Titan Attachments 120STMPGRNDRv2 User manual

SKID STEER STUMP GRINDER

120STMPGRNDRv2

124117

Operator’s Manual

Read the Operator’s Manual entirely. When you see this

symbol, the subsequent instructions and warnings are

serious follow without exception. Your life and the lives

of others depend on it!

.

2

NOTE: The wiring harness comes installed with a 14-pin connector. This connector

contains the wiring for your power source. If your machine does not have a 14-pin plug,

simply remove this adapter to the expose the wires to connect to power source directly.

This implement MUST be connected to an electrical power source to operate all

functions properly.

IMPORTANT SAFETY INFORMATION

THESE ARE STANDARD PRACTICES THAT MAY NOT APPLY TO THE PRODUCTS

DESCRIBED IN THIS MANUAL.

SAFETY AT ALL TIMES

Thoroughly read and understand the instructions given in this manual before

operation. Refer to the “Safety Label” section, read all instructions noted on them. Do

not allow anyone to operate this equipment who has not thoroughly read and

comprehended this manual. Do not allow anyone who has not adequately trained in

the safe operation of the equipment.

•The operator should be familiar with all functions of the unit.

•Operate implement from the driver’s seat only.

•Make sure all guards and shields are in place and secured before operating the

tool.

•Do not leave a tractor or implement unattended with the engine running.

•Dismounting from a moving tractor could cause severe injury or death.

•Do not allow anyone to stand between tractor and implement while backing up

to implement.

•Keep hands, feet, and clothing away from power-driven parts.

•Wear snug-fitting clothing to avoid entanglement with moving parts.

•Watch out for wires, trees, etc., when raising implements. Make sure all persons

are clear of the working area.

•Turning the tractor too tight may cause implement to ride upon wheels. This

activity could result in injury or equipment damage.

•Do not carry passengers on the tool at any time.

LOOK FOR THE SAFETY ALERT SYMBOL

The SAFETY ALERT SYMBOL indicates a potential hazard to personal safety, and

individuals must take safety precautions. When you see this symbol, be alert and

carefully read the message that follows it. In addition to the design and configuration of

equipment, hazard control and accident prevention depend on the awareness, concern,

prudence, and proper training of personnel involved in the operation, transport,

maintenance, and storage.

3

BE AWARE OF SAFETY ALERT WORDS

DANGER: Indicates imminently hazardous practices. A situation that, if not avoided, will result in

death or severe injury. The signal word is limited to the most extreme situation, typically for

machine components that, for functional purposes, cannot be guarded.

WARNING: Indicates a potentially hazardous situation that, if not avoided, could result in death

or severe injury, and includes hazards that are exposed when guards remove. Use warnings to

alert against unsafe practices.

CAUTION: Indicates a potentially hazardous situation that may result in minor or moderate

injury if not avoided. It may also be used to alert against unsafe practices.

FOR YOUR PROTECTION

Thoroughly read and understand the “Safety Label” section, read all instructions noted on

them.

SHUTDOWN AND STORAGE

•Lower machine to the ground, put the tractor in park, turn off the engine, and remove

the key.

•Detach and store implements in an area where children typically do not play

USE SAFETY LIGHTS AND DEVICES

•Slow-moving tractors, self-propelled equipment, and towed implements can create a

hazard when driven on public roads. They are challenging to see, especially at night.

•Flashing warning lights and we recommend turn signals whenever driving on the public

road.

TRANSPORT MACHINERY SAFELY

•Comply with state and local laws

•The maximum transport speed for implement is 20 mph, DO NOT EXCEED. Never travel

at a rate that does not allow adequate control of steering and stopping. Some rough

terrain requires a slower speed.

•Sudden braking can cause a towed load to swerve and upset. Reduce speed if the towed

load is not equipped with brakes.

Use the following maximum speed – tow load weight ratios as a guideline:

•20 mph when weight is less than or equal to the weight of the tractor.

•10 mph when weight is double the weight of the tractor.

IMPORTANT: Do not tow a load that is more than double the weight of the tractor.

4

KEEP RIDERS OFF MACHINERY

•Riders obstruct the operator’s view; they could be struck by foreign objects or thrown

from the machine.

•Never allow children to operate equipment.

•Practice Safe Maintenance

•Understand procedure before doing work. Use proper tools and equipment; refer to

Operator’s Manual for additional information.

•Work in a clean, dry area

•Lower the implement to the ground, put the tractor in park, turn off the engine, and

remove the key before maintenance.

•Allow implement to cool completely.

•Do not grease or oil implement while it is in operation.

•Inspect all parts. Make sure details are in good condition and installed correctly.

•Remove the buildup of grease, oil, or debris.

•Remove all tools and unused parts from implementation before operation.

PREPARE FOR EMERGENCIES

•Be prepared if a fire starts.

•Keep a first aid kit and fire extinguisher handy

•Keep emergency numbers for doctor, ambulance, hospital, and fire department near the

phone.

WEAR PROTECTIVE EQUIPMENT

•Wear protective clothing and equipment appropriate for the job. Avoid loose-fitting

clothing.

•Prolonged exposure to loud noise can cause hearing impairment or hearing loss. Wear

suitable hearing protection such as earmuffs or earplugs.

•Operating equipment safety requires the full attention of the operator. Avoid wearing

radio headphones while operating machinery.

AVOID HIGH-PRESSURE FLUIDS HAZARD

•Escaping fluid under pressure can penetrate the skin causing severe injury.

•Avoid the hazard by relieving pressure before disconnecting hydraulic lines or

performing work on the system.

•Ensure all hydraulic fluid connections are tight and all hydraulic hoses and lines are in

good condition before applying pressure to the system.

•Use a piece of paper or cardboard, NOT BODY PARTS, to check for suspected leaks.

•Wear protective gloves and safety glasses or goggles when working with hydraulic

systems.

•If an accident occurs, see a doctor immediately. Remember, any fluid injected into the

skin must be treated within a few hours, or gangrene may result.

