TLV PowerTrap GP10L-1AJ User manual

172-65510MA-05 (GP Series System Package) 27 December 2016

System Package

GP10L-1AJ

GP14L-1AJ

GP14M-1BJ

GP10-1CJ

GP10-2FJ

Copyright © 2016 by TLV CO., LTD.

All rights reserved

172-65510MA-05 (GP Series System Package) 27 Dec 2016

1

Contents

Introduction.......................................................................1

Safety Considerations.......................................................2

General Description..........................................................4

Specifications....................................................................5

Configuration.....................................................................6

Installation.........................................................................8

Installation and Maintenance Space...............................13

Operation and Periodic Inspection..................................15

Product Warranty............................................................18

Introduction

Thank you for purchasing the PowerTrap system package (hereinafter

referred to as "system package").

This product has been thoroughly inspected before being shipped from the factory.

When the product is delivered, before doing anything else, check the specifications

and external appearance to make sure nothing is out of the ordinary. Also be sure to

read this manual carefully before use and follow the instructions to be sure of using

the product properly.

This instruction manual only describes contents regarding installation of the system

package. Detailed instructions for PowerTrap unit(s) included in this system

package are not described. Please refer to the instruction manual(s) for each

PowerTrap unit.

If detailed instructions for special order specifications or options not contained in this

manual are required, please contact for full details.

This instruction manual is intended for use with the model(s) listed on the front cover.

It is necessary not only for installation, but for subsequent maintenance and

relocating the system package. Please keep it in a safe place for future reference.

The contents of this manual are subject to change without notice.

172-65510MA-05 (GP Series System Package) 27 Dec 2016

2

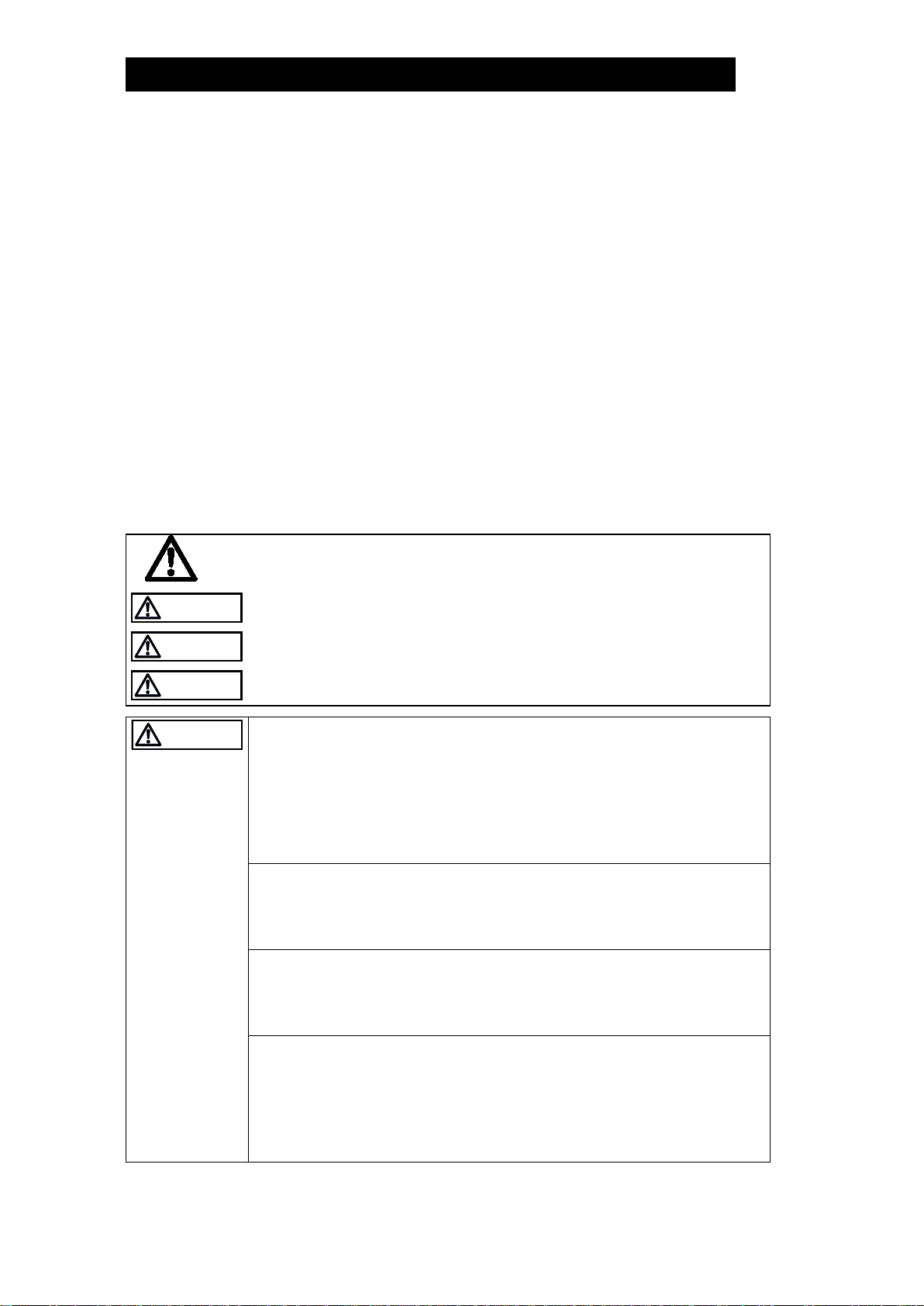

Safety Considerations

•Read this section carefully before use and be sure to follow the instructions.

•This instruction manual only describes contents regarding installation of the

system package. Detailed instructions for PowerTrap unit(s) included in this

system package are not described. Please refer to the instruction manual(s) for

each PowerTrap unit.

•Installation, inspection, maintenance, repairs, disassembly, adjustment and valve

opening/closing should be carried out only by trained maintenance personnel.

•The precautions listed in this manual are designed to ensure safety and prevent

equipment damage and personal injury. For situations that may occur as a result

of erroneous handling, three different types of cautionary items are used to

indicate the degree of urgency and the scale of potential damage and danger:

DANGER, WARNING and CAUTION.

•The three types of cautionary items above are very important for safety: be sure

to observe all of them as they relate to installation, use, maintenance and repair.

