Tlian T4 User manual

For professional use only

T4 PV CONNECTOR

INSTALLATION

MANUAL

A Canadian Solar subsidiary

T4 PV CONNECTOR

INSTALLATION MANUAL

2

|

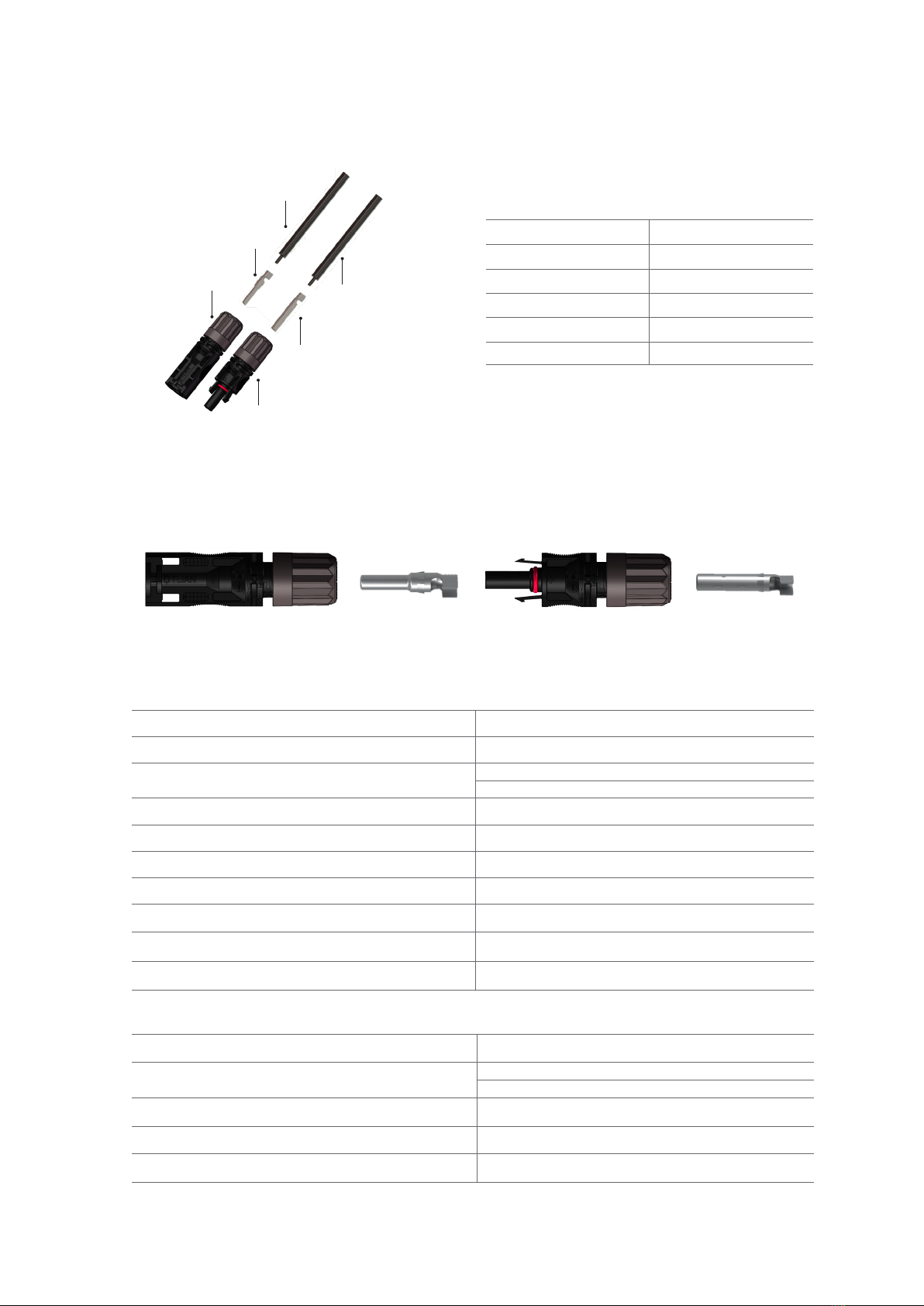

1. T4 CONNECTOR PARTS

2. T4 PRODUCT SPECIFICATIONS

3. T4 CONNECTOR TYPE

4. SAFETY PRECAUTIONS

5. T4 FIELD TOOLKIT

6. CONNECTOR & WIRE ASSEMBLY STEPS

7. THE CORRECT CONNECTION

8. DISCONNECTING THE CONNECTORS

|3

|3

|4

|4

|4

|5

|7

|7

AMENDED EDITIONS AND DATES |7

EN-Rev IM-TC-EN/1.7 Copyright © Mar.2021. Tlian (Changshu) Co., Ltd.