5

TIRE SAFETY

•Tire changing can be dangerous, and trained personnel should be the only ones using

correct tools and equipment.

•When inflating tires, use a clip-on chuck and extension hose long enough to allow you to

stand to one side and NOT in front of or over the tire assembly. Use a safety cage if

available.

•When removing and installing wheels, use wheel handling equipment adequate for the

weight involved.

AVOID ROLLOVER

The equipment may rollover, resulting in death or serious injury. To help prevent rollover:

•Travel at a slow speed.

•Avoid sharp turns & sudden movement on slopes.

•Carry stump grinder close to the ground.

•Avoid holes, ditches and other obstructions which may cause equipment to rollover.

•Use caution when operating on slopes and do not operate on excessively steep slopes.

•Do not exceed load capacity of equipment.

DO NOT ALLOW RIDERS

•NEVER lift or carry anyone on stump grinder.

•NEVER use stump grinder as a work platform.

•NEVER allow passengers on stump

AVOID POWER LINES & UNDERGROUND UTILITIES

DANGER!

•Prevent electrocution.

•Death or serious injury can result if equipment comes near or contacts power lines.

•Electrocution can occur without direct contact.

•Check clearance before raising equipment.

•Have local utilities locate and mark underground wires, cables, pipelines, and other

hazards before digging.

•DO NOT leave the operator’s seat if any part of the equipment contacts electric lines or

cables.

RAISED ATTACHMENT

WARNING!

•Crushing hazard.

•Raised, unsupported stump grinder can fall, resulting in death or serious injury.

•Never enter the area under a raised stump grinder.

•A raised stump grinder can lower unexpectedly, resulting in death or serious injury.

•NEVER enter area under a raised stump grinder.

•Lower stump grinder to ground, engage parking brake, shut off engine and remove key

before servicing.

6

DETACH STUMP GRINDER SAFELY

Detach stump grinder on a firm and level surface. Stump grinder may fall over if detached on

unlevel or soft surface.

TRANSPORT SAFELY

Carry stump grinder low. Travel slow and avoid slopes.

LOWER OPERATING SPEED

Keep stump grinder low and move at slow speeds on rough or uneven terrain.

OPERATION INSTRUCTIONS

•Operate all functions in an open area with skid steer in idle to get a good feel for the

controls.

•Quick-Attach must always be fully engaged and in the locked position.

•Keep bystanders away from equipment while in use.

•Always wear face or eye protection, safety shoes, and other protective equipment

•appropriate for the job.

•Do not operate, work on or around this machine while under the influence of alcohol,

drugs or if feeling ill.

•Always keep clear of moving machinery.

•Turn off machine before exiting operator station.

•It is your responsibility to operate this equipment safely. You must be familiar with the

equipment and all safety practices before use.

•Do not allow untrained or unqualified people to operate this equipment.

•Check the surrounding area for bystanders and clear them before starting the skid steer

or attachment.

•Before operating the attachment, always visually inspect and verify that the coupler lock

pins are fully engaged through the latch slots on the attachment plate.

ATTACHING AND DETACHING

1. Read and follow all safety instructions.

2. Attach skid steer to stump grinder. Verify pins

are secure in the correct position.

3. Connect hydraulic hoses. Verify hydraulic

hoses are clear of pinch areas. Case drain

hose must be connected!

4. Connect to 12V power source. Comes pre-

installed with 14-pin adapter; however, this can be removed to expose the wiring

needed for connecting to power source.

5. Move to a clear open area to test functions.

7

ROUTINE MAINTENANCE

REPLACE CUTTING TEETH

1. Support stump grinder to prevent falling.

2. Stop skid steer engine and remove key.

3. Inspect cutting teeth for damage. Rotated the tooth 3 times before replace it.

Replace individual teeth as needed.

1. Remove lock nut (1) and cutting tooth (2)

2. Rotated the tooth or install replacement tooth and lock nut. Tighten locknut (1) to 95

lb./ft. (129 Nm) of torque. Do not allow untrained or unqualified people to operate this

equipment.