Furthermore, TLV accepts no responsibility for any accidents or damage

occurring as a result of failure to observe these precautions.

Symbols

Indicates a DANGER, WARNING or CAUTION item.

DANGER

Indicates an urgent situation which poses a threat of death or

serious injury

WARNING

Indicates that there is a potential threat of death or serious injury

CAUTION

Indicates that there is a possibility of injury or equipment / product

damage

CAUTION

Install properly and DO NOT use this product outside the

recommended operating pressure, temperature and other

specification ranges.

Improper use may result in such hazards as damage to the

product or malfunctions that may lead to serious accidents. Local

regulations may restrict the use of this product to below the

conditions quoted.

Use hoisting equipment for heavy objects (weighing

approximately 20 kg (44 lb) or more).

Failure to do so may result in back strain or other injury if the

object should fall.

Take measures to prevent people from coming into direct

contact with product outlets.

Failure to do so may result in burns or other injury from the

discharge of fluids.

When disassembling or removing the product, wait until the

internal pressure equals atmospheric pressure and the

surface of the product has cooled to room temperature.

Disassembling or removing the product when it is hot or under

pressure may lead to discharge of fluids, causing burns, other

injuries or damage.

Safety considerations are continued on the next page.

172-65510MA-05 (GP Series System Package) 27 Dec 2016

3

CAUTION

Be sure to use only the recommended components when

repairing the product, and NEVER attempt to modify the

product in any way.

Failure to observe these precautions may result in damage to the

product and burns or other injury due to malfunction or the

discharge of fluids.

Do not use excessive force when connecting threaded pipes

to the product.

Over-tightening may cause breakage leading to fluid discharge,

which may cause burns or other injury.

Use only under conditions in which no freeze-up will occur.

Freezing may damage the product, leading to fluid discharge,

which may cause burns or other injury.

Use only under conditions in which no water hammer will

occur.

The impact of water hammer may damage the product, leading to

fluid discharge, which may cause burns or other injury.

172-65510MA-05 (GP Series System Package) 27 Dec 2016

4

General Description

Install properly and DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

CAUTION

Application

The PowerTrap is a non-electric mechanical pump used to discharge high-temperature

liquid from vacuum-pressure or low-pressure areas to high-pressure areas, or from lower

to higher elevations.

This system package is pre-assembled with all the necessary devices and pipes to

operate the PowerTrap, greatly reducing labor required for installation, pipings, and

maintenance.

The discharge capacity differs depending on the system package model. Check the

latest product information to make sure the system package model you purchased is

suitable for use on the application it is planned to be used on.

For the latest product information, please contact TLV.

172-65510MA-05 (GP Series System Package) 27 Dec 2016

5

Specifications

Install properly and DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

CAUTION

Use only under conditions in which no freeze-up will occur. Freezing

may damage the product, leading to fluid discharge, which may cause

burns or other injury.

CAUTION

(1) The system package model is indicated on the nameplate located on the

condensate receiver.

Please check the latest product information for the specifications of each model.

For the latest product information, please contact TLV.

Model

Serial Number

(2) For the model name of the PowerTrap unit(s), refer to the nameplate located on

the PowerTrap unit(s).

Please check the latest product information for the specifications of the

PowerTrap unit(s).

For the latest product information, please contact TLV.

Model

Serial Number

Maximum Allowable

Temperature*(TMA)

Maximum Operating

Temperature (TMO)

Maximum Allowable

Pressure*

Maximum Operating

Pressure

Valve No.**

Nominal Diameter

* Maximum allowable pressure (PMA) and maximum allowable temperature (TMA) are

PRESSURE SHELL DESIGN CONDITIONS, NOT OPERATING CONDITIONS.

** Valve No. is displayed for products with options. This item is omitted from the nameplate

when there are no options.

