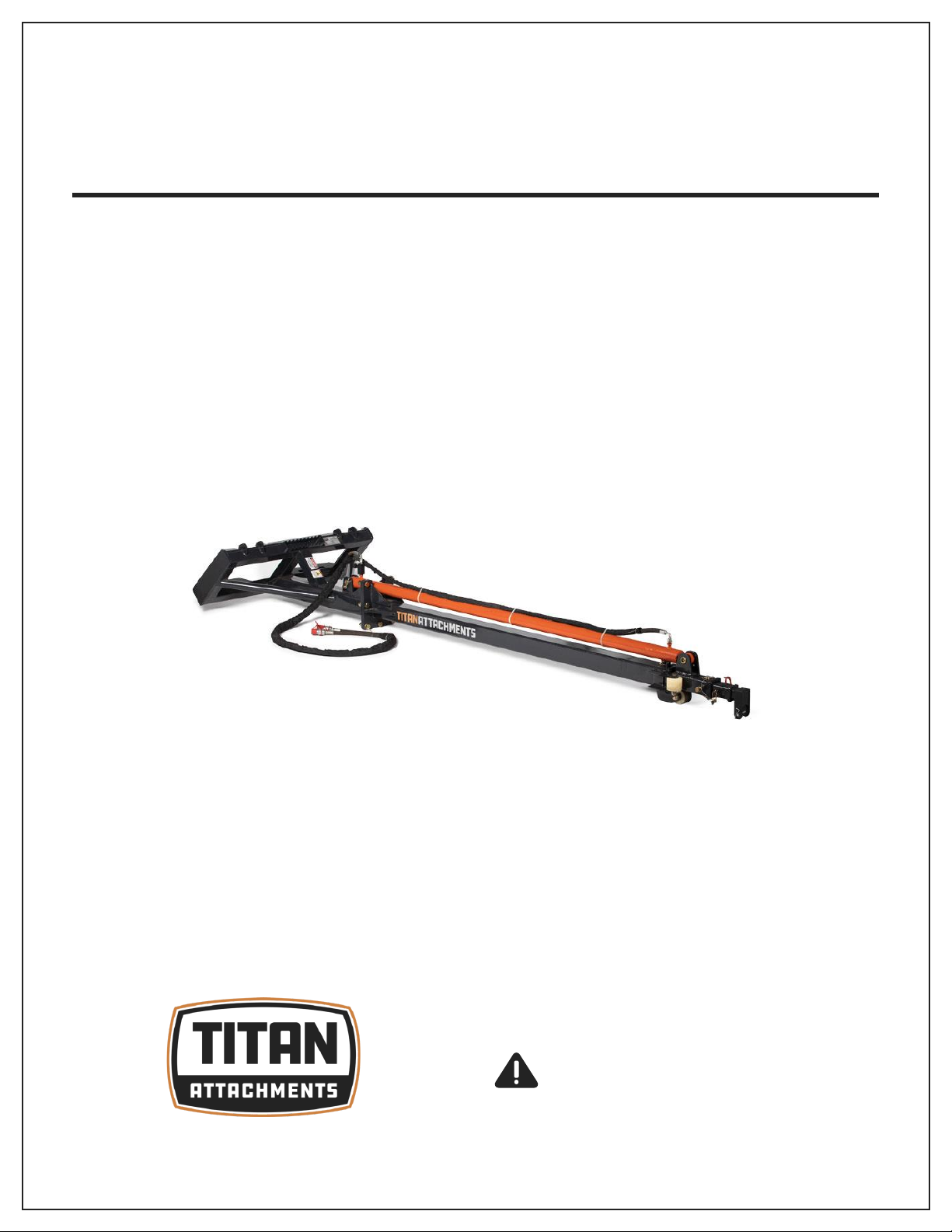

Titan Attachments SKID STEER TRUSS BOOM v3 User manual

SKID STEER TRUSS BOOM v3

SSTRUSSBOOMv3

194153

Operator’s Manual

Read the Operator’s Manual entirely. When you see this

symbol, the subsequent instructions and warnings are

serious follow without exception. Your life and the lives

of others depend on it!

