4

Warnings, Safety information and Guidance

Important Information . . . . . . . . . . . . . . . . . . . . . . . .2

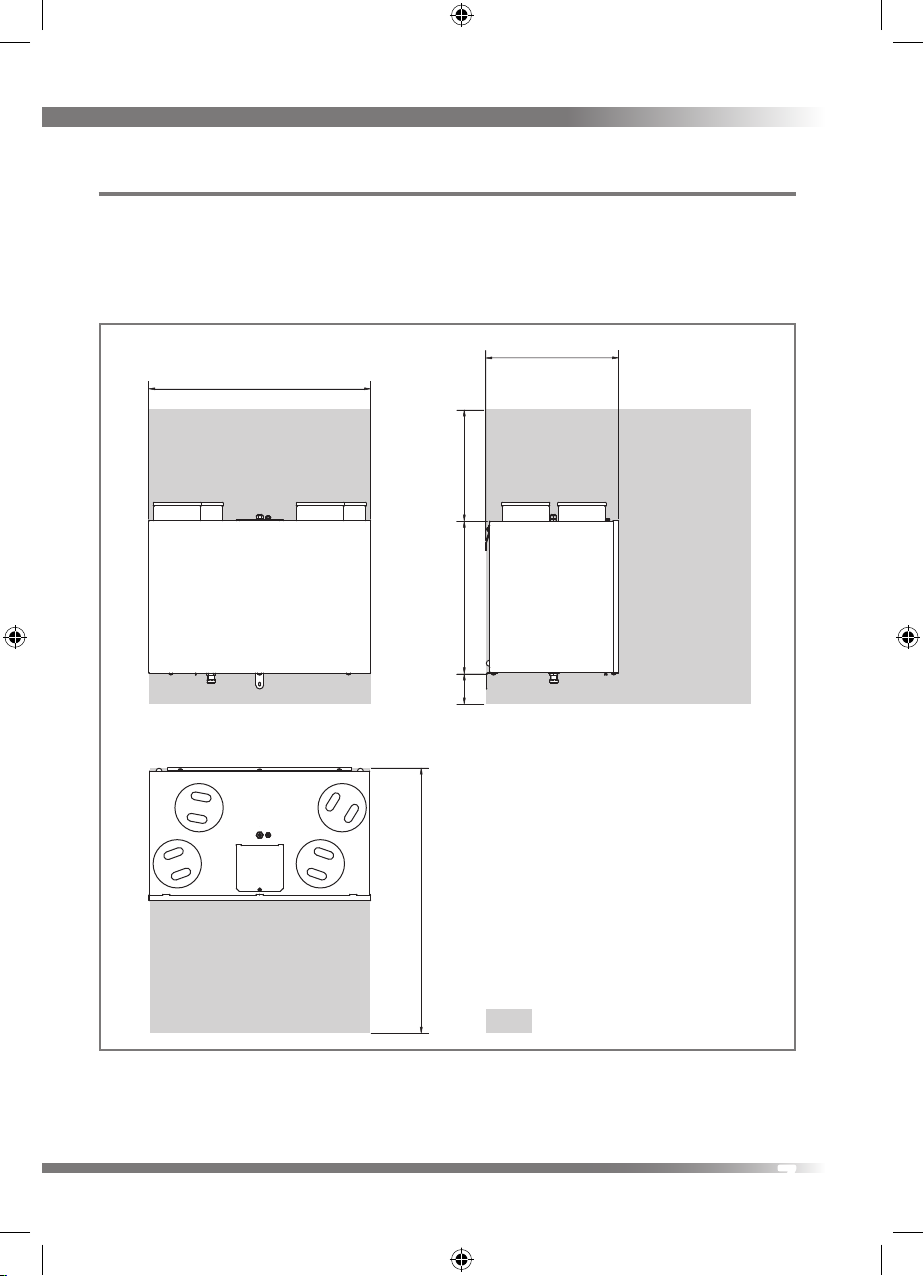

Dimensions HRV1 & 1.25 Q Plus � � � � � � � � � � � � �6

Dimensions HRV1.5, 1.75, 2, 2.75 & 3 Q Plus� � � �7

Product Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Controls & Features . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Setback Speed . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Boost Speed with Overrun Timer . . . . . . . . . . .9

SUMMERboost® ABS models only . . . . . . . . . .9

Summer Bypass . . . . . . . . . . . . . . . . . . . . . . . .10

Automatic Frost Protection. . . . . . . . . . . . . . .10

Duct Heater. . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Filter Covers . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Constant Volume Fans . . . . . . . . . . . . . . . . . . .10