172-65510MA-05 (GP Series System Package) 27 Dec 2016

6

Configuration

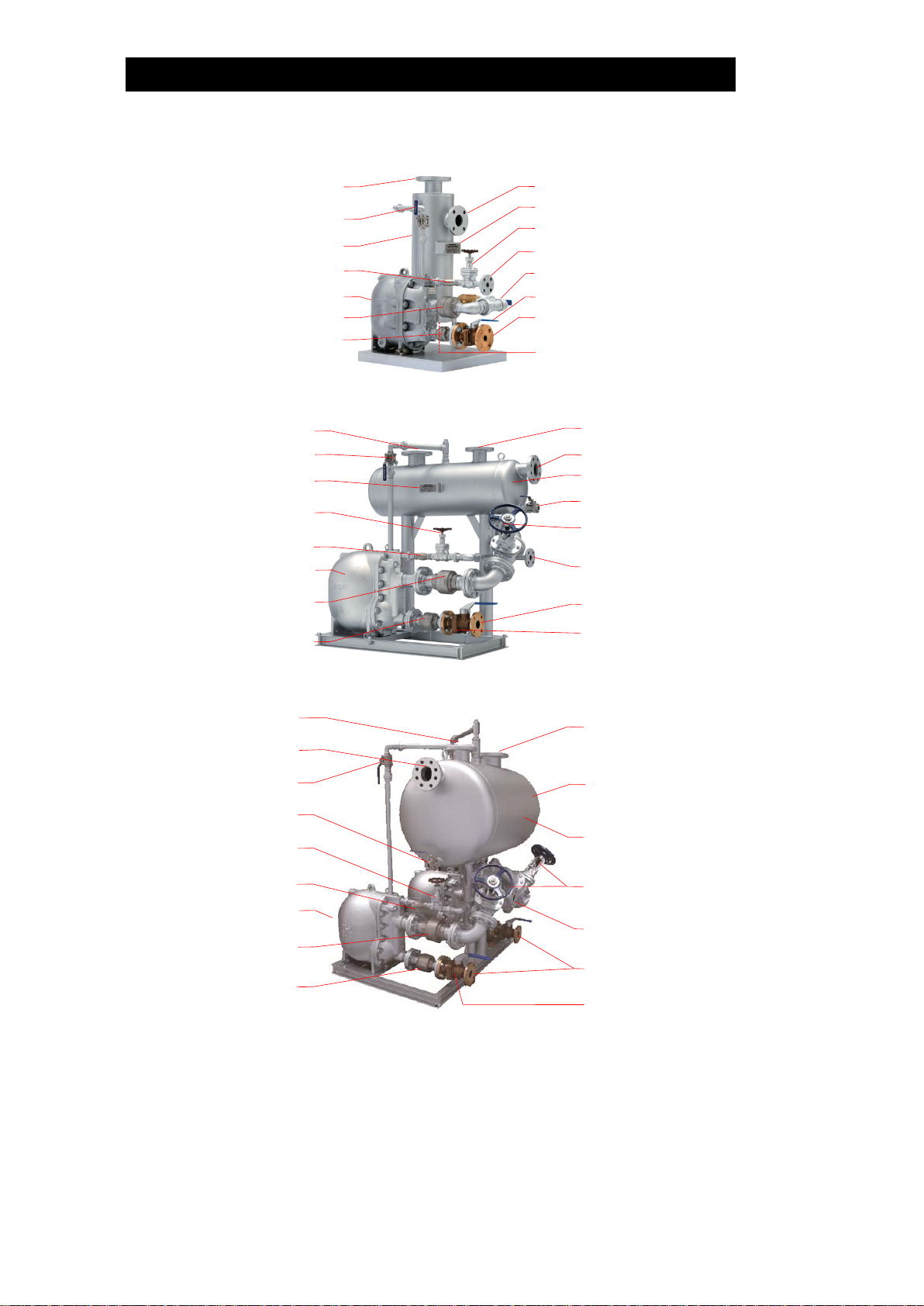

GP10L-1AJ

Condensate Inlet

Nameplate

Motive Medium Supply Valve

Motive Medium Supply Connection

Condensate Inlet Valve

Condensate Outlet

Condensate Outlet Valve

Blow Valve

(bottom of the condensate receiver)

Vent Pipe and

Overflow Connection

Exhaust Valve

Condensate Receiver*

Motive Medium Strainer

PowerTrap

Condensate Inlet Check Valve

Condensate Outlet Check Valve

GP10-1CJ

Overflow Connection

Condensate Receiver*

Condensate Inlet Valve

Motive Medium

Supply Connection

Condensate Outlet

Condensate Outlet Valve

Blow Valve

Vent Pipe Connection

Exhaust Valve

Nameplate

Motive Medium

Supply Valve

PowerTrap

Condensate Inlet

Check Valve

Condensate Outlet

Check Valve

Motive Medium Strainer

Condensate Inlet

GP10-2FJ

Vent Pipe Connection

Condensate Receiver*

Condensate Inlet Valve

Motive Medium

Supply Connection

Condensate Outlet

Condensate Outlet Valve

Blow Valve

Condensate Inlet

Exhaust Valve Nameplate

(side of the condensate

receiver)

Motive Medium

Supply Valve

PowerTrap

Condensate Inlet

Check Valve

Condensate Outlet

Check Valve

Motive Medium Strainer

Overflow Connection

* Condensate receiver may be referred to as condensate tank or condensate header.

