Titan Logix TD80 User manual

TD80™Level Gauging and Overfill Prevention System Product Manual

Rev. 2, August 4, 2015/ TD80 Introduction Page 1

TPM 001

WARRANTY

Please see our Terms and Conditions for details about our product warranty.

PROPRIETARY INFORMATION

The Information disclosed herein contains proprietary rights of Titan Logix Corp. Neither

this document nor the information disclosed herein shall be reproduced or transferred to

other documents, or used or disclosed to others for manufacturing purposes, or for any

other purpose except as specifically authorized in writing by Titan Logix Corp.

TD80™Level Gauging and Overfill Prevention System Product Manual

Page 2 TD80 Introduction/ Rev. 2, August 4, 2015

TPM 001

Table of Contents

1TD80 Introduction....................................................................................................................5

1.1 About This Manual..........................................................................................................5

1.2 Disclaimer.......................................................................................................................5

1.3 TD80 System Introduction and Description....................................................................6

1.3.1 About the TD80 System.........................................................................................6

1.3.2 TD80 System Components....................................................................................6

1.3.3 Optional Components ............................................................................................7

1.3.4 Theory of Operation...............................................................................................7

1.3.5 The TD80 Alarm System........................................................................................9

1.4 Overfill Prevention System Description ........................................................................11

1.5 Graphical Glossary of Terms........................................................................................14

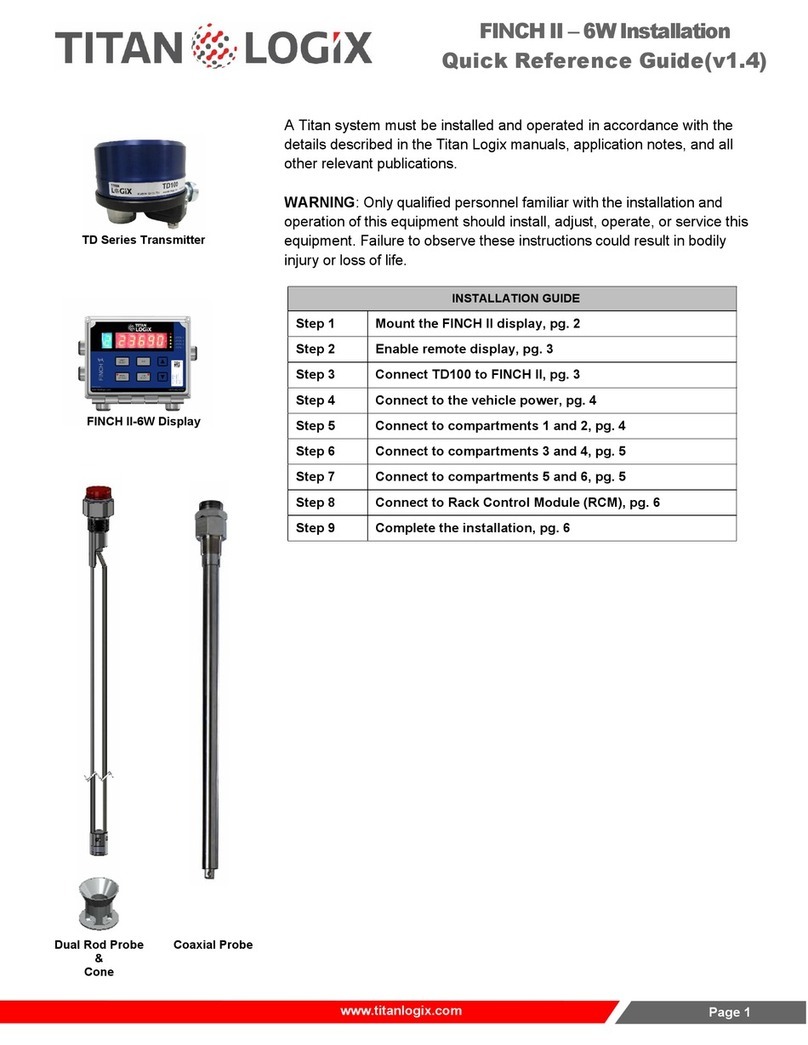

2TD80 Installation....................................................................................................................17

2.1 TD80 Installation Steps Overview ................................................................................17

2.1.1 Pre-Installation Requirements..............................................................................17

2.1.2 Installation Steps Overview..................................................................................17

2.1.3 TD80 Installation Guidelines................................................................................19

2.2 TD80 Installation Test and Calibration .........................................................................19

2.2.1 TD80 Basic Operation Tests................................................................................19

2.2.2 TD80 System Testing and Verification.................................................................19

2.2.3 Offset Calibration Methods ..................................................................................21

2.3 TD80 Probe and Transmitter Location .........................................................................24

2.3.1 Locating the Probe...............................................................................................24

2.3.2 Locating the Transmitter......................................................................................25

2.3.3 Mounting the Top Fitting ......................................................................................26

2.3.4 Mounting the Anchor Cone ..................................................................................27

2.4 TD80 Mechanical Installation........................................................................................28

2.4.1 Overview of the Installation Procedure................................................................29

2.4.2 Installation Procedure ..........................................................................................29

