TMG TMG-TMB55 User manual

►

www.tmgindustrial.com 0/18 TOLL FREE:1-877-761-2819

1. SAFTY.................................................................................................................................................................. 2

►

www.tmgindustrial.com 1/18 TOLL FREE:1-877-761-2819

1.1 General................................................................................................................................................................. 2

1.2 Safety Instructions................................................................................................................................................ 2

1.3 TMG Brush Mulch er –Description and Applications............................................................................................ 3

1.4 Operational Safety The Work Area......................................................................................................................... 4

1.5 The Hazard Zone................................................................................................................................................... 4

1.6 Dangerous Locations............................................................................................................................................ 5

1.7 Urban Precautions.................................................................................................................................................. 6

2. OPERATIONAL SAFETY/ THE OPERATOR............................................................................................................... 6

2.1 Sound Levels/ Hearing Protection.................................................................................................................. 6

2.2 Dust Protection...................................................................................................................................................... 7

2.3 Protection from Flying or Falling Objects................................................................................................................7

2.4 Avoid Power Lines..................................................................................................................................................7

2.5 Operator Protection................................................................................................................................................ 7

2.6 Stopping the Rotor Before Exiting the Carrier........................................................................................................ 9

3. CARRIER VEHICLE PREPARATION/MAINTENANCE................................................................................................. 9

3.1 Shielding................................................................................................................................................................. 9

3.2 Carrier Vehicle Preparation/Maintenance............................................................................................................ 10

3.3 Carrier Clean-up................................................................................................................................................... 10

4. POLICING THE WORK AREA................................................................................................................................. 11

4.1 Avoid Metal and Wire........................................................................................................................................... 11

4.2 Use Caution with Stringy Vegetation.....................................................................................................................11

4.3 Avoid Plastics....................................................................................................................................................... 11

4.4 Depth Shoe Adjustment...................................................................................................................................... 11

5. MULCHER OPERATION......................................................................................................................................... 12

5.1 Push working........................................................................................................................................................ 12

5.3 Stump Grinding................................................................................................................................................... 19

5.4 Finishing the Work................................................................................................................................................ 20

5.5 Hydraulic Push Bar Operation (Optional Equipment)........................................................................................... 20

5.6 Trap Door............................................................................................................................................................. 21

6. PREVENTATIVE MAINTENANCE........................................................................................................................... 22

6.1 SAFETY FIRST...................................................................................................................................................... 22

6.2 Rotor Power Belts................................................................................................................................................. 22

6.3 Lubrication Points............................................................................................................................................... 26

6.4 Tighten All Bolts................................................................................................................................................... 27

7. ROTOR MAINTENANCE........................................................................................................................................ 27

7.1 Visual Inspection.................................................................................................................................................. 27

7.2 Tool Replacement................................................................................................................................................ 28

8. DISPOSAL PROCEDURE........................................................................................................................................ 28

9. PART LIST........................................................................................................................................................... 28

WARNING

►

www.tmgindustrial.com 2/18 TOLL FREE:1-877-761-2819

1. Read manual before operating .

2. Do not operate or perform maintenance on your brush mulcher without reading and understanding this entire manual

first.

3. If this manual is lost or if you have any questions, contact TMG or your dealer before you proceed.

UNDERSTAND THE WRITTEN INSTRUCTIONS, RULES AND SAFETY PRECAUTIONS

1. The written instructions rules and safety precautions are outlined in this operation and safety manual.

2. Check the rules and regulations at your location. The rules include employer’s work safety regulations and local

government guidelines’ and restrictions for safe operation of the equipment.

PERFORM APPLICATION TRAINING WITH OPERATOR

1. Conduct felid instruction with a trained Operator. Application training should include complete vehicle safety,

operation training, complete mulching safety and application training.

2. Know and understand your work conditions; hazards should be reviewed and terrain surveyed at this time as well as

with all new work sites.

3. Verify that the machine is in complete safe working order and prepared for your application.

1. SAFETY

1.1 GENERAL

The forestry mulcher is designed to process heavy organic material such as branches, stumps, heavy timber and brush.

1.2 SAFETY INSTRUCTIONS

SAFETY ALERT SYMBOL

This symbol is used throughout this manual to call attention to safety procedures.

DANGER

The word DANGER indicates an immediate hazardous situation, which if not avoided, will result in death or serious injury.

WARNING

The word WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or serious

injury.

CAUTION

The word CAUTION preceded with a safety alert symbol indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury

NOTICE

Indicates information or a company policy that relates directly or indirectly to the safety off personnel or protection of

property.