172-65510MA-05 (GP Series System Package) 27 Dec 2016

7

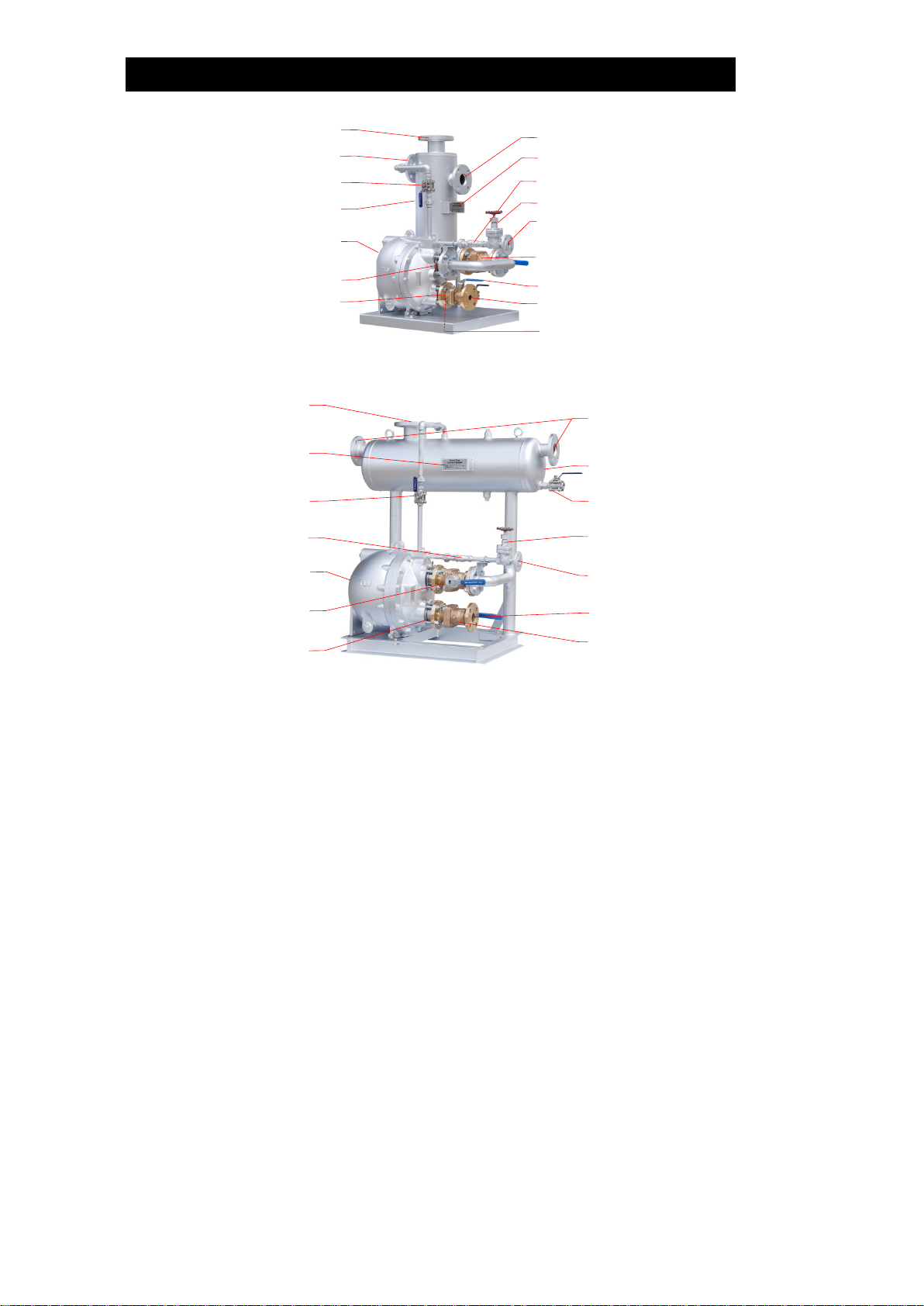

GP14L-1AJ

Condensate Inlet

Nameplate

Motive Medium Supply Valve

Motive Medium Strainer

Condensate Inlet Valve

Condensate Outlet

Condensate Outlet Valve

Vent Pipe Connection

Exhaust Valve

Condensate Receiver*

PowerTrap

Condensate Inlet Check Valve

Condensate Outlet Check Valve

Motive Medium

Supply Connection

Overflow Connection

Blow Valve

(bottom of the condensate receiver)

GP14M-1BJ

Condensate Inlet or

Overflow Connection**

Condensate Receiver*

Motive Medium

Supply Valve

Motive Medium

Supply Connection

Condensate Outlet

Condensate Outlet Valve

Blow Valve

Vent Pipe Connection

Exhaust Valve

Nameplate

PowerTrap

Condensate Inlet

Check Valve

Condensate Outlet

Check Valve

Motive Medium Strainer

* Condensate receiver may be referred to as condensate tank or condensate header.

** One connection should be used for the condensate inlet pipe, the other one should be

connected to the overflow pipe.

172-65510MA-05 (GP Series System Package) 27 Dec 2016

8

Installation

Be sure to install an overflow pipe and discharge to a safe area such as a

pit. Failure to install an overflow pipe is dangerous, as condensate may

spurt from the vent pipe and could result in burns and other injuries.

WARNING

Install properly an DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

Malfunctions which may lead to serious accidents. Local regulations may

restrict the use of this product to below the conditions quoted.

CAUTION

Use hoisting equipment for heavy objects (weighing approximately

20 kg (44 lb) or more). Failure to do so may result in back strain or other

injury if the object should fall.

CAUTION

Take measures to prevent people from coming into direct contact with

product outlets. Failure to do so may result in burns or other injury from

the discharge of fluids.

CAUTION

Do not use excessive force when connecting threaded pipes to the

product. Over-tightening may cause breakage leading to fluid discharge,

which may cause burns or other injury.

CAUTION

Use only under conditions in which no water hammer will occur. The

impact of water hammer may damage the product, leading to fluid

discharge, which may cause burns or other injury.

CAUTION

System Package Piping

Rm

[Si]

V

Ki

St

[So]

[Sf][Se] Ve

Vb

Pb

Lt

Vi

Ci

Vo

Co

Vt

Vm

Km

System package

Standard Range

Pipe the discharge to a safe area such as a pit

Condensate

Receiver

Motive Medium Supply Line Blow Line Condensate Line

Lg

Backflow

Water Hammer

Prevention

Check Valve

Condensate

Recovery

Line

[Sr]

Temperature

Controller

Equipment

Pressure

Steam for

Heating

Motive

Medium

Supply

Pressure

Pm

Primary

Pressure

for Motive

Medium

Flash

Steam

Vent Pipe

Overflow Pipe

Pump Exhaust

Back

Pressure

Steam Trap

TLV

Power

Trap Steam Trap

Steam Trap

Steam-using

Equipment

Other Steam-using

Equipment

If water hammer due to steam backflow in the

condensate recovery line is expected, installation

of a check valve vertically and as close as

possible to the recovery line is recommended.

When the rise in piping is 30 m (100 ft) or farther

from the PowerTrap installation of a check valve

is recommended for the prevention of return water

hammer.

Backflow

Water Hammer

Prevention

Check Valve

[Sv]

[Sm]

NOTE: This sketch is for explanation purposes only and is not intended as an installation design.

System Package (Standard)

System Package (Optional)

Piping & Accessories Provided by User

PowerTrap

Rm

Motive Medium Pressure

Reducing Valve

Sf

Overflow Pipe

Condensate Receiver

Sv

Vent Pipe

Vi

Valve on Condensate Inlet Pipe

Ki

Condensate Inlet Strainer

Sm

Motive Medium Supply Pipe

Ci

Condensate Inlet Check Valve

Lt

Liquid Level Gauge for Tank

(Condensate Receiver)

Si

Condensate Inlet Pipe

Co

Condensate Outlet Check Valve

So

Condensate Outlet Pipe

Vo

Valve on Condensate Outlet Pipe

Lg

Liquid Level Gauge for

PowerTrap

Sr

Condensate Recovery Line

Vm

Valve on Motive Medium

Supply Line

V

Valve on Condensate Inlet Pipe

St

Steam Trap on Drip Leg

Vb

Bypass Valve

Km

Motive Medium Strainer

Ve

Valve on Exhaust Pipe

Others

Se

Exhaust Pipe

Pm

Motive Medium Supply Pressure

Vt

Condensate Blow Valve on

Condensate Receiver

Pb

Back Pressure

172-65510MA-05 (GP Series System Package) 27 Dec 2016

9

Installation Procedure

Figure on previous page is a simplified flow sketch. For the devices such as control

valves, steam traps etc. that are not directly related to the system package, refer to

the instruction manual for each product regarding installation. Installation, inspection,

maintenance, repairs, disassembly, adjustment and valve opening/closing should be

carried out only by trained maintenance personnel.

(1) Pumped Medium:

•Fluids that can be discharged through the PowerTrap are limited to steam

condensate and water. PowerTraps that have been specially constructed for

other specific fluids are not limited by this restriction.

(2) Motive Medium Supply Piping [Sm]:

•The size of the motive medium supply pipe should be the same size as the

system package motive medium supply pipe connection.

•Motive medium inlet pressure should not exceed 1.05 MPaG (150 psig, 10.5

barg).

•Steam, compressed air, or nitrogen may be used as the motive medium.

