Toho Electronics TTM-i4N SERIES User manual

NOTICE/WARNING BEFORE OPERATION USE

ACCESSORY & CONFIGURATION

TTM-i4N SERIES USER'S MANUAL

: Cautions,Danger,Refer to a manual

: Alternating current

: Reinforced/dual insulation

: Cautions,Danger of Electric Shock

The meaning of the symbols indicated on the label found at the side of the unit is as follows.

CAUTION

WARNING

Due to mishandling,the serious damages may occur to the operator,such as death,

electrocution or skin burn.

Owing to mishandling,the operator may be inflicted with slight injury,or may cause some

damage to the unit.

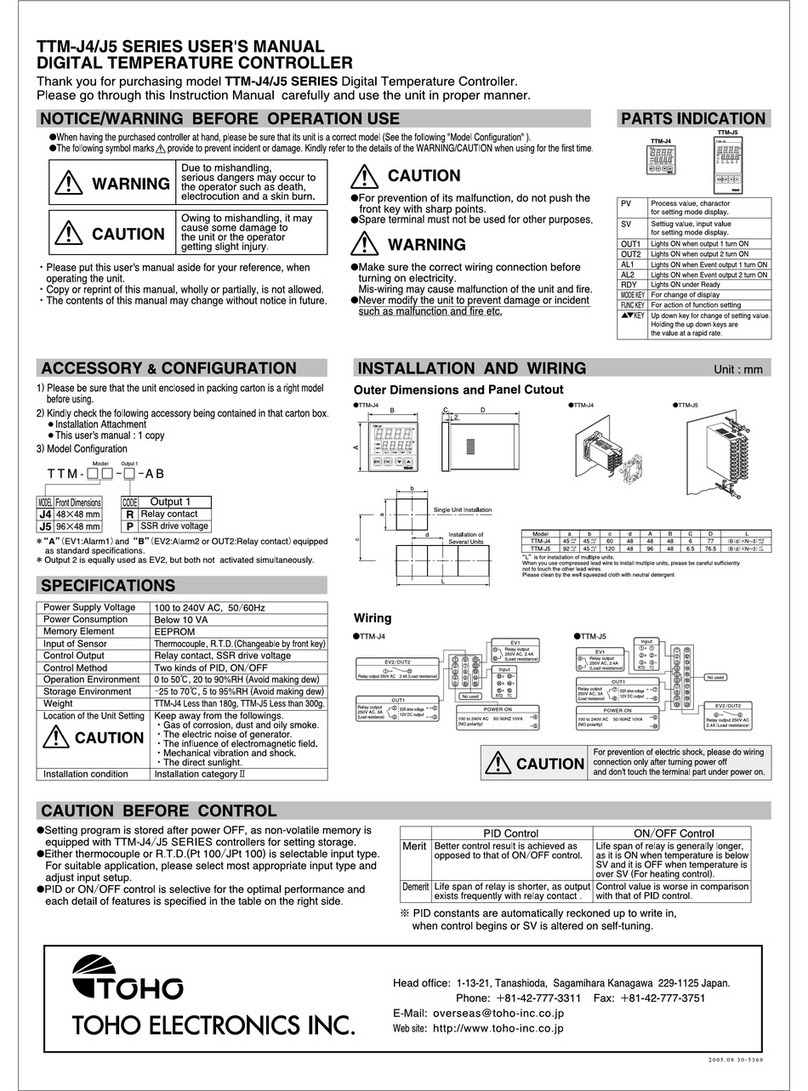

1) Please be sure that the unit enclosed in packing carton is a right model before using.

2) Kindly check the following accessory being contained in that carton box.

3) Model Configuration

Thank you for purchasing model TTM-i4N SERIES Digital Temperature Controller.

Please go through this Instruction Manual carefully and use the unit in proper manner.

If the unit is used in a manner not specified by the manufacturer,the protection provided the unit may be impaired.