2.5 TD80 Basic System Installation Wiring.........................................................................38

2.5.1 Finch 5332E/PS External Display, Red Terminal Board Wiring Instructions.......38

2.5.2 Finch 5332E External Display, Green Terminal Board Wiring Instructions .........38

2.5.3 Finch 5332, Internal Display Wiring Instructions..................................................39

2.6 TD80 Basic Alarm Installation Wiring ...........................................................................45

2.6.1 Finch 5332E/PS, Red Terminal Board Wiring Instructions..................................45

2.6.2 Finch 5332E, Green Terminal Board Wiring Instructions ....................................45

2.7 TD80 Overfill Prevention System Installation Wiring....................................................49

2.7.1 Finch Relay Module Installation Wiring................................................................49

2.7.2 P2000 Overfill Prevention System .......................................................................61

2.7.3 ABS Power Supply Wiring Example ....................................................................65

2.8 Finch Display Terminal and Jumper Locations.............................................................66

2.9 TD80 Installation Checklist...........................................................................................70

3TD80 and Overfill Prevention System Troubleshooting....................................................71

3.1 Overview and General Techniques ..............................................................................71

3.2 TD80 System Specific Troubleshooting .......................................................................72

3.2.1 Common System Wiring and Component Failures..............................................73

3.2.2 Common Installation Wiring and Component Problems......................................84

3.3 Alternate TD80 System Troubleshooting......................................................................88

3.4 TD80 System Tests ......................................................................................................88

4TD80 Technical Reference....................................................................................................98

4.1 Technical Specification Guide for Dual Rod Probes ....................................................98

4.2 Technical Specification Guide for Coaxial Probes......................................................106

5TD80 Operation....................................................................................................................114

TD80™Level Gauging and Overfill Prevention System Product Manual

Rev. 2, August 4, 2015/ TD80 Introduction Page 3

TPM 001

5.1 TD80 System Components.........................................................................................116

5.2 Introduction to Operation............................................................................................116

5.3 TD80 Operation ..........................................................................................................117

5.4 MODES OF OPERATION ..........................................................................................120

5.4.1 Alarm Disable Mode...........................................................................................120

5.4.2 Display Mode .....................................................................................................120

5.4.3 Monitor Mode .....................................................................................................120

5.4.4 Set Fill / Fall Mode .............................................................................................121

5.5 ALARMS.....................................................................................................................121

5.5.1 Spill Alarm..........................................................................................................121

5.5.2 Fill / Fall Alarm ...................................................................................................122

5.5.3 High High Alarm.................................................................................................122

5.5.4 Fail Alarm...........................................................................................................122

5.5.5 Disabling the 2 LO Message..............................................................................122

5.6 Alarms Settings...........................................................................................................123

5.6.1 Fill/Fall Alarm .....................................................................................................123

5.6.2 HH Alarm............................................................................................................123

5.6.3 Spill/Fail Alarm...................................................................................................123

5.7 Offset Calibration........................................................................................................124

5.8 Normal Operation Troubleshooting ............................................................................125

6TD80 Programming .............................................................................................................127

6.1 TD80 Transmitter and Probe Description...................................................................127

6.2 Programming the TD80 ..............................................................................................127

6.3 Birdfeeder 2 Programming Steps ...............................................................................128

6.3.1 Introduction ........................................................................................................128

6.3.2 Programming Procedure....................................................................................128

6.3.3 TD80 Birdfeeder 2 Detailed Programming Instructions.....................................131

6.3.4 Graphical TD80 Programming Instructions using Birdfeeder 2 .........................133

6.3.5 Connecting the TD80 for Programming Using the SVRS232 to USB Converter

...........................................................................................................................146

6.3.6 Advanced Birdfeeder 2 Programming Operations.............................................152

6.3.7 MDU (Birdfeeder) Programming........................................................................160

6.3.8 Programming Checklist......................................................................................162

Index of Figures

Figure 1-1: Dual Rod Probe Truck & Trailer Installation................................................................14

Figure 1-2: Coaxial Probe Truck & Trailer Installation...................................................................15

Figure 1-3: SV Programming Kit....................................................................................................16

Figure 2-1: Sample Depth Chart....................................................................................................23

Figure 2-2: Locating the Probe ......................................................................................................24

Figure 2-3: Trailer Mounted Tank ..................................................................................................25

Figure 2-4: Locating the Top Fitting...............................................................................................26

Figure 2-5: Locating the Anchor Cone...........................................................................................27

Figure 2-6: Mechanical Installation of the TD80 System ...............................................................28

Figure 2-7: Dual Rod Probe Measurement....................................................................................33

Figure 2-8: Cutting the Dual Rod Probe.........................................................................................34

Figure 2-9: Correct Probe Installation............................................................................................35

Figure 2-10: Coaxial Probe Measurement.....................................................................................36

Figure 2-11: Cutting the Coaxial Probe..........................................................................................37

Figure 2-12: Basic System Wiring Diagram for Finch 5332E/PS External Display .......................40

Figure 2-13: Basic System Wiring Schematic for Finch 5332E/PS External Display ....................41

Figure 2-14: Basic System Wiring Diagram for Finch 5332E External Display.............................42

Figure 2-15: Basic System Wiring Schematic for Finch 5332E External Display..........................43

Figure 2-16: Basic System Wiring Diagram for Finch 5332 Internal Display.................................44

Figure 2-17: Basic Alarm Wiring Diagram for Finch 5332E/PS External Display..........................47

Figure 2-18: Basic Alarm Wiring Diagram for Finch 5332E External Display................................48

TD80™Level Gauging and Overfill Prevention System Product Manual

Page 4 TD80 Introduction/ Rev. 2, August 4, 2015

TPM 001

Figure 2-19: Overfill Prevention Installation Example....................................................................49