LIST OF FORBIDDEN CHEMICAL SUBSTANCES |8

|

3

1. T4 CONNECTOR PARTS

③

①

①

④

⑤

②

Connector Specication T4-PC-1

Rated Voltage IEC 1500 V DC & UL 1500 V DC

Rated Current 48A (4 mm²)

54A (6 mm²)

Contact Resistance ≤ 0.25 mΩ

Pollution Degree ClassⅡ

Protection Class ClassⅡ

Protection Degree IP68

Fire Resistance UL 94-V0

Temperature Range - 40 °C ~+ 90 °C

Rated Impulse Voltage 16 kV

2. T4 CONNECTOR SPECIFICATIONS

Connector Specication T4-PC-1

Cable Range IEC: 4 mm² / 6 mm²

UL: 12 AWG / 10 AWG

Connector System Φ 4.0 mm

Contact Material Copper, Tin-plated

Type of Termination Crimping

Item Part Name

1 PV Cable

2 Male Pin Contact (-)

3 Male Connector (-)

4 Female Socket Contact (+)

5 Female Connector (+)

Male Connector (-) Male Pin Contact (-) Female Socket Contact (+)

Female Connector (+)

ELECTRICAL DATA:

MECHANICAL DATA:

4

|

4. SAFETY PRECAUTIONS

Products must be assembled and installed by

qualied personnel, ensuring all safety regulations

are followed. For protection against electric

shock, please ensure the system is not energized

during installation. Do not disconnect under load.

Ensure that the AC and the DC sides are both

disconnected and the system is not energized before

disconnecting.

Use only the tools and components listed in this

installation manual. Follow the instructions as stated

in this manual. Do not alter or willingly damage the

product in anyway.

• Sealing cap must be used on disconnected

connectors to prevent dust ingress.

• Connectors are IP68-rated when mated.

• Do not place connector directly on roof surface.

• CAUTION1 :

The exposure to or direct contact with chemicals or

oils of T4 product may cause corrosion, degradation

of performance, or cracking of the product, thus

such exposure or direct contact should be strictly

prohibited during the process of product manufactu-

ring, transportation, installation and application.

It is the user's responsibility to validate any chemi-

cal that may come into contact with or used in any

of the processes mentioned above,to ensure that

such chemical will not affect the performance of T4

products.

5. T4 FIELD TOOLKIT

3. T4 CONNECTOR TYPE

Article Cable Outside Diameter

(OD) Picture Required Torque

to Lock Reference Gap

Male

Connector (-) 4.3mm - 6.6mm

6.7mm -7.5mm (Large)

3.0 N•m ~ 4.0 N•m 0.5< gap ≤ 1.5mm

Female

Connector (+) 3.0 N•m ~ 4.0 N•m 0.5 < gap ≤ 1.5mm

Male

Pin Contact (-) —— —— ——

Female Socket

Contact (+) —— —— ——

Wire crimping tool

Wire stripper toolCuttingpliers

T4-PC-1(1500v)

spareconnetors

Disconnect tools

Crimping tool

accessory

EN-Rev IM-TC-EN/1.7 Copyright © Mar.2021. Tlian (Changshu) Co., Ltd.

Metal disconnect

tools

gap

gap

• CAUTION 2:

Interconnection of different connector models/brands with T4 is

not allowed.

• CAUTION 3:

Recycling and all other types of comparable disassembly of the

above mentioned products have to be performed by a qualied

waste management company, in compliance with national and

local waste management regulations.

|

5

Type Crimping Range

2.5/14 2.5 mm214 AWG

4.0/12 4.0 mm212 AWG

6.0/10 6.0 mm210 AWG

Mark Riveting Range

2.5/14 2.5 mm214 AWG

4.0/12 4.0 mm212 AWG

6.0/10 6.0 mm210 AWG Sealing ring

PARTS INCLUDED IN FIELD TOOLKIT:

Wire stripper tool

Wire crimping tool

Crimping tool accessory - part of wire crimping tool

Cutting pliers

Disconnect tools

1 set = 2 pieces

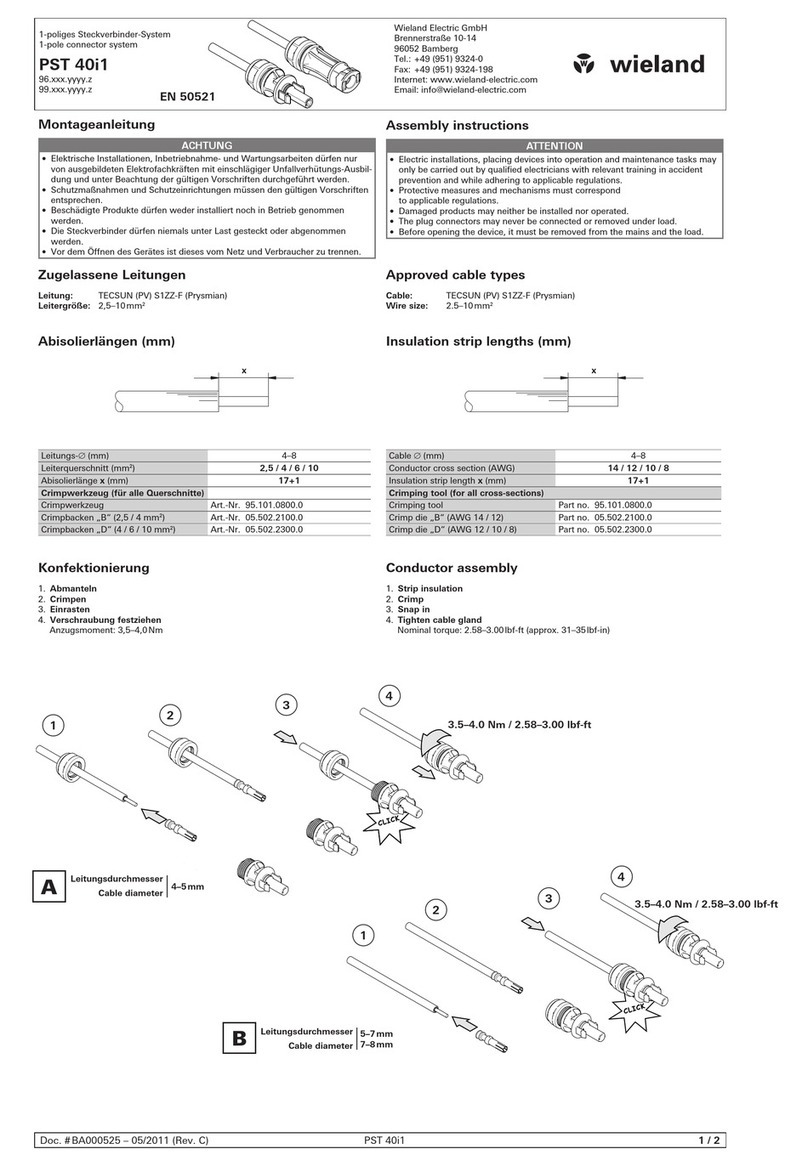

6. CONNECTOR & WIRE ASSEMBLY STEPS

STEP 1:

VISUAL INSPECTION OF CONNECTOR

FEMALE CONNECTOR

a. Sealing ring should t cleanly in the slot and

not be warped or distorted.

b. The two plastic clasps should be intact.

c. Female connectors should not be

obstructed by foreign objects or water.

d. Plastic components should not be cracked.

e. No damage should be visible on the cable.

MALE CONNECTOR

a. Male connector should not be obstructed by

foreign objects or water.

b. Plastic components should not be cracked.

c. No damage should be visible on the cable.

6

|

STEP 2:

STRIP THE INSULATION OFF THE CABLE

Using the wire stripper tool, remove the insulation

from the cable. Ensure that 7.5 mm of cable are

exposed, and that the wire strands are not damaged

during the process of stripping the insulation.

STEP 3:

CRIMP THE CONTACT

Place the contact around the bare section of the

stripped wire. Crimp the contact using the wire

crimping tool. The crimped contact should withstand

pull forces of ≥310 N.

STEP 4:

INSERT THE CONTACT

Push the crimped contact back into the connector until

you hear a click. Lightly pull the wire to ensure the

metal components of the connector are engaged.

STEP 5:

TIGHTEN THE CABLE GLAND

First, tighten the gland by hand, then use the

disconnect tools to tighten the gland to the connector

until it clicks, ensuring that it is locked. When tighteng

the male connector, please use aligner available on

the disconnect tool in order to ensure the pin is not

skewed.