TTM-i4N- -A

OUT1Option

Code

OUT1

R

Relay Contact Output

P

SSR Driving Voltage Output

Option

B

OUT2/EV2 Relay Contact Output

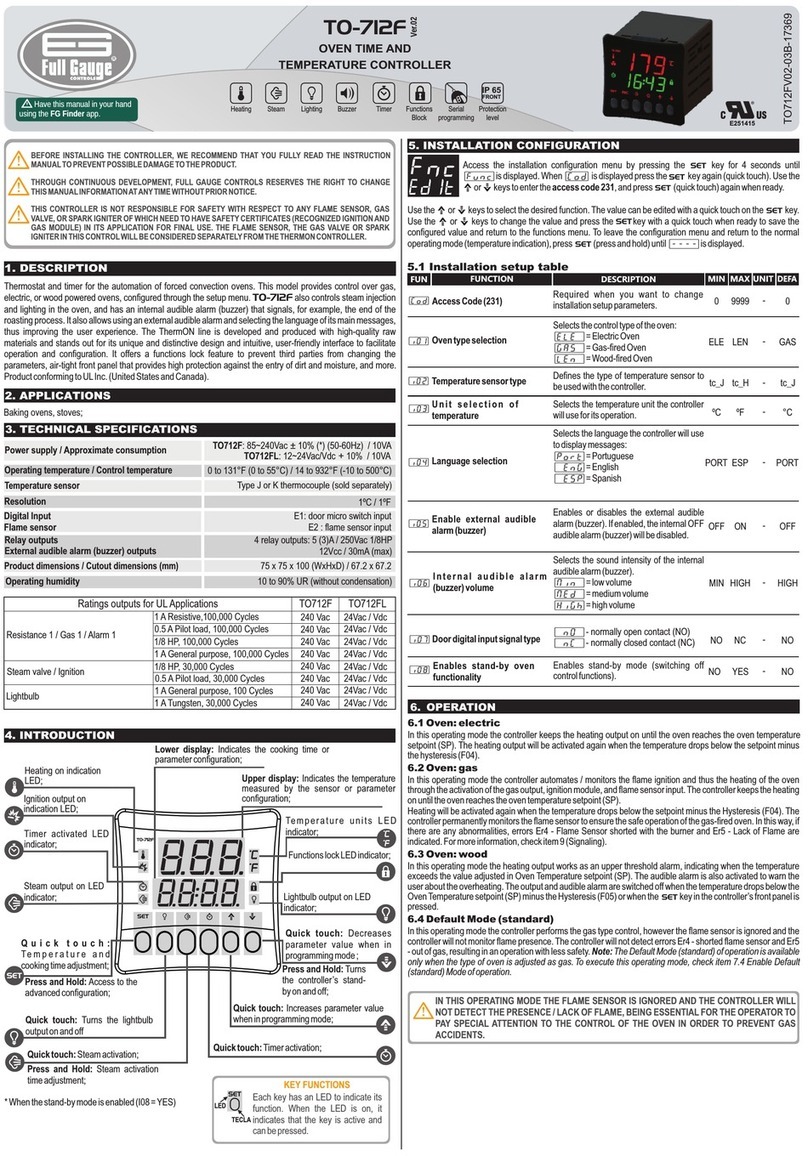

SPECIFICATIONS

※Clean the unit by well squeezed cloth with water.

OUTER DIMENSION

PANEL CUTOUT & INSTALLATION

WIRING

For change of display

For action of function setting

Up down key for change of setting value.

Holding the U/D keys changes value at a rapid rate.

Measured value indication,Charactor indication

F KEY

M KEY

▲▼KEY

PV

Set value indication,Operation quantity indicationSV

Output monitor(appears when OUT1 is ON)OUT

Alarm1 monitor(appears when EV1 is ON)AL1

・When fitting the product,give more than 12 mm space between the upper / lower / left & right

・Install the unit in either horizontal or vertical ( upward ) direction.

①

②

③

④

⑤

⑥

⑦

⑧

⑨

⑩

OUT1

SSR Driving Voltage Output DC12V

② ③

② ③

+ -

OUT2/EV2

Relay Output AC250V 1A (Load resistance)

Relay Output AC250V 3A (Load resistance)

① ⑥

POWER SUPPLY

100 to 240V AC 50/60HZ 6VA

(NO polarity)

④

⑤

EV1

⑦ ⑥

Temp. INPUT

RTD

⑧

⑨

⑩

b

B

A

TC

⑧

⑨

⑩

-

+

Exactly same potential wires for EV1 and EV2

circuits can be connected.

