TLV EF200 User manual

172-65639M-01 (EF200) 13 April 2018

Vortex Flowmeter

EF200

Copyright © 2018 by TLV CO., LTD.

All rights reserved

172-65639M-01 (EF200) 13 Apr 2018

2

Contents

1. Safety Instructions............................................................................................4

1.1 Correct Usage ............................................................................................................ 4

1.2 Dangers and Notes .................................................................................................... 4

1.3 Operational Safety...................................................................................................... 4

1.4 Installation, Commissioning and Operation ............................................................... 5

1.5 Repairs, Dangerous Chemicals ................................................................................. 5

1.6 Technical Improvements............................................................................................ 5

2. System Description...........................................................................................6

2.1 EF200 Measuring System.......................................................................................... 6

2.2 Steam Dryness Fraction Calculator ........................................................................... 7

3. Mounting and Installation.................................................................................8

3.1 Transport.................................................................................................................... 8

3.2 Degree of Protection .................................................................................................. 8

3.3 Installation Conditions................................................................................................ 9

3.3.1 Upstream and Downstream Sections...................................................................... 9

3.3.2 Flow Conditioner (Rectifier)................................................................................... 10

3.3.3 Installation Orientation .......................................................................................... 11

3.3.4 Pressure Measurement Points.............................................................................. 11

3.3.5 Pipeline Heat Insulation ........................................................................................ 12

3.3.6 Minimum Maintenance Space............................................................................... 12

3.3.7 Ensuring accurate measurements ........................................................................ 12

3.3.8 Other Considerations ............................................................................................ 13

3.4 Mounting the Flowmeter........................................................................................... 14

3.5 Mounting the Transmitter (Remote Version)............................................................ 15

3.6 Transmitter Housing / Display (Mounting/Rotating) ................................................. 16

3.7 Protect the Transmitter Against Direct Sunlight....................................................... 17

4. Electrical Connection......................................................................................18

4.1 Connecting the Transmitter...................................................................................... 18

4.2 Wiring Diagrams....................................................................................................... 19

4.3 Connecting to TLV EC351 Flow Computer and Parameter Settings....................... 20

4.4 Connecting the Remote Version.............................................................................. 21

5. Operation.........................................................................................................23

5.1 Display and Operating Elements.............................................................................. 23

5.1.1 Operating Display.................................................................................................. 23

5.1.2 Navigation view..................................................................................................... 24

5.1.3 Editing view........................................................................................................... 26

5.1.4 Operating elements............................................................................................... 27

5.2 Navigating the Operation Menu (Basic Operation of the Function Matrix) .............. 28

5.2.1 Calling up help text................................................................................................ 29

5.2.2 Disabling write protection via access code ........................................................... 29

5.2.3 Enabling and disabling the keypad lock................................................................ 29

6. Technical Data.................................................................................................30

6.1 Technical Data at a Glance...................................................................................... 30

6.1.1 Application............................................................................................................. 30

6.1.2 Function and System Design................................................................................ 30

6.1.3 Input...................................................................................................................... 30

6.1.4 Output ................................................................................................................... 31

6.1.5 Power Supply........................................................................................................ 32

6.1.6 Performance Characteristics................................................................................. 33

6.1.7 Mechanical Construction....................................................................................... 34

6.1.8 User Interface........................................................................................................ 35

6.2 Remote Transmitter Dimensions.............................................................................. 35

6.3 EF200W Dimensions – Flangeless Connection....................................................... 36

6.4 EF200F Dimensions – Flanged Connection ............................................................ 37

6.5 EF200R Dimensions – Flanged Connection............................................................ 39

6.6 Dimensions of Flow Conditioner (optional) .............................................................. 40

172-65639M-01 (EF200) 13 Apr 2018

3

7. Commissioning................................................................................................42

7.1 Function Check.........................................................................................................42

7.2 Commissioning.........................................................................................................42

7.2.1 Switching on the Measuring Device.......................................................................42

7.2.2 Device Setup..........................................................................................................42

8. Device Functions.............................................................................................43

8.1 Function Matrix .........................................................................................................43

8.2.1 Setting the Operating Language............................................................................44

8.2.2 Operation ...............................................................................................................44

8.2.3 Display: Operation →Display................................................................................45

8.2.4 Totalizer handling: Operation →Totalizer handling...............................................45

8.2.5 Medium selection: Setup →Medium selection......................................................46

8.2.6 Current output: Setup →Current output ................................................................47

8.2.7 Pulse/frequency/switch output: Setup →Pulse/frequency/switch output...............48

8.2.8 Display: Setup →Display.......................................................................................51

8.2.9 Output conditioning: Setup →Output conditioning................................................52

8.2.10 Low flow cut off: Setup →Low flow cut off...........................................................52

8.2.11 System units: Setup →Advanced setup →System units....................................53

8.2.12 Medium properties: Setup →Advanced setup →Medium properties .................55

8.2.13 Gas composition: Setup →Advanced setup →Medium properties →Gas

composition..........................................................................................................56

8.2.14 External compensation: Setup →Advanced setup →External compensation....56

8.2.15 Sensor adjustment: Setup →Advanced setup →Sensor adjustment.................57

8.2.16 Totalizer 1 to 3: Setup →Advanced setup →Totalizer 1 to 3 .............................58

8.2.17 Display: Setup →Advanced setup →Display.....................................................58

8.2.18 Configuration backup display: Setup →Advanced setup →Configuration backup

display..................................................................................................................59

8.2.19 Administration: Setup →Advanced setup →Administration ...............................60

8.2.20 Diagnostics...........................................................................................................61

8.2.21 Event logbook: Diagnostics →Event logbook .....................................................61

8.2.22 Device information: Diagnostics →Device information .......................................61

8.2.23 Measured values: Diagnostics →Measured values ............................................62

8.2.24 Output values: Diagnostics →Measured values →Output values......................63

8.2.25 Simulation: Diagnostics →Simulation .................................................................63

8.2.26 Expert...................................................................................................................64

9. Configuration of the Transmitter Housing (Display Unit) .............................65

10. Diagnostics and troubleshooting.................................................................66

10.1 Troubleshooting......................................................................................................66

10.2 Diagnostic message (Error message)....................................................................67

10.3 Overview of diagnostic information.........................................................................69

10.4 Overview of information events ..............................................................................72

11. Flow Rate Data...............................................................................................73

11.1 Flow Rate for Saturated Steam (kg/h)....................................................................73

11.2 Flow Rate for Air or Water (m3/h) ...........................................................................74

11.3 Function Matrix Details...........................................................................................75

12. Product Warranty...........................................................................................76

13. Service............................................................................................................77

172-65639M-01 (EF200) 13 Apr 2018

4

1. Safety Instructions

1.1 Correct Usage

•The EF200 measuring system is used to measure the flow of saturated steam,

superheated steam, air and water. Do not use to measure the flow of toxic,

flammable or otherwise hazardous fluids. Use this system only as intended.

•The primarily measured variables are volume flow and temperature. From

these values, the device can use stored data on density and enthalpy to

calculate and output information such as mass flow and heat flow.

•The manufacturer assumes no liability for damage or other accidents caused

by incorrect use of the instrument.