2

INTRODUCTION

•This manual is made at the time of manufacturing of the TRUSSBOOM that does not include

any subsequent modifications made afterward.

•This manual is intended to provide information to operators and owners to operate the

TRUSSBOOM safely and effectively, as well as to perform suitable maintenance for the

equipment.

•Before operating or performing maintenance of the equipment, it is critical to read,

understand and be acquainted with the operating, safety and maintenance

recommendations of this manual and the manual of your skid steer, or prime mover.

•Failure in operating and maintaining the TRUSSBOOM according to the instructions and

recommendations could lead to fatal accidence causing serious personal injury or death, as

well as damage to your equipment.

•Operators must conform with laws and regulations stipulated by OSHA as well as the local

applicable industrial safety regulations.

3

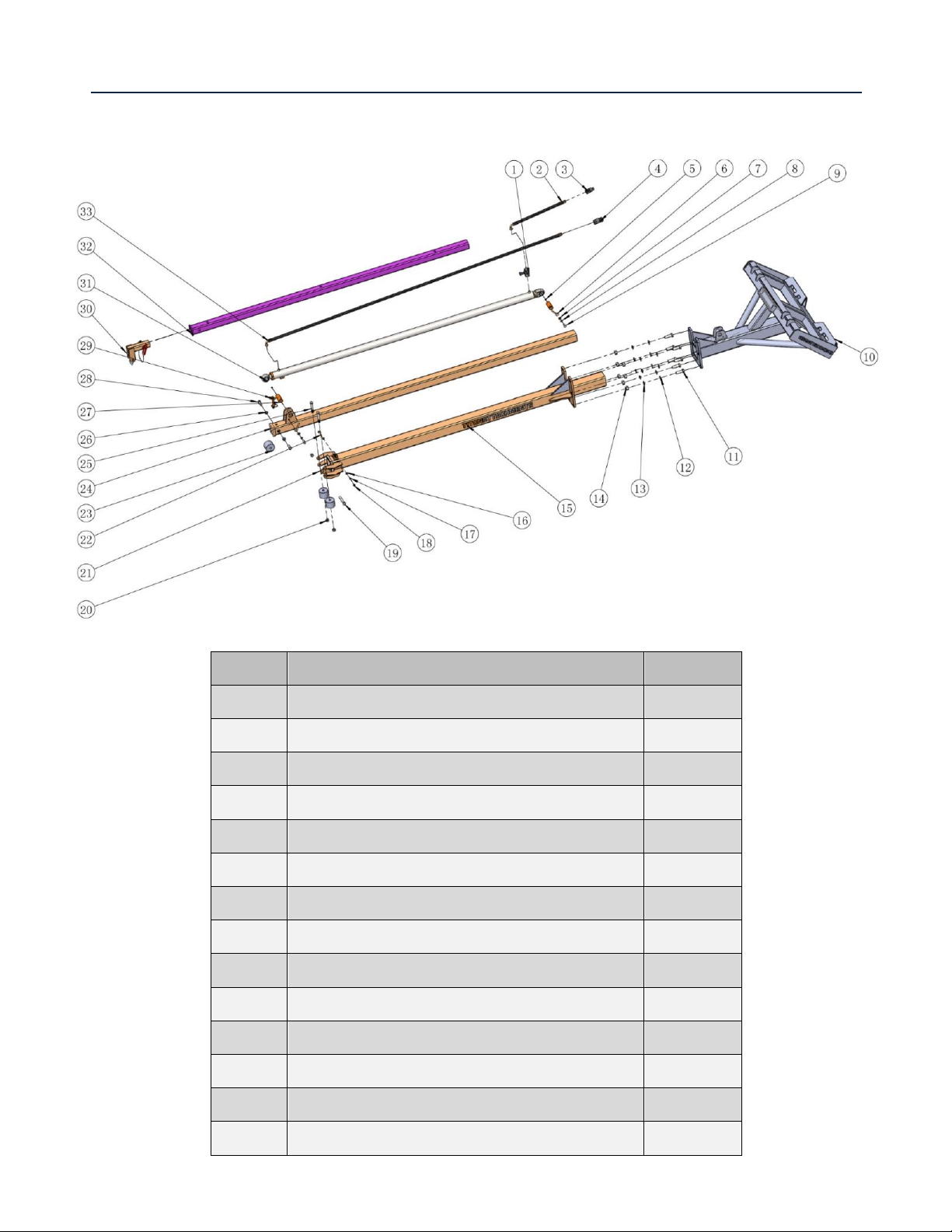

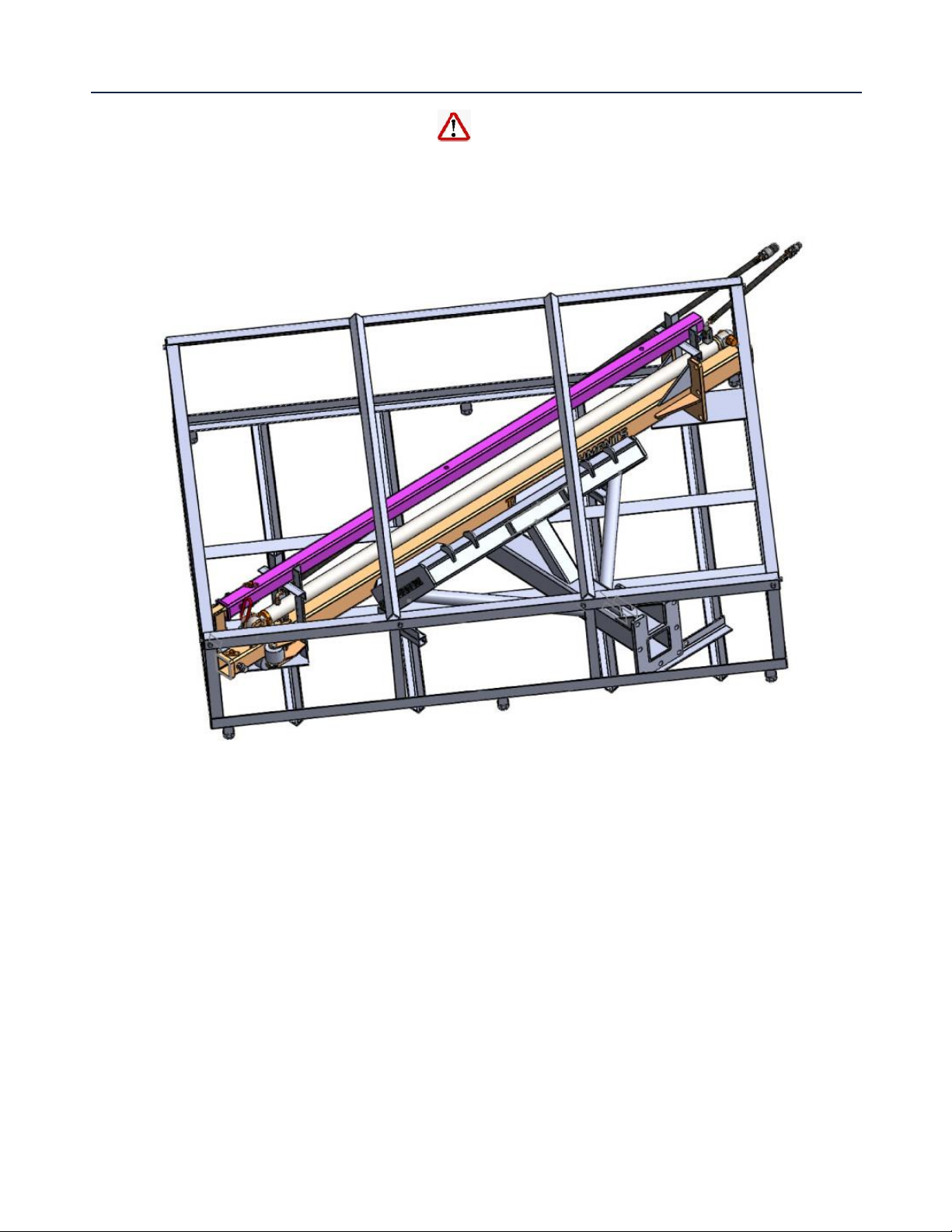

PARTS DIAGRAM / EXPLODED VIEW

KEY

DESCRIPTION

QTY

(1)