※Terminal ⑥

・Do not touch the terminal part while the power is on.

AC100 to 240V, 50/60Hz

85% to 110% of the rated voltage

Operating Voltage Range

Input Power Requirments

6VA MAXPower Consumption

EEPROMMemory Element

a) Thermocouple Input ( type:K,J,R,T,N,S,B )

b) 3-wire Resistance Temperature Detector Input ( type:Pt100,JPt100 )

(Changeable by input type selection)

3 kinds of PID,ON/OFF

Input of Sensor

Control Method

a) Relay Contact Output AC250V 3A MAX

b) SSR Driving Voltage Output DC12V 600Ω(ormore)

( Output type depends on the model. )

OUT1 (Control Output )

Relay Contact Output AC250V 1A MAX

Relay Contact Output AC250V 1A MAXOUT2 / EV2 ( Option )

Event1

0 to 50℃, 20 to 90%RH ( Avoid making of dew )

-25 to 75℃, 5 to 95%RH ( Avoid making of dew )

Operation Environment

Storage Environment

Less than 100 gms.Weight

Overvoltage Category Ⅱ

Installation Environment

Keep away from the following:

・Gas of corrosion,dust and oily smoke.

・The electrical noise of the generator.

・The influence of electromagnetic field.

・Mechanical vibration and shock.

・The direct sunlight.

Location of the Unit Setting

Installation Attachment

Watertight packing

※Thispacking is not attached

・The use of Noise Filter close to the Power Supply terminal is recommended.

Recommended Noise Filter:RSEL-2002W/A(available from TDK Lambda)

Noise filter's terminal 3 and 4 should be connected to the unit.

Noise filter's body may or may not to be connected to frame ground. Both are acceptable.

・Make sure the wiring is done correctly for any wires with polarity ( + and - ).

・For relay contact output, “C : common” and “NO : normal open” .

・Temp.INPUT and OUT1 in case of SSR Output,only the secondary circuits

with reinforced/dual insulation from the primary side can be connected.

・A conformity wire : copper / AWG18-24 / Temp.rating 80℃

・Use specified size (M3.5 width 7.3 mm or less) crimped terminals for wiring and

machines & tools.

・Tightening torqe : 0.5 Nm ( 5kgfm, 4.43 lb.fin)

CAUTION BEFORE CONTROL

PID Control

Better control result is achieved as opposed to that of ON/OFF control.

Life span of relay is shorter,as output exists freduently with relay contact.

Merit

Demerit

Merit

Demerit

ON/OFF Control

Life span of relay is generally longer,as it is ON when temperature is below SV

and it is OFF when temperature is over SV ( For heating control ).

Control value is worse in comparison with that of PID control.

・Setting program is stored after power OFF,as non-volatile memory is equipped with

・Either thermocouple or R.T.D ( Pt100 / JPt100 ) is selectable input type.

For suitable apprication,please select most appropriate input type and adjust input setup.

・PID or ON/OFF control is selective for the optimal performance and each detail of features is

specified in the table as bellow.

TTM-i4N SERIES controllers for setting storage.

NO C

NO CNO C

When having the purchased controller at hand,please be sure that its correct model.

See the following “Model Configuration” .

The following symbol marks provide to prevent incident or damage.Kindly refer to the details

of the WARNING/CAUTION when using for the first time.

For prevention of its malfanction,do not push the front key with sharp points.

Spare terminal must not be used for other purposes.

CAUTION

Make sure the correct wiring connection before turning on electricity.

Mis-wiring may cause malfunction of the unit and fire.

Never modify the unit to prevent damage or incident such as malfunction and fire etc.

・Please put this user's manual aside for your reference,when operating the unit.

・Copy or reprint of this manual,wholly or partially,is not allowed.

・The contents of this manual may change without notice in future.