1.2 Dangers and Notes

All instruments are designed to meet state-of-the-art safety requirements,

have been tested, and have left the factory in a condition in which they are

safe to operate. They can, however, be a source of danger if used incorrectly

or for anything other than the designated use. Consequently, always pay

particular attention to the safety instructions indicated in these Operating

Instructions by the following symbols:

Warning!

This symbol alerts you to a dangerous situation. Failure to avoid this situation

can result in serious or fatal injury.

Caution!

This symbol alerts you to a dangerous situation. Failure to avoid this situation

can result in minor or medium injury.

Note!

This symbol contains information on procedures and other facts which do not

result in personal injury.

1.3 Operational Safety

•The EF200 measuring system complies with EMC requirements of both

IEC/EN 61326 and NAMUR NE 21, and the general safety requirements in

accordance with EN 61010-01.

•EF200 fulfills all requirements for IP 66/67 to EN 60529.

•The appropriate error messages are shown on the LCD display.

•On power failure, the configuration data of the measuring system remain in

the EEPROM. The totalizer remains on the value last shown.

Note!

Warning!

Caution!

172-65639M-01 (EF200) 13 Apr 2018

5

1.4 Installation, Commissioning and Operation

•Mounting, electrical installation, commissioning and maintenance of the

device must be carried out by trained, qualified specialists authorized to

perform such work by the operator of the facility. The specialist must have

read and understand this manual before carrying out its instructions.

•The device may only be operated by personnel who are authorized and

trained by the operator of the facility. Strict compliance with the instructions

in these Operating Instructions is mandatory.

•In the case of corrosive fluids (incl. fluids for cleaning), the user is

responsible for verifying the suitability of the material resistance properties of

wetted parts, as regards their in-process resistance to corrosion; the

manufacturer refuses to accept liability.

•The installer must ensure that the measuring system is correctly wired in

accordance with the wiring diagrams.

Note!

There is no longer any contact protection once the housing cover is removed.

•Observe all local regulations governing the opening and repair of electrical

devices.

1.5 Repairs, Dangerous Chemicals

Warning!

The following procedures must be carried out before an EF200 is sent to TLV

for repair:

NOTE: References to use with hazardous fluids are for customers having

special permission and a signed contract with TLV for hazardous use.

•A note must be enclosed with the instrument, containing a description of the

fault, the application and the chemical and physical properties of the fluid

being measured.

•Remove all fluid residues that may be present. Pay special attention to the

gasket grooves and crevices where fluid may be present. This is especially

important if the fluid is dangerous to health, e.g. flammable, toxic, caustic,

carcinogenic, etc.

•No instrument should be returned to TLV without all dangerous material

being removed first.

Incomplete cleaning of the device may result in waste disposal requirements

or cause harm to personnel (burns, etc.). Any costs arising from this will be

charged to the operator of the device.

1.6 Technical Improvements

The manufacturer reserves the right to modify technical data without prior

notice. Your local TLV Distributor or Sales Office will supply you with all

current information and any updates to this manual.

Note!

Warning!

172-65639M-01 (EF200) 13 Apr 2018

6

2. System Description

The EF200 vortex flowmeter measures the temperature and volumetric flow of

steam, gases and liquids with temperatures in the range of -200 to +400 °C

and at nominal pressures of up to 4.96 MPaG (49.6 barg).

EF200 can measure the volumetric flow rate in operation and can be

programmed to supply the flow rate in mass, energy or corrected volume units

via temperature measurements by the internal temperature sensor.

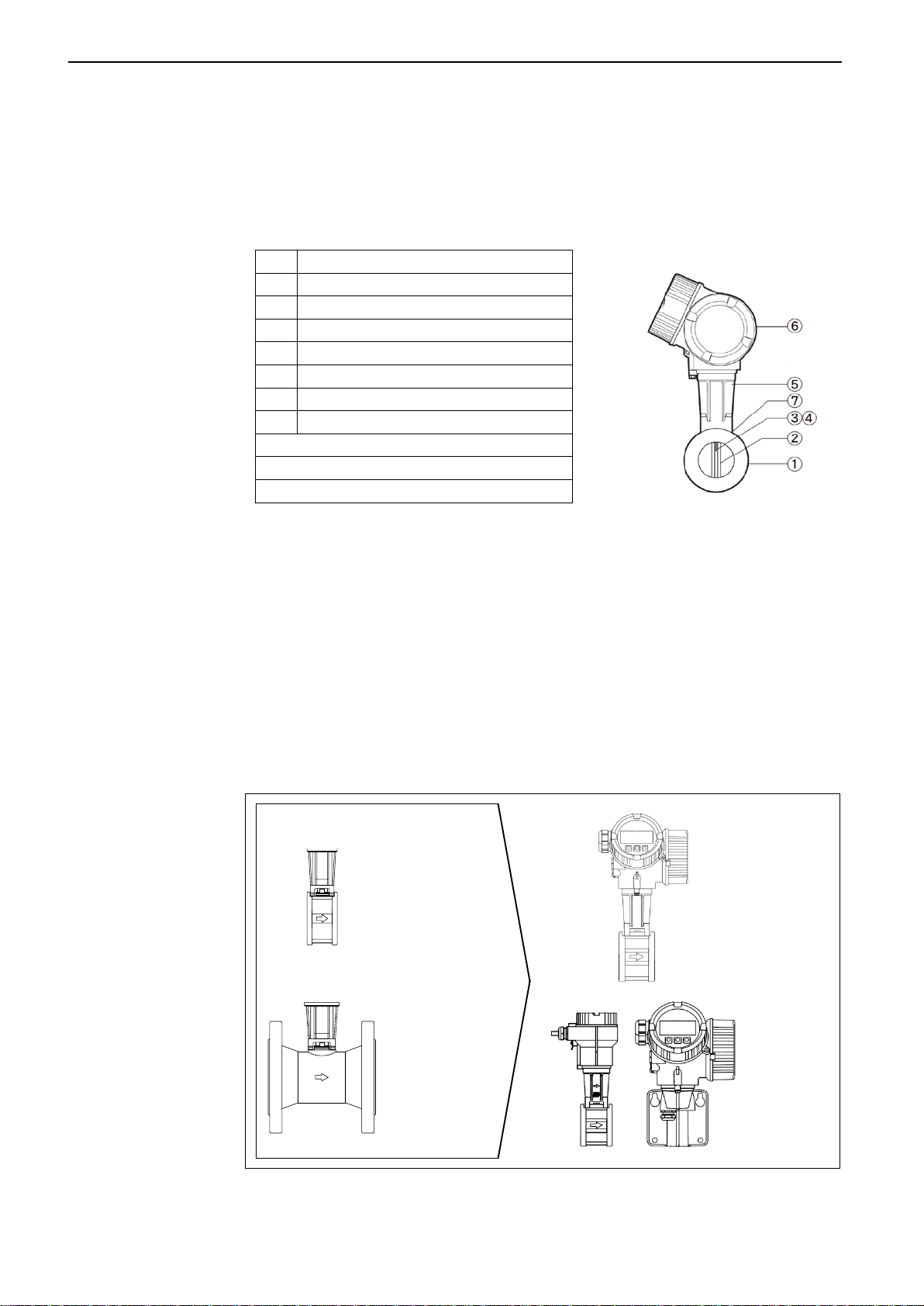

No.