Figure 2-20: Finch Relay Module Internal Wiring Diagram............................................................52

Figure 2-21: Finch Relay Module Overfill Prevention System Wiring Diagram for Finch 5332E/PS

with Horns and Lights............................................................................................................53

Figure 2-22: Finch Relay Module Overfill Prevention System Wiring Schematic for Finch

5332E/PS with Horns and Lights...........................................................................................54

Figure 2-23: Finch Relay Module Overfill Prevention System Wiring Diagram for Finch 5332E with

Horns and Lights ...................................................................................................................55

Figure 2-24: Finch Relay Module Overfill Prevention System Wiring Schematic for Finch 5332E

with Horns and Lights............................................................................................................56

Figure 2-25: Basic Shutdown Wiring Diagram for Finch 5332E/PS External Display ...................57

Figure 2-26: Basic Shutdown Wiring Schematic for Finch 5332E/PS External Display................58

Figure 2-27: Basic Shutdown Wiring Diagram for Finch 5332E External Display.........................59

Figure 2-28: Basic Shutdown Wiring Schematic for Finch 5332E External...................................60

Figure 2-29: Single P2000 Overfill Prevention System Wiring Diagram........................................61

Figure 2-30: Single P2000 Overfill Prevention System Wiring Schematic ....................................62

Figure 2-31: Dual P2000 Overfill Prevention System Wiring Diagram ..........................................63

Figure 2-32: Dual P2000 Overfill Prevention System Wiring Schematic.......................................64

Figure 2-33: ABS Power Supply Wiring Example Schematic........................................................65

Figure 2-34: Finch 5332E External Display Terminal Board..........................................................66

Figure 2-35: Finch 5332E/PS External Display Terminal Board....................................................67

Figure 2-36: Finch 5332 Internal Display Jumper Settings............................................................68

Figure 2-37: Finch 5332E(/PS) External Display Jumper Settings................................................69

Figure 3-1: Basic System Wiring Schematic for Finch 5332E/PS External Display......................90

Figure 3-2: Basic System Wiring Schematic for Finch 5332E External Display............................91

Figure 3-3: Basic System Wiring Diagram for Finch 5332 Internal Display...................................92

Figure 3-4: Single P2000 Overfill Prevention System Wiring Schematic ......................................93

Figure 3-5: Finch Relay Module Overfill Prevention System Wiring Schematic for Finch 5332E

with Horns and Lights............................................................................................................94

Figure 3-6: Basic Shutdown Wiring for Finch 5332E/PS External Display....................................95

Figure 3-7: Finch Relay Module Overfill Prevention System for Finch 5332E/PS with Horns and

Lights.....................................................................................................................................96

Figure 3-8: Basic Shutdown Wiring Schematic for Finch 5332E External Display........................97

Figure 5-1: Dual Rod Probe Truck & Trailer Installation..............................................................114

Figure 5-2: Coaxial Probe Truck & Trailer Installation.................................................................115

Figure 5-3: Coaxial Probe Alarm Settings....................................................................................123

Figure 5-4: Dual Rob Probe Alarm Settings.................................................................................123

Figure 6-1: Connecting the TD80 for Programming in the Shop .................................................146

Figure 6-2: Connecting the TD80 for Programming in the Shop Drawing...................................147

Figure 6-3: Connecting the TD80 for Programming on a vehicle with a Finch 5332E Display

(green board).......................................................................................................................148

Figure 6-4: Connecting the TD80 for Programming on a vehicle with a Finch 5332E Display

(green board) Drawing ........................................................................................................149

Figure 6-5: Connecting the TD80 for Programming on a vehicle with a Finch 5332E/PS Display

(red board)...........................................................................................................................150

Figure 6-6: Connecting the TD80 for Programming on a vehicle with a Finch 5332E/PS Display

(red board) Drawing.............................................................................................................151

Figure 6-7: MDU Text file sample ................................................................................................153

Figure 6-8: Blank Depth Chart Form............................................................................................159

Index of Tables

Table 1-1: Sequence of Events with Finch Relay Module installed...............................................13

Table 2-1: TD80 Installation Checklist ...........................................................................................70

Table 5-1: Normal Operation Troubleshooting.............................................................................126

Table 6-1: Programming Checklist...............................................................................................162

TD80™Level Gauging and Overfill Prevention System Product Manual

Rev. 2, August 4, 2015/ TD80 Introduction Page 5

TPM 001

1 TD80 Introduction

1.1 About This Manual

This instruction manual provides information specific to the Titan Logix Corp. TD80™

(hereafter referred to as the TD80) Level Gauging and Overfill Prevention System. Other

peripheral equipment should be supplied with its own instruction manual and that manual

should be referred to for proper operation of the peripheral equipment.

It is essential that this manual be read and understood for proper installation and

operation of your new TD80™Level Gauging and Overfill Prevention System.

THIS MANUAL INCLUDES:

Introduction Description of the key features and components of the

TD80 Level Gauging and Overfill Prevention System.

Installation Description of mounting and wiring of equipment.

Troubleshooting Description of possible problems, their probable causes,

and solutions.

Technical Reference Technical Specification Guides.

Operation Description of Operation and Alarms.

Programming Description of Programming requirements and steps.

1.2 Disclaimer

The information in this document is subject to change without notice. Titan Logix Corp.

makes no representations or warranties with respect to the contents hereof.

Only qualified personnel should install this product. Please read this manual before

installing this product and follow all applicable safety and electrical regulations as

required.