WARNING

INSTALLATION CONDITIONS

・Indoor use

・Altitude up to 2000m

・Pollution Degree 2

・Installation Attachment ( For installation,please see “PANEL CUTOUT & INSTALLATION” on the right.)

・This user's manual : 1 copy

Code

・This product is intended for use with industrial machineries,machine tools and measurement

instruments.(It is not to be used with medical equipment which involves human lives).

CAUTION

& backface portion to the product and the peripheral device or plates.

・When you use compressed lead wire to install multiple units,please be careful sufficiently

not to touch the other lead wires.

CAUTION

Relay Output AC250V 1A (Load resistance)

WARNING

・This Controller is not equipped with overcurrent protection device ( Fuse ).

when making power source wiring. A Fuse is connected to the live side.

Please prepare semi-time lag fuse ( rated voltage : 250V, rated current : 1A )

48

( 2)

4 59

48

Single Unit Istallation

Multiple Unit Installation

45

+0 .6

0

60(ormore)

45

0

(48×n−3)

+ 0 .6

0

+ 0 .6

PARTS INDICATION

AL2

RDY lamp(It appears in Ready condition)RDY

※OUT2 / EV2 is not available when Option-B is not specified.

CAUTION

Alarm2 monitor(appears when EV2 is ON)

It also lights when OUT2 is ON in Heating/Cooling Control mode.

It lights-up when the set value in the Temp. data is Celsius.

It lights-up when the set value in the Temp. data is Fahrenheit.

℃

℉

when Option-B is not specified.

WARNING

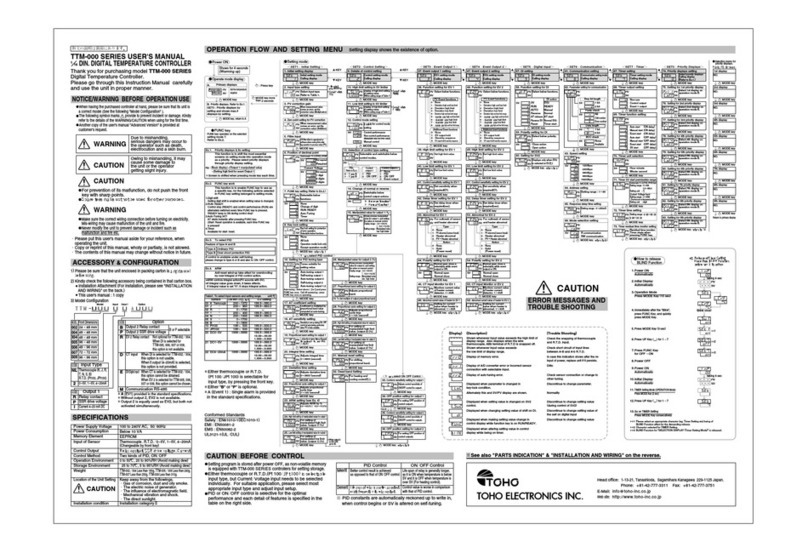

<SET1 : Input setting mode>

SET1

INP

1. Setting item selection screen

2. Input type setting

Select input type

00

INP

3. PV compensation gain setting

0.50 ~2.00

PVG

100

4.

PV compensation zero setting

-199 ~999

-199.9 ~999.9

PVS‘

0

5. PV Filter setting

0.0 ~99.9

PDF

00

6. Decimal point setting

0:Not required

0.1:Required

(Except R/S/B Thermocouple)

DP

0

7. Temperature unit setting

℃:

Celsius

℉

:Fahrenheit

C/F

*C

<SET2 : Key function setting mode>

SET2

KEY

1. Setting item selection screen

Setting related to

<SET3 : Control setting mode>

SET3

CNT

1.Setting item selection screen

<SET4 : EV1 setting mode>

SET4

AL1

Setting related to controlSetting related to input

key functions

<SET5 : EV2 setting mode>

SET5

AL2

<SET6 : Timer setting mode>

SET6

TIME

<SET7 : LCD setting mode>

SET7

LCD

<SET0 :

Priority screen setting mode

>

SET0

PR1

Setting for priority screen

(Refer to Ex.1.)