Description

Meter Body

Bluff Body

DSC Sensor (wetted parts)

DSC Sensor (non-wetted parts)

Housing Support

Transmitter Housing

Gasket

Mounting Kit*

Remote Transmitter Mount**

Connection Cable (30 m)**

* Flangeless model only, see 3.5

** Remote version only, see 4.4

2.1 EF200 Measuring System

The measuring system consists of:

•EF200 remote or compact versions

•EF200 flangeless or flanged connection body

In the compact version, the transmitter and sensor form a single mechanical

unit; in the remote version, they are mounted separate from each other. When

the sensor body must be installed in a high or otherwise difficult to reach

location, the remote version allows more accessible transmitter installation.

(See Fig. 1)

Sensor Body

EF200W

Flangeless

DN 15 – 150

Compact

Version

EF200F

Flanged

DN 15 – 300

EF200R

Flanged

DN 25 – 200

Remote

Version

Figure 1

EF200 measuring system

172-65639M-01 (EF200) 13 Apr 2018

7

2.2 Steam Dryness Fraction Calculator

EF200F ordered with the “Steam Dryness Fraction

Calculator” option is not only capable of flow rate

measurement but can also calculate the dryness

fraction of steam.

Measurable range: 80 to 100% (See the figure on

the right for measurement accuracy)

NOTE: Steam dryness fraction is an indication of steam quality. It shows the

ratio of steam by mass in wet saturated steam.

Steam Dryness Fraction (%)=Steam mass flow rate

Steam mass flow rate

+ Water mass flow rate

×100

Caution!

This option cannot be used with EF200W or EF200R.

There are a number of points to consider for the Steam Dryness Fraction

Calculator. Ensure these are met when installing.

Applicable Models

•EF200F (Flanged) DN 25 – 100

Applicable Operating Conditions

•Pressure: 0.1 to 1.0 MPaG (1.0 to 10 barg)

•Temperature: 120 to 185 °C (Saturation temperature for the pressures above)

•Use at a stable pressure and flow rate.

Steam pressure is input in fixed values, therefore correct measurement is

not possible with large pressure fluctuations.

•Make sure the flow rate falls within the measurable range of flow rates at

pressures between 0.1 and 1.0 MPaG (1.0 to 10 barg)

The measurable ranges for flow rate and for steam dryness fraction are

different. Refer to the table below to identify if the Steam Dryness Fraction

Calculator option is applicable.

Caution regarding installation of devices equipped with the Steam

Dryness Fraction Calculator (see 3.3)

•Ensure the required length of straight piping, without using a flow conditioner

•Install on horizontal piping with the display facing downward

Caution!

•When equipped with the Steam Dryness Fraction Calculator function, the

EF200F can be used with steam and water, but cannot be used with air.

•When using the Steam Dryness Fraction Calculator function, the measurement

accuracy for steam mass flow rate will decrease from ±2 °C to ±4 °C.

Measurable flow rates for saturated steam when used with the optional

Steam Dryness Fraction Calculator EF200F (Unit: kg/h)

Size (mm)/DN

25

40

50

80

100

Temp.

(°C)

Pressure

Min. Max. Min. Max. Min. Max. Min. Max. Min. Max.

MPaG

barg

0.1

1

11

66

27

233

44

349

99

872

171

906

120.4

0.2

2

14

96

35

340

57

510

128

1,272

221

1,323

133.7

0.3

3

19

126

45

445

75

668

167

1,666

289

1,731

143.7

0.4

4

23

156

55

548

92

823

206

2,054

356

2,135

151.9

0.5

5

27

185

66

651

109

978

244

2,438

423

2,534

158.9

0.6

6

31

214

76

753

126

1,131

282

2,820

489

2,931

165.0

0.7

7

35

243

86

855

143

1,283

320

3,200

555

3,326

170.5

0.8

8

39

272

96

956

160

1,435

358

3,579

620

3,720

175.4

0.9

9

43

301

106

1,057

177

1,586

396

3,955

686

4,111

179.9

1.0

10

48

329

116

1,158

194

1,737

434

4,333

751

4,503

184.1

Consult TLV for measurable flow rate data in imperial units.

Note!

Caution!

Caution!

80%

90

100

+5

0

-2

-5Measurable Range

Steam

Dryness

Measurement Accuracy of

Steam Dryness

Accuracy %

172-65639M-01 (EF200) 13 Apr 2018

8

3. Mounting and Installation

3.1 Transport

•The devices must be transported in the container supplied.

•Devices with nominal diameter 40 to 300 mm (DN 40 to 300) must not be

lifted at the transmitter housing (compact version) or at the connection

housing (remote version) when transporting (see Fig. 2). Use carrier slings

when transporting and put the slings around both process connections.

Avoid chains as these could damage the housing.

Warning!

The center of gravity of the entire measuring device might be higher than the

suspension points of the slings. Therefore, when hoisting, make sure that the

device does not unintentionally turn or slip, as there is the risk of injury if the

device falls.

3.2 Degree of Protection

IP66/67 (EN60529)

Caution!

The devices fulfill all the requirements for IP66/67, Type 4X enclosure.

Compliance with the following points is mandatory following installation in the

field or servicing in order to ensure that IP66/67, Type 4X enclosure protection

is maintained:

•Housing gaskets must be clean and undamaged when inserted in the

gasket groove. The gaskets may need to be dried, cleaned or replaced.

•All housing screws and screw caps must be firmly tightened.

•The cables used for connection must be of the specified outside diameters.

•Firmly tighten the cable entry (see Fig. 3).

•The cables must loop down before they

enter the cable entries (“water trap”, Fig.

3). This arrangement prevents moisture

penetrating the entry. Always install the

measuring device in such a way that the

cable entries do not point up.

•Replace all unused cable entries with

dummy plugs.

•Do not remove the grommet from the

cable entry.

Temperature Ranges

•The maximum allowable ambient and

process temperatures must be

observed (see 6.1.6).

•Ensure both pipeline heat insulation and

mounting position conditions are met

(see 3.3).

Figure 3

Protection Class

IP66/67, Type 4X

enclosure

Warning!

Figure 2

Instructions for

transporting sensors of

sizes 40 -300 mm

Caution!

172-65639M-01 (EF200) 13 Apr 2018

9

3.3 Installation Conditions

A vortex flowmeter requires a fully developed flow profile as a prerequisite for

measuring volume accurately. The following points must therefore be noted

when mounting the EF200 in the pipeline.

Pipe Inner Diameter

When ordering, ensure that the nominal diameter and pipe schedule

(DIN/ANSI/JIS) are correct, since calibration of the flowmeter and therefore the

achievable accuracy of the measuring point are dependent on these

specifications.