Packaging Contents. . . . . . . . . . . . . . . . . . . . . . . . . .11

Installation

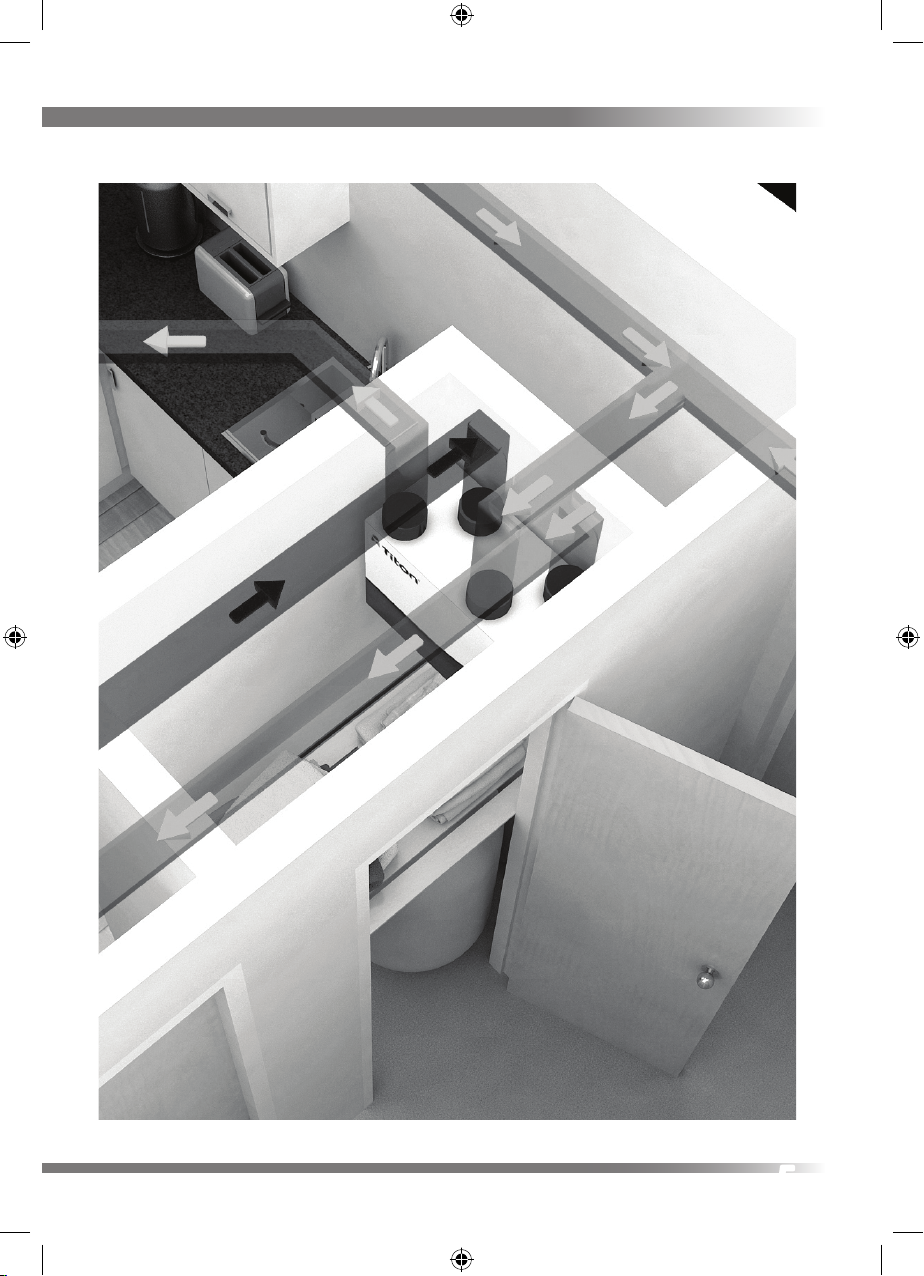

Fixing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Condensate Drain . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Ducting Connections. . . . . . . . . . . . . . . . . . . . . . . . .16

Wiring Connections Access. . . . . . . . . . . . . . . . . . . .18

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . .19

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . .20

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . .21

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . .22

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . .23

Duct Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Connection to Mains . . . . . . . . . . . . . . . . . . . .26

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . .27

Overheating . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Commissioning

Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Control Parameters . . . . . . . . . . . . . . . . . . . . . 28