STEP 6:

MAKE CONNECTION

Check the appearance of the connectors before

connecting them together. The sealing ring should

be in the slot with no warping or distortion. The

plastic clasps should not be damaged or broken. The

connectors should be free of moisture and foreign

objects. Plastic parts should not be cracked. Wire

should not be frayed or damaged. When attaching,

insert the connectors into each other until you hear a

“click”. Once attached, gently pull on the connectors to

ensure they are rmly connected and cannot be easily

disconnected by hand.

STEP 7:

VISUAL INSPECTION OF THE CONNECTION

To check the connection, ensure that you cannot see

the sealing ring. The gap between the connectors

should be less than 0.5 mm.

7.5 mm

EN-Rev IM-TC-EN/1.7 Copyright © Mar.2021. Tlian (Changshu) Co., Ltd.

√

×

|

7

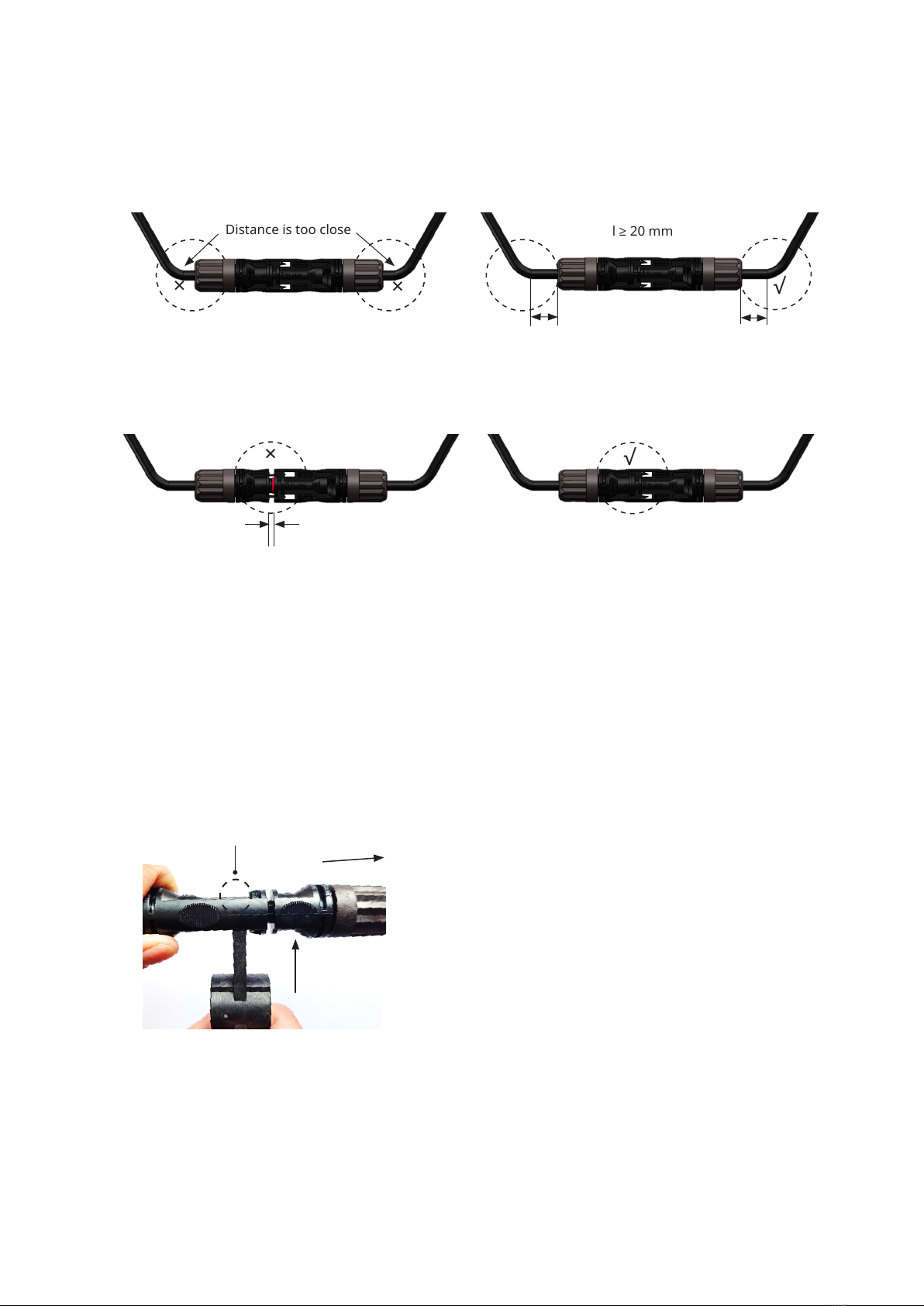

7. THE CORRECT CONNECTION

Please refer to the detailed instructions of the

minimum bend radius given by the cable

manufacturer

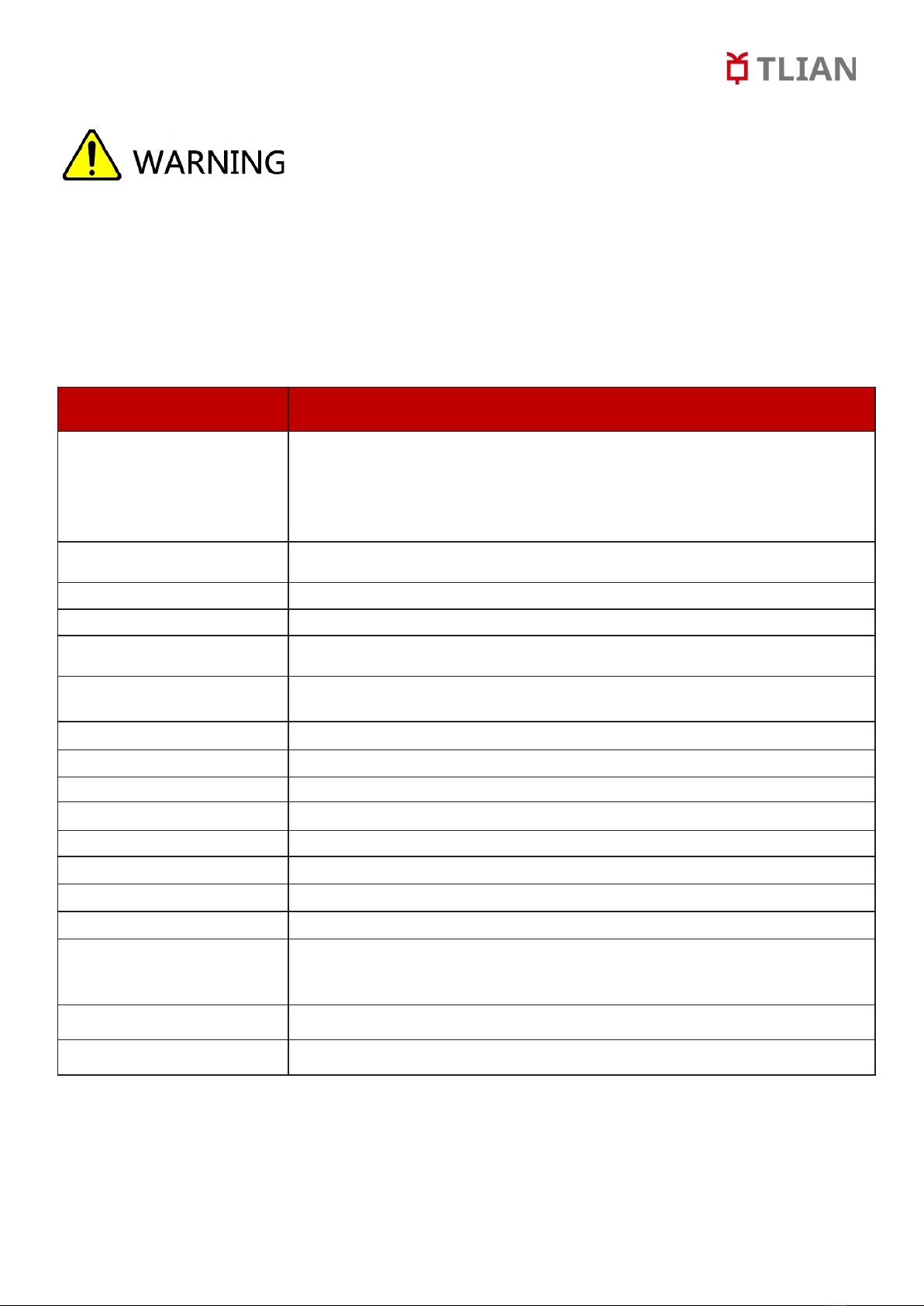

8. DISCONNECTING THE CONNECTORS

The mated connectors can only be disconnected by

using the disconnect tools.