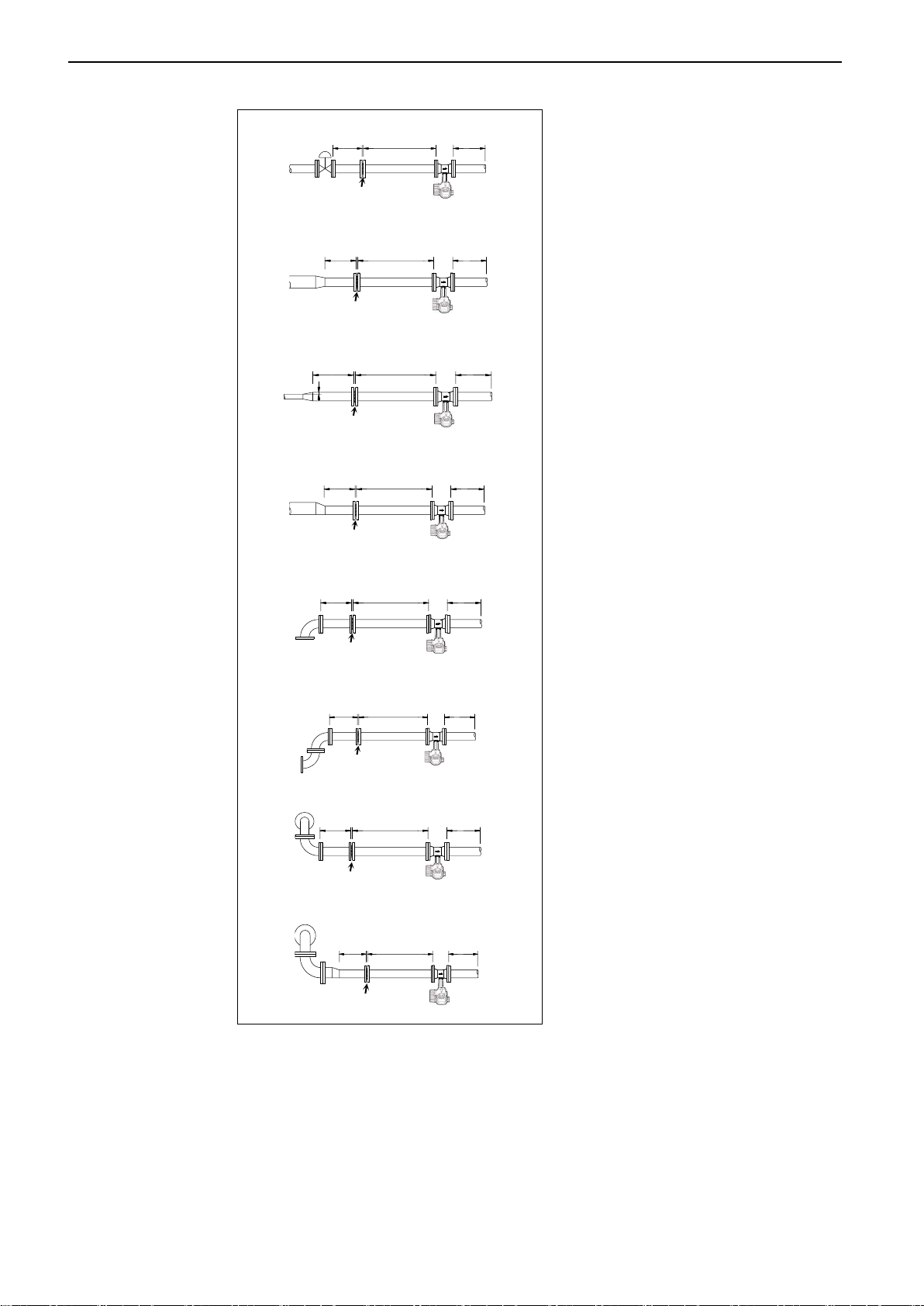

3.3.1 Upstream and Downstream Sections

To ensure an undisturbed flow profile,

the vortex flowmeter should be

mounted up- and downstream of any

flow disturbances such as pipe

elbows, reducers or valves, otherwise

the longest possible straight section

of piping should be between the

disturbance and the flowmeter. The

figures on the right show the

minimum section of straight piping up-

and downstream of the disturbance

as multiples of the nominal diameter

of the pipe (D, see Fig. 4-1). If two or

more flow disturbances are located

upstream, the minimum section of

straight piping upstream is equal to

the sum of each individual

disturbance’s requirements up to a

maximum of 50D.

Example:

For 25 mm diameter piping with one

90° elbow:

20D = 20 ×25 mm = 500 mm,

therefore straight piping length must

be at least 500 mm.

A = Upstream

B = Downstream

D = Nominal Diameter

Control Valve:

Concentric Reducer (Convergent-Pipe) :

Concentric Diffuser (Expansion Pipe):

Eccentric Reducer (Convergent-Pipe):

One 90° Elbow or T-piece:

Two 90° Elbows (2-Dimensional):

Two 90° Elbows (3-Dimensional):

Combination Pipe (Elbows & Eccentric

Reducer, etc.):

AB

50D 5D

AB

15D 5D

AB

18D 5D

AB

25D 5D

AB

20D 5D

AB

25D 5D

AB

40D 5D

AB

50D 5D

Figure 4-1

Upstream

and

downstream

piping

requirements

172-65639M-01 (EF200) 13 Apr 2018

10

3.3.2 Flow Conditioner (Rectifier)

Control Valve and Flow Conditioner:

Concentric Reducer and Flow

Conditioner:

Concentric Diffuser and Flow

Conditioner:

Eccentric Reducer and Flow

Conditioner:

One 90° Elbow or T-piece and Flow

Conditioner:

Two 90° Elbows (2-Dimensional) and

Flow Conditioner:

Two 90° Elbows (3-Dimensional) and

Flow Conditioner:

Combination Pipe (Elbows & Eccentric

Reducer etc.) and Flow Conditioner:

With limited space and large pipes,

it is not always possible to use the

upstream sections shown in Fig. 4-

1. In such cases the specially

developed perforated plate flow

conditioner (see 6.6) can be fitted

as shown on the right (see Fig. 4-

2). The flow conditioner is held

between two piping flanges and

centered with the flange bolts. It

reduces the length of the upstream

section downstream from flow

disturbances to 8D while

maintaining full measurement

accuracy. The total length of

straight piping downstream

becomes 10D to 13D. Note that a

flow conditioner cannot be used in

conjunction with the Steam

Dryness Fraction Calculator option.

A = Upstream

B = Downstream

D = Nominal Diameter

Flow Conditioner

5D 8D 5D

AB

Flow Conditioner

2D 8D 5D

AB

Flow Conditioner

2D+5h 8D 5D

AB

h

Flow Conditioner

5D 8D 5D

AB

2D 8D 5D

AB

Flow Conditioner

5D 8D 5D

AB

Flow Conditioner

5D 8D 5D

AB

Flow Conditioner

5D 8D 5D

AB

Flow Conditioner

Figure 4-2

Upstream and

downstream piping

requirements

172-65639M-01 (EF200) 13 Apr 2018

11

3.3.3 Installation Orientation

The EF200 can be mounted in any direction in

the piping. An arrow on the meter body shows

the direction of flow.

For measuring liquids in vertical pipes, the

meter should be installed with an upwards flow

direction, position A, to make sure pipes are

com

pletely flooded, avoiding partial filling (see

Fig.

5).

For horizontal pipelines, positions B, C and D

are possible (see Fig.

5). With hot piping (e.g.

steam), position C or D must be selected in

order to respect the maximum permissible

ambient temperatur

e at the electronics.

Do not mount the flangeless model

EF200W at

sizes of 100 mm or larger

in position B for use

with fluids

at temperatures equal to or greater

than

200 °C.

Refer to the Technical Data section for

ambient temperatures (see 6.1.6).

Caut

ion!

For use with the Steam Dryness Fraction

Calculator option, ensure the flowmeter is

mounted in position C.

