Tippkemper-Matrix Tippkemper LBS-235 SIL2 Series Installation instructions

ISO 9001:2008 / ATEX

Original Operating Manual:

Light Barriers series LBS/LBN/LBD-235-SHS/SDI/EHS(-OP)-SIL2

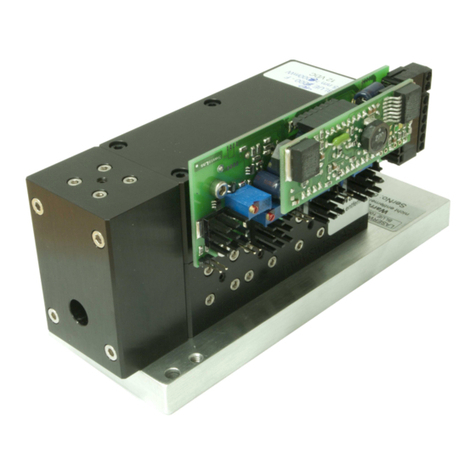

LBD-235-SHS/SDI/EHS-OP-SIL2 Housing M18 LBN-235-SHS/SDI/EHS-OP-SIL2

Page 1 of 2

•High penetration capacity in polluted areas.

•Optimal alignment by status visualization trough receiver optic

•Series LBD: ATEX and IECEx certified

•LBD: For use in Ex zones (0), 1, 2, (20), 21, 22

optical radiation can operate into Ex Zones 0, 20

•LBN: For use in Ex zones 2, 22

•Robust light barrier for industrial applications

0158

II 2(1)G

II 2(1)D II 3G Ex nA op is IIB T4 Gc

II 3D Ex tc op is IIIA T135°C Dc IP67

IECEx marking

Ex d [op is Ga] IIC T6 Gb

Ex tb [op is Da] IIIB T100°C Db IP67

IECEx BVS 14.0108X

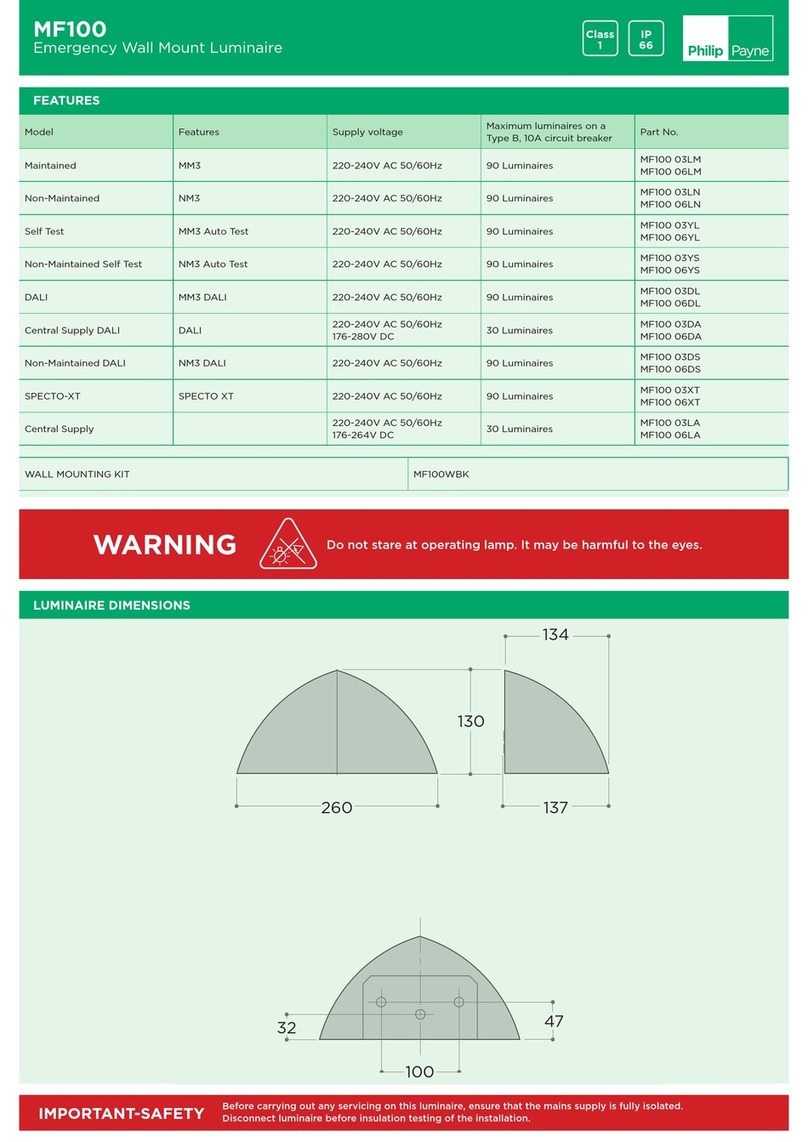

Type designation emitter, standard LBS-235-SHS-SIL2 LBN-235-SHS-OP-SIL2 LBD-235-SHS-OP-SIL2

Type designation emitter, with disable input "DI" LBS-235-SDI-SIL2 LBN-235-SDI-OP-SIL2 LBD-235-SDI-OP-SIL2

Technical Data Type designation receiver LBS-235-EHS-SIL2 LBN-235-EHS-OP-SIL2 LBD-235-EHS-OP-SIL2

Type of Ex protection Gas, according to 2014/34/EU NONE II 3G Ex nA op is IIB T4 Gc II 2(1)G Ex d [op is Ga] IIC T6 Gb

Type of Ex protection Dust, according to 2014/34/EU NONE II 3D Ex tc op is IIIA II 2(1)D Ex tb [op is Da] IIIB

T135°C Dc IP67 T100°C Db IP67

For use in Ex zones NONE Zones 2, 22 Zones (0), 1, 2, (20), 21, 22

Performance Level (PL) PL C, according to EN 13849-1

Safety Integrity Level (SIL) SIL 2, according to EN 61508

Mean probability of a dangerous failure per hour PFHd 2.06 x 10-6, at 13849-1 (without PELV power supply)

Sensingrange 120m

Minimum detectable object size 12mm (avoid mirror effects)

Light source Infrared 870nm

