4

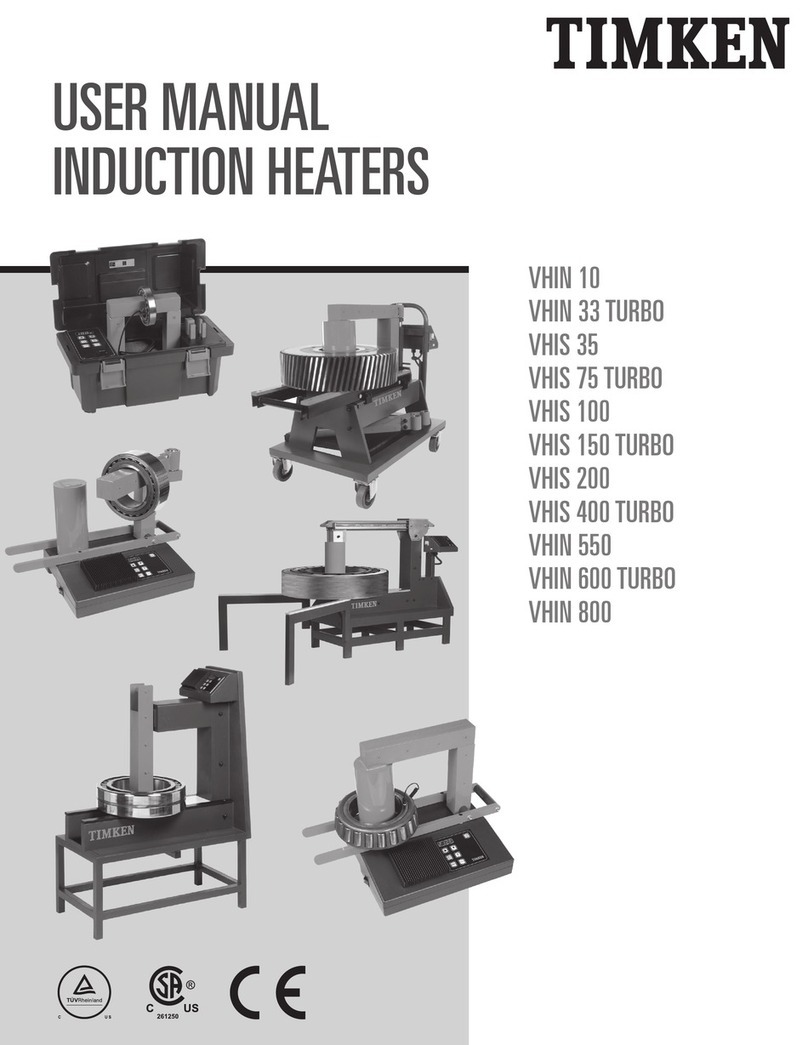

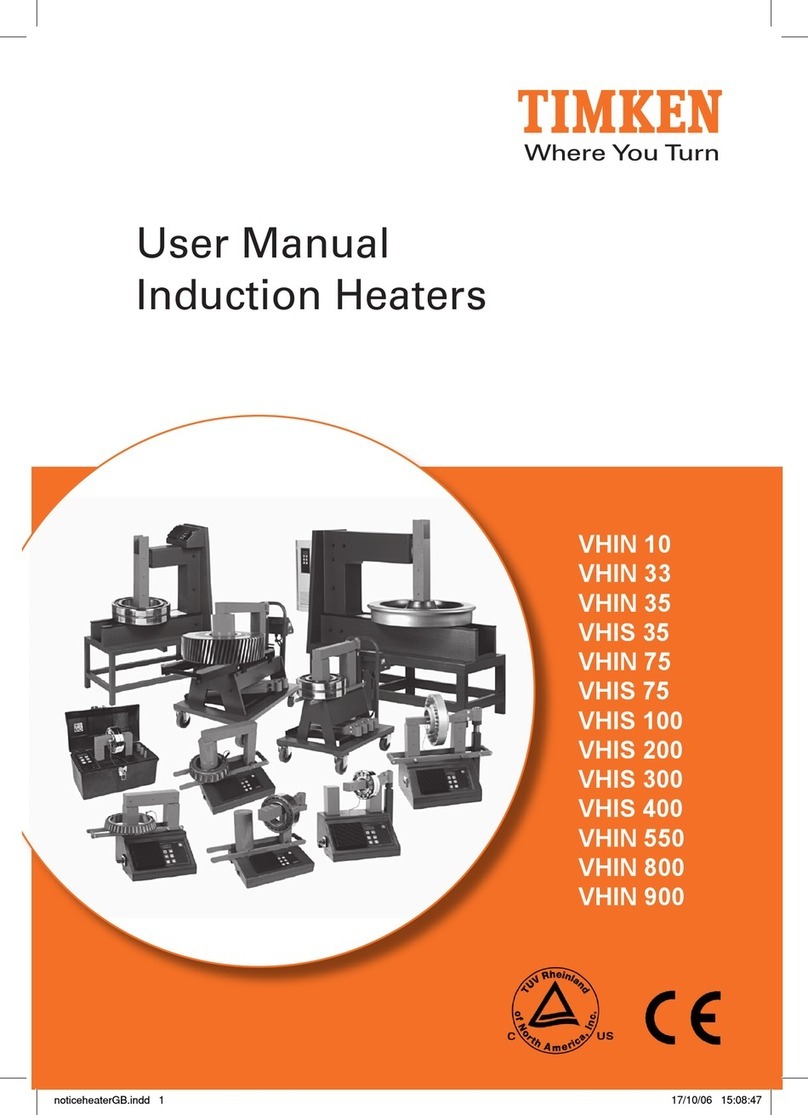

CONTENTS

Foreword ......................................................................................................................................................... 5

1. About the user manual ............................................................................................................................. 5

1.1 Availability .......................................................................................................................................................................................... 5

1.2 Legal guidelines .............................................................................................................................................................................. 5

1.3 Original user manual...................................................................................................................................................................... 5

2. Safety, warnings and potential hazards ................................................................................................ 6

2.1 Explanation of the pictograms ................................................................................................................................................. 6

2.2 Description of potential hazards ............................................................................................................................................. 7

2.3 Safety measures to be taken ..................................................................................................................................................... 9

2.4 Safety provisions .......................................................................................................................................................................... 10

3. Introduction ............................................................................................................................................. 11

3.1 Application....................................................................................................................................................................................... 11

3.2 Operating conditions ................................................................................................................................................................ 11

3.3 Principle of operation ................................................................................................................................................................. 11

4. Installation................................................................................................................................................ 12

5. Explanation of display and keys ........................................................................................................... 13

6.The magnetic temperature sensor ....................................................................................................... 14

7. Method of operation............................................................................................................................... 15