INSPECTIONS

1. Check hydraulic hoses and fittings daily for leaks. Replace hose if worn or damaged.

2. Inspect the unit for any buildup of contamination (dirt, stones, etc.).

3. Check cutting teeth every 2 hours of use. Keep cutting teeth in good condition. Unit will

cut faster, and remaining teeth will last longer if broken teeth are replaced

8

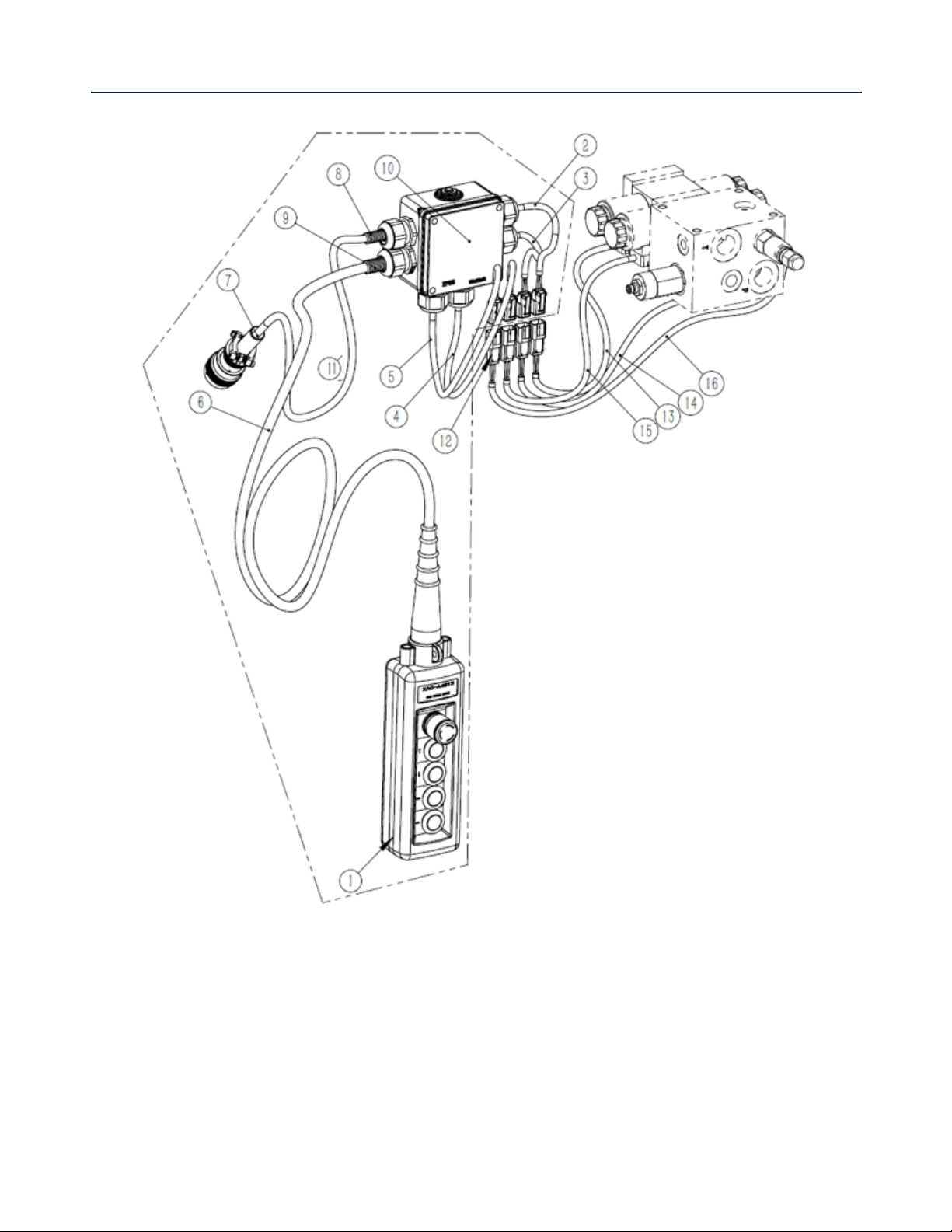

ELECTRICAL CONTROL HARNESS

ELECTRICAL CONTROL HARNESS

NOTE: This implement MUST be

connected to an electrical power

source to operate properly.

Show below is the 14-pin adapter that

comes installed. If your machine does

not have a 14-pin plug, simply remove

this piece to expose the wiring to

connect to a 12V power source.

Unit comes installed with 2-pin connectors that allow for simple connection/re-connection of

wiring harness and controller from the solenoids.

9

SPECIFICATIONS AND CAPACITIES

SPECIFICATIONS & CAPACITIES

120STMPGRNDv2

OVERALL LENGTH

72.3”

TELESCOPIC EXTENSION

11”

OUTPUT HEIGHT ABOVE GROUND

21.5”

OUTPUT HEIGHT BELOW GROUND

19”

OUTPUT TORQUE

100-120 LBS-FT

CUTTING WHEEL WIDTH

3.98”

CUTTING WHEEL DIAMETER

24”

CUTTING WHEEL SPEED

1100-1350 RPM

SWING RANGE

+/- 30°

TYPE OF TEETH

REVERSIBLE, ROTATED 3 TIMES

FORGED STEEL WITH CARBIDE FACE

NUMBER OF TEETH

16

DRIVELINE

GEAR MOTOR

HYDRAULIC FLOW

14-25 GPM

HYDRAULIC PRESSURE REQUIREMENT

2,320-3,000 PSI

NET WEIGHT

810 LBS.

GROSS WEIGHT

955 LBS.

PACKING SIZE

73” * 47” * 35”

