www.tmgindustrial.com 2 / 17 TOLL FREE: 1-877-761-2819

CONTENTS

IMPORTANT SAFETY INFORMATION ......................................................................................................................................... 3

YOUR SAFETY ............................................................................................................................................................................. 3

GENERAL SAFETY ....................................................................................................................................................................... 3

EQUIPMENT SAFETY GUIDELINES ................................................................................................................................................. 4

SAFETY TRAINING ....................................................................................................................................................................... 5

SAFETY SIGNS ............................................................................................................................................................................ 5

SAFETY DECALS .......................................................................................................................................................................... 6

................................................................................................................................................................................................... 6

PREPARATION ............................................................................................................................................................................. 6

MAINTENANCE SAFETY ............................................................................................................................................................... 7

HYDRAULIC SAFETY .................................................................................................................................................................... 7

TRANSPORT SAFETY ................................................................................................................................................................... 8

TO THE NEW OPERATOR OR OWNER ............................................................................................................................................ 8

OPERATION ............................................................................................................................................................................ 8

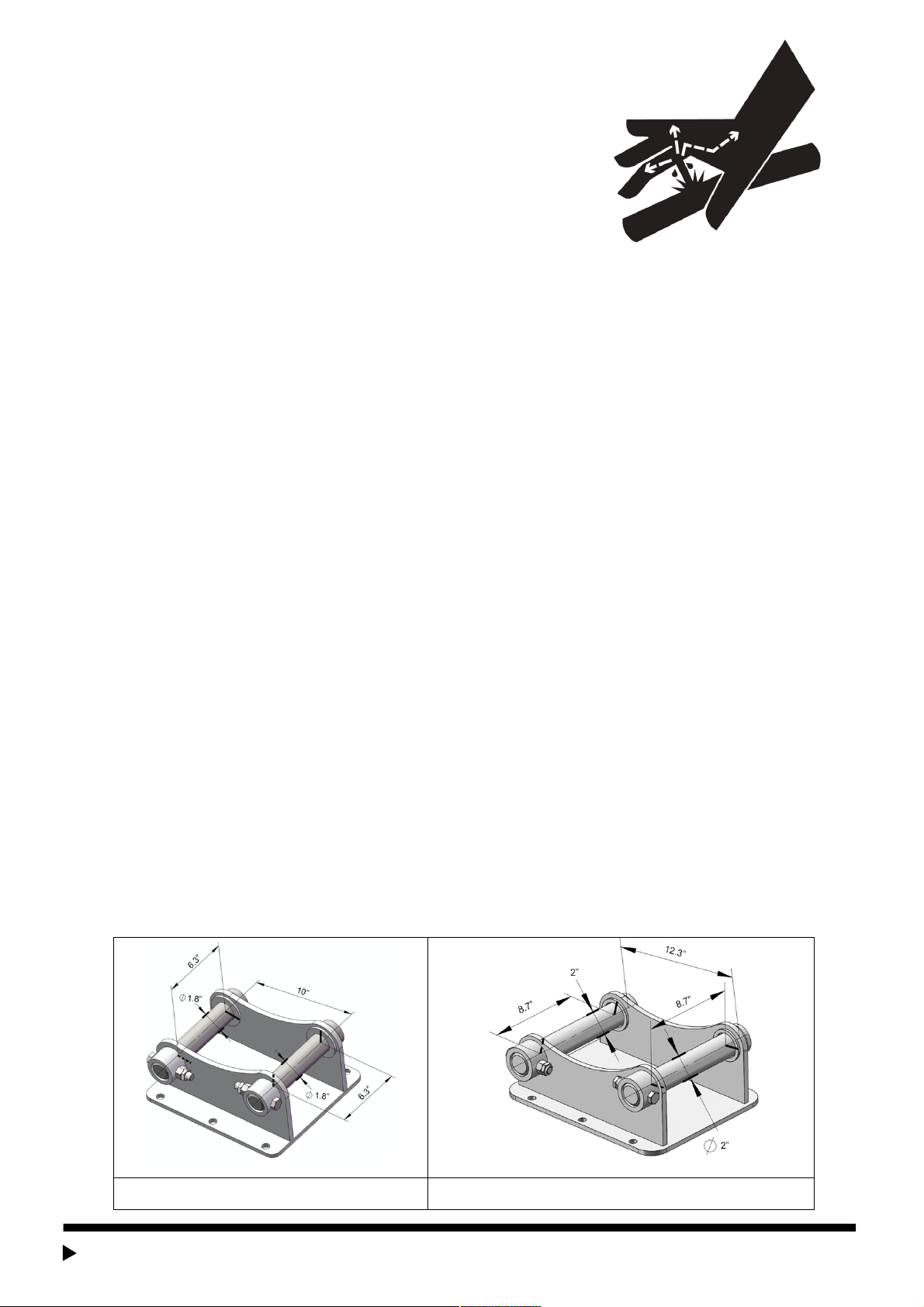

MOUNTING COUPLER ................................................................................................................................................................... 8

MAINTENANCE ....................................................................................................................................................................... 9

BEFORE EVERY USE ..................................................................................................................................................................... 9

EVERY WEEK ............................................................................................................................................................................... 9

AFTER EVERY SEASON ................................................................................................................................................................ 9

HYDRAULIC SYSTEM ................................................................................................................................................................. 10

BOLT TORQUE ........................................................................................................................................................................... 10

SPECIFICATION .................................................................................................................................................................... 11

SPECIFICATIONS &CAPACITIES ................................................................................................................................................ 11

PARTS LIST ......................................................................................................................................................................... 12

EXCAVATOR BRUSH FLAIL MOWER ASSEMBLY .......................................................................................................................... 12

TMG-EFM32 PARTS LIST ....................................................................................................................................................... 12

TMG-EFM40 PARTS LIST ....................................................................................................................................................... 14

TMG-EFM48 PARTS LIST ....................................................................................................................................................... 16