TD80™Level Gauging and Overfill Prevention System Product Manual

Page 6 TD80 Introduction/ Rev. 2, August 4, 2015

TPM 001

1.3 TD80 System Introduction and Description

1.3.1 About the TD80 System

The TD80 Level Transmitter is the heart of the TD80 level measurement

system. The TD80 transmitter uses Guided Wave RADAR (GWR) to

measure liquid level in a tank. It does not use any moving parts for level

measurement.

Guided Wave RADAR is a contacting level measurement method that uses a

probe as a wave guide to channel the radio frequency energy to the liquid

being measured. The probe provides an efficient path for the transmitted

energy and pulse reflections from the surface of the liquid.

The TD80 transmitter measures the time delay between transmitted and

reflected pulses to calculate distance to the material’s surface. This distance

is then used to determine level of the liquid in the tank.

The calculated level is converted into common volume units and is sent to a

Display such as the Finch 5332 Display. The display is also part of an

optional secondary overfill prevention system. TD80 generated alarms

provide the approaching overfill information to halt loading at industry

standard optic controlled loading racks, on-board loading pumps or valves.

The TD80 system consists of a TD80 transmitter, dual rod or coaxial probe

and a Finch Display. Optional components such as the Finch Relay Module,

horns and lights are installed as required.

1.3.2 TD80 System Components

TD80 Transmitter

The TD80 transmitter generates and processes the GWR signals to

determine liquid level in a tank. The TD80 is mounted on the tank top and

connected to the probe, is weatherproof and rated for use in hazardous

locations where explosive fumes may be present. TD80s are available in two

versions, dual rod or coaxial probe for compatibility with a wide range of

liquids.

Probe

The probe guides the transmitted pulse and reflection from the surface of the

liquid. Probes are available in dual rod or coaxial versions and require a

matching transmitter type. The probe is mounted on the tank top and is

connected to the bottom of the transmitter. Dual rod probes are designed for

viscous liquids. Coaxial probes are used mostly for tanks containing products

like aviation fuel.

Finch 5332 Display

Finch Displays are available in weather-proof external versions, the Finch

5332E and a smaller internal version, the Finch 5332. Both provide bright

LED numeric display of volume information, alarms and system error codes

from the TD80 transmitter. Various alarm and error conditions are detected

by the transmitter and display. These alarm states control three internal

relays for alarm annunciation, overfill and low level prevention.

TD80™Level Gauging and Overfill Prevention System Product Manual

Rev. 2, August 4, 2015/ TD80 Introduction Page 7

TPM 001

1.3.3 Optional Components

P2000

The P2000 is an accessory that enables secondary overfill prevention when

used with industry standard optic loading rack controllers.

MIC 10

The MIC 10 is an interface device for connecting multiple TD80s to a third

party modem.

Finch Relay Module

The Finch Relay Module is an accessory that enables overfill prevention by

control of an onboard pump or loading valve.

Horns and Lights

Alarm reporting is through optional vehicle mounted horns and lights.

1.3.4 Theory of Operation

Overview

The TD80 system consists of a TD80 transmitter, dual rod or coaxial probe

and an internal or external Finch Display. Optional components such as

horns and lights are installed as required.

The TD80 continuously measures liquid level in the tank and transmits

volume information with alarm states to the Finch Display. This information is

presented on a large 4 digit display and to alarm controlled relays. Alarms

and errors control three separate relays to signal or control external devices.

These relays indicate Spill, High-High (HH) and system Fail alarms to

external devices such as overfill prevention valves, lights, horns and

stationary loading controls.

The HH, Spill and system Fail alarms provide information to the P2000 or

Finch Relay Module and only permits loading while all conditions are safe.

HH is normally the first shutdown level; Spill is a backup level slightly higher

than HH, while Fail indicates failure of the TD80 system. Activation of any

alarm halts loading to prevent a dangerous overfill condition or spill at the

loading rack.

TD80 Transmitter and Probe

The TD80 transmits a continuous stream of radio frequency pulses into the

probe. These pulses travel along the probe and part of the pulse energy is

reflected back to the transmitter when encountering the surface of the liquid

in a tank.

Time delay between the transmit pulse and reflected pulse is used to

calculate the distance from the tank top mounted transmitter to the liquid

level.

TD80™Level Gauging and Overfill Prevention System Product Manual

Page 8 TD80 Introduction/ Rev. 2, August 4, 2015

TPM 001

The TD80 contains a table describing the tank depth and volumetric

characteristics. This table is programmed before installation and operation on

the tank. Liquid level is calculated from the table using maximum depth of the

tank and distance from the top to the liquid surface. The TD80 “sees” the

depth of air space in the tank and calculates the loaded volume.

Physical limitations of GWR create a dead band at the bottom of the probe

where the transmitted pulse interferes with the reflected echo. This region of

dead band is considered to be the bottom 5.5” of the tank. Any liquid level

measured at 5.5” or less is indicated by the Finch as “2 LO”, meaning “too

low”. An upper dead band exists at 7.5” from the top on the dual rod and 2.5”

on the coaxial probe. Level measurements within the dead bands are

inaccurate and unreliable.

Calculated volume is transmitted to a Finch Display by SV Bus while a

linearly scaled level is sent by the optional 4-20mA interface. The Finch is

able to display up to 4 numeric digits, including a decimal point. This numeric

display correctly indicates volume of loaded product in the tank. The 4-20mA

output is scaled linearly for a volume of 0% at an output of 4mA and 100%

volume at 20mA.