VOLTAGE REQUIRED

12V DC

10

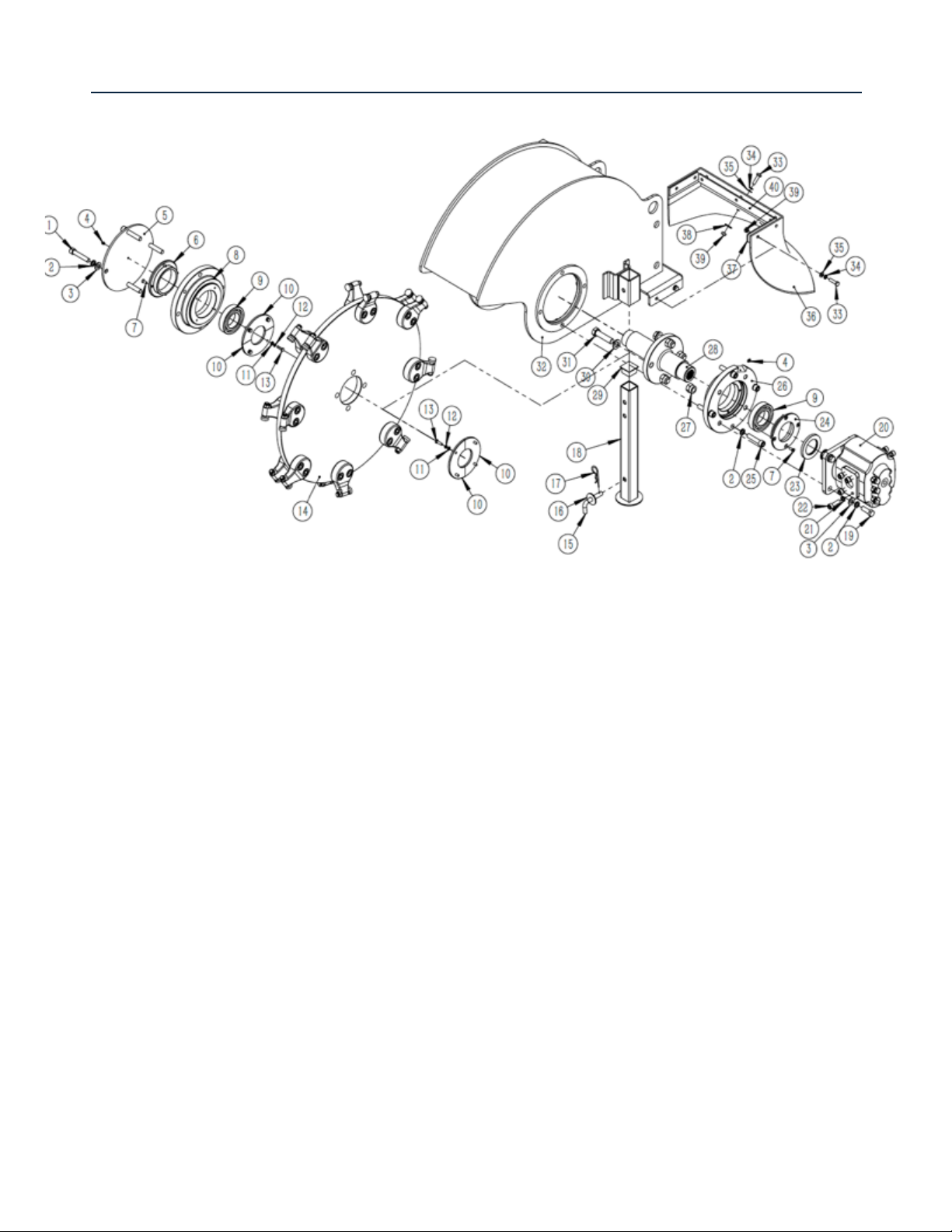

PARTS DIAGRAM/EXPLODED VIEW

11

120STMPGRNDR PARTS DIAGRAM/EXPLODED VIEW

12

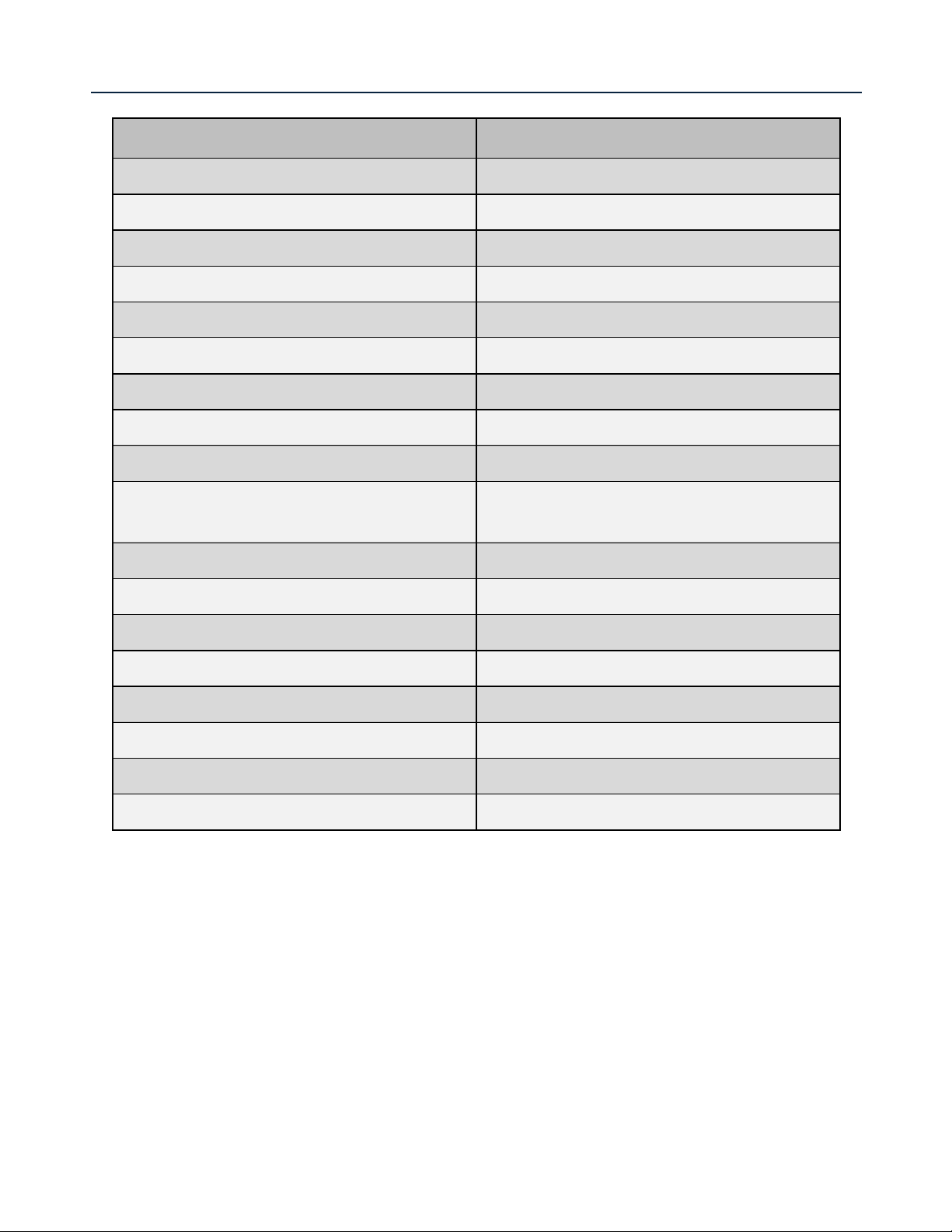

KEY BOX DESCRIPTION QTY KEY BOX DESCRIPTION QTY

1 GB/T 70.1 HEX SOCKET HEAD CAP

SCREW M12*65 4 40 SSG61.16 PRESS PLATE 02 1

2 GB/T 93 SPRING WASHER 12 11 41 GB/T 5783 BOLT M20*55 4

3 GB/T 97.1 FLAT WASHER 12 8 42 GB/T 97.1 FLAT WASHER 20 8

4 JB/T 7940.1 GREASE NIPPLE M6*1 5 43 GB/T 5783 BOLT M10*70 3

5 ESG47.5 COVER PLATE 1 44 SSG61.10 LIFTING FRAME 1

6 ESG47.7 BACKING PLATE 01 1 45 GB/T 6182 LOCK NUT M20 6

7 GB/T 70.3 HEX SOCKET HEAD CAP

SCREW M6*16

8 46 GB/T 6170 NUT M10 6

8 ESG47.6 BEARING SEAT 01 1 47 SSG61.20 PIN 1

9 GB/T 276-

2013

BEARING 6210-RS 2 48 SF-2X BEARING 3030 4

10 ESG47.8 BEARING SEAT COVER 4 49 SSG61.22 PIN01 1

11 GB/T 97.1 FLAT WASHER 6 8 50 JBT 7940.1-

1995 GREASE NIPPLE M8*1 8

12 GB/T 93 SPRING WASHER 6 8 51 SSG61.12 LINKAGE WELDMENT 1

