TLV PowerTrap GT5C User manual

172-65473MA-03 (GT5C PowerTrap) 17 July 2019

GT5C

Copyright © 2019 by TLV CO., LTD.

All rights reserved

172-65473MA-03 (GT5C PowerTrap) 17 Jul 2019

1

Contents

Introduction......................................................................... 2

Safety Considerations........................................................ 3

General Description............................................................ 5

Application................................................................................................................5

Operation............................................................................ 6

Specifications..................................................................... 7

Configuration...................................................................... 8

Installation.......................................................................... 9

Steam System Example ...........................................................................................9

Installation Procedure.............................................................................................11

Sizing the Condensate Reservoir Pipe ...................................................................13

Maintenance Space and Tolerance Angle for Installation 14

Operation and Periodic Inspection................................... 15

Operation................................................................................................................15

Periodic Inspection and Diagnosis..........................................................................16

Disassembly/Reassembly................................................ 17

Recommended Tools List for Disassembly/Reassembly ........................................18

1. Before Removing/Reattaching............................................................................19

2. Removing/Reattaching the Body from / to the Cover..........................................20

3. Removing/Reattaching the Snap Action Unit......................................................20

4. Removing/Reattaching Each Unit.......................................................................22

5. Removing/Reattaching of Air Vent Unit...............................................................23

6. Positioning Adjustment of the Trap Valve...........................................................24

Troubleshooting................................................................ 25

Determining the Problem from the Symptoms........................................................25

Types of Failure and their Causes..........................................................................26

Causes and Corrective Measures...........................................................................27

Replacement Parts........................................................... 30

Product Warranty ............................................................. 31

Service ............................................................................. 32

172-65473MA-03 (GT5C PowerTrap) 17 Jul 2019

2

Introduction

Thank you for purchasing theTLV PowerTrap.

This product has been thoroughly inspected before being shipped from the

factory. When the product is delivered, before doing anything else, check the

specifications and external appearance to make sure nothing is out of the

ordinary. Also, be sure to read this manual carefully before use and follow the

instructions to be sure of using the product properly.

If detailed instructions for special order specifications or options not contained in

this manual are required, please contact TLV for full details.

This instruction manual is intended for use with the model listed on the front

cover. It is necessary not only for installation, but for subsequent maintenance,

disassembly/reassembly and troubleshooting. Please keep it in a safe place for

future reference.

172-65473MA-03 (GT5C PowerTrap) 17 Jul 2019

3

Safety Considerations

Read this section carefully before use and be sure to follow the instructions.

Installation, inspection, maintenance, repairs, disassembly, adjustment and valve

opening/closing should be carried out only by trained maintenance personnel.

The precautions listed in this manual are designed to ensure safety and prevent

equipment damage and personal injury. For situations that may occur as a result of

erroneous handling, three different types of cautionary items are used to indicate the

degree of urgency and the scale of potential damage and danger: DANGER,

WARNING and CAUTION.

The three types of cautionary items above are very important for safety: be sure to

observe all of them as they relate to installation, use, maintenance and repair.

Furthermore, TLV accepts no responsibility for any accidents or damage occurring

as a result of failure to observe these precautions.

Symbols

Indicates a DANGER, WARNING or CAUTION item.

DANGER

Indicates an urgent situation which poses a threat of death or serious

injury

WARNING

Indicates that there is a potential threat of death or serious injury

CAUTION

Indicates that there is a possibility of injury or equipment / product

damage

WARNING

NEVER apply direct heat to the float.

The float may explode due to increased internal pressure, causing

accidents leading to serious injury or damage to property and

equipment.

CAUTION

Install properly and DO NOT use this product outside the

recommended operating pressure, temperature and other

specification ranges.

Improper use may result in such hazards as damage to the product

or malfunctions that may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

Use hoisting equipment for heavy objects (weighing

approximately 20 kg (44 lb) or more).

Failure to do so may result in back strain or other injury if the object

should fall.

Take measures to prevent people from coming into direct

contact with product outlets.

Failure to do so may result in burns or other injury from the discharge

of fluids.

When disassembling or removing the product, wait until the

internal pressure equals atmospheric pressure and the surface

of the product has cooled to room temperature.

Disassembling or removing the product when it is hot or under

pressure may lead to discharge of fluids, causing burns, other injuries

or damage.

Continued on next page

172-65473MA-03 (GT5C PowerTrap) 17 Jul 2019

4

CAUTION

Be sure to use only the recommended components when

repairing the product, and NEVER attempt to modify the product

in any way.

Failure to observe these precautions may result in damage to the

product and burns or other injury due to malfunction or the discharge

of fluids.

Do not use excessive force when connecting threaded pipes to

the product.

Over-tightening may cause breakage leading to fluid discharge, which

may cause burns or other injury.

Use only under conditions in which no freeze-up will occur.

Freezing may damage the product, leading to fluid discharge, which

may cause burns or other injury.

Use only under conditions in which no water hammer will occur.