SAFETY VALVE

1

(2)

OIL HOSE - FEED

1

(3)

FLAT FACE COUPLER - MALE

1

(4)

FLAT FACE COUPLER - FEMALE

1

(5)

GREASE ZERK

2

(6)

EYE PIN

2

(7)

FLAT WASHER M12

2

(8)

SPRING WASHER M12

2

(9)

HEX BOLT M12x30

2

(10)

MAIN FRAME

1

(11)

HEX BOLT M20x60

7

(12)

FLAT WASHER M20

7

(13)

SPRING WASHER M20

7

(14)

HEX NUT M20

7

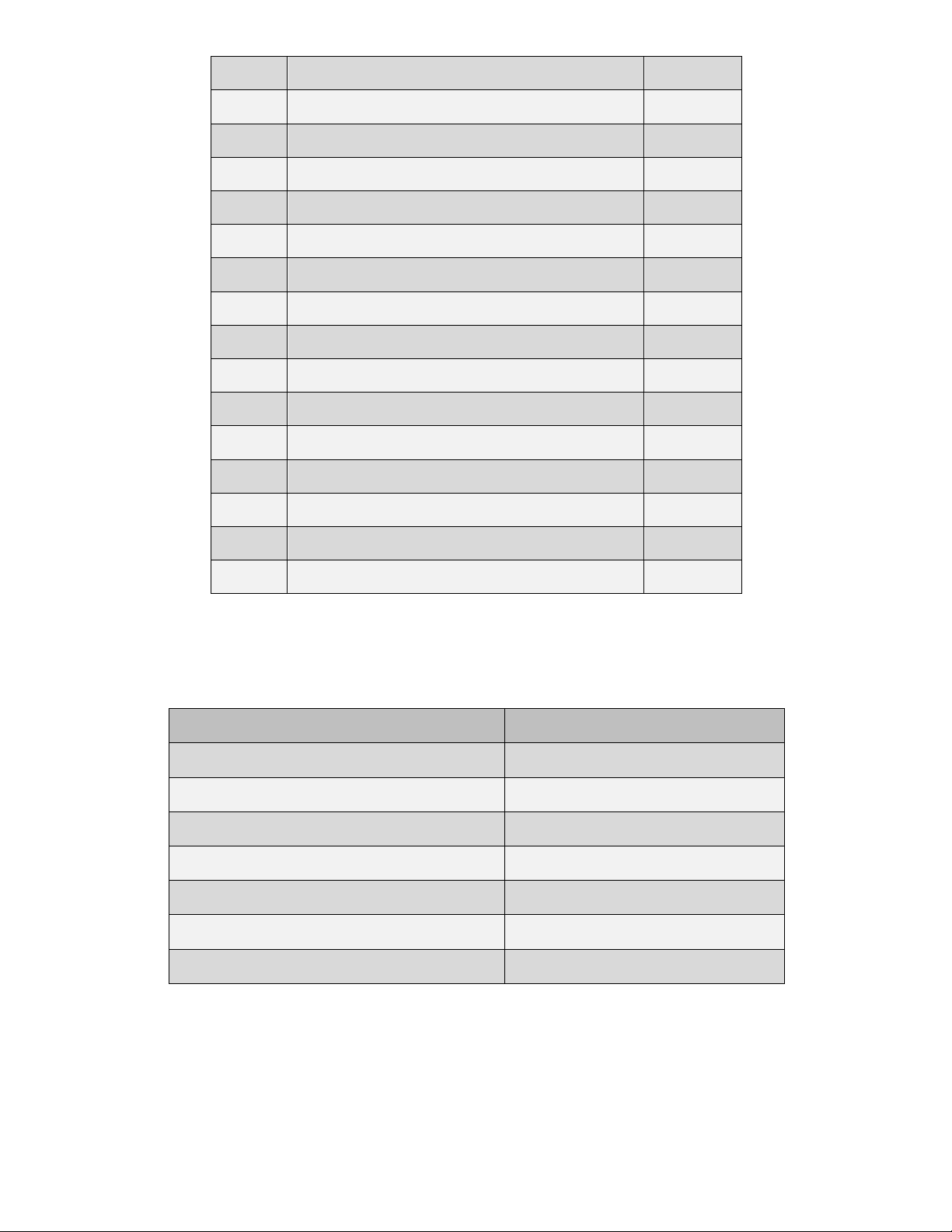

4

DESCRIPTION

SPECIFICATION

FULLY RETRACTED LENGTH:

134"

FULLY EXTENDED LENGTH:

313"

HYDRAULIC PISTON:

3" BORE X 90.5" STROKE

FULLY RETRACTED CAPACITY:

850 LB

FIRST EXTENSION CAPACITY:

520 LB

FULLY EXTENDED CAPACITY:

330 LB

PRODUCT WEIGHT:

612 LB

(15)

TITAN ATTACHMENT DECAL

2

(16)

FLAT WASHER M10

2

(17)

SPRING WASHER M10

1

(18)

HEX NUT M10

1

(19)

HEX BOLT M16x110

1

(20)

HEX LOCK NUT M16

2

(21)

TELEBOOM-1 (FIRST SECTION)

1

(22)

HEX BOLT M10x50

1

(23)

SLIDE ROLLER

3

(24)

TELEBOOM-2 (SECOND SECTION)

1

(25)

HEX BOLT M16x100

2

(26)

HEX NUT M16

2

(27)

CYLINDER PIN

2

(28)

HEX BOLT M16x40

2

(29)

LOCK PIN

1

(30)

HOOK ASSEMBLY

1

5

ASSEMBLY INSTRUCTIONS

1. REMOVE PARTS FROM STEEL CRATE

The fork blade used to lift the steel crate should be at least 2/3 of the length of the crate.

It is recommended that the left and right fork blades should move to the farthest ends.

Failure to do so may lead to imbalance causing the crate to slide out that may cause injury.

•Take off steel crate’s top panel, cut off wire tying the parts and take out TELEBOOM-3 (32)

(note that HOOK ASSEMBLY (30) is pre-installed on it).

•Take out TELEBOOM-2 (24) (note that TELEBOOM-1 (21), CYLINDER (31), OIL HOSE –FEED (2)

and OIL HOSE RETURN (33) are pre-installed as assembly).

•Take off steel crate’s side panels, cut off wire tying MAIN FRAME (10), and move skid steer

loader towards the mount plate of MAIN FRAME (10). Engage skid steer loader quick attach

arm to the mount plate of MAIN FRAME (10) and pick up the MAIN FRAME (10).