•When the motive medium is steam, if the application will require that the

equipment be shut down (non-operating) for periods of 2 months or longer,

install a drip leg on the motive medium supply line, and a steam trap [St] on the

drip leg. The outlet pipe from the steam trap [St] may be connected to the

exhaust pipe [Se] close to where it connects to the condensate receiver.

This measure is not necessary when the motive medium is compressed air or

nitrogen.

(3)Pressure Reducing Valve on the Motive Medium Supply Piping [Rm]:

•When the supply pressure of the motive medium is greater than 1.05 MPaG

(150 psig, 10.5 barg), install a TLV COSPECT Series pressure reducing valve.

Make sure that the motive medium pressure is lower than the maximum

operating pressure of the PowerTrap. Use good piping practices when

selecting the installation location for COSPECT.

In this case, be sure to install a safety valve between the pressure reducing

valve and the PowerTrap.

•When the motive medium pressure is less than 1.05 MPaG (150 psig, 10.5

barg), if a pressure reducing valve is to be installed to slow the speed of the flow,

the installation of a safety valve is not required.

•Install the pressure reducing valve as far away from the PowerTrap as

possible.

When the motive medium pressure is less than 0.5 MPaG (72.5 psig, 5 barg): at

least 3 m (10 ft).

When the motive medium pressure is 0.5 MPaG or greater (72.5 psig or greater,

5 barg or greater): at least 3 m + 1 m (10 ft + 3 ft) for every 0.1 MPaG (4.5 psig,

1 barg) over 0.5 MPaG (72.5 psig, 5 barg).

•The pressure setting on the pressure reducing valve should be between 0.05

and 0.15 MPa (7 – 20 psi, 0.5 – 1.5 bar) higher than the back pressure.

When the discharge capacity of the PowerTrap is insufficient for the set

motive pressure, increase this set pressure even further.

172-65510MA-05 (GP Series System Package) 27 Dec 2016

10

(4)Exhaust Piping [Se]:

•Unless problems occur, leave the exhaust pipe connected to the condensate

receiver as designed.

•When steam is not used as the motive medium, steam clouds (flash steam)

may come out from the vent pipe [Sv]. In this case it is possible to disconnect

the exhaust line from the condensate receiver.

If the exhaust line has to discharge to atmosphere, a sound level of

approximately 90 – 100 dB may be emitted from the exhaust pipe discharge

outlet for two to three seconds. If soundproofing measures are necessary,

install a silencer. (If the exhaust line is connected to the condensate receiver,

the sound level will be below 60 dB.)

(5)Condensate Inlet Piping [Si]:

•Condensate Inlet Pipe [Si] should be as short and straight as possible so that

condensate naturally flows down into the PowerTrap.

•Install a 40-mesh or finer strainer [Ki] on the PowerTrap condensate inlet pipe.

The installation should be in a location that allows sufficient space for

maintenance of the strainer.

•Install a valve [V] and a bypass valve [Vb] on the condensate inlet pipe. This

allows operation of the equipment while carrying out maintenance work if the

PowerTrap is malfunctioning or needs maintenance. Use a gate valve for

valve [V] and a globe valve for the bypass valve [Vb].

(6)Condensate Outlet Piping [So], Condensate Recovery Line [Sr]:

•The flow velocity in the pipe should be considered when determining the pipe

size.

Condensate in the PowerTrap is discharged by the motive medium supply

pressure. The instantaneous flow through the condensate outlet pipe during the

discharge operation is between 2 and 40 metric tonnes (530 and 10,600 U.S.

gal) per hour.

The instantaneous discharge amount should be considered when determining

the outlet pipe diameter. For each system package, motive medium supply

pressure and back pressure instantaneous discharge amount, contact . If

you have the "PowerTrap Design & Data Sheet", installed piping should be the

size recommended by TLV.

172-65510MA-05 (GP Series System Package) 27 Dec 2016

11

(7)Vent Pipe [Sv] and Overflow Pipe [Sf]:

•Be sure to install a vent pipe and an overflow pipe. Failure to install an

overflow pipe is dangerous, as condensate may spurt from the vent pipe

and could result in burns and other injuries.

•Pipe the vent pipe and the overflow pipe to a safe place such as a pit.

•Piping size of the overflow pipe should be the same or larger than

condensate inlet pipe.