7.1 Heating a hanging workpiece ............................................................................................................................................... 16

7.2 Heating a horizontal workpiece............................................................................................................................................ 17

7.3 Maximum weights ....................................................................................................................................................................... 17

8. Operation.................................................................................................................................................. 18

8.1 Heating in temperature mode (default setting)........................................................................................................... 18

8.2 Heating in time mode ................................................................................................................................................................ 19

8.3 Workpiece installation................................................................................................................................................................ 19

8.4 Error message ................................................................................................................................................................................. 19

8.5 Switching between Celsius and Fahrenheit ................................................................................................................... 19

9. Cleaning, maintenance and troubleshooting .................................................................................... 20

10.Technical data and accessories ........................................................................................................... 22

10.1 Technical specication VHIN-G2-10 - VHIS-G2-150 .................................................................................................. 22

10.2 Technical specication VHIS-G2-200 - VHIN-G2-800 ............................................................................................... 23

10.3 Machine ID and certication ................................................................................................................................................ 24

10.4 Yokes ................................................................................................................................................................................................. 26

10.5 Scope of delivery ........................................................................................................................................................................ 27

11. Disclaimer ............................................................................................................................................... 28

12. Waste disposal ...................................................................................................................................... 28

13. Certicate of conformity ...................................................................................................................... 29

ENGLISH