Continuous Supply & Extract Speeds: . . . . . .29

Boost Supply & Extract Speeds: . . . . . . . . . . .29

Boost Overrun. . . . . . . . . . . . . . . . . . . . . . . . . .29

Controller Reset . . . . . . . . . . . . . . . . . . . . . . . .30

Hardware Reset . . . . . . . . . . . . . . . . . . . . . . . .30

Maintenance

Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . 31

Front Cover Removal . . . . . . . . . . . . . . . . . . . .31

Cleaning Interior . . . . . . . . . . . . . . . . . . . . . . .32

Cleaning Exterior . . . . . . . . . . . . . . . . . . . . . . .32

Condensate Tray. . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Filter Replacement . . . . . . . . . . . . . . . . . . . . . . . . . .33

How to Change Filters . . . . . . . . . . . . . . . . . . .34

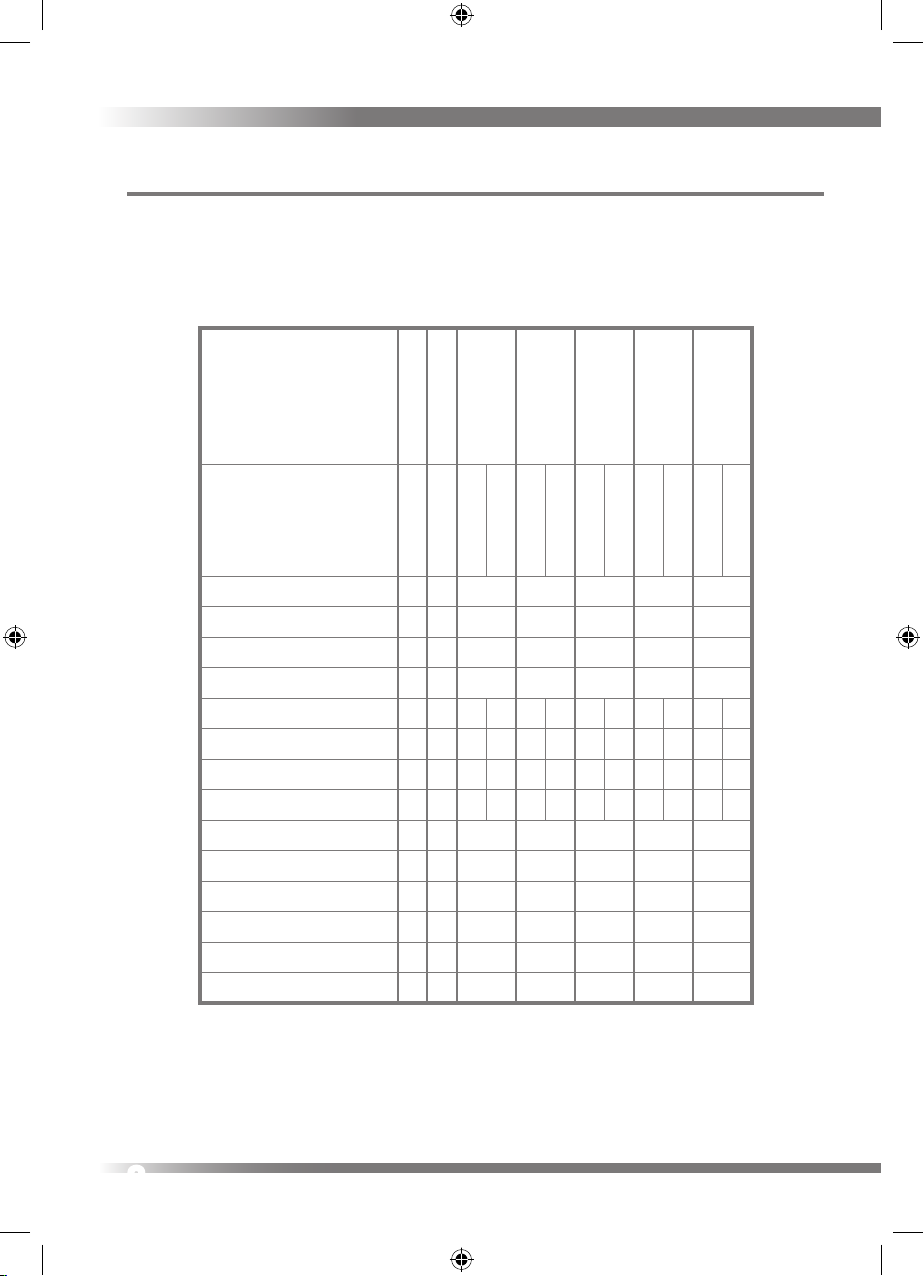

Service Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35