A

B

C

D

3.3.4 Pressure Measurement Points

If a pressure measuring point is installed

after the device, ensure that there is a

large enough distance between the

device and the measuring point so that

there are no negative effects on vortex

formation in the sensor.

(see Fig. 6)

D = Nominal Diameter

Down stream

3D –5D

Figure 6

Mounting pressure

sensors

Figure 5

Installation position

Caution!

172-65639M-01 (EF200) 13 Apr 2018

12

3.3.5 Pipeline Heat Insulation

Caution!

When insulating, please ensure that a sufficiently large area of the housing

support is exposed. The uncovered part serves as a radiator and protects the

electronics from overheating (or undercooling).

The maximum insulation height permitted is illustrated in Figure 7 (marked

“max.” with a limiting line). These apply to both the compact version and the

sensor in the remote version, as well as all installation orientations.

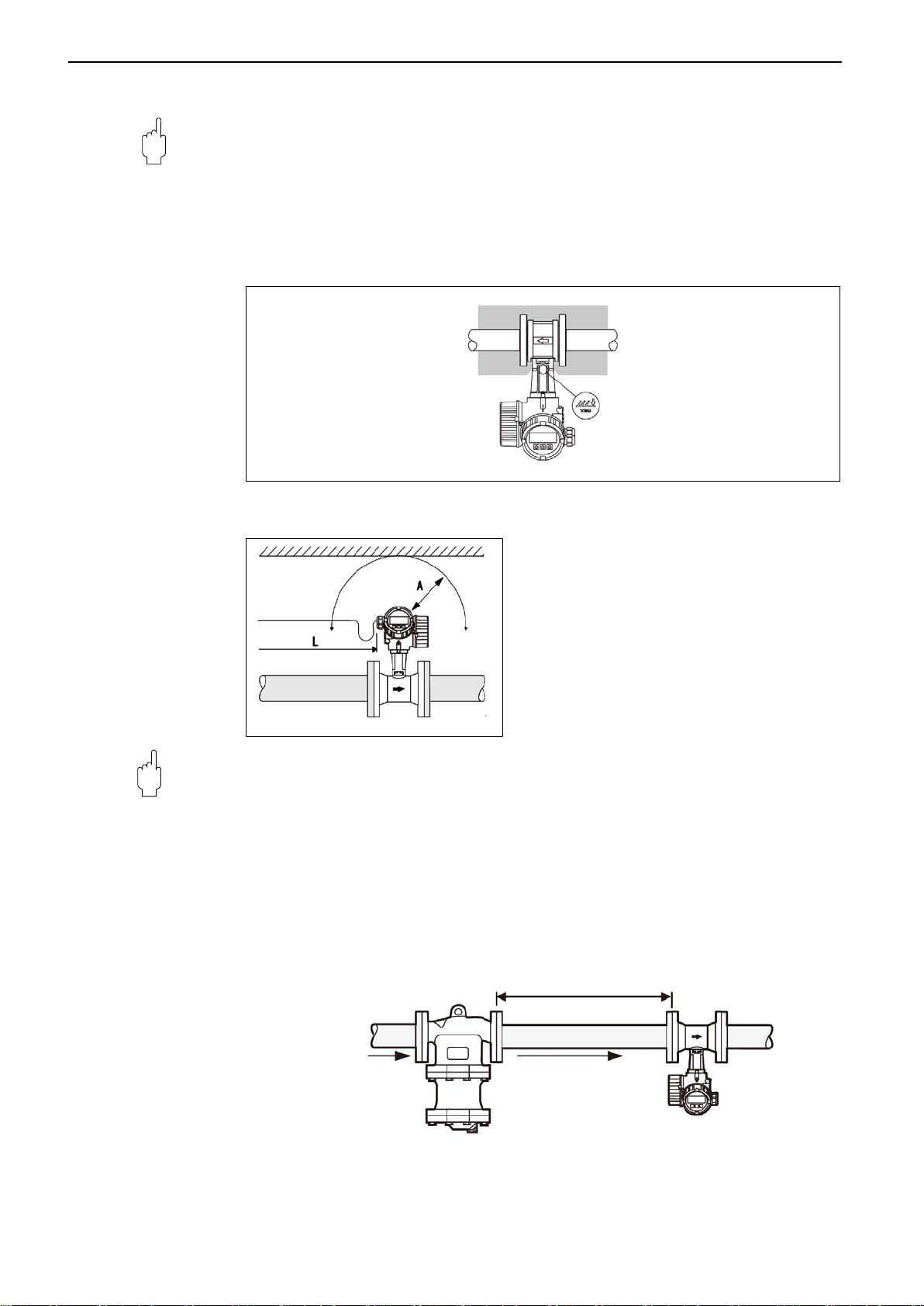

3.3.6 Minimum Maintenance Space

When servicing, it is necessary to

remove the transmitter housing from the

housing support.

When installing in the piping, be sure to

secure the following cable lengths and

minimum maintenance space:

•Minimum maintenance space in all

directions: A = 100 mm

•Cable length required: L + 150 mm

Caution!

Removing the transmitter from the housing support is to be carried out by

qualified TLV appointed service personnel only!

3.3.7 Ensuring accurate measurements

In some cases where steam is mixed with condensate, it may not be possible

to obtain accurate flow rate measurements.

To remove these causes for concern about flow rate measurements, it is

recommended to install a separator upstream of the flowmeter.

Saturated steam

without droplets

Wet steam

with droplets

50 ×D

Figure 8

Minimum spacing for

mounting and removing

the transmitter housing

Caution!

Figure 7

Pipeline insulation

flangeless/flanged

version

Caution!

172-65639M-01 (EF200) 13 Apr 2018

13

3.3.8 Other Considerations

Vibrations

The correct operation of the measuring system is not influenced by plant

vibrations up to 1 g, 10 to 500 Hz. Consequently, the sensors require no

special measures for attachment. If higher levels of vibration are expected, be

sure to secure piping before and after the flow meter.

Preventing Excessive Flow

Caution!

To ensure long service life for the flowmeter, excessive instantaneous/

periodical flow rates should be held below the flow meter’s maximum flow rate.

Failing to do so might result in damage to the sensor. Special care is

necessary for steam at startup when the pressure is low, or when a valve is

opened rapidly, such as by a solenoid valve, as excessive instantaneous flow

rates often occur.

Pulsating Influences

The ability of the flowmeter to measure correctly may be adversely affected if

there are large variations of pressure or pulsating pressure from compressors

and/or soot blowers. Use the procedures below to minimize pulsating

pressures:

•Move the source of the pulsations to the downstream side of the flowmeter.

Alternatively, put as much distance as possible between the source and the

flowmeter.

•Install a pulsation dampening device, such as a chamber.

•Close the valves before and after the flowmeter when there is no flow.

(This is to prevent false non-zero readings under zero-flow conditions.)

Prevent Mixed Phase Flow

This flowmeter is designed to measure both gases and liquids. However,

accurate measurement cannot be guaranteed when gases and liquids are

mixed together (i.e. gas-liquid mixed phase flow).

Ensure Pipe is Flooded

When measuring liquids ensure that the pipe is flooded, as this will have an

influence on the accuracy of flow rate measurements.

