Lift-Rite, Tel: Toll Free from USA: 1-800-558-6012, Greene, NY 13778, Publication Number 1156118D ©2022 Dated 23 Sep 2022

3

SAFETY PROCEDURES

(Read and understand prior to using this product)

• Read and obey all labels on this product. If you have any questions about these, ask your

supervisor.

• Do not operate this hand pallet truck unless you are authorized and trained to do so.

• Never overload your hand pallet truck. Stay within its rated capacity.

• Do not operate this truck if damaged or not in proper working order.

• Distribute the load evenly on the forks. Do not concentrate loads at one point or load one fork

more than the other.

• When the load impairs visibility, the hand pallet lift truck should be pulled and not pushed.

• Always look where you are operating. Keep a clear view.

• Only handle loads on flat level surfaces. Do not use a loaded truck on inclines or declines.

• Never carry passengers.

• Never put your feet, hands, or any other body part under the frame assembly.

• Always yield right of way to pedestrians.

• Do not allow your hand pallet truck to drop from one level to another. Even a drop of 1 in.

(25 mm) more than doubles the effective load momentarily and results in a loading that can

bend or break components.

• Move loads only with the hand pallet truck in its lowest position.

• Always make sure that the load is stable before moving to eliminate the opportunity for load

shift.

• Use extreme care when rounding corners. Too fast a speed could cause a hand pallet lift truck to

tip. If loaded, the load could shift and fall.

• When not in use, fully lower the forks.

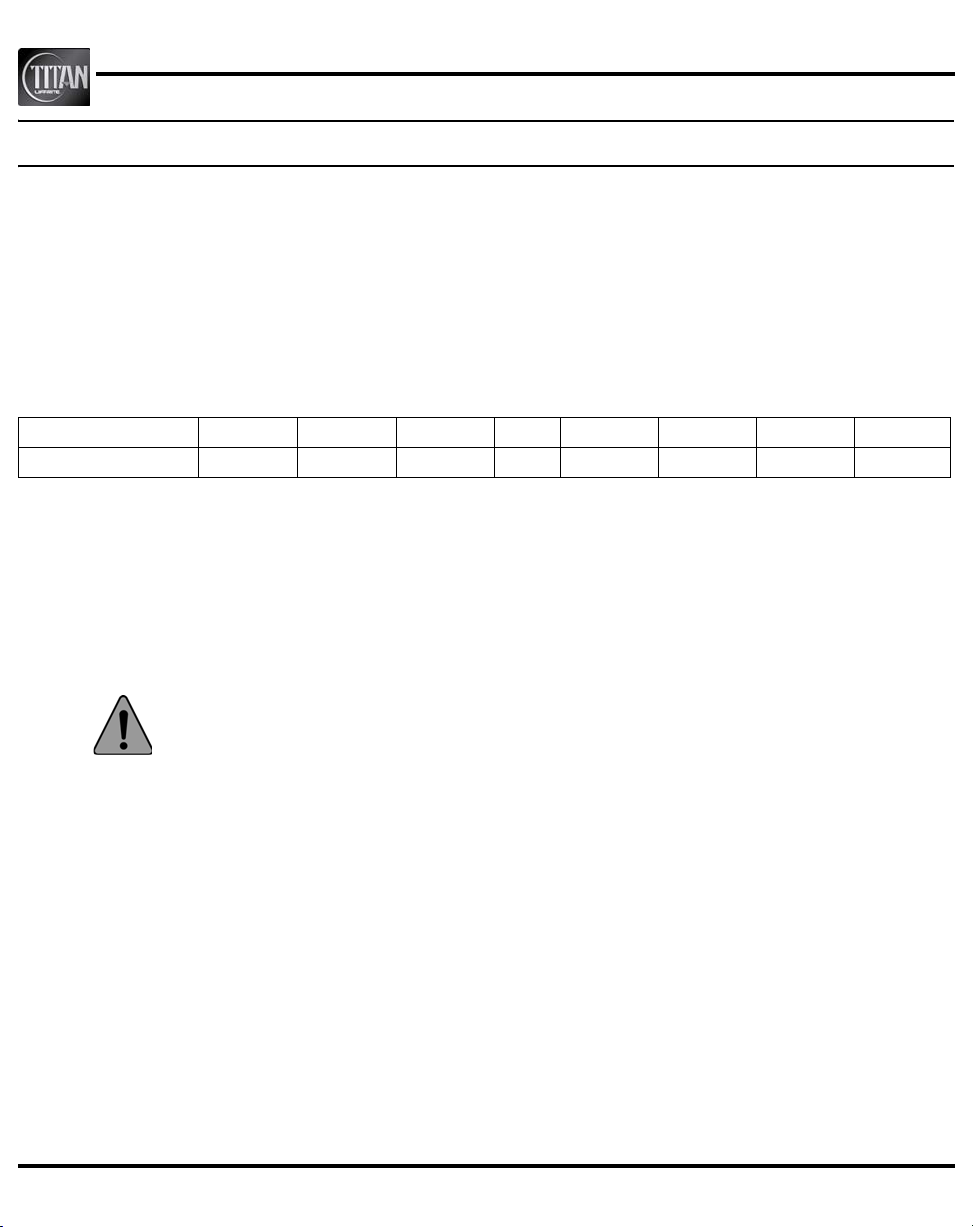

DAILY INSPECTION

At the start of your shift, check the items listed below. Report any malfunction or unsafe conditions

to your supervisor. Do not use this product until it is repaired.

CHECK

POINTS Steering

Hydraulic

System Wheels

Chassis/

Handle

Lifting/

Lowering Labels

ACTION Check full

rotation

Check for

excessive oil

on exterior

and check for

function

Check for wear,

damage, and

remove debris

Check for

damage and

remove debris

Check for

function

Check for

readability