The impact of water hammer may damage the product, leading to fluid

discharge, which may cause burns or other injury.

Take measures to ensure the proper handling, such as recovery

or dilution, of hazardous fluids discharged at product outlets.

Outflow of fluid or fluid leaks may lead to hazards such as flammable

conditions or corrosion, which may result in injury, fires, damage or

other accidents.

172-65473MA-03 (GT5C PowerTrap) 17 Jul 2019

5

General Description

Install properly and DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges. Improper

use may result in such hazards as damage to the product or malfunctions

which may lead to serious accidents. Local regulations may restrict the

use of this product to below the conditions quoted.

CAUTION

Application

PowerTrap GT5C can be used as a standard steam trap, and also has an integrated

pumping function that can eliminate and pump out condensate even if condensate

cannot be discharged due to very low supply steam pressure because of reduced load

in the steam using equipment (this phenomenon is referred to in this document as

‘stall’).

GT5C can also discharge the accumulated condensate when the steam using

equipment stops operation, and prevent water hammer when it re-starts operation.

172-65473MA-03 (GT5C PowerTrap) 17 Jul 2019

6

Operation

Take measures to prevent people from coming into direct contact with

product outlets. Failure to do so may result in burns or other injury from

the discharge of fluids.

CAUTION

(1) When condensate flows from the condensate inlet pipe through the inlet check valve

into the body of the unit, the float rises and the main valve of the trap unit is open as

shown in (A) below.

The main valve on the trap unit opens as the float rises. When Pi> Pb(when the

equipment pressure (Pi) is greater than the back pressure (Pb)), the condensate

passes through the outlet check valve and is discharged through the condensate

outlet pipe (normal trapping function).

In this case, the integrated air vent unit exhausts internal air to the outlet.

When Pi≤Pb, the condensate is not discharged and collects in the body of the

unit.

(2) When the float rises to its high level, the push rod on the snap-action unit rises

quickly, simultaneously closing the exhaust valve and opening the intake (motive

medium) valve. The pressure supplied by the motive medium causes the internal

pressure in the unit to become greater than the back pressure. The inlet check valve

closes and the outlet check valve is pushed open, thus discharging the condensate in

the unit through the outlet pipe, as shown in (B) below.

(3) As a result of the condensate in the unit being discharged, the water level in the unit

drops and the float descends. When the float reaches its low level, the push rod on

the snap-action unit moves down quickly, simultaneously opening the exhaust valve

and closing the intake (motive medium) valve and the status reverts to that shown in

(A) below.

Outlet Check Valve

Intake Valve [Open]

Exhaust Valve [Close]

Condensate Outlet

Pipe

Body

Exhaust Valve [Open]

Intake Valve [Close]

Operation Shaft

Cover

Trap unit

Float

Snap Action unit

Inlet Check Valve

Condensate Inlet Pipe

(A) Condensate Inflow (B) Condensate Discharge

(Exhaust) (Motive Medium Intake)

Air Vent Unit

172-65473MA-03 (GT5C PowerTrap) 17 Jul 2019

7

Specifications

Install properly and DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

CAUTION

Use only under conditions in which no freeze-up will occur. Freezing

may damage the product, leading to fluid discharge, which may cause

burns or other injury.

CAUTION

Refer to the product nameplate for detailed specifications.

Valve No.**

Nominal Diameter

Model

Maximum Allowable

Pressure*

Maximum Allowable

Temperature*

Serial No.

Maximum Operating

Temperature

Maximum Differential

Pressure

* Maximum allowable pressure (PMA) and maximum allowable temperature (TMA) are PRESSURE SHELL

DESIGN CONDITIONS, NOT OPERATING CONDITIONS.

** Valve No. is displayed for products with options. This item is omitted from the nameplate when there are

no options.

172-65473MA-03 (GT5C PowerTrap) 17 Jul 2019

8

Configuration

Exhaust Outlet Plug

Motive Medium Inlet

Condensate Inlet

Condensate Outlet

N0.

Parts

Maintenance

Kit

Repair Kit *¹

Float

Snap

Action

Spring

A

B

C

D

E

1

Body

2

Cover

3

Gaskets, etc.

Gasket

✔

Seal set

✔

4

Cover Bolt

5

Nameplate

6

Float

✔

7

Snap-Action Unit

✔*²

8

Snap Action Spring

✔

9

Intake-Exhaust Valve Unit

✔

10

Trap Unit

✔

11

Air Vent Unit

✔

12

Inlet Check Valve

✔

13

(Flange)

14

Plug (for drainage)

Please refer to the replacement parts list for maintenance and repair kits.

*¹ The maintenance kit should be purchased along with a repair kit, as gaskets might be required.

*² A snap action spring is also contained in the snap-action unit.

172-65473MA-03 (GT5C PowerTrap) 17 Jul 2019

9

Installation

Install properly and DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

CAUTION

Use hoisting equipment for heavy objects (weighing approximately

20 kg (44 lb) or more). Failure to do so may result in back strain or other

injury if the object should fall.