13 GB/T 5783 HEX SCREW M6*20 8 52 GB/T889.1 NUT M24 1

14 SSG61.4 KNIFE DISH 1 53 GB/T 97.1 FLAT WASHER 24 1

15 EFGC175.37 LEG PIN 4 54 SSG61.19 PIN 2

16 GB/T 96 BIG WASHER 12 2 55 GB/T 97.1 FLAT WASHER 20 2

17 EFGC125.110 R PIN 3.2 4 56 GB/T889.1 NUT M20 2

18 SSG61.28 SUPPORT LEG 2 57 SSG61.21 PIN 1

19 GB/T 5783 BOLT M12*35 4 58 SSG61.23 PIN 02 1

20 CMZZ HYDRAULIC MOTOR 1 59 SSG61.17 SUPPORT LEG 2

21 GB/T 93 SPRING WASHER 10 12 60 GB/T 5783 BOLT M20*65 2

22 GB/T 70.1 HEX SOCKET HEAD CAP

SCREW M10*35 8 61 SSG61.27 SUPPORT MOUNT PLATE 2

23 GB

/

T13871.1 PLATE 50×80×8 1 62 GB/T 5783 BOLT M16*60 4

24 ESG47.11 BACKING PLATE 02 1 63 GB/T 6170 NUT M8 4

25 GB/T 70.1 HEX SOCKET HEAD CAP

SCREW M12*55

4 64 GB/T 5783 BOLT M8*50 2

13

26 ESG47.9 BEARING SEAT 02 1 65 SSG61.13 SKID STEER MOUNT

PLATE 1

27 GB/T 6182 LOCK NUT M16 8 66 WSG37.24 PIN 02 2

28 SSG61.3 SHAFT 1 67 SSG61.1 VALVE BLOCK 1

29 SSG61.33 LEG COVER 32*32 2 68 GB/T 97.1 FLAT WASHER 8 8