Maximum radiant intensity NOTLIMITED <=5mWm2<=5mWm2

Maximumradiantpower NOTLIMITED < 35mW < 15mW

Optical angle of aperture (at a distance of 10m) Emitter: appr.30° / Receiver: appr.25°

Response time 5ms (Switch off time)

Power up delay time 300ms

Supply voltage 24 VDC +-10% (Power supply type PELV at EN 60204, item 6.4.2)

Absolute maximum supply voltage Um 30VDC

Current consumption, emitter 60mA

Current consumption, receiver 40mA

Maximum power dissipation Emitter: max. 1.6W / Receiver: 1.1W

Output PNP type, double guided, 100mA, short circuit protected

Permissible line resistance between device and load 10R

Pollution indication output "VA" PNP type, single guided, 100mA, short circuit protected

Emitter disable (test) input SDI, optional PNP compatible

Housing M18, brass Ms 58, nickel plated

Enclosure rating, in accordance with EN 60529 IP 65 IP 67 IP67

Ambient working temperature range Tamb 0°C up to +50°C

Storagetemperature range -20°C ... +70°C

Relative humidity 15% ... 90%, noncondensing

Vibration and shock resistance Vibration: 30g over 20Hz to 2kHz. Shock: 100g for 3ms

Pollution degree, in accordance with EN 60664-1:2007 4

Device designation, in accordance with EN 60947-5-2 LBS/LBN/LBD-235-***(-OP)-SIL2: T3A30BP1 / LBS/LBN-235-***(-OP)-SIL2--S099: T3A30BP2

Connection cable TPU insulation, AWM 20236, 2/3/4+PE x 0.5mm2, shielded,

leads numbering marked, oil resistant cable for trailing, length: 10m

Socket M12, only types LBS/LBN-235-(OP)-SIL2-S099 Socket , Lumberg RSFM 5, 5 pins

Accessories, all types, included - 4xnuts M18 (or optional 2x clamps, on request)

Accessories, only LBN-235-***-SIL2-S099, included - 1xSafety lock device, mount at the cable connection, for locking the connection.

- 1xWarning plate "Do not open/close when supply voltage connected",

self-sealing, for gluing on the cable connector.