Insert the clasp of the disconnect tool in the slots of

the male connector, and the female connector will

automatically get disconnected .

The technical descriptions herein are only for

reference when using these products.

Clasp of the

disconnect tool

Insert into

the slot

Automatically

disconnected

AMENDED EDITIONS AND DATES

Incorrect bend Correct bend

Incorrect connection Correct connection

√

××√

×√

Gap ≥ 0.5 mm

l ≥ 20 mm

Distance is too close

l ≥ 20 mm l ≥ 20 mm

Rev 1.0 was released in November 2016.

Rev 1.1 was amended and released in May 2017.

Rev 1.2 was amended and released in Sep 2017.

Rev 1.3 was amended and released in Apr 2019.

Rev 1.4 was amended and released in Sep 2019.

Rev 1.5 was amended and released in Apr 2020.

Rev 1.6 was amended and released in Jun 2020.

Rev 1.7 was amended and released in Mar 2021.

8

|

Class Chemical Name

Commonly used chemicals

Food release spray,Herbicide,Insecticide,Grease,Lubricate oil,Rust inhibitors

,REMA New punch oil,Stamping oil,Engine Oil,Banana Oil,WD-40,Oily seal-

ing agent,Doduconta B25 Kontaktol,Evabrite S,Virex TB,Suma Lima L3,Suma

Rinse,Detergent,Plasticizer,Spray cleaner8188,CM-31S,REMA cleaner oil,DX-

1,CH1160,Dry lubricating oil,Paint remover,hydraulic oil,Special glue quick sol-

vent,Gasification rust inhibitor,Dehumidifying anti-rust lubricant,Cutting oil.

Disinfectants/Cleaners Betadine,Cide,Ammonia,Organic Ammonium Chloride,

Hydrogen peroxide,Bleach,Saline,Detergent.

Cosmetics Hand cream,Sunscreen,Lipstick,Sun screen,Makeup remover.

Oils Die Cut(OELHELD) ,Machine Oil KV46(Nippon Oil),Infeld stamping oil.

Edible Corn oil,Cola,Light syrup,Rapeseed oil,Blend oil,Olive oil,

Castor oil,Soybean oil,Coconut oil.

Acid,Alkali,Salt Ammonium hydrogen,Potassium hydroxide,Salt acid,Sulfuric acid,Nitric acid,-

Phosphoric acid,Acetic acid,Ammonia,Sodium hydroxide.

Grease Vaseline ,Molykote EM-50L(Dow Corning),Molykote PG-641(Dow Corning).

Mould Release Agent Pelicoat S-6(Chukyo-Kasei).

Binder Chemlok(LORD).

Alcohols Ethylene glycol,Amyl alcohol,Ethanol,Isopropanol,Isopropyl alcohol(IPA).

Fatty hydrocarbons Heptane,Hexane,Cyclohexane,Liquid paraffin.

Halogenated hydrocarbon Freon,Carbon tetrachloride,Trichloromethane,Virex 256.

Ketone Methyl Ethyl Ketone (MEK),Acetone,Methyl ethyl ketone.

Aromatic Hydrocarbon Toluene,Xylene,Cresol.

Other,Organic solvent

Oleic acid C18H34O2,Nonanal C9H18O,Oleic acidC9H18O2,Ethyl acetate,

Butyl acetate,Tributyl phosphate,Kerosene,Gasoline,

Varnish,Esters,Ethers,Amines,Glacial acetic acid,Print ink,3M.

Adhesion sealant APF125(Wacker Chemical) 3M adhesive,Avancis adhesive.

Potting Material KE-200(ShinEtsu),CX-200(ShinEtsu).

Users of T4 products should prevent the exposure of T4 products to any of the following chemical substances

listed below. These chemicals may cause corrosion, degradation of performance, or cracking of product and

might lead to potential safety issues in applications.

Lists of all known chemicals:

Remarks:

For any chemical not listed above that may come into contact with any T4 product,it is the user's responsibility to

validate that such chemical will not affect the performance of T4 products.

Final interpretation is owned by TLIAN

LIST OF FORBIDDEN CHEMICAL SUBSTANCES

|

9

TLIAN (CHANGSHU) CO., LTD.

Guanghuahuan Road No.6, Changshu, China

EN-Rev IM-TC-EN/1.7 Copyright © Mar.2021. Tlian (Changshu) Co., Ltd.

Other manuals for T4

1

This manual suits for next models

1

Table of contents

Other Tlian Cables And Connectors manuals