidity

♦Generic Temperature/Humidity Single Stage

♦Generic Temperature/Pressure (Altitude and Space Chambers)

♦Generic Temperature/Humidity/Pressure

♦Generic Temperature/Humidity/Vibration (HALT/HASS Chambers)

♦Generic Temperature/Vibration (HALT/HASS Chambers)

♦Generic Pressure (Altitude and Space Chambers)

♦Retro Temperature Only

See section 6.10 for the specifics of each application.

Contact Tidal Engineering for custom configurations.

Synergy Controller Technical Manual, Revision H

Page 13

1.3Company Information and Assistance

Congratulations on purchasing the Synergy Controller designed and manufactured by Tidal Engineering.

Headquartered in Randolph, New Jersey, Tidal Engineering designs and manufactures embedded hardware

and software for test & measurement and data acquisition products. Tidal also provides engineering

services, custom electronic product development and provide turnkey distributed data acquisition and control

systems.

Tidal Engineering Corporation

2 Emery Ave

Randolph, NJ 07869

Tel: 973-328-1173

Fax: 973-328-2302

Email: support@tidaleng.com

Web Site: www.tidaleng.com

Please have the application version of your Synergy Controller available when contacting us.

Parts Replacement

The Synergy controller has been designed and manufactured to provide years of reliable service. In the

event a system should fail, only OEM approved parts should be used as replacements. A list of replacement

parts appears at the end of this manual. Please contact the Tidal Engineering for component replacement,

or repair.

Notice to Users

TIDAL ENGINEERING PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL

COMPONENTS IN LIFE-SUPPORT DEVICES OR SYSTEMS UNLESS A SPECIFIC WRITTEN

AGREEMENT REGARDING SUCH USE IS OBTAINED FROM TIDAL ENGINEERING PRIOR

TO USE.

Life-support devices or systems are devices or systems intended for surgical implantation into

the body or to sustain life, and whose failure to perform, when properly used in accordance with

instructions for use provided in the labeling and user’s manual, can be reasonably expected to

result in significant injury.

No complex software or hardware system is perfect. Bugs are always present in a system of any

size. In order to prevent danger to life or property, it is the responsibility of the system designer

to incorporate redundant protective mechanisms appropriate to the risk involved.

All Tidal Engineering products are 100 percent functionally tested. Additional testing may include visual

inspections. Specifications are based on characterization of tested sample units rather than testing over

temperature and voltage of each unit. Additional testing or burn-in of a system is available by special order.

Tidal Engineering reserves the right to make changes and improvements to its products without providing

notice.

TIDAL ENGINEERING IS A REGISTERED TRADEMARK OF TIDAL ENGINEERING CORPORATION

Synergy Controller Technical Manual, Revision H

Page 14

2.0 SPECIFICATIONS

2.1 Data Sheet

Synergy Controller Technical Manual, Revision H

Page 15

2.2 Block Diagrams

The Synergy Controller is a flexible multi-channel control system designed to handle virtually all temperature

control applications. The block diagram in the following section identifies the major systems of the controller

and their relationships. Two small block diagrams in the two sections following the main block diagram

identify each block diagram section and provide a description of each.

Synergy Controller Technical Manual, Revision H

Page 16

Synergy Controller Block Diagram

(2) RTD

Inputs

(4) High Res.

Analog

(8) Low Res.

Analog

(64) UUT

Inputs

Channel 1

Calibration

Channel 2

Calibration

Channel 3

Calibration

Channel 4

Calibration

Channel 1

PIDs

(30) Digital

Outputs

(2) Alarm

Relay

Outputs

(2) Analog

Outputs

Channel 2

PIDs

Channel 3

PIDs

Channel 4

PIDs

Channel

Primitives

User Alarm 1

User Alarm 2

User Alarm n

Logging Database

Selectable Log Interval, Log File Size, Etc.