M key

2.

Priority screen 1 setting

PRI1

OFF

Select 1st screen on

Run mode B

Select 2nd screen on

Select 3rd screen on

Select 4th screen on

Select 5th screen on

3.

Priority screen 2 setting

PRI2

OFF

4.

Priority screen 3 setting

PRI3

OFF

5.

Priority screen 4 setting

PRI4

OFF

6.

Priority screen 5 setting

PRI5

OFF

7.

Priority screen 6 setting

PRI6

OFF

8.

Priority screen 7 setting

PRI7

OFF

9.

Priority screen 8 setting

PRI8

OFF

10.

Priority screen 9 setting

PRI9

OFF

<When select PID control> <When select ON/OFF control>

KThermocouple

J

R

T

N

S

00

01

02

03

04

05

B

Pt100

JPt100

06

10

11

●Setting mode●POWER ON

●RUN mode

A.Primary screen

Measured value

Set the temperature

required

Set value

(Press for 4 seconds)

▲KEY

▼KEY

▲KEY

▼KEY

●Protect setting mode

Setting screen

Mode to set the protection level

“Input type setting screen” appears for 4seconds,

then it will oriceed to “Run mode” .

PTLV

0

Non-Protect

0

1

2

3

parameters except for the following:

Setting Change not possible.

PV compasation zero setting

Alarm reset

AT start/reset

Proportional band setting for OUT1/OUT2

Integral time setting

Deviative time setting

Control sensitivity setting for OUT1/OUT2

Upper limit setting for EV1/EV2

Lower limit setting for EV1/EV2

・The Setting Mode Parameter blinds

・Setting change for SV/Priority Screen is Possible

B.Priority screens (1 ~9)

Priority displays by setting

and shows max.9 screens by setting.

●EX1.Priority screens & its setting

This function enables the selection of the most necessary screen indication

from all the screen indication found in the setting mode,and assign it to

eg:Basic screen → OUT1 manipulated value → Setting high limit for EV1

*Screen is shifted when pressing M key each time.

the RUN mode on priority basis.

Please select priority screen indication through the priority screen setting mode.

●EX2.Function key works

This function is to enable F key to use as a specific key,for the following actions

selected in F key setting belonging to setting mode.

1. Digit shift

Setting digit shift is enabled when setting value is changed.

2. RUN/READY

Control stop(READY) and control performance(RUN) are

alternately switched by F key.

3. AT Start / Reset

AT(Auto -Tuning) starts instantly after pressing F key.

Start and Reset are alternately switched by F key.

4. Timer Start / Reset

Press once for function.

Press once for function.

5. Alarm Reset

6. Enter

Function

Effective

in all modes

Effective only

in Operating mode

●EX3.

To select PID

Features of type A,B,FUZZY

TypeA

If control is unstable under self-tuning,

please change to type A ,B or FUZZY and also ON/OFF control.

TypeB

FUZZY

the RUN mode on priority basis.

Basic PID

Over shoot protection PID

Effectively control the over shoot in the beginning of PID control.

●EX4. ARW (Anti-Reset-Windup)

ARW take effect for overshooting by over-integral of PID action.

・ARW controls integral action (PV accords with SV).

・If integral value goes down,it takes effects.

If integral value is set “0” ,it stops integral action.

Table1. To select input sensors and setting range. unit : ℃

Symbol

K

Thermocouple

Low limit

~

High limit

-200 ~ 1372

0.0 Setting

J -200 ~ 850

R 0 ~ 1700

T -200 ~ 400

N -200 ~ 1300

S 0 ~ 1700

B 0 ~ 1800

Pt100 -200 ~ 500

JPt100 -200 ~ 500

OPERATION FLOW AND SETTING MENU

*12*13

(Press for 2 seconds)

・Setting change is possible with SV only.

・The priority screen is with indication/

・All setting mode parameters will be blinded.

・SV is with indication / setting change not possible.

not possible.

・Priority Screen is with indication / setting change

・All setting mode parameters will be blinded.