SV Bus

SV Bus is a single wire serial digital communication interface with an error

checking protocol that eliminates false communication between the TD80

transmitter and Finch Display. SV Bus is one of the three wires required for

TD80 operation with the Finch. The other two wires are power and ground.

This bus is designed for reliable communications in stationary and transport

environments.

Finch Display

The Finch Display receives a continuous stream of volume information and

alarm states from the TD80 on the SV Bus. Volume, alarm states and errors

are shown on the 4 digit numeric display. An additional alarm is controlled

directly by the Finch. Alarms and errors control three separate relays to

signal or operate external devices.

TD80 controlled relays indicate Spill, High-High and system Fail alarms to

external devices such as overfill prevention valves, lights, horns and

stationary loading controls. The Finch controlled alarm and relay indicates a

preset, increasing Fill or decreasing Fall level to warn of an approaching

operator action while loading or unloading product.

The Fill/Fall and High-High Alarms remain active until acknowledged by the

operator. The Spill alarm remains active until the spill condition is cleared by

unloading product below the spill alarm level while the system is powered

and monitoring the changing level.

Alarms are acknowledged by button presses on the Finch or a push button

connected to the Alarm Acknowledge input.

TD80 reported errors or malfunctions are indicated by the Finch showing

“E xx”, where xx is an error code and activating the Fail alarm.

Finch reported loss of communication with the TD80 is indicated by showing

“----”and activating the Fail alarm.

TD80™Level Gauging and Overfill Prevention System Product Manual

Rev. 2, August 4, 2015/ TD80 Introduction Page 9

TPM 001

Relay Module

A Finch Relay Module is available to combine the Finch Spill/Fail and High-

High alarm relays with a signal from the vehicle mounted Power Take-Off

(PTO) to safely control an onboard overfill prevention system. The Relay

Module contains high current relays to energize a bottom loading valve or

hydraulic motor bypass valve for loading control. It also contains a terminal

strip for power and alarm accessory interconnections.

P2000

The P2000 is an accessory that enables secondary overfill prevention when

used with industry standard optic loading rack controllers. The Finch

controlled alarms provide an intrinsically safe signal to the P2000 that

permits or denies loading at the rack. The loading rack connections are

made through a standard 7-pin or 10-pin optic socket.

MIC 10

The MIC 10 is an interface device for connecting multiple TD80s to a third

party modem. Level, alarm and error information from the TD80s is collected

by the MIC 10 and forwarded to the modem. The modem is then able to

wirelessly transmit data to the back office for asset management and

tracking purposes.

It can be set to automatically transmit TD80 data at intervals based on a user

preferred configuration, or else can send data on command from the modem.

The MIC 10 features a PTO signal input to enable data transmission only

when the PTO is engaged. This limits the data bandwidth required by a

wireless modem.

1.3.5 The TD80 Alarm System

This description refers to TD80 transmitters and Finch 5332E/PS Display

(Red Terminal Board version). See notes in parentheses for the Finch 5332E

Display (Green Terminal Board version). Internal Finch 5332 description is

the same as the 5332E version. Internal Displays are connected by a pigtail

with labeled wires instead of a terminal board as in the external Finch

versions.

The TD80 alarms are listed below. A vehicle mounted Power Take Off (PTO)

unit may signal a loading or unloading event when alarms are required to be

activated. A Display Enable (PTO) (or Gauge Enable (PTO) on 5332E

Displays) signal to the Finch Display enables these alarms. An inactive PTO

signal holds all alarms in the non-alarming state to prevent false triggering

due to sloshing while driving. This PTO signal is usually a dry contact switch

closed by the mechanical engagement of the PTO.

TD80™Level Gauging and Overfill Prevention System Product Manual

Page 10 TD80 Introduction/ Rev. 2, August 4, 2015

TPM 001

Fill/Fall Alarm

Fill and Fall alarms share one relay output. The alarm is configured as a Fill

or a Fall alarm with Finch Display jumper J9. The alarm point is settable by

the operator. The Fill alarm is typically used to warn the operator when the

loading process is nearing maximum capacity. The Fall alarm is usually used

when unloading and a minimum volume of product must be retained in the

tank to prevent pump damage. Fill or Fall operation is determined when the

system is installed and is configured inside the Finch Display.

The Finch Display is the source of this alarm. Fill/Fall alarms are indicated by

the flashing the current level on the display and activating the Fill/Fall alarm

relay.

High-High (HH) Alarm

The High-High alarm is set during transmitter programming and is normally

the maximum safe volume of the tank. Dual Rod TD80 transmitters and

probes are settable to a volume from 8” below the tank top and lower while

the Coaxial TD80 transmitters and probes are able to be set from 3” and

lower.

The TD80 transmitter is the source of this alarm. The HH alarm is activated

by a measured volume equal to or exceeding the alarm level set during

programming. High-High alarms are indicated by alternately flashing “HH”

along with the current level on the Display and activating the HH alarm relay.

Spill Alarm

Spill is an approaching overfill condition. Dual Rod TD80 transmitters and

probes are factory set at 7.5” below the tank top while Coaxial TD80

transmitters and probes are selectable in the range of 2.5” down to 15.5”

from the top.

The TD80 transmitter is the source of this alarm. Spill alarms are indicated

by showing “SPill” on the display and activating the spill alarm through the

Spill/Fail (or Fail on the 5332E Displays) relay.