WARNING

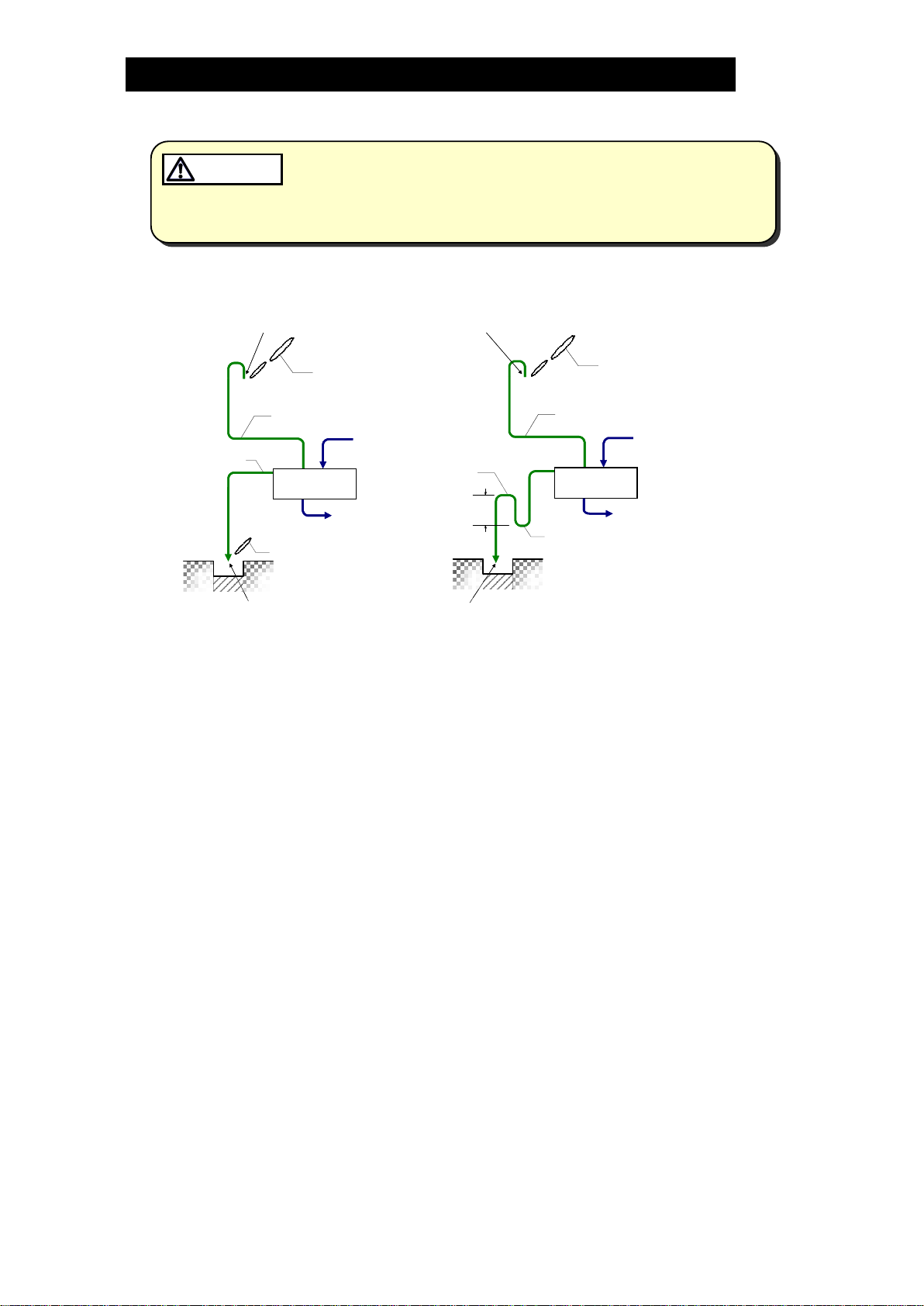

•Models other than the GP10L-1AJ

(12 in)

Condensate

Receiver

Flash Steam

Flash Steam

Condensate

Receiver

To PowerTrap

Flash Steam

Overflow Pipe Overflow Pipe

Condensate

Loop Seal

300 mm

(12 in)

1) 2) Flash Steam

Condensate

Receiver

Vent Pipe

Overflow Pipe Overflow Pipe

Condensate

NOTE:

This sketch is for explanation

purposes only and is not intended

as an installation design.

NOTE:

This sketch is for explanation

purposes only and is not intended

as an installation design.

Pipe the discharge to a safe place such as a pit.

High temperature steam or hot water may splash.

There is a possibility of condensed hot water dripping from vent pipe

outlet. Make sure to extend to where people do not pass.

Condensate

Receiver

Vent Pipe

Flash Steam

To PowerTrap

Flash Steam

The flow velocity in the pipe should be considered when determining the pipe

size.

1) If flash steam can be discharged from overflow pipe

Install overflow pipe and vent pipe separately.

2) If flash steam should not be released from overflow pipe (prevent flash

steam release)

Install overflow pipe and vent pipe separately. For overflow pipe, install loop

seal (approx. 300 mm (12 in)). Flash steam release from overflow pipe can

be prevented since water always accumulates at loop seal. Piping size

should be the same or larger than condensate inlet pipe.

NOTE: • There is a possibility of rust becoming clogged and/or corrosion

since water always present in the loop seal; the possibility is greater

if the piping diameter is too small (generally 25 mm (1 in) or smaller)

• If the loop seal becomes clogged, hot overflow water will blow from

vent pipe; make sure to install vent pipe to lead to a safe place

• Do not install loop seal on the vent pipe

Contact TLV if neither 1) nor 2) above can be installed.

172-65510MA-05 (GP Series System Package) 27 Dec 2016

12

• Model: GP10L-1AJ

Unlike other models, the GP10L-1AJ has an outlet port for the dual installation of

the overflow pipe and vent pipe. When installing the piping, connect the piping to

the flange on the top of the condensate receiver, and then install the overflow

pipe and vent pipe by separating each pipe as shown below.

Observe the same precautions as for other models for installation.

Overflow Pipe

Vent Pipe

(8)Check Valve to Prevent Return Water Hammer ①:

If length "A" in the following figure (from the PowerTrap to a rise in the piping) is

longer than 30 m (100 ft), return water hammer may occur in the piping after a

discharge cycle finishes. To prevent this, installation of a spring-return type check

valve just above the rise is recommended.

(9)Check Valve to Prevent Backflow Water Hammer ②:

If length "B" in the following figure is longer than 500 mm (1911/16 in) and steam

(including flash steam) enters the condensate recovery line, backflow water

hammer may occur in the piping. To prevent this, installation of a spring-return

type check valve close to the condensate recovery line is recommended.

VoCo

A

B

②

Backflow Water Hammer

Prevention Check Valve

①

Backflow Water

Hammer Prevention

Check Valve

Condensate

Recovery Line

[Sr]

TLV

Power

Trap

Steam with

condensate

When a layer

of steam exists

172-65510MA-05 (GP Series System Package) 27 Dec 2016

13

Installation and Maintenance Space

Anchoring the Body

Anchor the 4 corners of the base with anchor bolts. Anchor bolts are not supplied with

the system package, so prepare appropriate anchor bolts separately.

GP10L-1AJ: Anchor Bolt M12 ×4 pcs

Embedment depth of 50 mm (2 in) or more is recommended

GP14L-1AJ: Anchor Bolt M12 ×4 pcs

Embedment depth of 50 mm (2 in) or more is recommended

GP14M-1BJ: Anchor Bolt M12 ×4 pcs

Embedment depth of 50 mm (2 in) or more is recommended

GP10-1CJ: Anchor Bolt M16 ×4 pcs

Embedment depth of 150 mm (6 in) or more is recommended

GP10-2FJ: Anchor Bolt M16 ×4 pcs

Embedment depth of 150 mm (6 in) or more is recommended

Refer to the latest drawings for the anchoring positions of each model.

For the latest product information, please contact TLV.