CAUTION

Take measures to prevent people from coming into direct contact with

product outlets. Failure to do so may result in burns or other injury from

the discharge of fluids.

CAUTION

Do not use excessive force when connecting threaded pipes to the

product. Over-tightening may cause breakage leading to fluid

discharge, which may cause burns or other injury.

CAUTION

Use only under conditions in which no water hammer will occur. The

impact of water hammer may damage the product, leading to fluid

discharge, which may cause burns or other injury.

CAUTION

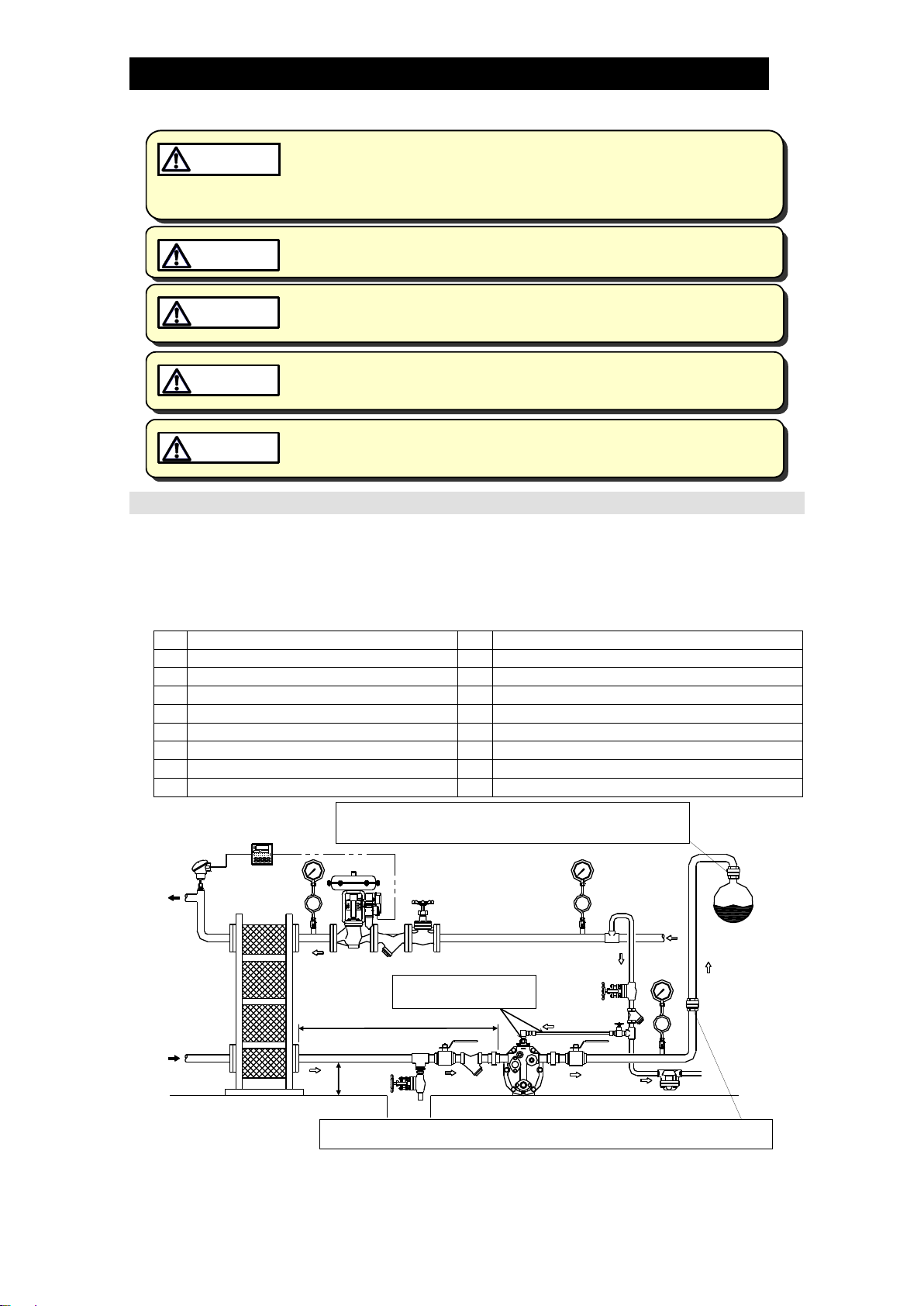

Steam System Example

For non-standard options, please refer to the additional instruction manual(s) provided.

1. Standard Installation Example

The example below shows the inlet piping is connected to the inlet of GT5C in the

same way as a standard steam trap. The condensate inlet pipe [Si] acts like a

condensate reservoir. Refer to “Sizing the Condensate Reservoir Pipe”at the end of

this section for the size of condensate inlet pipe [Si] (length of Dh).