- 1xProtection cap for the sensor socket.

Accessories, only LBN-235-***-SIL2-S099, not included - Single ended cordset, types RKTS 5-298/xx or RKWTH 5-298/xx, Lumberg

Options - LBS/LBN/LBD-235-***(-OP)-SIL2-S094: Lenses special luted

- LBS/LBN-235-***(-OP)-SIL2-S099: With socket M12, 5 pins

- LBS/LBN/LBD-235-SDI(-OP)-SIL2: Emitter with disable input DI

- Cable length: Up to 100m, on request

Light beam free

LED's shows yellow or green

Light beam interrupted

LED's shows red

LED display and

output function

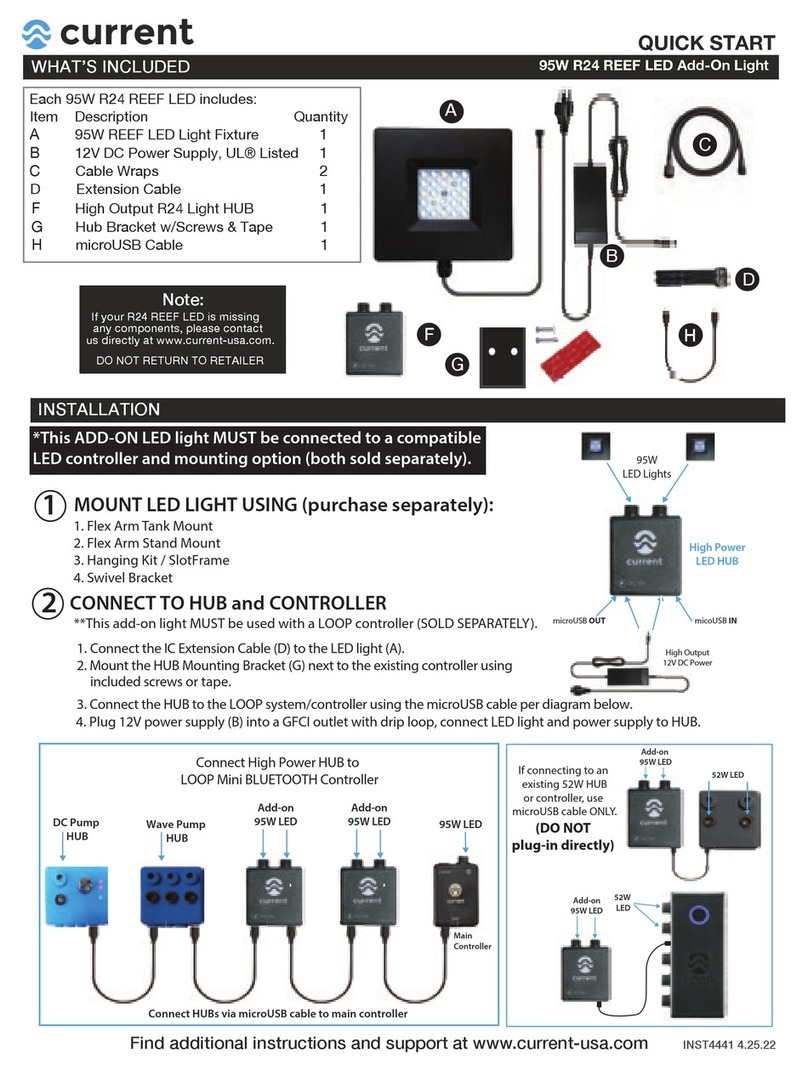

Output function and wiring diagram (cable):

Receiver: Emitter:

1: =+24VDC 1: =+24VDC

2: = 0V 2: = 0V

3: = Output 3: =SDI,optional

4: = Pollution indication output "VA"

(Cable shields, connect to PE)

For connector types, see on page 2 of this operating

manual

Channel1

Channel2

+24VDC

Output

0V

+24VDC

Output

0V

PNP=ON

PNP=OFF Channel1

PNP=ON

PNP=OFF Channel2

Alignment and controlling by LED display

(Status visualization trough receiver optic and LED at the

rearside of the receiver)