6

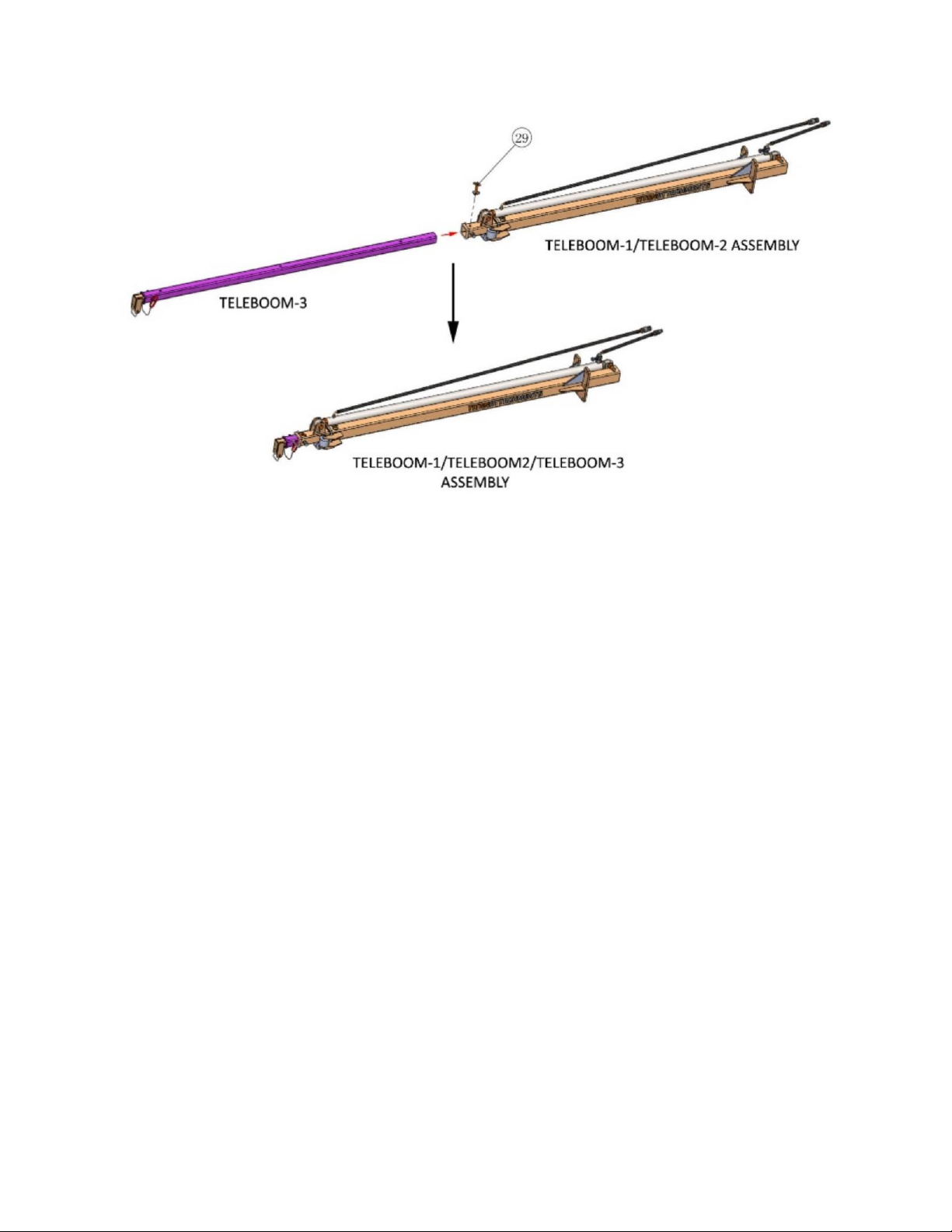

2. PUTTING TOGETHER TELEBOOM ASSEMBLY

•Place TELEBOOM-1/TELEBOOM-2 Assembly on a table. Insert TELEBOOM-3 (32) into

TELEBOOM-2 (24).

•Align holes of TELEBOOM-2 (24) to the farthest holes of TELEBOOM-3 (32) and insert LOCK

PIN (29) through these holes to lock the TELEBOOM Assembly together.