Q

Pumped medium

Dh

Condensate Receiver/Reservoir

A

Filling Head

Ki

Condensate Inlet Strainer

Pm

Motive Medium Supply Pressure

Km

Motive Medium Strainer

Pb

Back Pressure

St

Steam Trap

Si

Condensate Inlet Pipe

Vi

Valve on Condensate Inlet Pipe

So

Condensate Outlet Pipe

Vo

Valve on Condensate Outlet Pipe

Sr

Condensate Recovery Line

Vm

Valve on Motive Medium Supply Pipe

Sm1

Motive Medium Supply Pipe

Vb

Blowdown Valve

Sm2

Motive Medium Supply Tube

Pi

Equipment Pressure

PowerTrap

Pm

Sr So

Pb

Sm1

Vm

Km

Vo

St

Sr

Si

QVb

Vi

Ki

A

Dh

Pi

Sm2

Backflow

Water Hammer

Prevention

Check Valve

If water hammer due to steam backflow in the condensate

recovery line is expected, installation of a check valve vertically

and as close as possible to the recovery line is recommended.

When the rise in piping is 30 m (100 ft) or farther from the PowerTrap, installation

of a check valve is recommended for the prevention of return water hammer.

Inner diameter should be

at least 8 mm (5/16 in)

Backflow

Water Hammer

Prevention

Check Valve

*Refer to diagrams shown in “Installation Procedure”and “(4)Inlet and Outlet Piping”in this section for the

length of condensate reservoir (Dh) in cases where the exhaust pipe is eliminated and there is vertical piping

on the pumped medium inlet due to elevated position ofthe equipment condensate outlet.

172-65473MA-03 (GT5C PowerTrap) 17 Jul 2019

10

2. Installation Example for Increasing Pump Discharge Capacity

The pumping discharge capacity can be increased by raising the filling head [A].

Refer to the latest GT5C data sheet for the discharge capacity on each filling head

and “Sizing of the Condensate Reservoir Pipe”at the end of this section for the size

of condensate inlet pipe [Si] (length of Dh).

Q

Condensate Supply

Dh

Condensate Reservoir

A

Filling Head

Ki

Condensate Inlet Strainer

Pm

Motive Medium Supply Pressure

Km

Motive Medium Strainer

Pb

Back Pressure

St

Steam Trap

Si

Condensate Inlet Pipe

Vi

Valve on Condensate Inlet Pipe

So

Condensate Outlet Pipe

Vo

Valve on Condensate Outlet Pipe

Sr

Condensate Recovery Line

Vm

Valve on Motive Medium Supply Pipe

Sm1

Motive Medium Supply Pipe

Ve

Valve on Exhaust Pipe

Se

Exhaust Pipe/Tube

Vb

Blowdown Valve

Sm2

Motive Medium Supply Tube

Pi

Equipment Pressure

A

Pm

Pi

PowerTrap

So

Pb

Sm1

Vm

Km

Vo

St

Sr

Si

Q

Vb

Vi

Ki

Dh

Sm2

Backflow

Water Hammer

Prevention

Check Valve

If water hammer due to steam backflow in the condensate

recovery line is expected, installation of a check valve vertically

and as close as possible to the recovery line is recommended.

When the rise in piping is 30 m (100 ft) or farther from the PowerTrap, installation

of a check valve is recommended for the prevention of return water hammer.

Backflow

Water Hammer

Prevention

Check Valve

Inner diameter should be

at least 8 mm (5/16 in)

In the above case, exhaust pipe [Se] should be connected from exhaust outlet to the

top of condensate inlet pipe [Si] (= condensate reservoir [Dh]).

The exhaust pipe [Se] should be 10 mm (3/8”) or a tube with an inner diameter of at

least 8 mm (5/16”). Insert the supplied fitting tube into the exhaust port after taking the

exhaust outlet plug out, and then attach the pipe to the GT5C. The discharge capacity

will not be increased effectively if the fitting tube is not installed properly.

Point the split ends upward, and

then insert while squeezing

Squeeze the fitting tube

while inserting

Insert the fitting tube, and then

connect to the port

Exhaust port

Fitting tube

172-65473MA-03 (GT5C PowerTrap) 17 Jul 2019

11

Installation Procedure

Installation, inspection, maintenance, repairs, disassembly, adjustment and valve

opening/closing should be carried out only by trained maintenance personnel.

(1) Pumped Medium:

Fluids that can be discharged through the PowerTrap are limited to steam

condensate. PowerTraps that have been specially constructed for other specific

fluids are not limited by this restriction.