Channel

Primitives

Channel

Primitives

Channel

Primitives

Channel

Primitives

Set Points

Touch Screen

Profile

Remote

Input

Calibration

and Scaling

User Alarm System

Primitives

Retransmit

Control

Synergy Controller Technical Manual, Revision H

Page 17

2.1.1 Process Inputs

The Synergy Controller has multiple inputs. (See detail above) These are listed in the table below.

Inputs

Channels

Application

RTD channels

2

Temperature Measurements

High Resolution

0-5VDC channels, 16-Bit

4

Humidity, temperature and other process

variables. 0.0001 Volt resolution

Low Resolution

0-5VDC channels, 10-Bit

8

For refrigeration pressure and process variables.

0.005 Volt resolution

UUT Temperature Inputs

T-Type Thermocouples

16 per Module

64 max

Temperature Measurements

Note: All of these inputs can be logged and checked using the user programmable alarm system.

2.1.2 Input Calibration and Scaling

Each Input can be calibrated for the physical measurement, Ohms, Volts or Degrees C.

Each Input can also be scaled to appropriate engineering units. (See the Calibration section)

2.1.3 Channel Calibration

Each Channel is assigned an input. In addition, channel data can be scaled and offset to accommodate

Channel errors caused by sensor position, thermal gradients, etc.

2.1.4 Channel PIDs

Each Channel has a set of PID constants and variables. Each channel implements a PID control algorithm

that determines its Heat and Cool outputs. The PID variables can be logged for documentation and tuning

purposes.

2.1.5 Channel Primitives

The channel primitives are the algorithms that control each output device such as fans, compressors,

heaters, etc. The Synergy Controller supports multiple instances of the same primitive. For example in the

thermal shock application there are two hot chambers and one cold chamber and thus uses two Heat output

primitives. Each primitive output is displayed in the Events/Digital Outputs folder.

2.1.1

Process

Inputs

2.1.2

Input Cal.and

Scaling

2.1.3

Channel

Calibration

2.1.4

Channel

PIDs

2.1.5

Channel

Primitives

Synergy Controller Technical Manual, Revision H

Page 18

2.1.6 Channel Setpoints

Each channel has a setpoint. The setpoint can be a steady-state value, a profile generated setpoint or a

remote setpoint from a computer or PLC.

2.1.7 User Programmable Alarm System

A user programmable alarm can be specified for one or more alarms using any input or channel value.

These alarms can be used for various purposes including chamber protection, unit-under-test protection, or

chamber control. See the user programmable alarm Section 6.14 for details.

2.1.8 Logging System

The logging system is used to capture test results and chamber performance data as well as alarm

conditions. The logging system can acquire data from any controller input, channel or PID output. See the

logging section 6.11 of the manual for detailed setup instructions.

2.1.9 Analog Retransmit Outputs

The Analog Retransmit Outputs can be used to retransmit process or control variables as a proportional

voltage to chart recorders or proportional control valves. There are two retransmit outputs. See Analog

Retransmits in the Special Function Section 6.4 for more details,

2.1.6

Channel

Setpoints

2.1.8

Logging

System

2.1.7

User Program.

Alarm System

2.1.9

Analog

Retransmit

Synergy Controller Technical Manual, Revision H

Page 19

3.0 APPLICATIONS

The Synergy Controller support s a variety of systems including environmental test chambers, process

ovens, thermal platforms, and chillers.

3.1 Environmental Test Chambers

The Synergy Controller series can handle a variety of standard and special environmental test chambers

including:

•Multiple Communications options

•WebTouch Remote ™ for remote control with any browser

•Cascade control loops

•Data logging and printing.

•Bar code reader features for error proof setup.

•Temperature Humidity Chambers

•Temperature Humidity Altitude Chambers

•Thermal Vacuum Ovens

•Thermal Vacuum Chambers (Space Simulation)

•HALT/HASS Chambers

•HAST Chambers

•Thermal Shock, 2 Zone and 3 Zone

3.2 Process Ovens

Cascade control loops, data logging and printing, and bar code reader features provide a lot of value in

process oven applications in manufacturing operations.