Press for

2 seconds

Effective

in all modes

"

"

"

"

"

"

Select 6th screen on

Select 7th screen on

Select 8th display on

Select 9th screen on

M key

M key

M key

M key

M key

M key

M key

M key

M key , return to 1

M key , return to 1

M key

M key

M key

M key

M key

"

"

"

"

"

"

M key

M key

M key

M key

M key

seconds

times

-199.9 ~ 999.9

-199.9 ~ 850.0

-199.9 ~ 400.0

-199.9 ~ 999.9

-

-

-199.9 ~ 500.0

-199.9 ~ 500.0

-

*1

No indication when the type of control OUT1 is ON/OFF Control.

*2

No indication when the type of control OUT1 is PID Control.

*3

No indication when the OUT1 loop error determination time is “0” .

*4

No indication when the type of control OUT2 is either “None” or “EV2” .

*5

No indication when the type of control OUT2 is ON/OFF Control.

*6

No indication when the type of control OUT2 is PID Control.

*7

No indication when the OUT2 loop error determination time is “0” .

*8

No indication when the EV1 Function is set at “No Function” .

*9

No indication when the EV1 Function is not used in the Upper Limit Alarm.

*10

No indication when the EV1 Function is not used in the Lower Limit Alarm.

*11

No indication when the EV1 & 2 Functions to “No Function” .

*14

No indication when EV2 Function is set at “No Function” .

*15

No indication when the EV2 Function is not used in the Upper Limit Alarm.

*16

No indication when the EV2 Function is not used in the Lower Limit Alarm.

*17

No indication when the EV 1 & 2 Functions to “No Function” .

*12

No indication when Option-B is not specified.

*13

No indication when the type of Control OUT2 is set to anything other than “EV2” .

*18

No indication when the Timer Output is set to “Timer Not Used” .

*19

No indication when the Timer Function is set to other than “SV Start” .

2. Function key function setting

FU

00++

① Function setting

0 : None

1 : Digit shift

2 : RUN/READY

3 : AT start/stop

4 : Timer start/stop

5 : Alarm reset

6 : ENTER

②

Pressing time setting

0 : None

1 : Pressing time 1 second

2 : Pressing time 2 seconds

3 : Pressing time 3 seconds

4 : Pressing time 4 seconds

5 : Pressing time 5 seconds

3. Key-lock setting

0

LOC

Lock OFF

Lock all

Lock run mode

Lock except run mode

※Protect Level Setting is not subjected to

Key-Lock Setting.

0

‘1

‘2

‘3

4. Alarm reset

0 0

ALRS

No alarm occurrence

Only EV1 is occurring

Only EV2 is occurring

0 0

0 1

1 0

1 1

Both EV1/EV2 are occurring

Screen for Alarm reset of EV1/EV2

※Press F key for 1 second to reset the alarm.

(The indication momentarily disappears as

the Alarm reset is executed).

2. SV limiter upper limit

SLH‘

1200

3. SV limiter lower limit

SLL‘

0

4. Control mode setting

RUM

MD

Control start

Control stop

Manual

RUN

RDY

MAN

Setting for control mode

5. Control type setting

CNT

‘020++

①Function

0 : TypeA

1 : TypeB

2 : Fuzzy

③Control type of OUT2

0 : None

1 : PID control

2 : ON/OFF control

3 : EV2 output

②Coutrol type of OUT1

1 : PID control

2 : ON/OFF control

①

②

③

②

①

※When Option B is not specified,Control type of

OUT2 shall be fixed at “None” .

6. Forward/reverse operation setting

0:Reverse operation

DIR‘

0

1:Forward operation

7. Operating amount for OUT1

MV1‘

00

M key M key

8. Tuning type setting

1

TUN

*1

Auto-tuning

Self -tuning

Auto-tuning

Self -tuning

Auto-tuning

1

2

3

4

5

:OUT1

: OUT1

: OUT2

: OUT2

: OUT1/OUT2

9. AT coefficient setting

ATG

10

10. AT sensitivity setting

ATC

2

11. AT start/stop

AT

OFF

AT stop

AT start

※ATstart and ATstop are alternately switched

OFF

ON

12.