LED red: Light beam interrupted / not aligned

LED yellow: Polluted lenses / badaligned

LED green: Light beam free / wellaligned

Function pollution indication output "VA" Output VA = 0V (LED's shows red) Output VA =24V if LED's shows yellow

Visible red light source

through the emitter

lens

EX related markings CE0158 Manufacturerwithaddress

TypesLBD: Exd [opisGa]IICT6Gb, Extb[opisDa]IIIBT100°CDbIP67

TypesLBN: II 3GExnAopisIIBT4Gc, II3DExtcopisIIIAT135°CDcIP67

TypesLBD: ATEXcertification No:BVS10ATEXE130XDEKRA

TypesLBD: IECExcertification IECEx BVS14.0108X

TypesLBN: ATEXdeclarationbymanufacturer inaccordancewiththeATEXdirective2014/34/EU

Tamb: 0°C < Tamb < +50°C Electricaldataaccordingtothetable"Technicaldata"

Dateofproduction: Numerals5to8oftheserialnumber(Year/calendarweek)

(Xdesignationofthecertificationnumber:Fibreopticsmustonlybeusedwithsensorswithcertificatedlimitedopticalpower)

LBD-235-OP-SIL2-IECEX_e2,2016-09-19/HB

Matrix Elektronik AG (Manufacturer) Tippkemper - Matrix GmbH

Kirchweg24 CH-542OEhrendingen MeegenerStr.43 D-51491 Overath

Tel.:+41 56 20400-20 Fax -29 Tel.:+49 2206 9566-0 Fax -19

Page 2 of 2

Safe equipotential Bonding

for Ex Devices:

to use light barriers with emitters with disable input. By using the disable input

DI, each emitter can be controlled in a short reaction time. If only one emitter

is activated in the same time, a mutual influence is precluded.

DI= 0V or not connected = emitter enabled

DI= High (24VDC) = emitter disabled

The Disable Input SDI must be activated for >= 15ms. The SDI input is PNP

compatible. The Emitter-Disable-Input DI can also be used for testing the

associated receiver. By a short-time shut-off of the emitter, the switching

off of the receiver output and with it the correct function of the receiver will

be checked.

Alignment of the Light Barrier:

The three color indication in the receiver optic allows an optimal alignment.

1. The emitter must be aligned this way, that the emitter lens is fully illuminated

(By watching from the receiver at the emitter).

2. The receiver should be moved, until the LED (from the receiver) shows

"green". Search the middle of the green range.

Maintenance:

No special maintenance is required. If the lenses becomes dirty, they should

be cleaned with a non-aggressive solvents. Equipment must only be repaired

by the manufacturer.

General safety instructions:

The operating manual provide the machine manufacturer’s or machine

operator’s technical personnel instructions on the safe mounting, configu-

ration, electrical installation, commissioning, and on the operation and

maintenance of the light barrier. Please read the operating instructions

carefully. Types: LBN-235-SHS/SDI-OP-SIL2-S099, LBN-235-EHS-OP-

SIL2-S099: : "WARNING - EXPLOSION HAZARD - WHEN IN HAZARD-

OUS LOCATIONS, TURN OFF POWER BEFORE REPLACING OR

WIRING MODULES. DO NOT DISCONNECT EQUIPMENT UNLESS

POWER HAS BEEN SWITCHED OFF OR THE AREA IS KNOWN

TO BE NONHAZARDOUS". The mounting of the sensor in dusty locations

without fixed cordset or protection cap results in a high ignition risk. In worst

case of breakdown, the output can change to any state! When installing

and operating with the sensor, it is necessary to take into consideration

the relevant international and other national regulations: EN 60079-14,

ATEX 118a, single directive 1999/92/EC. The sensors are conform to the

following standards:

IEC/EN 60079-0:2012 + A11:2013, IEC/EN 60079-1:2007, EN 60079-

15:2010, IEC/EN 60079-28:2007, IEC/EN 60079-31:2010, EN 13849-1:2008,

EN 61508-3:2010, EN 61326-3:2008, EN 60204-1:2005, EN 60529:2014,

EN 60950-1:2006; EN 61000-4-2 to EN 61000-4-6, EN 61000-6-1/-2, EN

61000-6-4, ATEX directive: 2014/34/EU, Machine directive: 2006/42/EC,

EMC directive: 2014/30/EU, RoHS directive: 2011/65/EU.