30 GB/T 97.1 FLAT WASHER 16 12 69 SSG61.26 VALVE MOUNT PLATE 1

31 GB/T 5783 BOLT M16*65 4 70 GB/T 6170 NUT M4 8

32 SSG61.2 THE COVER WELDMENT 1 71 GB/T 97.1 FLAT WASHER 4 4

33 GB/T 5783 BOLT M8*30 13 72 GB/T 823

CROSS RECESS HEAD

SCREW M4*70

4

34 GB/T 93 SPRING WASHER 8 13 73 GB/T 5783 BOLT M10*25 4

35 GB/T 97.1 FLAT WASHER 8 9 74 GB/T 97.1 FLAT WASHER 10 4

36 SSG61.14 RUBBER FLAP 1 75 GB/T 93 SPRING WASHER 6 1

37 SSG61.15 PRESS PLATE 01 2 76 SSG61.18 HYDRAULIC COMPONENTS 1

38 GB/T 96 BIG WASHER 8 2 77 SSG61.25 ELECTRICAL COMPONENT 1

39 GB/T 6170 NUT M8 14

14

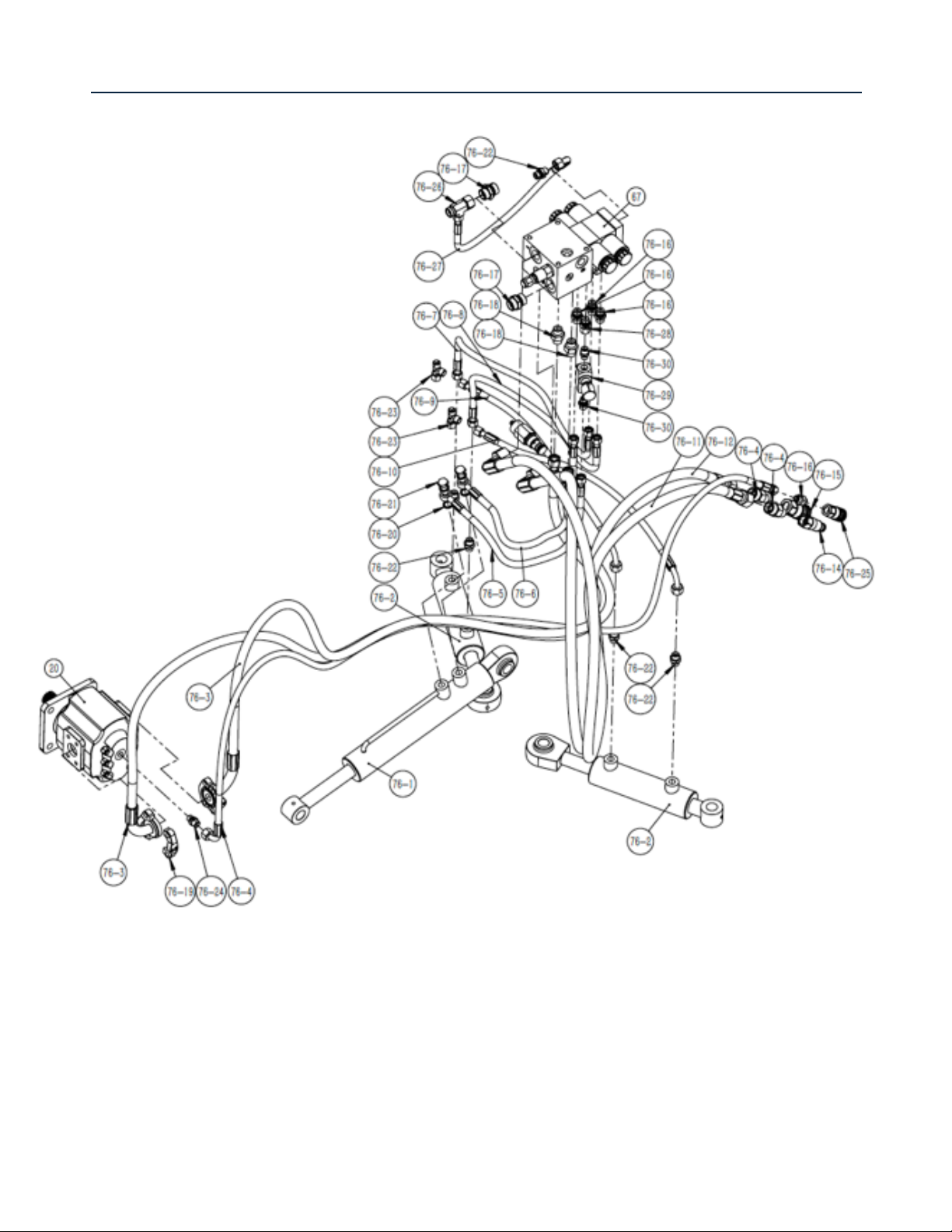

HYDRAULIC COMPONENT PARTS DIAGRAM/EXPLODED VIEW

15

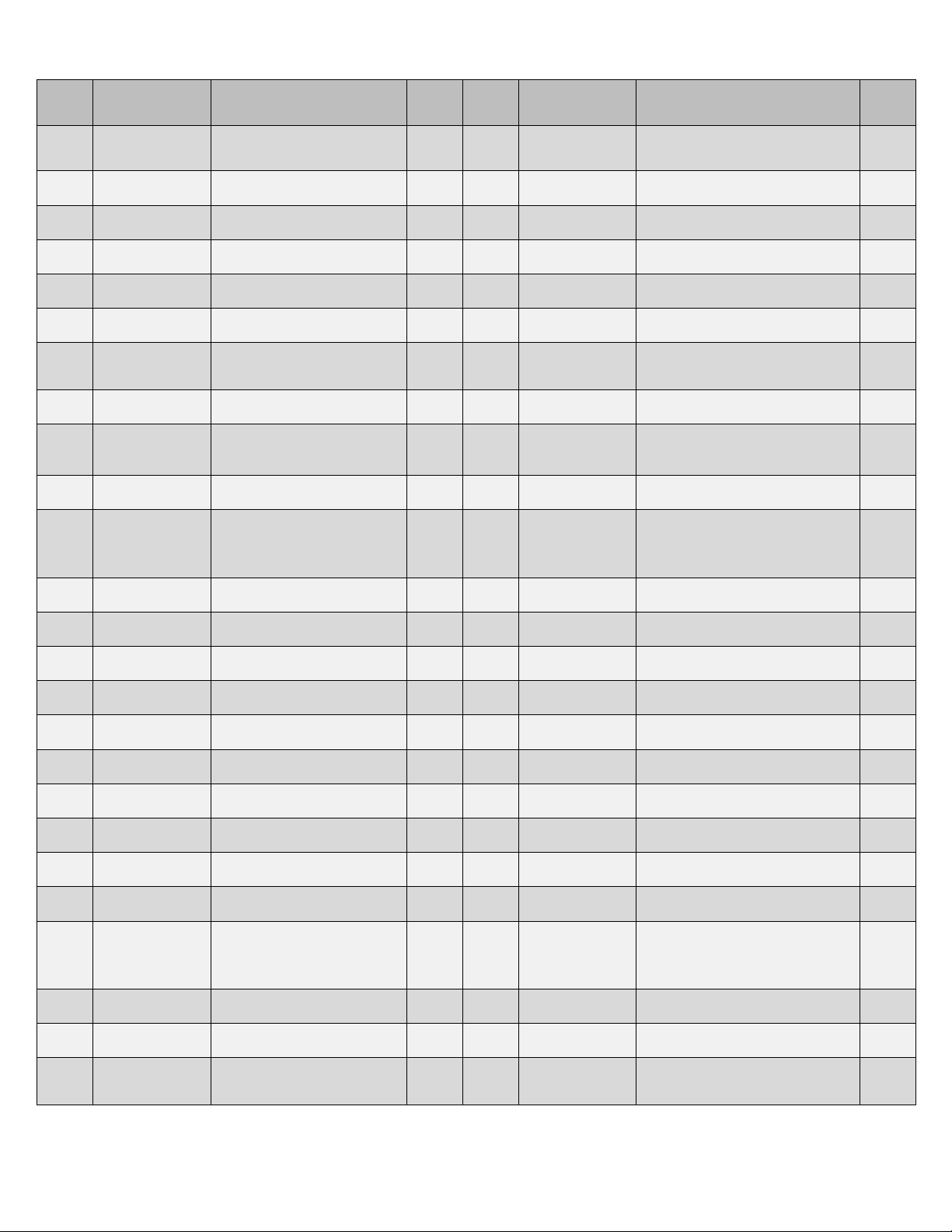

KEY BOX DESCRIPTION QTY KEY BOX DESCRIPTION QTY

76-1 SSG61.18.1 LIFT CYLINDER 1 76-16 GE10LR3/8E

DOMD CONNECTOR M16*1.5-G3/8" 5

76-2 SSG61.18.2 SWING CYLINDER 2 76-17 GE18LR3/4E

DOMD CONNECTOR M27*1.5-G3/4" 2

76-3 SSG61.18-3 OIL HOSE 01 2 76-18 GE15LREDO

MD CONNECTOR M22*1.5-G1/2" 2