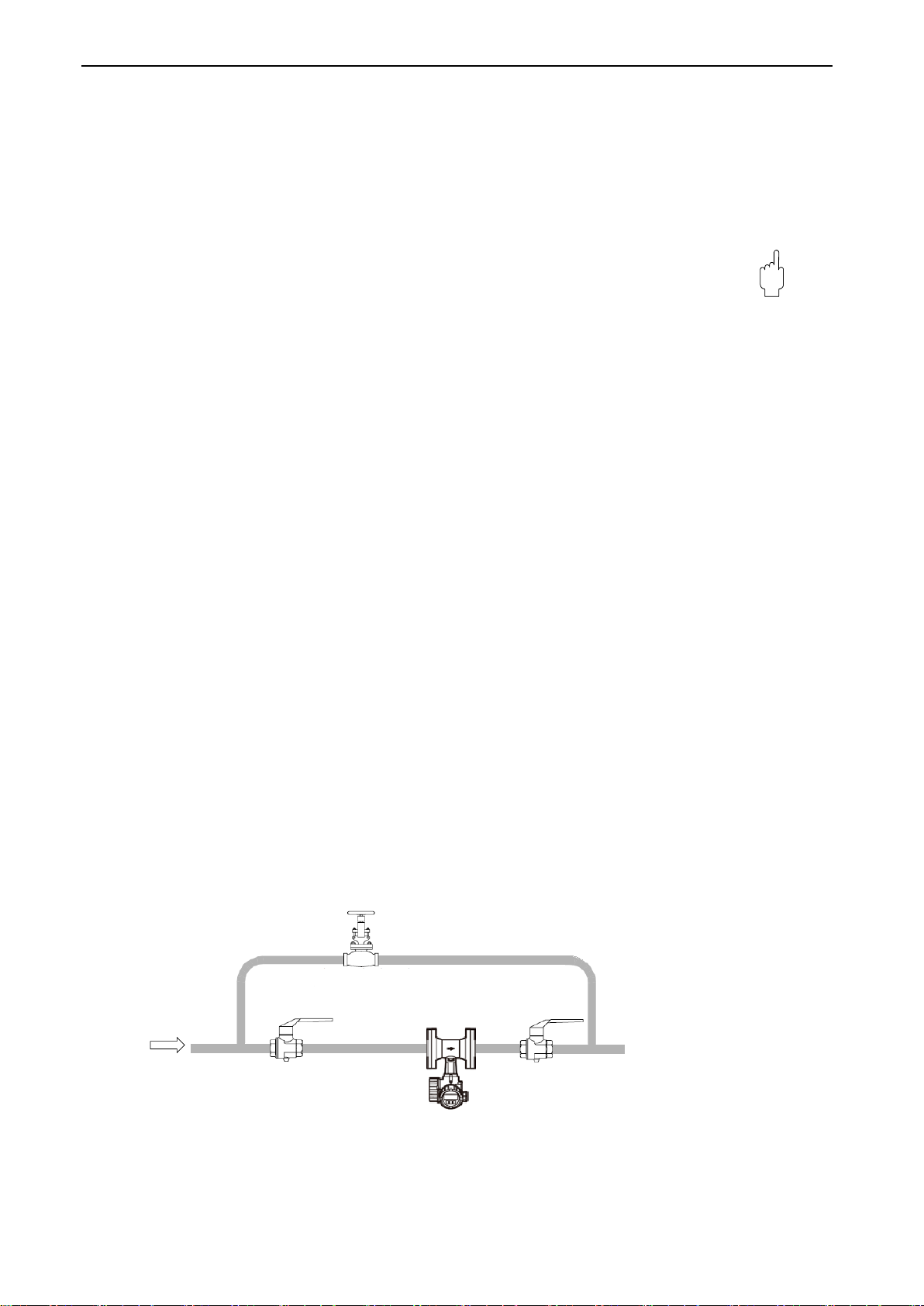

Bypass Lines

The installation of bypass lines can facilitate maintenance and inspections.

When installing a bypass line, use upstream and downstream valves of a type

that does not disturb the flow profile, and secure sufficient length of straight pipe.

EF200

Bypass Valve

Ball Valve

Direction of

Flow

Ball Valve

Caution!

172-65639M-01 (EF200) 13 Apr 2018

14

3.4 Mounting the Flowmeter

Warning!

Note the following points before installing the flowmeter:

•Remove all packaging used for transport and protective coverings from the

flowmeter before installing the flowmeter in the pipeline.

•Ensure that the inner diameters of the gaskets are identical to or larger than

those of the meter body and process piping. Gaskets that protrude into the

flow affect vortex formation behind the bluff body and lead to inaccurate

measurement. Therefore, the gaskets delivered by TLV come with a slightly

larger inner diameter than the measuring pipe.

•Confirm the gaskets are not dirty or damaged.

•Ensure that the direction of the arrow on the sensor body matches the flow

direction (direction of medium flow in the piping).

•Mount the flowmeter or rotate the transmitter housing so that the cable

entries do not face upward.

Mounting EF200 Flangeless Version

Mounting the flangeless body is carried out using a mounting set (see Fig. 9)

Caution!

By tightening the bolts (tie rods) after fitting the centering rings to the flange

rims on the meter body, it is possible to align the meter body with the piping

and fill the space between the bolts (tie rods) and the meter body. However

the centering rings are not secured to the meter body.

Gasket

Centering

ring

Bolt (tie rod) set

Figure 9

Mounting the EF200

flangeless version

Caution!

Warning!

172-65639M-01 (EF200) 13 Apr 2018

15

3.5 Mounting the Transmitter (Remote Version)

Where the flowmeter body is installed on piping in a high position or in cases

where there is poor accessibility to the display, the remote transmitter display

may be installed in an easily visible location.

The transmitter can be mounted in the following ways:

•Wall mounting (Fig. 10.A)

•Pipe mounting (with optional pipe mounting kit) (Fig. 10.B)

Caution!

Install the transmitter in a location out of direct sunlight and with an ambient

temperature range of -40 to +80 °C. (See 3.7)

However, the display performance of the LCD may be affected or it may be

difficult to read the display if the ambient temperature is below -10°C or above

+60°C.

A: Wall Mounting

B: Pipe Mounting

Unit: mm

Caution!

Take care not to overtighten the nuts when installing the remote transmitter on

piping.

The transmitter housing is constructed from die-cast aluminum, therefore may

be damaged. (Recommended torque: 5 N⋅m)

M8

19 80

80

∅8.6

∅20 –70

Pipe Mounting Kit

(optional)

Caution!

Figure 10

Mounting the transmitter

(remote version)

Caution!