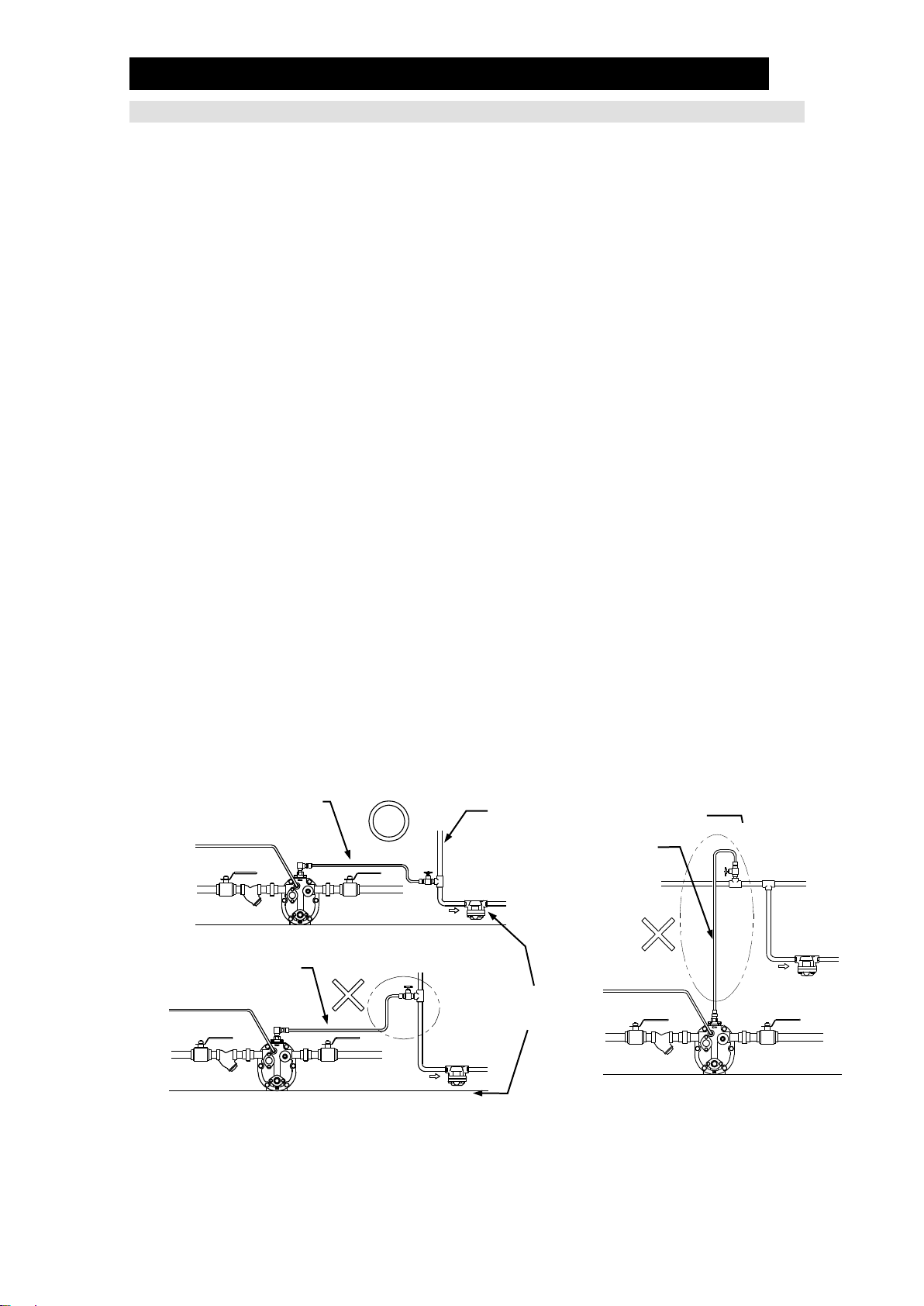

(2) Motive Medium Supply Pipe [Sm1] and Motive Medium Supply Tube [Sm2]:

The motive medium supply pipe [Sm1] and valve on motive medium supply pipe

[Vm] diameter should be at least 15 mm (1/2”). If copper or stainless steel tubes are

used for the connection from the motive medium supply pipe [Sm1] to the

PowerTrap, make sure that the tube’s inner diameter is at least 8 mm (5/16”) but no

more than 3 m (10’) in length.

The inner diameter of the valve and tube fittings connecting to the PowerTrap

should also be at least 8 mm (5/16”).

Install a strainer [Km] (at least 15 mm (1/2in) and at least 40-mesh) on the

PowerTrap motive medium supply pipe [Sm1] as close to the PowerTrap as

possible and install a union joint for maintenance, while allowing sufficient space

for maintenance of the strainer. Strainers should be angled in the 3 or 9 o’clock

positions for horizontal installations.

Only use steam as the motive medium.

The maximum motive medium supply pressure is 0.5 MPaG (75 psig, 5 barg).

Install a drip leg on the motive medium supply pipe [Sm1], and a steam trap [ST] on

the drip leg.

Proper discharge capacity may not be achieved if condensate accumulates in the

motive medium supply pipe [Sm1] or tube [Sm2]. In addition, rust and scale cause

steam leakage, which results in the PowerTrap becoming inoperable.

Make sure to use steel pipe for the motive medium supply tube [Sm2].