7

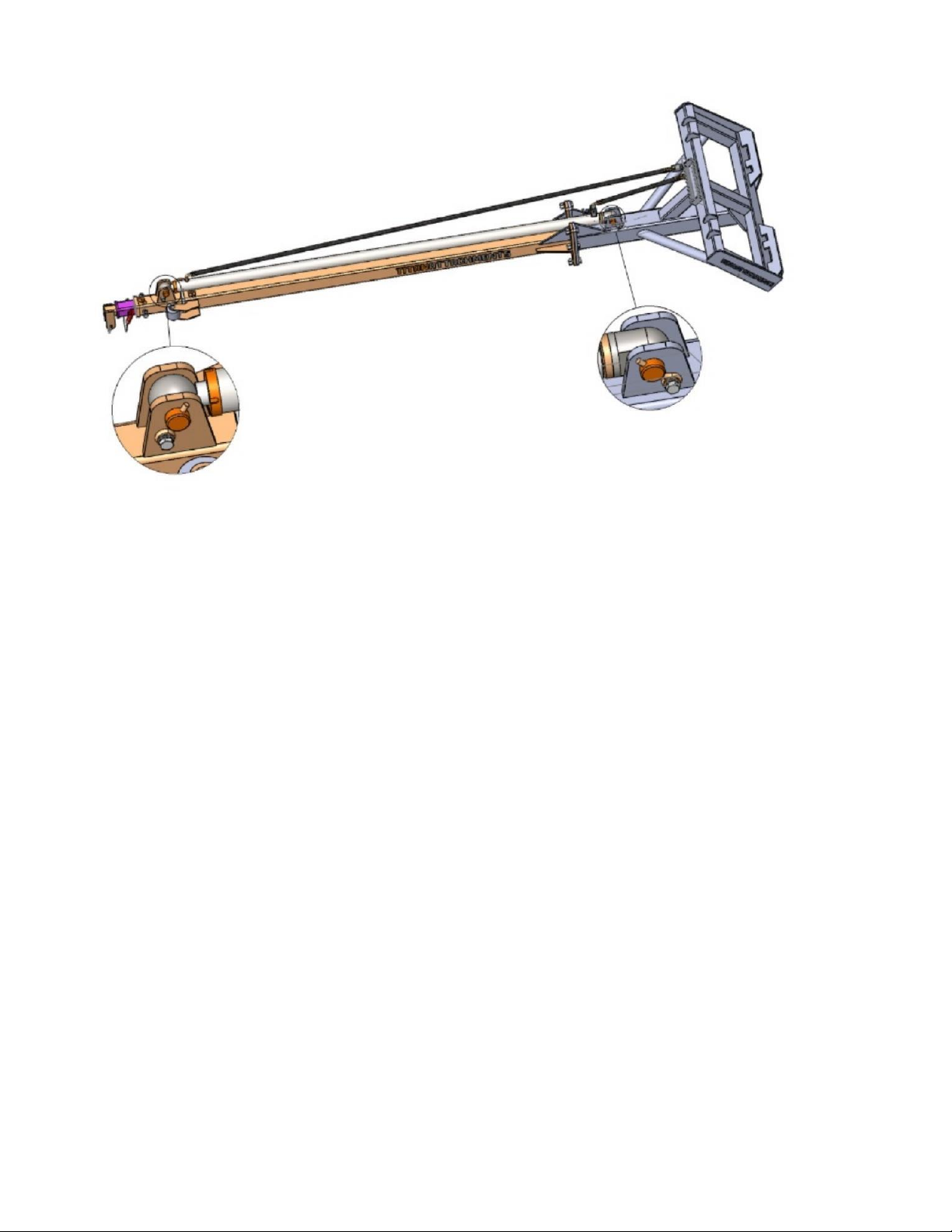

3. ATTACHING MAIN FRAME TO THE TELEBOOM ASSEMBLY

•Move skid steer loader that picks up the MAIN FRAME (10) to the table where the TELEBOOM

Assembly is placed.

•The hardware sets that are used to mount the Main Frame onto the Teleboom Assembly are

attached to the main frame for transportation. Take off the hardware for use in mounting.

•Tilt the MAIN FRAME (10) to vertical position and move the MAIN FRAME (10) towards the

Teleboom Assembly and insert the tube of TELEBOOM-2 (24) into the MAIN FRAME (10).

•Align the bolt holes of the mounting brackets on the MAIN FRAME (10) and TELEBOOM-2 (24)

and attach the MAIN FRAME (10) and TELEBOOM-2 (24) using HEX BOLT M20x60 (11), FLAT

WASHER M20 (12), SPRING WASHER M20 (13) and HEX NUT M20 (14). The order of assembly

is to insert HEX BOLT M20x60 (11) through these parts, and then place FLAT WASHER M20

(12), SPRING WASHER M20 (13) and HEX NUT M20 (14) onto the end of the bolt.

