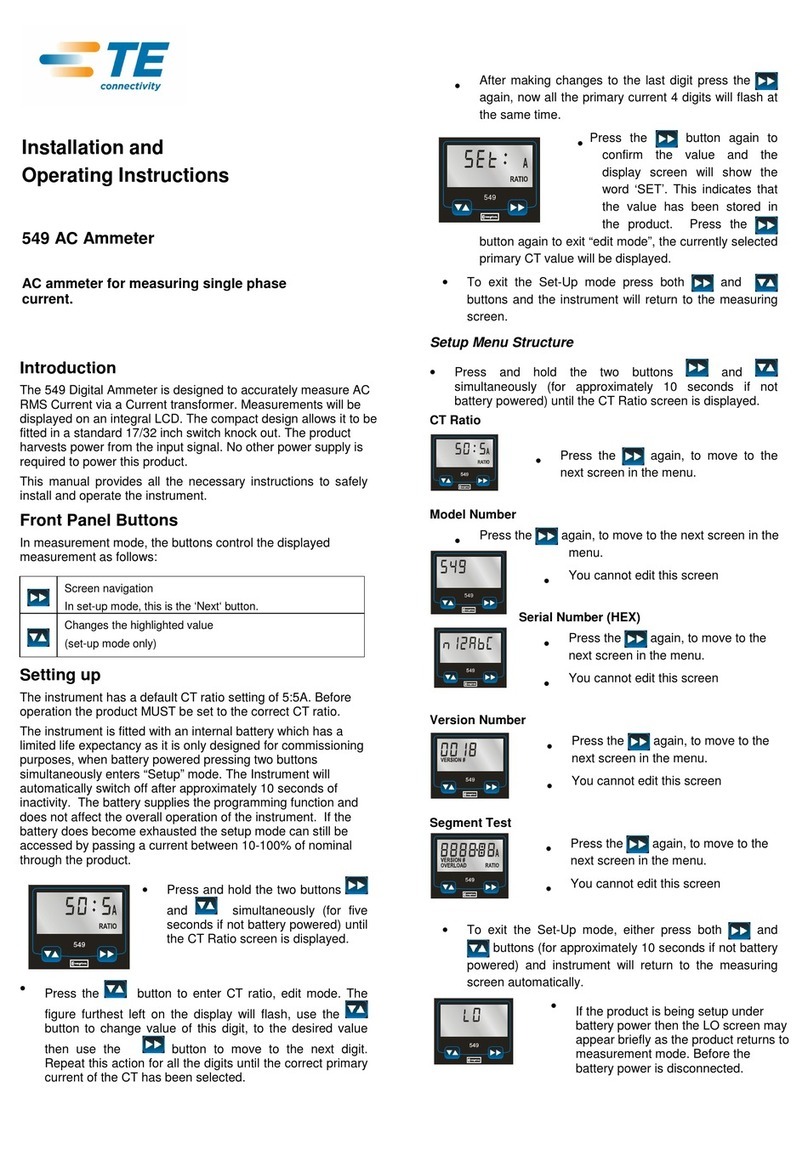

Installation and Operating

Instructions

Analogue Instruments

Panel Indicators - Challenger Series

361-**, 362-**, 363-** 364-** (* = additional characters)

This product range includes multiple functions:

AC Ammeters and AC Voltmeters

DC Ammeters

DC Voltmeters

Frequency meters

Barrel side labels show function and electrical rating. The terminals are

connected directly across the input to be measured.

Note: that the electrical rating may differ from the dial scale marking, and

the unit side label is definitive.

INDOOR USE

These meters are intended for a rated temperature range of 0 to +40°C

and at an altitude not exceeding 2000m.

Maximum Relative Humidity 80% for temperatures up to 31°C

decreasing linearly to 50% Relative Humidity at 40°C

Pollution Degree 1 or 2

Measurement Category III

The product should be panel mounted using the mounting kit provided.

Consideration should be given to the space required behind the unit to

allow for bends in the connecting cables. Additional protection to the panel

may be obtained by the use of an optional panel gasket. The terminals at

the rear of the case should be protected from liquids. Units should be

mounted in a reasonably stable ambient temperature.

The unit should not be mounted where it can be subjected to excessive

direct sunlight and vibration should be kept to a minimum. Connection

wires should be sized to comply with local regulations and should be

terminated on to tags suitable for screw connection. The products do not

have internal fuses, therefore; external fuses must be used for safety

protection under fault conditions.