Motive Medium Supply Tube

(No condensate accumulates)

Motive Medium Supply Pipe [Sm]

Correct

Steam Trap [ST]

Incorrect

Motive Medium Supply Tube

(Condensate accumulates)

Incorrect

Motive Medium Supply Tube

(Condensate accumulates)

172-65473MA-03 (GT5C PowerTrap) 17 Jul 2019

12

(3) Pressure Reducing Valve on the Motive Medium Supply Piping:

When the motive medium pressure [Pm] is greater than 0.5 MPaG (75 psig, 5

barg), install a TLV pressure reducing valve (such as the DR20) in order to reduce

the motive medium pressure to the PowerTrap. In order to prevent the pressure

from rising at dead end shut off, be sure to install a relief valve between the

pressure reducing valve and the PowerTrap.

The pressure setting on the pressure reducing valve should be between 0.05 and

0.15 MPa (7 and 20 psi, 0.5 and 1.5 bar) higher than the back pressure [Pb].

When the pumping capacity of the PowerTrap is insufficient for the set motive

pressure, increase this set pressure even further.

(4) Inlet and Outlet Piping

Install condensate inlet pipe [Si] to help

condensate flow into the PowerTrap by

gravity. Even if the exhaust tube is not

used (see drawing to the right), use a tee

so that the exhaust tube can be

connected when needed. The pipe

thickness should be schedule 40 or less

for proper operation.

Install a condensate inlet strainer [Ki] (40-mesh or finer) on the PowerTrap pumped

medium inlet pipe and install a union joint for maintenance. The installation should

be in a location that allows sufficient space for maintenance of the strainer [Ki].

Condensate outlet pipe [So] diameter should be at least 25 mm (1”).

Refer to “Sizing the Condensate Reservoir Pipe”at the end of this section for the

size of condensate inlet pipe [Si] (length of Dh).

During pumping operation, the PowerTrap uses the motive medium supply

pressure to push out the condensate in the trap. The GT5C can discharge

approximately 1.4 liters (3/8US Gallons) of pumped medium for each discharge

operation. The amount of time required for each discharge operation will be

between 5 and 30 seconds, depending on the back pressure and the motive

medium pressure. This means that the instantaneous flow through the condensate

outlet pipe [So] during the discharge operation is between 170 kg (370 lb) and 1

metric ton (2200 lb) per hour.

Flow meters must not be installed on the condensate outlet pipe [So]. Install a

steam flow meter at the equipment inlet if necessary.

Tee with Plug

Correct

Correct

Incorrect

Incorrect

Dh

Si

Filling head [A]

172-65473MA-03 (GT5C PowerTrap) 17 Jul 2019

13

(5) Valves on the Various Pipes

In order to ensure the proper discharge capacity, use full bore ball valves or gate

valves on the pumped medium inlet [Vi] and outlet lines [Vo].

Be sure to install blowdown valve [Vb]. A bellows sealed valve is recommended,

due to the lack of leakage from the gland and easy flow rate adjustment.

Install union or flanged joints between the valves and the PowerTrap to allow for

easy maintenance.

Be sure to provide the necessary maintenance space for PowerTrap disassembly

and repair (see “Maintenance Space”).

(6) Reservoir Pipe and Filling Head [A]

Please refer to “Size of the Condensate Reservoir

Pipe” shown below.

The size and length (volume) are determined by

the amount of pumped medium held back while

the PowerTrap is discharging. Therefore, the area

belowthe inlet piping cannot be considered in the

effective volume of the reservoir [Dh].

The filling head [A] represents the distance from the installation surface of the

PowerTrap (from grade) to the bottom of the inlet piping (condensate reservoir

[Si]), shown as [A] in the sketches in “Steam System Example”. The minimum

filling head for GT5C is 155 mm (6”).

Sizing the Condensate Reservoir Pipe

The PowerTrap reservoir pipe size for each condensate discharge amount should be

selected from the following table.

Condensate

Amount

kg/h

Diameter [mm (in)] and Length [m] of

Condensate Reservoir Pipe

25 (1)

32 (1¼)

40 (1½)

50 (2)

80 (3)

50

0.6 (m)

100

1.2

0.6

0.4

150

1.8

1.0

0.6

0.4

200

2.4

1.3

0.8

0.5

300

2.0

1.2

0.7

400

2.6

1.5

1.0

500

2.0

1.2

0.5

Condensate

Amount

lb/h

Diameter [in] and Length [ft] of

Condensate Reservoir Pipe

1”

1¼”

1½”

2”

3”

100

2.0 (ft)

150

3.0

1.5

200

3.9

2.0

1.3

300

5.6

3.0

2.0

1.3

500

4.9

3.0

2.0

700

6.9

4.0

2.5

1.0

1000

5.5

3.5

1.5

If the motive medium supply pressure [Pm]/back pressure (Pb) ≥2, the length of

condensate reservoir pipe can be reduced by ½.