Fail Alarm

System failures such as internal transmitter errors, probe faults or loss of

communications are reported by the Spill/Fail (or Fail on the 5332E Displays)

relay.

The Finch Display reports communication failure. The TD80 transmitter is the

source for all other system errors. Errors are displayed as “E xx”, where xx is

an error code. Loss of communication between the TD80 and Finch is

displayed as “----“.

Alarm Relays

1. Fill/Fall relay

2. High-High relay

3. Spill/Fail (or Fail on 5332E Displays) relay.

TD80™Level Gauging and Overfill Prevention System Product Manual

Rev. 2, August 4, 2015/ TD80 Introduction Page 11

TPM 001

Devices such as horns and lights are connected to these alarm relays for

operator action. The Fall, High-High and Spill/Fail relays typically operate

shutdown controls including external relays, and solenoid operated valves.

1.4 Overfill Prevention System Description

The description below incorporates the recommended Finch Relay Module.

See the Overfill Prevention System Installation Section 2.7 for detail.

1. Power On

The TD80 and Finch proceed through the normal start-up sequence as

described below. Once completed; “OFF” will be displayed on the Finch.

Level is displayed for 30 seconds by a momentary press of the Up or Down

buttons.

2. PTO Engaged

The operator engages the truck mounted PTO to begin loading. The PTO

signal to the Finch is controlled by an air/electric switch that causes the

following to occur:

1. Finch Display to an active mode with all alarms enabled and continuous

level display.

2. A Solenoid is energized to allow loading by controlling a Normally

Closed bottom loading valve or a Normally Open hydraulic motor

bypass valve.

3. The Green Light is on to indicate loading is permitted.

4. The Red Light and Horn are off at the start of the loading process.

Bottom Loading Valves:

The unpowered condition of a bottom loading valve is normally closed. The

solenoid must be powered to allow loading. Any alarm condition for system

errors, failures or overfill will cause the solenoid to be de-energized and halt

the loading process. A disengaged PTO will also close the valve.

Hydraulic Bypass Valves.

The unpowered condition for a hydraulic motor bypass valve is normally

open. The solenoid must be powered to allow loading by closing the bypass

circuit. Any alarm condition for system errors, failures or overfill will cause the

solenoid to de-energize and halt the loading process. A disengaged PTO will

also open the valve.

3. Operator fills the tank

The liquid is loaded into the tank using either the on-board or a stationary

pump. When the liquid reaches the Fill alarm level, the following occurs:

a. The Red light and Horn turn on to alert the operator that he is getting

close to the loading limit and has to prepare to turn off the pump and

close the valve.

b. The Green Light stays on to indicate continued loading is permitted.

TD80™Level Gauging and Overfill Prevention System Product Manual

Page 12 TD80 Introduction/ Rev. 2, August 4, 2015

TPM 001

c. The Solenoid continues to be energized to allow loading.

d. The Finch Display flashes the level indication to indicate the active Fill

alarm.

The operator then presses either the Up or Down button on the Finch to

silence the horn, turn off the Red light and return to a normal level display.

The operator continues to load. He will likely manually shut off the pump and

close the valve before the liquid level reaches the HH alarm level. If he does

not and the liquid level reaches the HH alarm level, then the following occurs:

a. Green light turns off

b. The solenoid de-energizes, closing the bottom loading valve or opening

the on-board pump bypass valve. This halts the loading process.

If the tank has been loaded to the required amount, then the operator turns

off the pump, closes the valve, disconnects the hoses and drives away.

If the tank has not been loaded to the required amount, then the operator

clears the HH alarm on the Finch with the UP/UP/DOWN/UP button

sequence. This resets the alarm response and allows further loading with the

following:

a. The Green Light turns back on

b. The Solenoid is re-energized

c. The Solenoid either opens the bottom loading valve or closes the on-

board pump bypass valve to allow loading to continue.

The operator is likely to stop loading before the level reaches the Spill alarm

level.

If the operator continues to load and reaches the Spill alarm level, the

following occurs:

a. Green Light turns off

b. The Solenoid is de-energized

c. The de-energized solenoid either closes the bottom loading valve or

opens the on-board pump bypass valve to halt the loading process.

The operator cannot reset or acknowledge the Spill alarm. The liquid must be

pumped out of the tank until it drops several inches below the HH alarm

level. The Spill alarm then clears and enables loading through a bottom

4. PTO Disengaged

When the operator has completed the loading procedure, he turns off the

PTO. This deactivates the Finch alarms, displays “OFF” and prevents the

solenoid from energizing to disable loading through a bottom loading valve or

a bypass valve on a hydraulic motor.

He now drives to a new location to load or unload.

TD80™Level Gauging and Overfill Prevention System Product Manual

Rev. 2, August 4, 2015/ TD80 Introduction Page 13

TPM 001

5. Sequence of Events with Finch Relay Module installed

Table 1-1: Sequence of Events with Finch Relay Module installed

Event Sequence

Finch

Display

Red Light,

Horn

Green Light

Solenoid

Truck started, PTO NOT

engaged

“OFF”

Pulsed, then

OFF

OFF

OFF

PTO engaged

2 LO or

Level

OFF

ON

ON

Liquid loaded to Fill level

Flashing

Level

ON

ON

ON

Operator presses UP or DOWN

button

Level

OFF

ON

ON

Liquid loaded to HH alarm level

“HH”/Level

OFF

OFF

OFF

Operator presses

UP/UP/DOWN/UP

Level

OFF

ON

ON

Liquid loaded to Spill level

“SPILL”

OFF

OFF

OFF

PTO is disengaged. Operator

drives to next site.