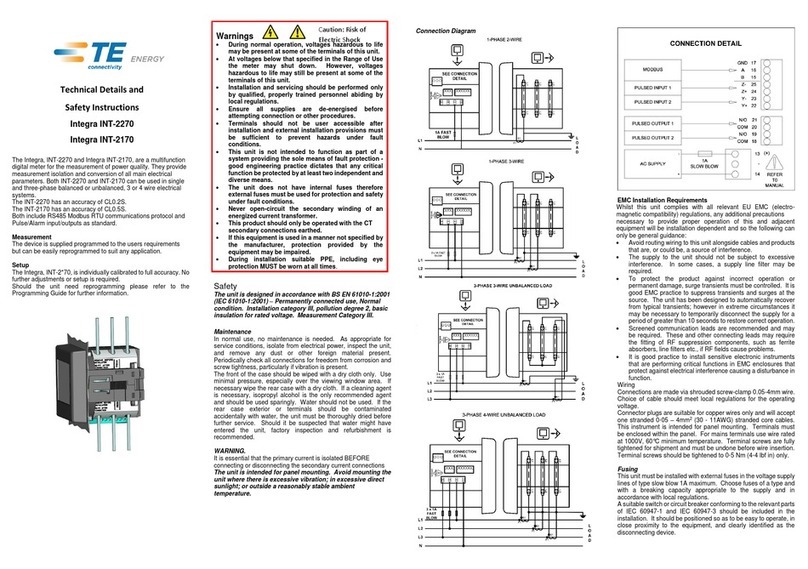

Fusing and Connections

Connection diagrams should be carefully followed to ensure correct

polarity. Terminals are suitable for use with insulated ring lugs.

Voltage input lines where required should be fused with a quick blow fuse

1A maximum. Current metering circuits directly connected in line with the

load must be fused at the rated current for the meter. Do not fuse CT

circuits.

The equipment into which this meter is installed must have an adjacent

means of isolating the supply voltage to permit safe access for subsequent

maintenance.

External voltage transformers (PTs) and current transformers may be

used where appropriate to extend the range, provided that the ratings

marked on the side label are not exceeded at point of connection to meter.

These products are designed for permanently connected use, normal

condition measurement category III, pollution degree 2 (e.g. non ventilated

panels or ventilated panels with filters, without condensation occurring),

basic insulation, for rated voltage.

•During normal operation, voltages hazardous to life may

be present at some of the terminals of this unit.

•At voltages below that specified in the Range of Use the

meter may shut down. However, voltages hazardous to life

may still be present at some of the terminals of this unit.

•Installation and servicing should be performed only by

qualified, properly trained personnel abiding by local

regulations.

•Ensure all supplies are de-energised before attempting

connection or other procedures.

•Terminals should not be user accessible after

installation and external installation provisions must be

sufficient to prevent hazards under fault conditions.

•This unit is not intended to function as part of a system

providing the sole means of fault protection - good

engineering practice dictates that any critical function be

protected by at least two independent and diverse means.

•The unit does not have internal fuses therefore external

fuses must be used for protection and safety under fault

conditions.

•Never open-circuit the secondary winding of an

energized current transformer.

•This product should only be operated with the CT

secondary connections earthed.

•If this equipment is used in a manner not specified by

the manufacturer, protection provided by the equipment may

The unit is designed in accordance with BS EN 61010-1:2010

(IEC 61010-1:2010) – Permanently connected use, Normal

condition. Installation category III, pollution degree 1 or 2, basic

insulation for rated voltage. Measurement Category III.

EMC Installation Requirements

•

Whilst this unit complies with all relevant FCC and other

(electro-magnetic compatibility) regulations, any additional

precautions necessary to provide proper operation of this and

adjacent equipment will be installation dependent and so the

following can only be general guidance:

•Avoid routing wiring to this unit alongside cables and

products that are, or could be, a source of interference.

•The supply to the unit should not be subject to excessive

interference. In some cases, a supply line filter may be required.

•To protect the product against incorrect operation or

permanent damage, surge transients must be controlled. It is

good EMC practice to suppress transients and surges at the

source. The unit has been designed to automatically recover

from typical transients; however, in extreme circumstances it

may be necessary to temporarily disconnect the supply for a

period of greater than 10 seconds to restore correct operation.

•Screened communication leads are recommended and may

be required. These and other connecting leads may require the

fitting of RF suppression components, such as ferrite absorbers,

line filters etc., if RF fields cause problems.

•It is good practice to install sensitive electronic instruments

that are performing critical functions in EMC enclosures that

protect against electrical interference causing a disturbance in

Risk of Electric Shock

Risk of Electric Shock

It is essential that the primary current is isolated

BEFORE connecting or disconnecting the secondary