SAFETY FIRST

With any piece of equipment, new or used, the most important part of its operation is safety! We encourages you and

your employees to familiarize yourselves with your new equipment and to stress safe operation!!

PRIOR TO OPERATION:

Read the owner’s manual in its entirety and follow all safety procedures.

Check all grease points per the owner’s manual.

Inspect all fasteners for tightness with power off.

►

www.tmgindustrial.com 3/18 TOLL FREE:1-877-761-2819

Inspect all fasteners for tightness with power off.

Manually turn rotor to inspect tool bolts with engine off.

Check gearbox oil (PTO models) for proper level per owner is manual.

Obey all safety labels on the forestry mulcher. They are provided for your protection. If any labels are removed, damaged,

or made unreadable in any way, call your dealer for a replacement.

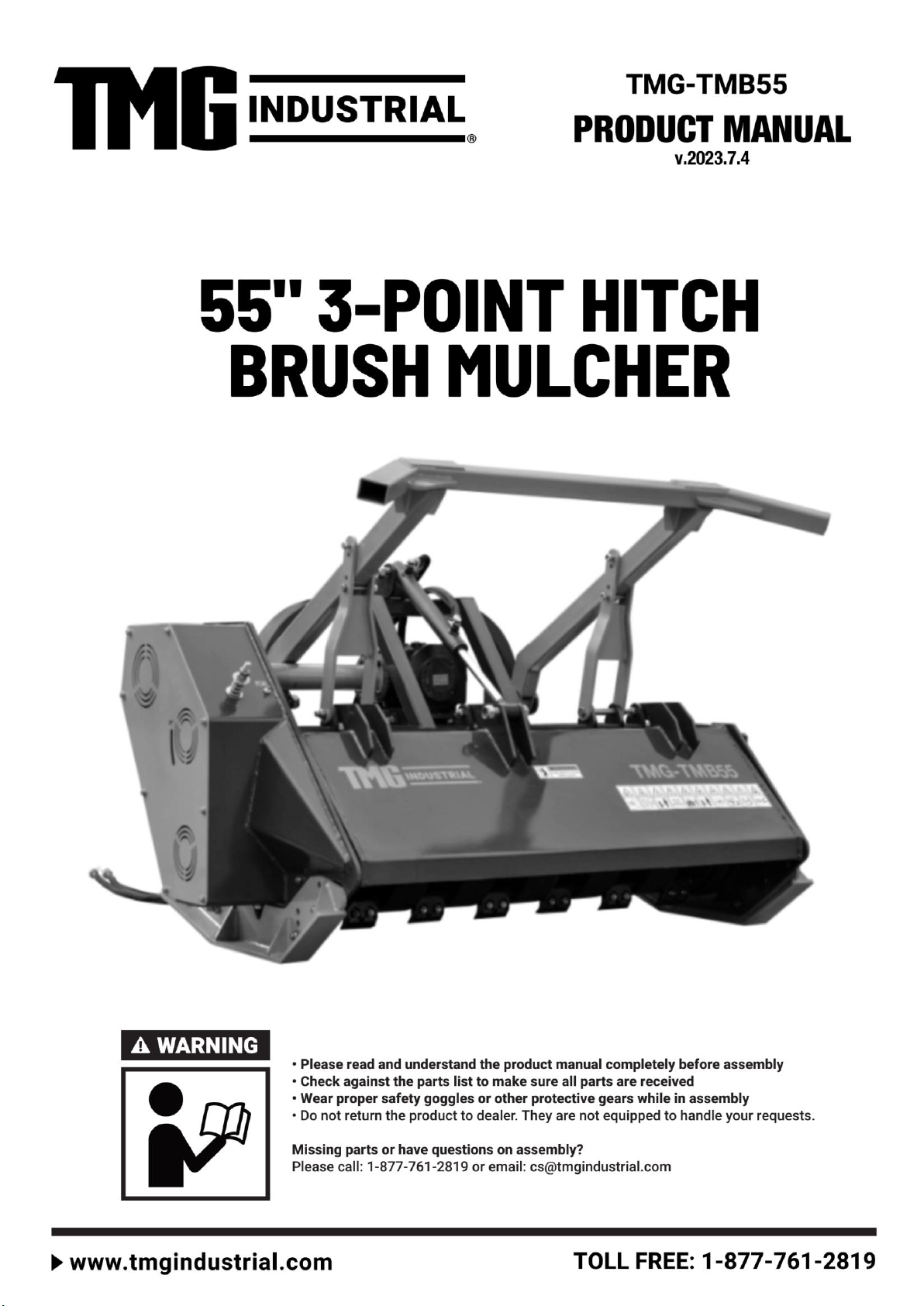

1.3 TMG BRUSH MULCHER –DESCRIPTION AND APPLICATIONS

Forestry

Orchard Removal

Land Clearing

Transfer Stations

Stump Grinding

ROW Maintenance

Yard Waste Process

Forest Fire Prevention

Brush and Slash Piles

The versatile forestry mulcher was designed for shredding woody materials. The forestry mulcher excels at processing

yard waste, land preparation and slash reduction. It has multiple uses for farmers, parks, golf courses, loggers, land

clearing companies, ranchers, foresters and silvaculturists.