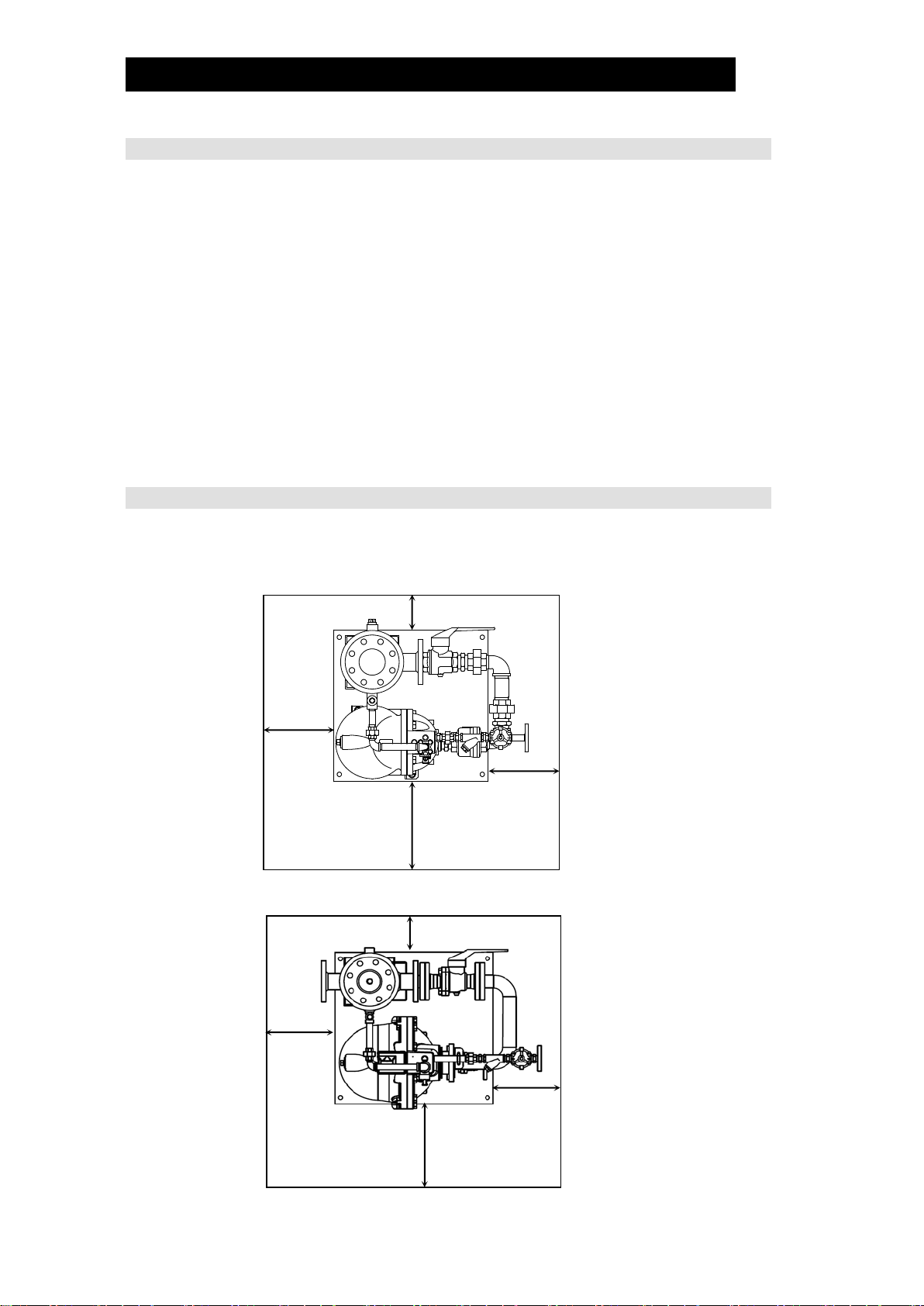

Maintenance Space

The maintenance space shown in the figure below should be provided to enable

disassembly, inspection and replacement of the system package. If there is

insufficient maintenance space, TLV may decline to perform maintenance work.

GP10-1AJ

200 mm (73/4in)

400 mm

(153/4in)

400 mm

(153/4in)

500 mm

(1911/16 in)

GP14L-1AJ

200 mm (73/4in)

400 mm

(153/4in)

400 mm

(153/4in)

500 mm

(1911/16 in)

172-65510MA-05 (GP Series System Package) 27 Dec 2016

14

GP14M-1BJ

400 mm

(15

3

/

4

in)

400 mm

(15

3

/

4

in)

800 mm

(30

1

/

2

in)

800 mm

(30

1

/

2

in)

GP10-1CJ

400 mm

(153/4in)

800 mm

(301/2in)

800 mm

(301/2in)

400 mm

(153/4in)

GP10-2FJ

800 mm

(301/2in)

800 mm

(301/2in) 800 mm

(301/2in)

500 mm

(1911/16 in)

172-65510MA-05 (GP Series System Package) 27 Dec 2016

15

Operation and Periodic Inspection

•After all piping work has been completed in accordance with the

specific piping system designed when the decision to utilize the

PowerTrap System Package was made, check once again to make sure

that all pipe connections have been tightened, gaskets have been

inserted where needed and all parts are securely installed.

•During commissioning and test runs, as well as during start-up of normal

operation, take measures to prevent people from coming into direct

contact with vent and overflow outlets. At the start-up of operation, large

quantities of condensate may flow, causing the Power Trap System

Package to momentarily overload. If this occurs, hot Condensate may

spurt from the pipe connections, the vent piping or overflow piping and

could result in burns, other injuries or damage to equipment.

WARNING

When disassembling or removing the product, wait until the internal

pressure equals atmospheric pressure and the surface of the product

has cooled to room temperature. Disassembling or removing the

product when it is hot or under pressure may lead to discharge of fluids,

causing burns, other injuries or damage.

CAUTION

During maintenance/disassembly all connections, piping and bolts should

be removed slowly to prevent fluids from spurting due to the release of

retained internal pressure. Failure to do so may result in burns or other

injury with the discharge of fluids.

CAUTION

Install properly and DO NOT use this product outside the recommended

operating pressure, temperature and other specification ranges.

Improper use may result in such hazards as damage to the product or

malfunctions which may lead to serious accidents. Local regulations

may restrict the use of this product to below the conditions quoted.

CAUTION

Be sure to use only the recommended components when repairing the

product, and NEVER attempt to modify the product in any way. Failure to

observe these precautions may result in damage to the product or burns

or other injury due to malfunction or the discharge of fluids.