76-4 SSG61.18-4 OIL HOSE 02 1 76-19 ISO6161-1/-

2 FHS35/12SAE SPLIT FLANGE 4

76-5 SSG61.18-5 OIL HOSE 03 1 76-20 JBT 982 COMBINED WASHER 4

76-6 SSG61.18-6 OIL HOSE 04 1 76-21 GB/T 3750.3

BANJO BOLT M16X1.5 2

76-7

SSG61.18-7 OIL HOSE 05

1 76-22 GE10LM16X

1.5EDOMD

CONNECTOR M16*1.5-

M16*1.5

4

76-8 SSG61.18-8 OIL HOSE 06 1 76-23 EL10LOMD THREE-WAY CONNECTOR 2

76-9

SSG61.18-9

OIL HOSE 07

1 76-24

GE10LMEDO

MD

CONNECTOR M14*1.5-

M16*1.5

1

76-10

SSG61.18-10

OIL HOSE 08

1 76-25 KIS-PT-

G03SF

QUICK

-

CHANGE CONNECTOR

G3/8

1

76-11 SSG61.18-11

OIL HOSE 09 1 76-26 SSG61.18-14

THREE-WAY CONNECTOR 1

76-12 SSG61.18-12

OIL HOSE 10 1 76-27 SSG61.18-13

OIL HOSE 11 1

76-13 GE18LREDO

MD CONNECTOR G1/2-M27*1.5 2 76-28 EGE10LR3/8

ED

CONNECTOR

M16*1.5-G3/8" 1

76-14

KIS-PT-

G04SP

QUICK-

CHANGE CONNECTOR

G1/2 (MALE)

1 76-29

STU-1/4 CONTROL VALVE

1

76-15 KIS-PT-

G04SP

QUICK-

CHANGE CONNECTOR

G1/2 (FEMALE)

1 76-30

GEO10LR1/4

CONNECTOR M16*1.5-G1/4"