The mulcher fixed tools are designed to withstand daily brush shredding, land clearing and stump grinding operations.

The forestry mulch shreds material into a fine particle size by going over the shredded material until the desired texture

is achieved.

If left on the ground the shredded material is beneficial to the soil. On steep slopes the output from the mulcher is ideal

for interim erosion control.

1.4 OPERATIONAL SAFETY THE WORK AREA:

For the sake of this manual, the front of the mulcher is the side with the rotor exposed. The rear has defection chains. For

crawlers and rubber tire machines, when the mulcher is mounted on the front of the machine, the front of the mulcher is

facing the same forward direction. If mounted on the rear, the front of the mulcher is facing away from the rear of the

carrier. Mounting for excavators and other boom-type installations may vary but references to the front and rear of the

mulcher remain the same.

1.5 THE HAZARD ZONE

Flying debris or objects and falling objects can cause serious injury or death Improper operation and failure to follow

safety precautions can cause serious injury or death. All personnel must be clear of the hazard zone while the mulcher is

in operation.

The Hazard Zone is illustrated in Figure 1.1 on the following page. All personnel should be kept clear of this zone while

the mulcher is operating.

The shaded area in the hazard zone must be considered off limits to all individuals! The operator should follow the

precautions below before and during operation of the mulcher.

HAZARD ZONE PRECAUTIONS

It is the operators responsibility to ensure that no one enters the hazard zone!Warn all persons in the area of the hazard

zone.

Stay alert for outsiders entering the work area who may not be aware of thehazard zone.

Land clearing operations generally involve other machinery and people on the site.

Maintain an awareness of all working traff c within 150 ft (45 m) (to each Side) and 300 ft (90 m) (in front and behind) of

the mulcher operation.

►

www.tmgindustrial.com 4/18 TOLL FREE:1-877-761-2819

1.6 DANGEROUS LOCATIONS

Flying debris or objects and falling objects can cause serious injury or death

Improper operation and failure to follow safety precautions can cause serious injury or death. All personnel must be clear

of the hazard zone while the Mulcher is in operation.

DANGER EXISTS MOST PROMINENTLY IN FRONT OF AND BEHIND THE MULCHER.

Pieces of wood and rock can project from the mulcher. This condition is dangerous. This will occur when the mulcher is

raised high enough to allow material to escape.

FOLLOW THESE PRECAUTIONS:

1. NEVER allow anyone to enter the Safety Zone of the mulche while it is in operation.

2. INSPECT the Carrier and mulcher daily for damaged or missing defection chains and flaps.

Be especially careful when:

When the mulcher is being raised up and out of the material that it is working in.

When the mulcher is lowered into new material.

CLOSE the hydraulic trap door (if equipped) while pull-working to better contain material. This also increases the

fineness of the shredded product.

(See section 5.2, Mulcher Operation –Pull-working).

1.7 URBAN PRECAUTIONS

A step-up of safety procedures and precautions is required when working:

Near streets

Near highways

In parks, on golf courses or other inhabited areas

Near buildings

Table of contents

Other TMG Lawn And Garden Equipment manuals

Popular Lawn And Garden Equipment manuals by other brands

Sunforce

Sunforce SOLAR user manual

GARDEN OF EDEN

GARDEN OF EDEN 55627 user manual

Goizper Group

Goizper Group MATABI POLMINOR instruction manual

Rain Bird

Rain Bird 11000 Series Operation & maintenance manual

Cub Cadet

Cub Cadet BB 230 brochure

EXTOL PREMIUM

EXTOL PREMIUM 8891590 Translation of the original user manual

Vertex

Vertex 1/3 HP Maintenance instructions

GHE

GHE AeroFlo 80 manual

Land Pride

Land Pride Post Hole Diggers HD25 Operator's manual

Yazoo/Kees

Yazoo/Kees Z9 Commercial Collection System Z9A Operator's & parts manual

Premier designs

Premier designs WindGarden 26829 Assembly instructions

Snapper

Snapper 1691351 installation instructions