172-65639M-01 (EF200) 13 Apr 2018

16

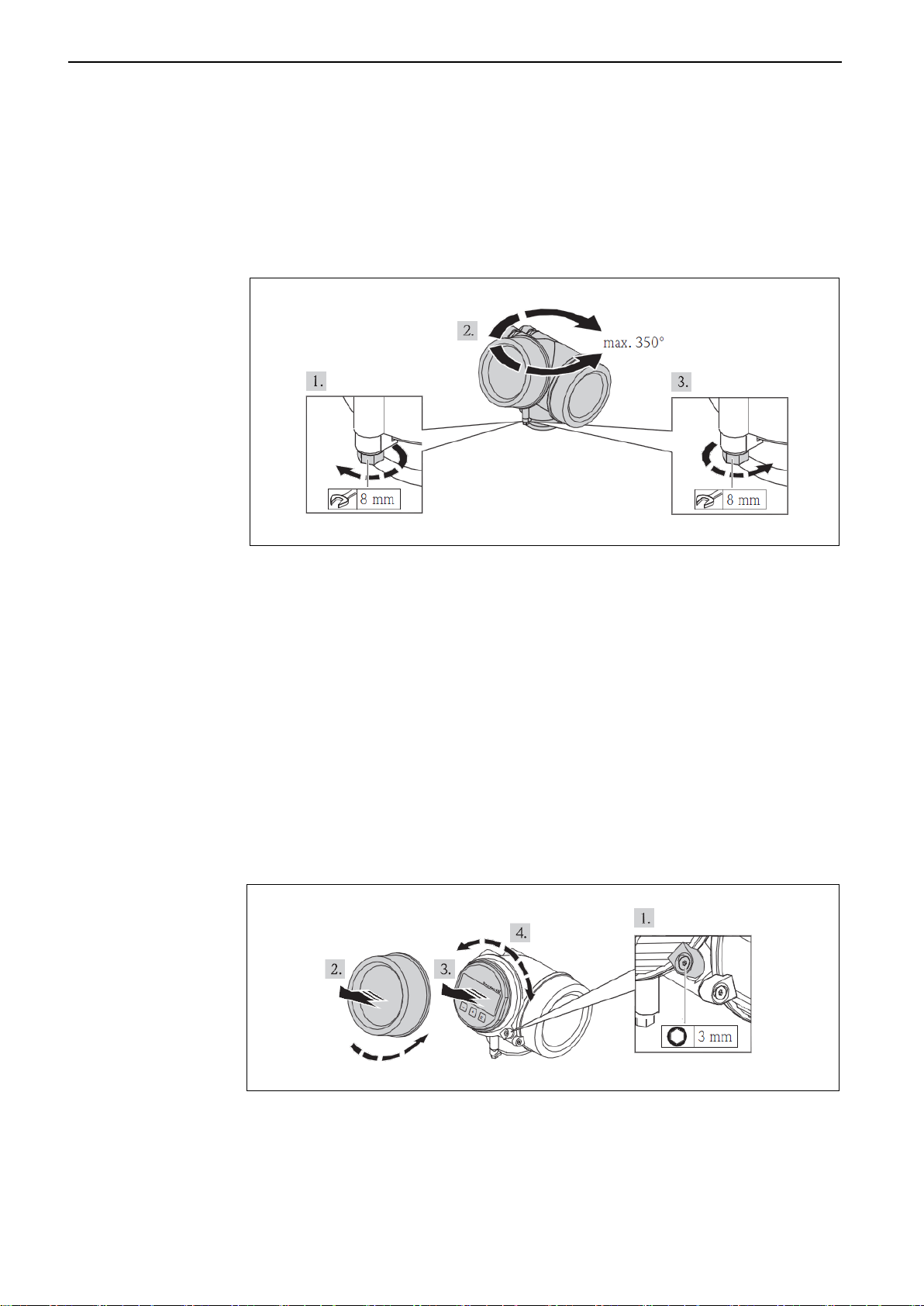

3.6 Transmitter Housing / Display (Mounting/Rotating)

Rotating the Transmitter Housing

The transmitter housing of EF200 can be rotated on the housing support up

to 350° clockwise or counterclockwise to reposition the optional local display

for easy reading.

This is carried out as follows (see Fig. 11):

1. Loosen the securing screw (minimum one turn).

2. Turn the transmitter housing to the desired position.

3. Fasten the securing screw firmly.

Rotating the Display

The display module can be rotated for easy reading in any position (see Fig. 12).

1. Loosen the securing clamp of the electronics compartment cover using a

hex key.

2. Unscrew cover of the electronics compartment from the transmitter

housing.

3. Optional: pull out the display module with a gentle rotational movement.

4. Rotate the display module into the desired position: Max. 8 × 45° in each

direction.

5. Without display module pulled out:

Allow display module to engage at desired position.

6. With display module pulled out:

Feed the cable into the gap between the housing and main electronics

module and plug the display module into the electronics compartment until

it engages.

7. Reverse the removal procedure to reassemble the transmitter.

Figure 12

Rotating the local display

Figure 11

Rotating the

transmitter

housing

172-65639M-01 (EF200) 13 Apr 2018

17

3.7 Protect the Transmitter Against Direct Sunlight

Install the transmitter in a location out of direct sunlight if possible. If the

transmitter is subjected to direct sunlight, even when ambient temperature is

within operational range (80 °C or below), the temperature inside the

transmitter may become higher. Additionally, sunlight may promote

deterioration of the finish and appearance of the unit.

If installation outdoors in an uncovered location in unavoidable, installing the

optional sunshade is recommended. (This is not required when installing

compact version with the transmitter oriented downwards.)

Figure 13

Installing the optional

sunshade

172-65639M-01 (EF200) 13 Apr 2018

18

4. Electrical Connection

4.1 Connecting the Transmitter

Warning!

•Power must be switched off until wiring is completed.

Caution!

•All relevant national installation regulations must be observed.

•The power supply is max. 35 V DC.

Procedure (see Fig. 14)

1. Loosen the securing clamp of the connection compartment cover.

2. Unscrew the connection compartment cover.

3. Push the cable through the cable entry. To ensure tight sealing, do not

remove the sealing ring from the cable entry.

4. Strip the cable and cable ends. In the case of stranded cables, also fit

ferrules.

5. Connect the cable in accordance with the terminal assignment. For HART

communication: when connecting the cable shielding to the ground

terminal, observe the grounding concept of the facility.

6. Firmly tighten the cable glands.

7. Warning!

Housing protection class may be void due to insufficient sealing of the

housing. Reinsert the screw without using any lubricant. The screw threads

on the cover are coated with a dry lubricant.

Reverse the removal procedure to reassemble the transmitter.

To remove a cable from the terminal, use a flat-blade screwdriver to push

the slot between the two terminal holes while simultaneously pulling the

cable end out of the terminal.

Caution!

Figure 14

Procedure for connecting

the transmitter

Warning!

Warning!

172-65639M-01 (EF200) 13 Apr 2018

19

4.2 Wiring Diagrams

EF200 Only, Connecting Power Supply

Frequency (Pulse) Output for an Electronic Counter or PLC

Caution!

The residual voltage of pulse output is 2 V at load current of 2 mA or less,

or 8 V at 10 mA. Make sure to select an electronic counter or PLC

conforming to these specifications or an instrument that can be set to “Low”

level.

Current Output for an Analog Data Receiver

NOTE: Shielded cable recommended for current output.

Power

Supply

+24V

+

–

Electric Counter

or PLC

(Open collector input)

Power

Supply

+24V

+

–

Power

Supply

+24V

+

–

+

–

Data Receiver

(Analog 4 –20 mA

current input)

Figure 15

Power Supply DC24V

Figure 17

Analog current output

connection

Figure 16

Pulse output to electronic

counter or PLC

Caution!

