Timberwolf PTO/300H User manual

Other Timberwolf Chipper manuals

Timberwolf

Timberwolf TW 280TDHB User manual

Timberwolf

Timberwolf PTO 100G User manual

Timberwolf

Timberwolf TW 190TFTR User manual

Timberwolf

Timberwolf TW 18/100G User manual

Timberwolf

Timberwolf TW 280TFTR User manual

Timberwolf

Timberwolf TW 280FTR (Petrol) User manual

Timberwolf

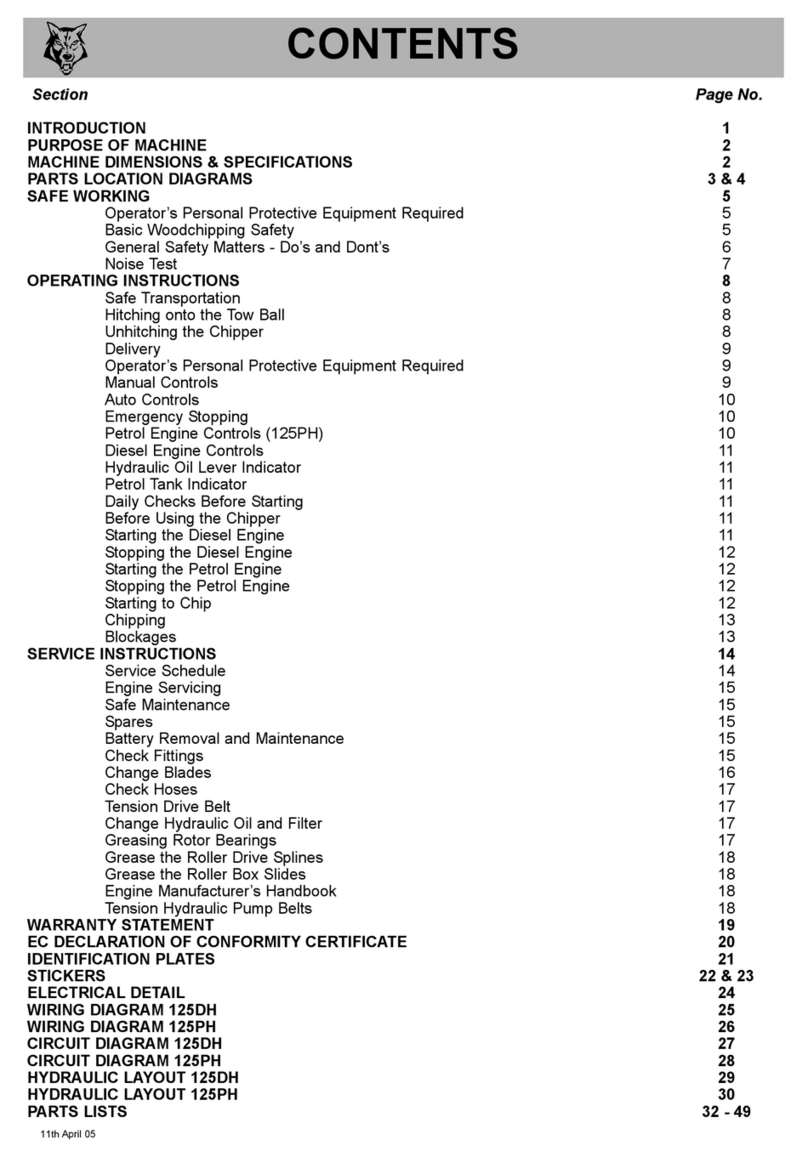

Timberwolf 125PH User manual

Timberwolf

Timberwolf TW PTO/100G User manual

Timberwolf

Timberwolf TW 18/100G User manual

Timberwolf

Timberwolf TW 280TVGTR User manual

Timberwolf

Timberwolf TW 230HB (Diesel) User manual

Timberwolf

Timberwolf TW 18/100G User manual

Timberwolf

Timberwolf TW 190TVGTR User manual

Timberwolf

Timberwolf tw pto 150h User manual

Timberwolf

Timberwolf PTO/300H User manual

Timberwolf

Timberwolf TW 13/75G User manual

Timberwolf

Timberwolf TW190TDHB User manual

Timberwolf

Timberwolf TW 230DHB User manual

Timberwolf

Timberwolf TW150FTR User manual

Timberwolf

Timberwolf tw pto 150h User manual

Popular Chipper manuals by other brands

Value Leader

Value Leader z9400 Assembly, operation and parts manual

Salsco

Salsco 600PTO Operator and parts manual

Cub Cadet

Cub Cadet 24A-424M710 Operator's manual

Champion

Champion 91050 Owner's Manual and Operating Instructions

Kellfri

Kellfri 13-WC17H2 operating instructions

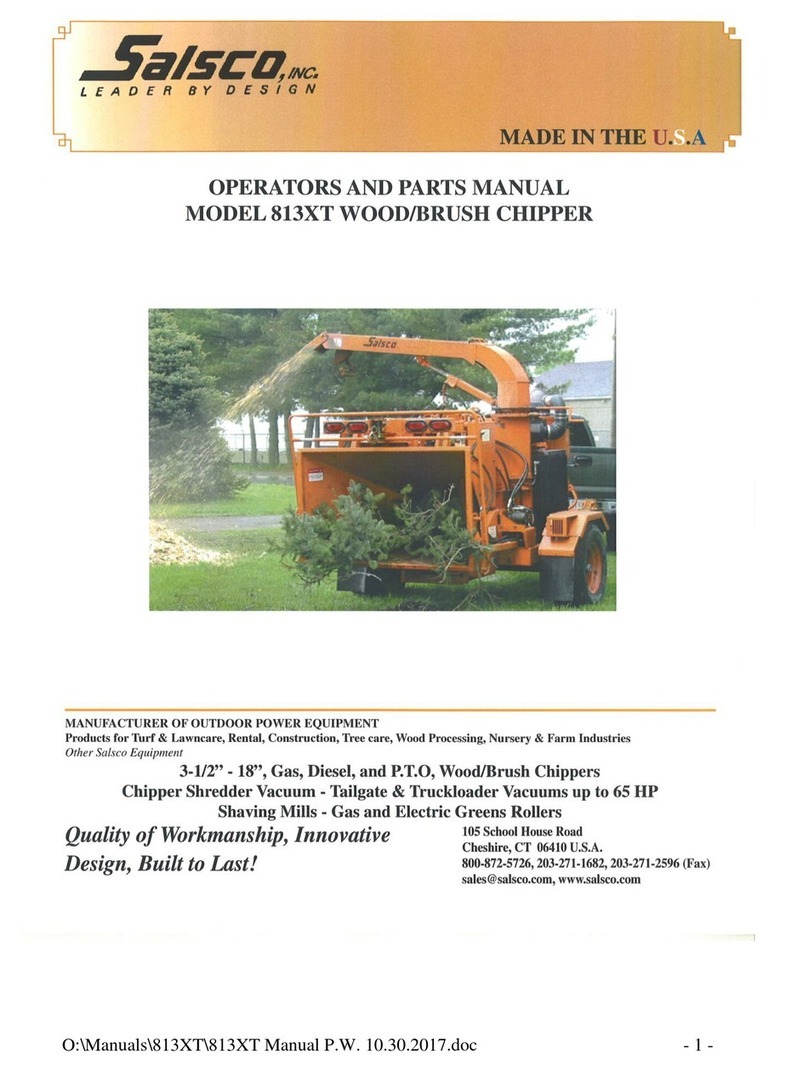

Salsco

Salsco 813XT Operator and parts manual