2

16

ELECTRICAL COMPONENT PARTS DIAGRAM/EXPLODED VIEW

17

KEY BOX DESCRIPTION QTY

1 XAC-A4813 BUTTON SWITCH 1

2 SSG61.25-1 ELECTRIC CABLE 01 1

3 SSG61.25-2 ELECTRIC CABLE 02 1

4 SSG61.25-3 ELECTRIC CABLE 03 1

5 SSG61.25-4 ELECTRIC CABLE 04 1

6 SSG61.25-5 ELECTRIC CABLE 05 1

7 HD36-18-14SN-059 14 PIN ADAPTERS 1

8 SSG61.25-7 CABLE CONDUIT 01 1

9 SSG61.25-8 CABLE CONDUIT 02 1

10 SSG61.25.9 JUNCTION BOXES 1

11 SSG61.25-6 ELECTRIC CABLE 06 1

12 DT06-2S 2 PIN ADAPTERS 4

13 SSG61.25-9 ELECTRIC CABLE 09 1

14 SSG61.25-10 ELECTRIC CABLE 10 1

15 SSG61.25-11 ELECTRIC CABLE 11 1

16 SSG61.25-12 ELECTRIC CABLE 12 1

18

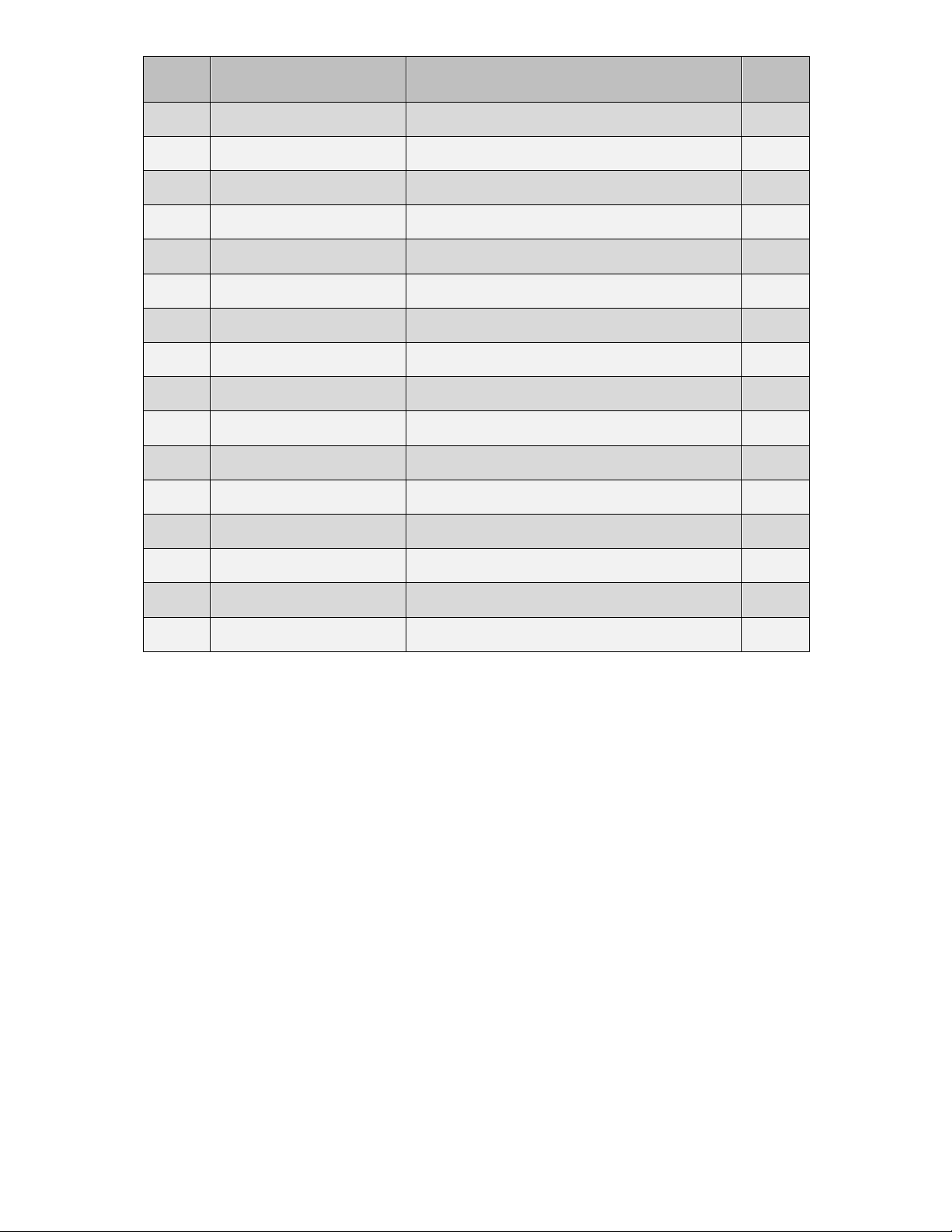

ELECTRICAL COMPONENT PARTS DIAGRAM/EXPLODED VIEW

KEY BOX DESCRIPTION QTY

14-1 SSG61.4-7 CUTTING WHEEL 1

14-2 ESG47.4-2 TEETH BASE900-2 6

14-3 ESG47.4-8 TEETH 900 16

14-4 ESG47.4-3 TEETH BASE900-3 6

14-5 ASME B18.16.6 NYLON INSERT LOCK NUTS 16

14-6 ASME B18.3 HEX SOCKET HEAD BOLT 16

14-7 ESG47.4-4 TEETH BASE900-4 1

14-8 ESG47.4-5 TEETH BASE900-5 1

14-9 ESG47.4-6 TEETH BASE900-6 1

14-10 ESG47.4-1 TEETH BASE900-1 1

19

REPLACEMENT TEETH PARTS DIAGRAM/EXPLODED VIEW

KEY BOX DESCRIPTION QTY

14-3 ESG47.4-8 TEETH 900 16

14-5 ASME B18.16.6 NYLON INSERT LOCK NUTS 16

20

SKID STEER STUMP GRINDER ELECTRICAL SCHEMATIC DIAGRAM

Table of contents

Other Titan Attachments Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

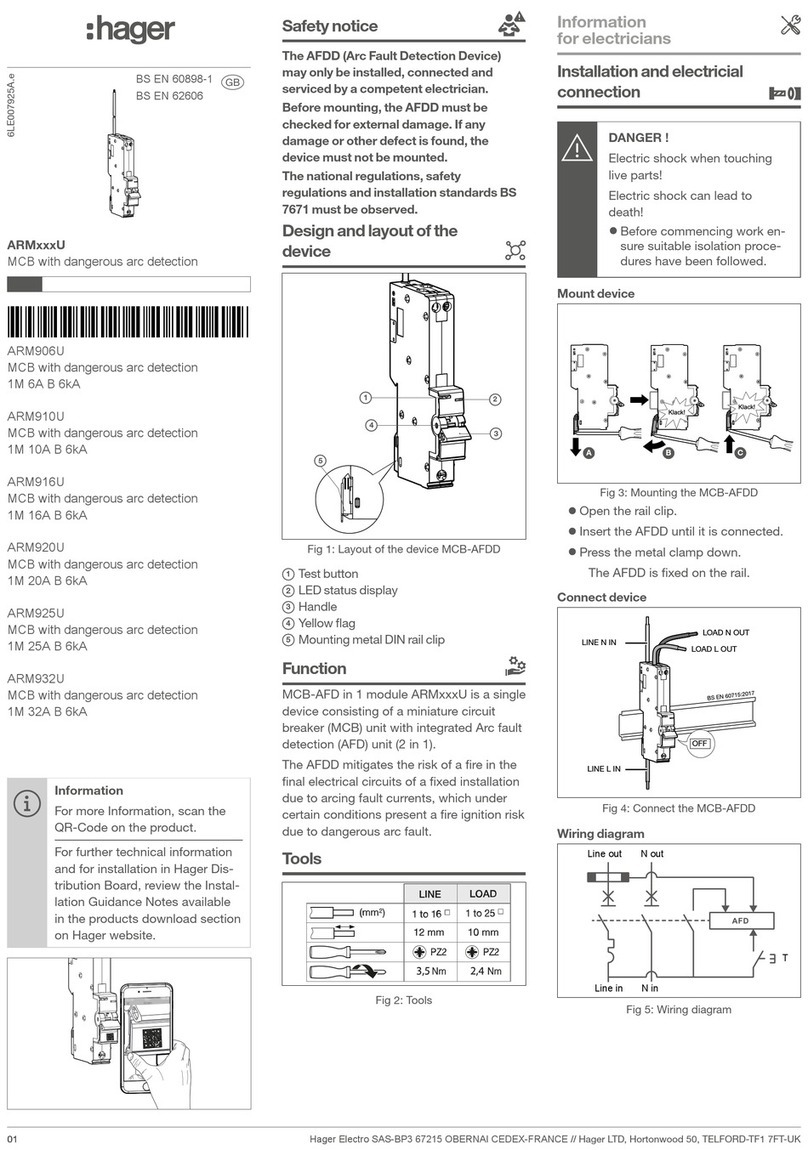

hager

hager ARM U Series instruction manual

Mitsubishi Electric

Mitsubishi Electric BC34 Installation, operation & maintenance manual

Maschio

Maschio VELOCE PIEGHEVOLE Use and maintenance

Nexen

Nexen Air Champ S-450 user manual

Baltimore Aircoil Company

Baltimore Aircoil Company BCP3D Installation, Operating, Maintenance

JDS Uniphase

JDS Uniphase SWS15100 user manual