172-65639M-01 (EF200) 13 Apr 2018

20

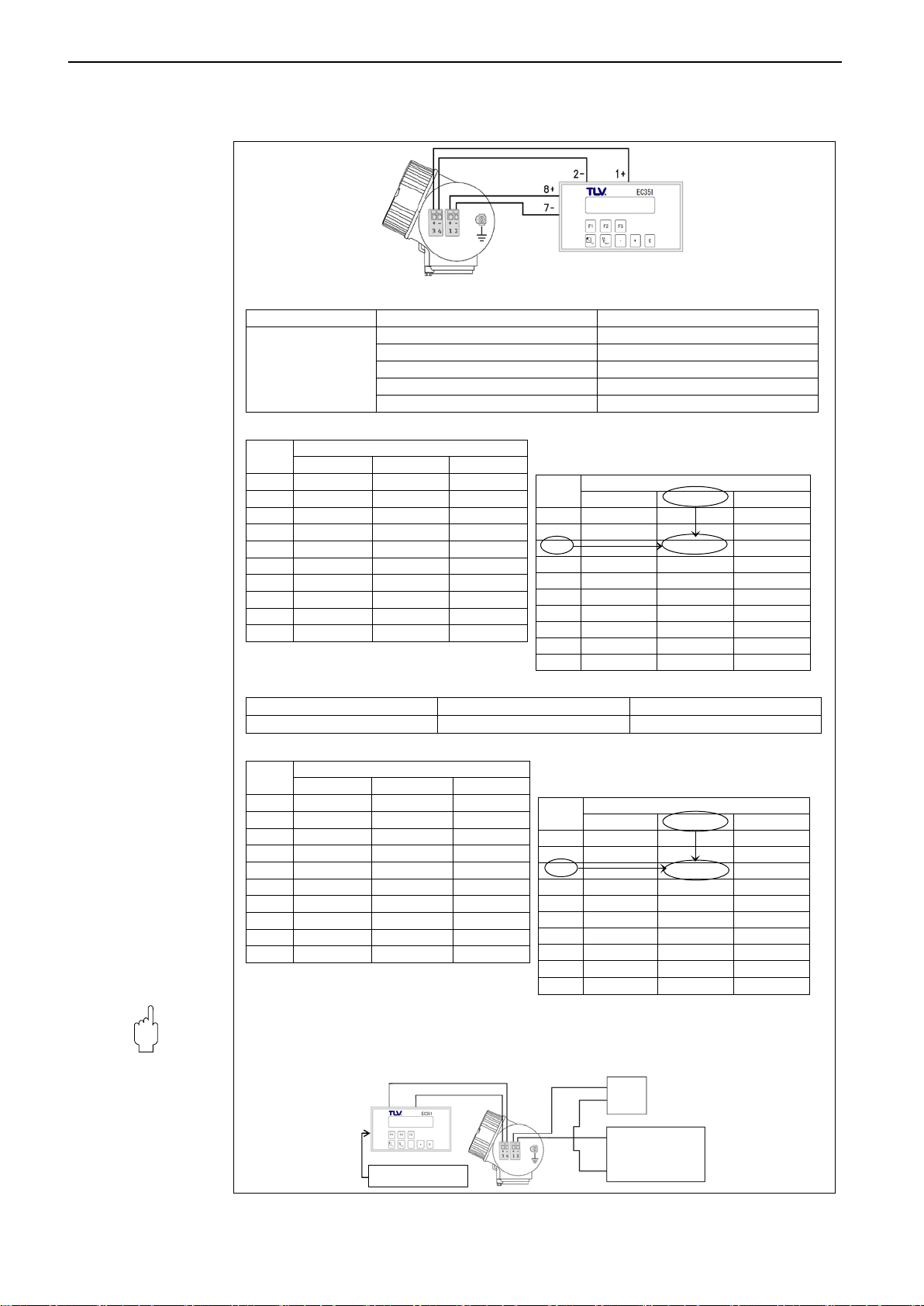

4.3 Connecting to TLV EC351 Flow Computer and Parameter

Settings

EF200 Pulse Output Settings

Submenu

Parameter

Selection

Pulse/

frequency/

switch output

Operating mode

Pulse

Assign pulse output

Volume flow

Volume unit

L (liter)

Value per pulse

See Table A

Pulse width

5 ms

Table A

Size

Value per pulse [dm3/P]

e.g. When connecting a DN 40 EF200F to

EC351, enter a “Value per pulse” of 0.855103

Size

Value per pulse [dm3/P]

EF200W

EF200F

EF200R

15

0.098400

0.068400

–

25

0.448700

0.347799

0.068400

40

1.039101

0.855103

0.347799

50

1.685999

1.425801

0.855103

80

3.793483

3.199488

1.425801

100

6.462871

5.542008

3.199488

150

14.47387

12.60716

5.542008

200

–

24.20136

12.60716

250

–

38.15338

–

300

–

54.73454

–

EF200W

EF200F

EF200R

15

0.098400

0.068400

–

25

0.448700

0.347799

0.068400

40

1.039101

0.855103

0.347799

50

1.685999

1.425801

0.855103

80

3.793483

3.199488

1.425801

100

6.462871

5.542008

3.199488

150

14.47387

12.60716

5.542008

200

–

24.20136

12.60716

250

–

38.15388

–

300

–

54.73454

–

EC351 Flow Rate Input Settings

Function group

Function

Selection

FLOW INPUT

K-FACTOR

See Table B

Table B

Size

K-FACTOR [P/I]

e.g. When connecting a DN 40 EF200F to

EC351, enter a “K-FACTOR” of 1.16945

Size

K-FACTOR [P/I]

EF200W

EF200F

EF200R

15

10.1626

14.61988

–

25

2.22866

2.87522

14.61988

40

0.96237

1.16945

2.87522

50

0.59312

0.70136

1.16945

80

0.26361

0.31255

0.70136

100

0.15473

0.18044

0.31255

150

0.06909

0.07932

0.18044

200

–

0.04132

0.07932

250

–

0.02621

–

300

–

0.01827

–

EF200W

EF200F

EF200R

15

10.1626

14.61988

–

25

2.22866

2.87522

14.61988

40

0.96237

1.16945

2.87522

50

0.59312

0.70136

1.16945

80

0.26361

0.31255

0.70136

100

0.15473

0.18044

0.31255

150

0.06909

0.07932

0.18044

200

–

0.04132

0.07932

250

–

0.02621

–

300

–

0.01827

–

Caution!

An additional sensor is required to convert steam flow rates to mass flow rates when

assigning measurements such as steam dryness fraction calculation to the analog

output (except temperature).

Power

Supply

+24V

+

–

+

–

Data Receiver

(Analog 4 – 20 mA

current input)

-2 1+

Compensation Signal

(Pressure or temperature)

Figure 18

Connecting to TLV flow

computer EC351

Caution!

NOTE: - Assign temperature to the analog output

-

Shielded cable recommended for analog

output

Table of contents

Other TLV Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Datakom

Datakom DKM-250 user manual

Gemu

Gemu 1211 Installation, operating and maintenance instructions

Sper scientific

Sper scientific 840080 instruction manual

Apogee Instruments

Apogee Instruments SP-722-SS Operator's manual

Sentinel

Sentinel Hub installation guide

Demtech

Demtech Pro-Tester Double-Pull Operator's manual

TE Connectivity

TE Connectivity Challenger 361 Series Installation and operating instructions

netvox

netvox R718WA2 user manual

Linear Technology

Linear Technology LTC2944 manual

Extech Instruments

Extech Instruments LT300 user guide

Keysight Technologies

Keysight Technologies B2900 Series user guide

Hach

Hach TL2350 Basic user manual