Shadowed area is not included in

reservoir volume calculations

172-65473MA-03 (GT5C PowerTrap) 17 Jul 2019

14

Maintenance Space and Tolerance Angle for Installation

Maintenance Space

The maintenance space shown in the figure below should be provided to enable

inspection and disassembly/repair of the PowerTrap.

Tolerance Angle for Installation

The product should be inclined no more than 3°. Make sure the body is installed with the

raised TLV lettering on the body horizontal.

Unit: mm (in)

100 (4)

100 (4)

100 (4)

172-65473MA-03 (GT5C PowerTrap) 17 Jul 2019

15

Operation and Periodic Inspection

After all piping work has been completed in accordance with the

specific piping system designed when the decision to utilize the

PowerTrap was made, check once again to make sure that all pipe

connections have been tightened, gaskets have been inserted where

needed and all parts are securely installed.

At the start-up of operation, large quantities of condensate may flow,

causing the PowerTrap to momentarily overload. Open the inlet valve

gradually so that the condensate flows in slowly.

WARNING

Install properly and DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

CAUTION

When disassembling or removing the product, wait until the internal

pressure equals atmospheric pressure and the surface of the product

has cooled to room temperature. Disassembling or removing the

product when it is hot or under pressure may lead to discharge of fluids,

causing burns, other injuries or damage.

CAUTION

Be sure to use only the recommended components when repairing the

product, and NEVER attempt to modify the product in any way. Failure to

observe these precautions may result in damage to the product or burns

or other injury due to malfunction or the discharge of fluids.

CAUTION

Installation, inspection, maintenance, repairs, disassembly, adjustment and valve

opening/closing should be carried out only by trained maintenance personnel.

Operation

(1) Valve Operation

During the first operation after installation, or re-operation after a long shutdown,

open blowdown valve [Vb] (ensuring that the area around the opening is safe) to

eliminate rust and scale completely. Refer to the “Steam System Example”drawings

in the “Installation”section to become familiar with the symbols used for the various

valves.

If water hammer has occurred, immediately cease operation and close any valves

that are operating.

a) Slowly open the valve [Ve] on the exhaust pipe.

b) Slowlyopen the valve [Vm] on the motive medium supply pipe. Make sure that there

is no sound of flow from the exhaust pipe [Se] or the condensate inlet pipe [Si].

c) Slowly open the valve [Vo] on the pumped medium outlet pipe.

d) Slowly open the valve [Vi] on the pumped medium inlet pipe.

e) During normal trapping operation (equipment side pressure > back pressure), the

GT5C discharges condensate continuously. During stall or reverse pressure

(equipment side pressure ≤ back pressure), the GT5C switches to pumping

operation. The PowerTrap is normal if it operates intermittently during pumping

operation; first exhausting the motive medium to fill with pumped medium, then

taking in motive medium to force the condensate out.

The interval of operation will vary greatly depending on the amount of pumped

medium inflow, the temperature, the motive medium (steam) pressure. (The

interval of operation is considered the length of time between the start of one

discharge cycle and the start of the next discharge cycle.)

172-65473MA-03 (GT5C PowerTrap) 17 Jul 2019

16

The relation between the interval of operation Tc(seconds) and the amount of

inflowing pumped medium (Q or Qp) can be roughly determined using the

following formula:

Tc= 5,000/Q Q = 5,000/TcQ: amount of inflowing pumped medium (kg/h)

Tc= 11,111/Qp Qp= 11,111/TcQp: amount of inflowing pumped medium (lb/h)

(2) If an error such as a leak or water hammer occurs after beginning PowerTrap

operation, shut off the valves immediately in the following order:

valve [Vm] on motive medium supply pipe pumped medium inlet valve [Vi]

pumped medium outlet valve [Vo] valve [Ve] on exhaust pipe

(3) Whenever any type of malfunction is suspected in the PowerTrap, refer to the

“Troubleshooting” section.

Periodic Inspection and Diagnosis

There are two types of periodic inspection: the visual inspection and the disassembly

inspection.

(1) Visual Inspection

As a general rule, this inspection should be performed at least once every 3

months.

Check the following items:

a) There should be no leakage from the PowerTrap or from any of the connections.

b) The PowerTrap unit should make continuous sound during trapping operation

(equipment side pressure > back pressure).

c) The PowerTrap unit should be operating cyclically without continuous sound in

the motive medium supply pipe or the exhaust pipe during the pumping

operation (equipment side pressure ≤ back pressure).

d) Pumped medium should not accumulate in the (steam-using) equipment, and

the temperature of the equipment should not be abnormally low.

e) There should not be any abnormal noise (such as water hammer) from the

pumped medium outlet pipe or the pumped medium recovery line when the

PowerTrap operates.

(2) Disassembly Inspection

Refer to the “Disassembly/Reassembly” section.

As a general rule, this inspection should be performed at least once every 2 years.