“OFF”

OFF

OFF

OFF

Operator pumps out liquid with

PTO engaged.

Level

OFF

ON

ON

All liquid is pumped out

2 LO

OFF

ON

ON

PTO is disengaged. Operator

drives to next site

“OFF”

OFF

OFF

OFF

TD80™Level Gauging and Overfill Prevention System Product Manual

Page 14 TD80 Introduction/ Rev. 2, August 4, 2015

TPM 001

1.5 Graphical Glossary of Terms

Dual Rod Probe Truck and Trailer Installation

Figure 1-1: Dual Rod Probe Truck & Trailer Installation

TD80™Level Gauging and Overfill Prevention System Product Manual

Rev. 2, August 4, 2015/ TD80 Introduction Page 15

TPM 001

Coaxial Probe Truck and Trailer Installation

Figure 1-2: Coaxial Probe Truck & Trailer Installation

TD80™Level Gauging and Overfill Prevention System Product Manual

Page 16 TD80 Introduction/ Rev. 2, August 4, 2015

TPM 001

TD80 Programming

SV PROGRAMMING KIT

Figure 1-3: SV Programming Kit

PC PROGRAMMING SOFTWARE,BIRDFEEDER 2

Figure 1-4: PC Programming Software Birdfeeder 2

TD80™Level Gauging and Overfill Prevention System Product Manual

Rev. 2, August 4, 2015/ TD80 Installation Page 17

TPM 001

2 TD80 Installation

2.1 TD80 Installation Steps Overview

2.1.1 Pre-Installation Requirements

1. When choosing a location to install the TD80 components, the following guidelines

must be followed:

a. Appropriate industry, national, provincial/state and local codes

b. Fuses and components appropriate for the area classification

2. The tank is completely drained of liquid and vapour free

3. No drilling or welding to the tank and frame without first consulting with the tank

manufacturer.

4. Refer to the TD80 installation guidelines 2.1.3 for the following:

a. Probe and Transmitter location

i. Dual Rod

ii. Coaxial

b. Finch Display location

c. Finch Relay Module location

d. Electrical requirements

2.1.2 Installation Steps Overview

1. Program the TD80

a. The TD80 must be programmed before use. Programming may be done at the

factory when purchased, by the customer prior to installation or after installation

on the vehicle when necessary.

b. See the Programming Instructions 6.3 for detail.

2. Install the 1” NPT Top Fitting (collar)

a. Ensure that the top fitting position allows the probe to fit vertically into the tank.

b. Weld the top fitting to the tank top

c. See the Mechanical Installation Instructions 2.4 for detail.

3. Install the Anchor Cone

a. Ensure that the anchor cone is directly under the collar, within 3 degrees from

vertical.

b. Weld the anchor cone to the tank bottom

c. See the Mechanical Installation Instructions 2.4 for detail.

4. Install the Probe

a. Cut probe to length

b. Install with Teflon tape or anti-seize compound

c. The probe must fit into the anchor cone without bending, twisting or binding.

d. See the Mechanical Installation Instructions 2.4 for detail.

5. Mount the Transmitter

a. Do not use Teflon tape or anti-seize compound

b. Hand-tighten the transmitter nut, and then use a wrench to secure the

connection.

c. See the Mechanical Installation Instructions 2.4 for detail.

6. Mount the Finch Display

a. See the Mechanical Installation Instructions 2.4 for detail.

TD80™Level Gauging and Overfill Prevention System Product Manual

Page 18 TD80 Installation/ Rev. 2, August 4, 2015

TPM 001

7. Mount the Relay Module (optional)

a. See the Mechanical Installation Instructions 2.4 for detail.

8. Mount the Alarm Accessories (optional)

a. Lights

b. Horns

c. Alarm Acknowledge push button

d. See the Mechanical Installation Instructions 2.4 for detail.

9. Inspect the Mechanical Installation

a. See the Mechanical Installation Instructions 2.4 for detail.

10. Install the Electrical Wiring

a. The TD80 transmitter is provided with a 50’ or 75’ cable kit. It is recommended to

use the kit with included sealing fitting for connection to the Finch Display.

b. All electrical grounding is to the vehicle or trailer electrical ground connection and

not to the chassis.

c. For trailers, connect the TD80 system power and ground to the nose box

electrical connector. For trucks, connect TD80 system power to a switched

accessory power connection from the battery.

d. Wire splices should be made inside a weather proof enclosure or junction box to

prevent premature failure due to corrosion.

e. Secure all wires and cabling with clips or cable ties

f. Tighten all compression fittings

g. Refer to the specific installation wiring diagrams and instructions for details. See

sections 2.5, 2.6, 2.7 for wiring examples.

11. Set and Verify the Finch Display Jumpers. Place the following jumpers in the

positions required for the installation. See Figure 2-36 & Figure 2-37.

a. Decimal point, J2 to J5

b. Fill alarm relay, J1

c. Fail/Spill relay, J10

d. Fill/Fall alarm, J9

12. Confirm Finch 5332E/PS (red terminal board) Fuses are Installed with Correct Type

(Ceramic, Sand Filled, 5x20mm) and Rating (F1, F3-F5: 2A, F2: 5A) or Finch 5332E

(green terminal board) 3A Blade Fuse is installed in a non-hazardous location. See

Figure 2-35.

13. Perform the TD80 Basic Operation Test

a. See section 2.2.1.