•Data logging and printing.

•E-mail alarms and chart data delivery

•Bar code reader features for error proof setup.

3.3 Thermal Platforms

Thermal platforms are used in testing applications where thermal conduction is the most efficient way to

control the test temperature of the Unit-Under-Test (UUT). These are popular in RF component testing

application as well as transducer applications. Controller features that add value in these applications are:

•Cascade control loops

•Multi-Channel capability for dual platform applications

•Data logging and printing.

•Bar code reader features for error proof setup.

3.4 Chillers

The remote control and remote sensing features of the Synergy Controller are beneficial in chiller

applications.

•Multiple Communications options; Ethernet and RS-232

•WebTouch Remote ™ for remote control with any browser

•Cascade control loops

•Data logging and printing.

•Bar code reader features for error proof setup.

3.5 Other Equipment

Plant growth chambers, Wind Tunnels, and food processing.

Synergy Controller Technical Manual, Revision H

Page 20

4.0 EQUIPMENT SAFETY AND CONTROLLER ALARMS

No complex software or hardware system is perfect. Defects are always present in a

software

system of any size. In order to prevent danger to life or property, it is the

responsibility of the system designer to incorporate redunda

nt protective mechanisms

appropriate to the risk involved.

Make sure you completely understand the operation and function of the chamber and the

Synergy Controller before you begin

using your test chamber.

Dangerous voltages are present in this eq

uipment. Disconnect electrical service of source

and tag circuit out before servicing or replacing components.

Do not use the Synergy Controller in any manner not specified in this manual. Improper use

may impair the safety features employed and

may void your test chamber and controller

warranty. Failure to follow the proper operating procedures listed throughout any of the

information provided could cause damage to your equipment, personal injury or death.

The Synergy Controller offers multiple built-in alarms to protect the equipment (test chamber, process oven,

thermal platform etc.) and the unit-under-test from conditions outside their ratings. The alarms should be

carefully set to appropriate limits based on the capabilities of the equipment and the safe limits of product

exposure. In addition to these built-in alarms, a secondary controller should always be employed to offer

further protection in the case of sensor or controller failure.

4.1 Standard Alarm Limits

The Synergy Controller features standard high and low absolute limits and high and low deviations limits for

each channel. Look for the alarms in the setup folder for each channel in section 6.2 under

SETUP/Calibration/Channel 1, 2, etc.

4.2 User Programmable Alarm Limits

In addition to the standard alarm limits, the Programmable User Alarm System can provide additional

protection against open or failed sensors and process variable outside expected limits. User alarms can be

created using redundant sensors for any channel and provide shut down protection to reduce the probability

of machinery failure. See section 6.14.

4.3 Secondary Controller Alarms

Redundant protective mechanisms such as a TempGard limit controller should be used to provide complete

protection against controller and/or sensor failure. When used with a separate sensor, secondary alarm

controllers reduce the probability that a single point failure will cause damage to the chamber or to the

product inside. The secondary controller should be wired to remove power from all of the chamber’s

machinery in order to provide maximum protection.

4.4 Alarm System Testing

It is important that users periodically verify all alarm systems by test. As a minimum, it is important to confirm

that chamber shut down occurs and power is removed from heaters, compressor, etc. when standard alarm

limits, user programmable alarm limits and secondary controller limits are reached.

This manual suits for next models

10

Table of contents

Popular Data Logger manuals by other brands

MadgeTech

MadgeTech Logicbus Temp1000Ex Product user guide

MadgeTech

MadgeTech QuadTCTempV2 Product user guide

Inductosense

Inductosense WAND user manual

GHM

GHM Delta OHM HD33MT.4 operating manual

Endress+Hauser

Endress+Hauser Tankvision Multi Scan NXA83B operating instructions

National Instruments

National Instruments NI 781 R Series user manual