General Notes, disposal:

We reserve the right to modify our equipment. Our equipment is designed

such way, that it has the least possible adverse effect on the environment.

It neither emit or contain any damaging or siliconized substances and use

a minimum of energy and resources. No longer usable or irreparable units

must be disposed of in accordance with local waste disposal regulations.

EU-Declaration of conformity:

IECEx certification, types LBD: Ex d [op is Ga] IIC T6 Gb, Ex tb [op is Da]

IIIB T100°C Db IP67. Certification No. IECEx BVS 14.0108X.

http://iecex.iec.ch/iecex/iecexweb.nsf/0/FE79714C0BAEF6F5C1257D7E0044F6A9?opendocument

ATEX certification, types LBD: II 2(1)G Ex d [op is Ga] IIC T6 Gb, II 2(1)D

Ex tb [op is Da] IIIB T100°C Db IP67. Certification No. BVS 10 ATEX E 130

X, DEKRA EXAM GmbH, Zertifizierungsstelle, Carl-Beyling-Haus,

Dinendahlstrasse 9, D-44809 Bochum, Kennnummer: 0158.

ATEX certification, types LBN: II 3G Ex d op is IIB T4 Gc, II 3D Ex tc op

is IIIA T135°C Dc IP67. ATEX declaration by manufacturer in accordance

to the ATEX directive 2014/34/EU. ATEX certification of quality type

production of Ex devices in accordance to the directive 2014/34/EU, CE

0158. Certification No: BVS 12 ATEX ZQS / E118. The conformity of the

devices with the EC standards and directives and the EC-type examination

certificate and the observation of the Quality Safety System ISO

9001:2008 with the ATEX module "Production", declares:

Hans Bracher, Matrix Elektronik AG

Correct use

The barrier is a non-separating protective device at machinery directive

2006/42/EC. It must not be possible to start the machinery/system as

long as personnel are within the hazardous area. The double guided output

is only switched ON, when the light beam is not interrupted. The light

barriers are composed of an emitter and a receiver device only of the

same type. The types must not be mixed. The light barriers must only

be operated with post-switched emergency-stop devices or program-

mable safety devices. All relevant standards and directives for the

complete system or machinery, for performance level Plc, at EN ISO

13849-1, must be observed. The applicant is responsible to realize a

restart interlock at the machinery if requisite. This can be realized with

a with an external equipment. All warranty claims against Matrix Elektronik

AG are forfeited in the case of any other use, or alterations being made

to the system – even as part of their mounting or installation.

General prescriptions for all Ex devices:

It is necessary to take into consideration the valid international and national

rules and regulations (EN 60079-14). The maximum input voltage Um=30VDC

must not be exceeded. The local equipotential bonding have to be done.

The protective earth (PE) terminal is solid connected with the housing. The

cable have to be protected against damages. The cable with termination

fittings, or in cable tray systems and installed in a manner to avoid tensile

stress at the termination fittings. To connect cables inside hazardous

locations only use certificated Ex housings. All cable terminals must be

connected outside hazardous locations. Use only original manufactured

fibre optics and additional optical lenses, other additional optical lenses

are not allowed in hazardous locations.

Emitter: LBD-235-SHS/SDI-OP-SIL2, Receiver: LBD-235-EHS-OP-SIL2:

Applicable in Ex zones 1, 2, 21, 22. The limited optical radiation can operate

into hazardous locations 0 or 20 over certificated fibre optics or through

a viewing glass.

Emitter: LBN-235-SHS/SDI-OP-SIL2, Receiver: LBN-235-EHS-OP-SIL2:

Applicable only in Ex zones 2, 22.

Emitter: LBN-235-SHS/SDI-OP-SIL2-S099, Receiver: LBN-235-EHS-

OP-SIL2-S099: Applicable only in Ex zones 2, 22. WARNING! Do not

separate the connector when the supply voltage is connected to the cable.

