Application Note

September 2018

Table of Contents

1. Customer Support ................................................................................................................................................. 3

2. Returns For Repair, Replacement, or Cre it ......................................................................................................... 3

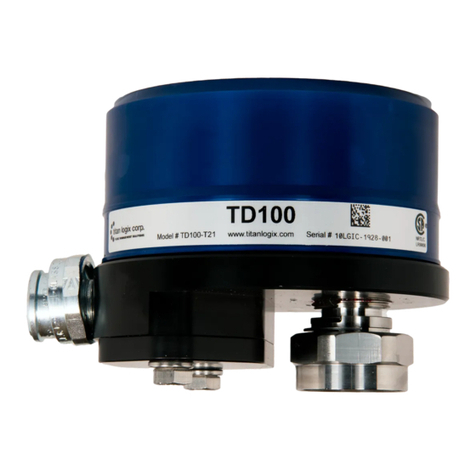

3. Intro uction .......................................................................................................................................................... 4

3.1 Disclaimer ............................................................................................................................................. 4

3.2 Safety .................................................................................................................................................... 4

4. Pre-Installation ...................................................................................................................................................... 4

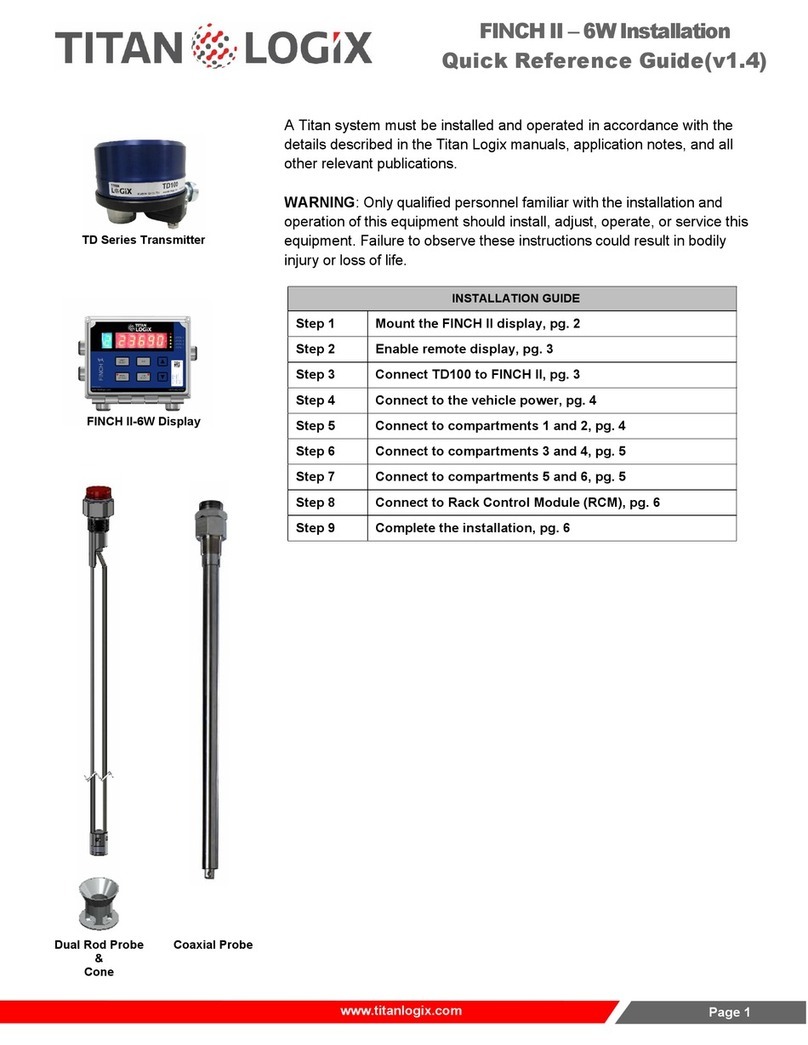

4.1 Require Materials ............................................................................................................................... 4

4.2 Initial Steps ............................................................................................................................................ 5

5. Retrofit Proce ures with flui in the tank ............................................................................................................ 6

5.1 Retrieve the TD80 strap table ............................................................................................................... 6

5.2 Exchange the Transmitter ..................................................................................................................... 6

5.3 Transferring the TD80 strap table to the TD100 ................................................................................... 6

5.4 Performing Offset Calibration on the TD100 ........................................................................................ 7

5.5 Confirming Offset Calibration on the TD100 ........................................................................................ 7

6. Retrofit Proce ures with empty tank ................................................................................................................... 8

6.1 Retrieve the TD80 strap table ............................................................................................................... 8

6.2 Exchanging the transmitter .................................................................................................................. 8

6.3 Transferring the TD80 strap table to the TD100 ................................................................................... 9

6.4 Performing Offset Calibration on the TD100 ...................................................................................... 10

6.5 Installing the TD100 ............................................................................................................................ 11

6.6 Confirming Level Rea ings of the TD100 ............................................................................................ 11

7. Revision History .................................................................................................................................................. 11