CAUTION

Installation, inspection, maintenance, repairs, disassembly, adjustment and valve

opening/closing should be carried out only by trained maintenance personnel.

Operation

(1) Valve Operation

Refer to the drawings in "Installation" on page 8 to become familiar with the

symbols used for the various valves.

If water hammer has occurred, immediately cease operation and close any valves

that are operating.

a) Drain condensate in the condensate receiver by opening the condensate blow

valve [Vt], making sure the condensate blow valve [Vt] is piped to a safe area.

If the condensate receiver is filled up with condensate, condensate may spurt

from the vent pipe [Sv] during PowerTrap exhaust.

Make sure to close the condensate blow valve [Vt] after condensate is

drained.

b) Slowly open the exhaust valve [Ve].

c) Slowly open the valve [Vm] on the motive medium supply pipe. Make sure that

there is no sound of flow from the exhaust pipe [Se] or the check valve [Ci] on

the condensate inlet pipe.

d) Slowly open the valve [Vo] on the condensate outlet pipe.

172-65510MA-05 (GP Series System Package) 27 Dec 2016

16

e) Slowly open the valve [Vi] on the condensate inlet pipe.

The PowerTrap is normal if it operates intermittently; first exhausting the

motive medium to fill with condensate, and then taking in motive medium to

force the condensate out.

•The interval of operation will vary greatly depending on the amount of condensate

inflow, the temperature, the motive medium (steam or gas) and the motive

pressure. The interval of operation is considered to be the length of time between

the start of one discharge cycle and the start of the next discharge cycle.

•The interval of operation Tc (s) can be roughly determined using the following

formula:

GP10L-1AJ: Tc = 21,600/Q Tc = 47,600/Qp

GP14L-1AJ: Tc = 28,800/Q Tc = 63,500/Qp

GP14M-1BJ: Tc = 45,000/Q Tc = 99,200/Qp

GP10-1CJ/GP10-2FJ: Tc = 108,000/Q Tc = 238,000/Qp

Q : amount of inflowing condensate (kg/h)

Qp: amount of inflowing condensate (lb/h)

•The GP10L, GP14L, GP14M and GP10 condensate discharge capacity for each

discharge operation is listed below. The amount of time required for each

discharge operation will be between 3 and 30 seconds, depending on the back

pressure and the motive medium pressure.

GP10L-1AJ: approx. 6 liters (1.6 U.S. gal)

GP14L-1AJ: approx. 8 liters (2.1 U.S. gal)

GP14M-1AJ: approx. 12.5 liters (3.3 U.S. gal)

GP10-1CJ/GP10-2FJ*: approx. 30 liters (8 U.S. gal)

*Value per GP10

(2) If an error such as a leak or water hammer occurs after beginning operation of the

system package, shut off the valves immediately in the following order:

valve [Vm] on the motive medium supply pipe →valve [Vi] on the condensate inlet

pipe →valve [Vo] on the condensate outlet pipe →valve [Ve] on the exhaust pipe.

(3) Whenever any type of malfunction is suspected in the system package, refer to the

"Troubleshooting" in the corresponding product’s instruction manual, as shown

below:

System Package

Instruction Manual

GP10L-1AJ

GP14L-1AJ

GP14M-1BJ

PowerTrap GP10L/GT10L/GP14L/GT14L/GP14M/GT14M

GP10-1CJ

GP10-2FJ

PowerTrap GP10/GT10/GP14/GT14

172-65510MA-05 (GP Series System Package) 27 Dec 2016

17

Periodic Inspection and Diagnosis

There are two types of periodic inspection: the visual inspection and the disassembly

inspection.

(1)Visual Inspection

•As a general rule, this inspection should be performed at least once every 3 months.

•Check the following items:

a) There should be no leakage from the PowerTrap or from any of the

connections.

b) The PowerTrap unit should be operating cyclically (one indication being the

sharp, mechanical sound of the snap-action unit operating at the transition

between the filling and the discharge parts of the cycle). Immediately after

the end of the discharge part of the cycle and during the filling part of the

cycle, the sound of flow in the exhaust pipe should be heard. During the

pumping (discharge) part of the cycle, flow in the motive medium supply pipe

should be heard.

c) Condensate should not accumulate in the steam-using equipment, and the

temperature of the equipment should not be abnormally low.

d) There should be no condensate overflow from the overflow pipe or vent pipes.

e) There should be no continuous steam discharge through the vent pipe (it is

normal for the PowerTrap to release retained steam from the vent pipe after

motive steam forces the condensate discharge.)

f) There should not be any abnormal noise such as water hammer from the

condensate outlet pipe or the condensate recovery line while the

PowerTrap operates.

(2)Disassembly Inspection

•Only the PowerTrap unit(s) and check valves need disassembly inspection.

For the disassembly inspection, refer to the corresponding product’s instruction

manual.

172-65510MA-05 (GP Series System Package) 27 Dec 2016

18

Product Warranty

1. Warranty Period

One year following product delivery.

2. Warranty Coverage

TLV CO., LTD. warrants this product to the original purchaser to be free

from defective materials and workmanship. Under this warranty, the product

will be repaired or replaced at our option, without charge for parts or labor.

3. This product warranty will not apply to cosmetic defects, nor to any product

whose exterior has been damaged or defaced; nor does it apply in the

following cases:

1) Malfunctions due to improper installation, use, handling, etc., by other

than TLV CO., LTD. authorized service representatives.

2) Malfunctions due to dirt, scale, rust, etc.

3) Malfunctions due to improper disassembly and reassembly, or

inadequate inspection and maintenance by other than TLV CO., LTD.

authorized service representatives.

4) Malfunctions due to disasters or forces of nature.

5) Accidents or malfunctions due to any other cause beyond the control of

TLV CO., LTD.

4. Under no circumstances will TLV CO., LTD. be liable for consequential

economic loss damage or consequential damage to property.

* * * * * * *

For Service or Technical Assistance:

Contact your representative or your regional office.

Manufacturer

CO., LTD.

881 Nagasuna, Noguchi

Kakogawa, Hyogo 675-8511 JAPAN

Tel: 81-(0)79 - 427 - 1800

This manual suits for next models

4

Table of contents

Other TLV Water Pump manuals