When installing the sensor, the safety lock device must be fitted at the

cable connector. The additional adhesive warning label must be fixed

to the connector housing at the connection cable. Lumberg cordsets RKTS

5-298/xx (Straight type) or RKWTH 5-298/xx (Right angle type) are allowed

ONLY. It is necessary to take into consideration the mounting prescription

of the connector manufacturer. In dusty locations, the socket protection

cap must be fitted, when the connection cable is not connected.

General mounting prescriptions:

Do not exceed the maximum ratings. The electrical connections must be

exactly as shown in the connection diagram. The cable shield must be

connected short. The cable shield should be connected to the protection

earth, large-surfaced. Connection cables must not be installed parallel to

high voltage cables.

Function

If the light beam is not interrupted the output switches to ON (+24V). If

the light beam is interrupted the output switches to OFF. (The output is

built by 2 different PNP transistors, wired in series). The light barrier LBx-

235 works with two different light sources, visible red light and infrared. The

high density and the two different wavelengths gives a high penetration

capacity at a heavy polluted ambiance. The load (Relay or other loads) must

be connected at " - " (minus). Because the emitters has a very high optical

power, it's to avoid mirroring effects at the background, when not all

receivers are located at the same side.

Pollution indication output "VA"

The VA output will be activated by polluted lenses or a bad alignment. If

the lenses are polluted, the LED shows yellow and the VA output switches

to ON (+24V). This function gives the possibility to recognize pollutions

in a short time.

Arrangement of light barriers, types LB*-235-SDI(-OP)-SIL2 (op-

tional): If several light barriers are installed close to another, it is necessary

OperatingManual, EU-DeclarationofConformity:

The cable shield is to connect to PE in

a wide area.

12345678901234567890

12345678901234567890

12345678901234567890

12345678901234567890

12345678901234567890

12345678901234567890

12345678901234567890

1234567890123456789012345678901212345678901234567890123456789012123456

1234567890123456789012345678901212345678901234567890123456789012123456

1

1

1

1

1

1

1

1

1

1

1

1

1

123456

123456

12

12

12

12

12

123

1

The end of the cable must be connected

outside the hazardous locations.

Check the reliable, noncorrosive holding of

the protection earth connection.

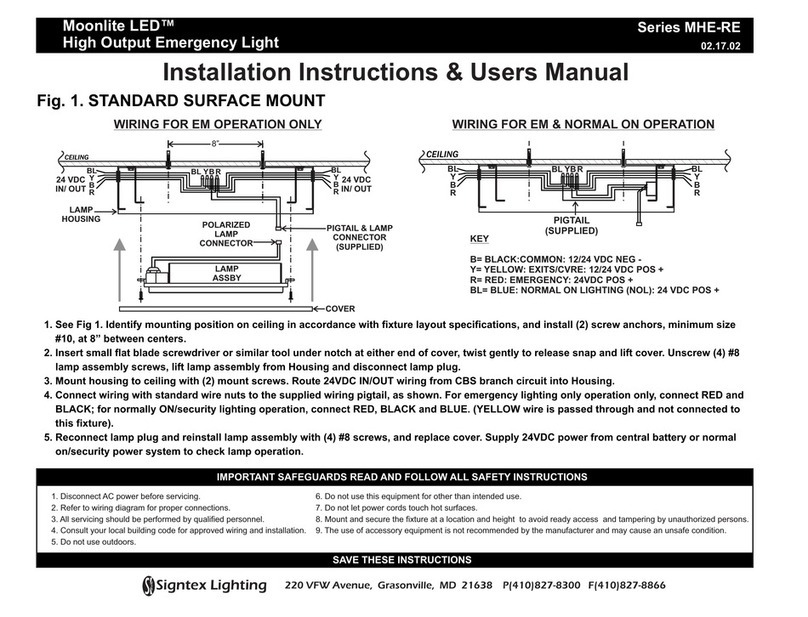

LB*-235-SDI(-OP)-SIL2 (Emitter with optional disable input SDI)

Uin: SDI=+24V=disabled / 0V=enabled

Response time: <=5ms

Holdtime: >=15ms

+24V

DI

I**.-SDI Emitter

works

>=15ms SDI

=24V Emitterdisabled

output mustbeswitchedOFF SDI

=0V

5ms 5ms

Receiver: Emitter:

1/brown +24VDC +24VDC

2/white Pollutionindication output SDI (Disable input)

3/blue 0V 0V

4/black Output NC

5/grey PE PE

Wiring LBS/LBN-235-***(-OP)-SIL2-S099:

M12

LumbergRSF5,malesocket

51

4

3

2

LBD-235-OP-SIL2-IECEX_e2,2016-09-19/HB

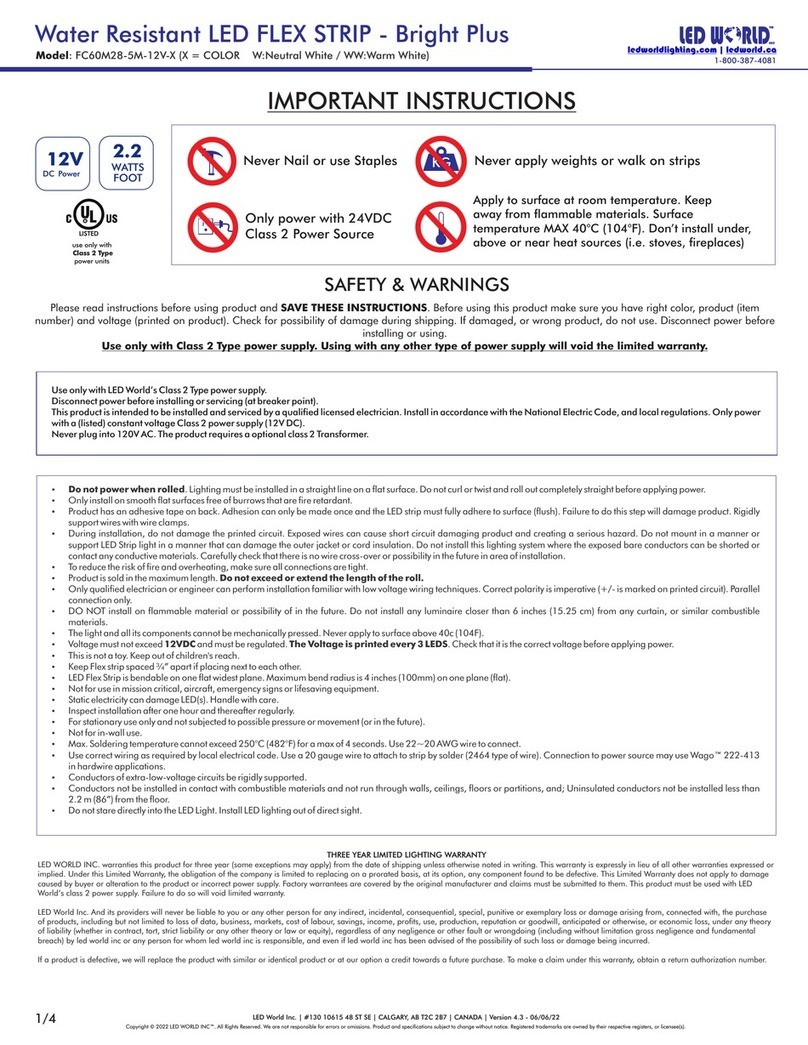

DimensionsLBS/LBN-235-***(-OP)-SIL2-S099:

Same dimensions for

emitter and receiver SocketM12

Lumberg

RSF5

68

38

M18x1

108

D12

14

122

1234567890123456789012

1234567890123456789012

1234567890123456789012

1234567890123456789012

1234567890123456789012

1234567890123456789012

1234567890123456789012

1234567890123456789012

1234567890123456789012

123

1

2

3

1

2

3

1

2

3

1

2

3

123

LBN:Dust

protectioncapfor

thesocket

Receiver: Emitter:

+24VDC 1/brown 1/brown

0V 3/blue 3/blue

Output 4/black 4/black

VA-Output 2/white --

DI -- 2/white

PE 5/grey 5/grey

LEDatthe

receiver

1234567890123456789012345

1234567890123456789012345

1234567890123456789012345

1234567890123456789012345

1234567890123456789012345

1234567890123456789012345

1234567890123456789012345

1234567890123456789012345

1234567890123456789012345

1234567890123456789012345

Receiver: Emitter:

+24VDC 1 1

0V 2 2

Output 3 --

VA-Output 4 --

DI -- 3

PE yellow-green yellow-green

DimensionsLBS/LBN/LBD-235-***(-OP)-SIL2:

Same dimensions for

emitter and receiver

78

38 120

M18x1

D12

Dimensions: Tubus M18/90/8:

(Optional accessory for reduction the

directional angle) Aperture D8

D25

90

Screwing

M18x1 Material:

POM

88

This manual suits for next models

11

Table of contents

Popular Lighting Equipment manuals by other brands

Perel

Perel LBOXA5 user manual

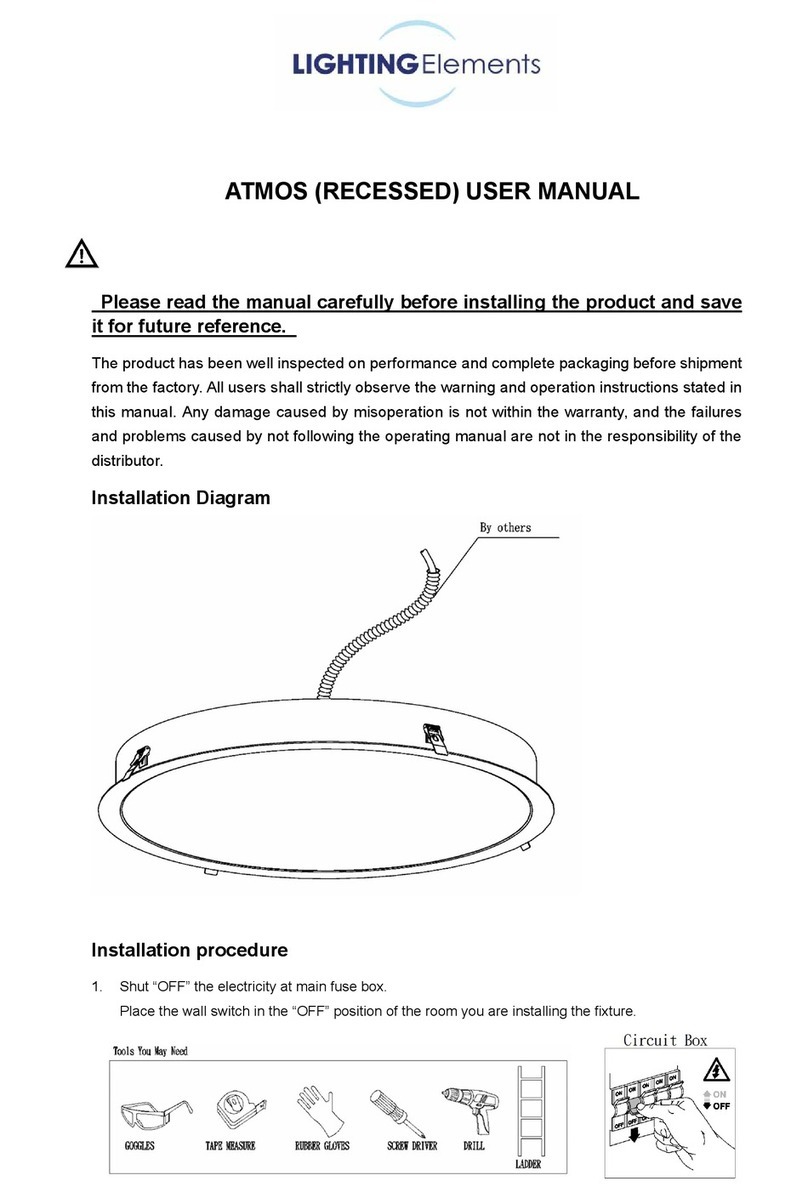

LIGHTING Elements

LIGHTING Elements ATMOS user manual

Anslut

Anslut 422-363 operating instructions

Kaiser Fototechnik

Kaiser Fototechnik RB 550 AS operating instructions

DÖRR

DÖRR DSL-40 instruction manual

Francis Searchlights

Francis Searchlights A7179-L300RC User instruction & installation manual