14. Verify the TD80 Programming Information

a. Correct depth chart and units

b. Fill or Fall alarm level

c. HH level

d. Spill Level

15. Set the Fill or Fall Alarm Level Volume

16. Perform TD80 System Test and Verification

a. See section 2.2.2

17. Perform the Offset Calibration

a. See section 2.2.3

TD80™Level Gauging and Overfill Prevention System Product Manual

Rev. 2, August 4, 2015/ TD80 Installation Page 19

TPM 001

2.1.3 TD80 Installation Guidelines

Probe and Transmitter Location: See TD80 Probe and Transmitter Location 2.3 for

details.

Finch Display Location:

a. Locate Finch 5332, internal Display

i. Sheltered from weather and moisture

ii. Easily visible and within reach of the operator

iii. Must be located in a non-hazardous area

b. Locate Finch 5332E external Display

i. Shielded from wheel spray and stones

ii. Easily visible and within reach of the operator

c. Avoid the following locations:

i. Direct sunlight

ii. Temperatures less than -40C and greater than +65C

iii. Near high voltage/current wiring, contactors, inverters and radio transmitters.

Finch Relay Module Location:

a. Must be located in a non-hazardous area.

Electrical Requirements: See the TD80 Dual Rod or Coaxial Technical Specifications for

details.

2.2 TD80 Installation Test and Calibration

2.2.1 TD80 Basic Operation Tests

The following steps describe basic tests to confirm that the TD80 system is functional

after installation or repair. Troubleshoot and repair all problems if the test results differ

from the ones shown.

1. Inspect installation before power is applied.

2. Turn power on to the TD80 system. The Display should turn on and go through its

start-up sequence (approximately 10 seconds long).

a. Display is tested, showing numbers 0 thru 9 and then letters A thru F

3. Display will show “----”for up to several seconds, then one of the following:

a. “2 LO” if the tank is empty or contains liquid and the depth is less than 5.5”

b. Level if the tank contains liquid and the depth is greater than 5.5”

c. Error message “E xx”, where xx is a number

d. “SPill”

2.2.2 TD80 System Testing and Verification

The following steps describe tests and to be completed after mechanical and electrical

installation of the TD80 system. These tests may also be used to confirm correct system

operation after repair. Normal responses are indicated for each test. Proceed to

troubleshooting if the test results differ from the ones shown.

1. Turn power on to the TD80 system. The Display should turn on and go through its

start-up sequence (approximately 10 seconds long).

a. Display is tested, showing numbers 0 thru 9 and then letters A thru F

b. Fill/Fall alarm is pulsed

TD80™Level Gauging and Overfill Prevention System Product Manual

Page 20 TD80 Installation/ Rev. 2, August 4, 2015

TPM 001

i. Installed light will blink

ii. Installed horn will briefly sound

iii. Installed underfill prevention system will activate then deactivate

c. Fail/Spill alarm is pulsed

i. Installed light will blink

ii. Installed horn will briefly sound

iii. Installed Overfill prevention system will activate then deactivate

2. Display will show “----”for up to several seconds, then one of the following:

a. “2 LO” if the tank is empty or contains liquid and the depth is less than 5.5”

b. Level if the tank contains liquid and the depth is greater than 5.5”

c. Error message “E xx”, where xx is a number

d. “SPill”

3. Test the volume display by doing the following:

a. For dual rod probes, run your hand along the probe to check the volume display

and alarm settings. If the probe is not within reach, use foil or a metal rod to short

the two probe rods together.

i. Volume displayed will increase as the hand or shorting rod moves toward the

top of the compartment

ii. Volume displayed will decrease as the hand or shorting rod moves toward

the bottom of the compartment

b. For coaxial probes, insert a small metal rod into the holes along the probe. Short

the center rod to the outer tube to check the volume and alarm settings.

i. Volume displayed will increase as the shorting rod moves toward the top of

the compartment

ii. Volume displayed will decrease as the shorting rod moves toward the bottom

of the compartment

4. Set the Fill alarm according to the customer’s requirements.

5. Clear all active alarms.

6. Confirm that the following occurs when the probe is shorted at selected points:

a. “2 LO” is displayed when the tank level is less than 5.5”. Volume is displayed

when the level is above 5.5”.

b. Installed Fall alarm activates when the tank level decreases to or is less than the

Fall alarm setting.

i. Display flashes the volume

ii. Installed light and horn activate

iii. Installed underfill prevention system activates

c. Installed Fall alarm deactivates when either the Up or Down button is pressed.

i. Display returns to normal, not flashing

ii. Installed light and horn deactivate

iii. Installed underfill prevention system deactivates

d. Installed Fill alarm activates when the tank level increases to or exceeds the Fill

alarm setting.

i. Display flashes the volume

ii. Installed light and horn activate

e. Installed Fill alarm deactivates when either the Up or Down button is pressed.

i. Display returns to normal, not flashing

ii. Installed light and horn deactivate

f. HH alarm activates when the tank level reaches the HH alarm setting.

Other manuals for TD80

1

Table of contents

Other Titan Logix Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Elcometer

Elcometer 319/2 operating instructions

Blue-White

Blue-White ProSeries-M MS-6 Series quick start guide

BEANAIR

BEANAIR BeanDevice Wilow AX-3D quick start

National Instruments

National Instruments PCIe-5763 Getting started guide

Kobold

Kobold SMV operating instructions

Kobold

Kobold DRS Series Operating instruction