•Fasten the hardware, but do not tighten until all the hardware is attached.

TORQUE REQUIREMENT OF TIGHTENING THE M20 HARDWARE SET IS 363 NM (268 FT-LB).

8

4. MOUNTING CYLINDER

•Align holes of CYLINDER (31) with the mount tabs on MAIN FRAME (10) and insert CYLINDER

PIN (27) Into these holes.

•Insert EYE PIN (6) into the holes of CYLINDER PIN (27) and secure the EYE PIN (6) onto MAIN

FRAME (10) using HEX BOLT M12x30 (9), FLAT WASHER M12 (7) and SPRING WASHER M12

(8). The order of assembly is to place FLAT WASHER M12 (7) and SPRING WASHER M12 (8)

onto the end of the bolt that is inserted through the eye of the EYE PIN (6), and then fasten

HEX BOLT M12x30 (9) onto the threaded hole on the MAIN FRAME (10).

•TORQUE REQUIREMENT OF TIGHTENING THE M12 HARDWARE SET IS 86 NM (64 FT-LB).

•Hook up hydraulic hoses and the TRUSSBOOM is ready for use.

9

HYDRAULIC SYSTEM

SAFETY VALVE

•Titan TRUSSBOOM is equipped with safety valve that

serves to regulate hydraulic oil flows so that in the event

of hydraulic failure, the boom will not collapse instantly

causing hazard.

•Speed of cylinder retraction is adjustable. Turning control

knob clockwise will reduce flow and slow down retraction

speed. Turning control knob anticlockwise will increase

flow and speed up retraction speed.

•Slow retraction speed is recommended.

•Hydraulic pressure range of the safety valve is 2320 to

3625 PSI.

KEY

DESCRIPTION

QTY

(31)

HYDRAULIC CYLINDER

1

(1)

SAFETY VALVE

1

(35)

GASKET Ø3/8”

1

(34)

HOSE CONNECTOR G3/8”

1

(2)

OIL HOSE - FEED

1

(3)

FLAT FACE COUPLER - MALE

1

(4)

FLAT FACE COUPLER -FEMALE

1

(33)

OIL HOSE - RETURN

1

10

ACKNOWLEDGEMENT OF RISK AND RELEASE OF LIABILITY

The use of any equipment, including this one, involves the potential risk of injury. Apart from any

warranty claim that might be presented for a claimed defect in material or workmanship of the product,

you accept and assume full responsibility for any and all injuries, damages (both economic and non-

economic), and losses of any type, which may occur, and you fully and forever release and discharge

Titan, its insurers, employees, officers, directors, associates, and agents from any and all claims,

demands, damages, rights of action, or causes of action, present or future, whether the same be known

or unknown, anticipated, or unanticipated, resulting from or arising out of the use of said equipment.

This equipment must be used with care by capable and competent individuals under supervision, if

necessary.

WARNING

Do not overfill! Mower should be level

when checking oil in gear box.

some activities might be able to cause

electric shock

Sharp objects may be involved.

Use protective cover during maintenance.

TITAN LIMITED WARRANTY: TERMS, EXCLUSIONS AND LIMITATIONS OF REMEDIES

This product comes with a one (1) year limited warranty that can be found at

www.palletforks.com/warranty.html. Please review the same for all details regarding the Titan Limited

Warranty.

THE TITAN LIMITED WARRANTY FOUND AT WWW.PALLETFORKS.COM/WARRANTY.HTML IS

EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY

IMPLIED WARRANTY OF MERCHANTABILITY AND/OR FITNESS FOR A PARTICULAR PURPOSE, EACH

OF WHICH IS HEREBY DISCLAIMED.

11

NEED HELP? CONTACT US FIRST.

1-800-605-7595

www.palletforks.com

© 2023 Titan Brands

This manual suits for next models

2

Table of contents

Other Titan Attachments Industrial Equipment manuals