When inspecting the interior of the unit, check the following items:

a) Make sure the snap-action unit moves up and down smoothly as the float rises

and falls.

b) Make sure the valve of the trap unit moves up and down smoothly as it opens

and closes.

c) Make sure the intake/exhaust valves move up and down smoothly.

d) Make sure the float is not damaged and is not filled with water.

e) Make sure all nuts and bolts are properly installed and fastened.

f) Check to make sure that there is no foreign matter sticking to the shafts and

levers of any of the units, and make sure there is no abnormal wear.

When reassembling, be sure to replace the body and cover gaskets with new

gaskets if damaged.

Also, replace any parts that are broken or show serious wear.

If any parts require replacement, refer to the “Replacement Parts” List.

172-65473MA-03 (GT5C PowerTrap) 17 Jul 2019

17

Disassembly/Reassembly

NEVER apply direct heat to the float. The float may explode due to

increased internal pressure, causing accidents leading to serious injury

or damage to property and equipment.

WARNING

Use hoisting equipment for heavy objects (weighing approximately

20 kg (44 lb) or more). Failure to do so may result in back strain or other

injury if the object should fall.

CAUTION

When disassembling or removing the product, wait until the internal

pressure equals atmospheric pressure and the surface of the product

has cooled to room temperature. Disassembling or removing the

product when it is hot or under pressure may lead to discharge of fluids,

causing burns, other injuries or damage.

CAUTION

Do not use excessive force when connecting threaded pipes to the

product. Over-tightening may cause breakage leading to fluid

discharge, which may cause burns or other injury.

CAUTION

Use the procedures on the following pages to remove components. Use the same

procedures in reverse to reassemble. (Installation, inspection, maintenance, repairs,

disassembly, adjustment and valve opening/closing should be carried out only by trained

maintenance personnel.)

In cases where sufficient maintenance space has been provided for (see “Maintenance

Space”), maintenance can be carried out without disconnecting the inlet and outlet

piping. Where there is insufficient maintenance space, first disconnect the inlet and

outlet piping, and then move the unit to a spacious area in which maintenance can be

carried out safely.

When reassembling:

Also replace any gaskets, units or parts that are broken or show serious wear. If

any parts require replacement, refer to “Replacement Parts”.

When reassembling, coat threads and bolts with anti-seize. Tighten the body and

cover bolts in a uniform manner left and right, being careful to avoid uneven

tightening.

If drawings or other special documentation were supplied for the product, any

torque given there takes precedence over values shown here.

172-65473MA-03 (GT5C PowerTrap) 17 Jul 2019

18

Recommended Tools List for Disassembly/Reassembly

No.

Tool Name

Step Used

Tool

1

Torque Wrench (Ratchet)

0 –100 Nm

(0 –73 lbfft)

1,2,3,4,5,6

2

Sockets

Distance across flats = S

13 mm (½”)

19 mm (¾”)

22 mm (78")

3,4,6

2,5

4

S

3

Extension Bar

L = 150 mm (578")

5

4

Offset Wrench

13 mm (½”)

19 mm (¾”)

22 mm (78")

3,4,6

2

4

5

Adjustable Wrench

L=200 –300 mm

(8”–12”)

1, 6

6

Needle-Nose Pliers

3

7

Hex Key

2.5mm (332”)

6

8

Internal Snap Ring Pliers

4

(1 Nm 10 kgcm2)

L

S

172-65473MA-03 (GT5C PowerTrap) 17 Jul 2019

19

1. Before Removing/Reattaching

Discharge the condensate from the body before removing parts.

(1 Nm 10 kgcm2)

Part

Disassembly

Reassembly

Plug

•Discharging condensate is carried out with the intake

(motive medium), exhaust, inlet and outlet piping still

connected to the unit.

•Using an adjustable wrench, slowly loosen plug to release

pressure and discharge fluid. Take care to avoid being

burned by fluid discharge. (Opening this plug may help to

discharge condensate in the body more easily when the

drain plug is opened.)

• Wrap threads with 3

–3.5 turns of sealing

tape or apply sealing

compound.

• Tighten to a torque of

30 Nm (22 lbfft).

Drain Plug

•Using an adjustable wrench, slowly loosen plug to release

pressure and discharge fluid, take care to avoid being

burned by fluid discharge.

• Wrap threads with

3 –3.5 turns of

sealing tape or apply

sealing compound.

• Tighten to a torque of

30 Nm (22 lbfft).

Plug

Drain Plug

Other manuals for PowerTrap GT5C

1

Table of contents

Other TLV Water Pump manuals

Popular Water Pump manuals by other brands

Graco

Graco SaniForce 1590 HS Instructions-parts list

Pratissoli

Pratissoli MW Series Use and maintenance manual

Ingersoll-Rand

Ingersoll-Rand ARO PD10P Series Operator's manual

Kärcher

Kärcher BPE 4200/50 instructions

Alemlube

Alemlube O30060 instruction manual

Wilo

Wilo DrainLift M2/8 Installation and operating instructions