Proportional band setting for OUT1

P1

30

13. Integral time setting

I

0

14. Deviative time setting

D

0

15.

Proportional cycle setting for OUT1

T1

20

16. ARW setting (see Ex.4)

ARW

1100

17. Operating amout limiter upper limit for OUT1

MLH1

1000

18. Operating amout limiter lower limit for OUT1

MLL1

00

19. Sensitivity setting for OUT1

C1

1

21. Loop anormaly time setting for OUT1

LOP1

0

seconds

22.

Loop anormaly PV change threshold for OUT1

PS1

0

23.

Loop anormaly PV threshold for OUT1

TS1

0

24.

Protection OFF timer time setting for OUT1

FDT1

0

25.

Protection ON timer time setting for OUT1

NDT1

0

26. Operating amount for OUT2

Displays operating amount for OUT2

and set the amount on manual control.

MV2‘

00

0.0 ~100.0(%)

MLL2 ~MLH2

(%)

27.

Proportional band setting for OUT2

0.10~10.00

P2

100

28.

Proportional cycle setting for OUT2

T2

20

29.

Operating amout limiter upper limit for OUT2

MLH2

1000

MLL2 ~

100.0

%

30.

Operating amout limiter lower limit for OUT2

MLL2

00

0.0

~MLH2

%

20. OFF point position setting for OUT1

CP1

0

*1

*2

*3

*3

*2

*2

*4

*4 *5

*4 *5

*4 *5

*4 *5

*1

*1

*1

*1

*1

*1

*1

*1

*1

*2

M key

M key

M key

M key

M key

M key

M key

M key

M key

M key

Mkey (Go to 21)

31. Sensitivity setting for OUT2

C2

1

32. OFF point position setting for OUT2

CP2

0

*4 *6

*4 *6

33.Loop anormaly time setting for OUT2

LOP2

0

※At “0” setting,there is no loop error determination.

34.

Loop anormaly PV change threshold for OUT2

PS2

0

35.

Loop anormaly PV threshold for OUT2

TS2

0

36.

Protection OFF timer time setting for OUT2

FDT2

0

37.

Protection ON timer time setting for OUT2

NDT2

0

*4 *7

*4

38. Balance less / Bump less

BMP

1

No Balance less / Bump less function

With Balance less / Bump less function

0

1

39. Manual reset setting

PBB

00

0.0 ~100.0%

-100.0 ~100.0% (

Heat / Cool

)

*1

40. Dead band setting

DB

0

-100 ~100

*4

41. Ramp time setting

RMP

00

※Ramp function OFF at 0.0

42. Control back up function setting

PWZ

00

0.0 ~10.0

*4 *7

*6 *4

2. EV1 setting mode

EV1 alarm function 1 setting

A1F1

000++

①Function

0 : None

1 : Deviation upper and lower limits

2 : Deviation upper limit

3 : Deviation lower limit

4 : Deviation range

5 :

Absolute value upper and lower limits

6 : Absolute value upper limit

7 : Absolute value lower limit

8 : Absolute value range

③

②

①

③Control mode interlocking function

②Add-on function

0 : None

1 : Hold

2 : Standby

3 : Delay

4 : Hold+Standby

5 : Hold+Delay

6 : Standby+delay

7 : Hold+standby+delay

3. EV1 alarm upper limit setting

A1H

0

-1999 ~3276 or -199.9 ~999.9

※In case of thermocouple R/S/B : -1999 ~3276

4. EV1 alarm lower limit setting

A1L

0

5. EV1 alarm sensitivity setting

A1C

0

0~999 or 0.0 ~999.9

6. EV1 alarm delay timer setting

A1T

0

0〜9999

seconds

7. EV1 alarm function 2 setting

EV1 alarm function 2 setting

for PV error

A1F2

000++

①Function

0 : None

1 : PV error

③

②

①

②Add-on function

0 : None

1 : Hold

2 : Delay

3 : Hold+Delay

8. EV1 alarm function 3 setting

EV1 alarm function 3 setting

A1F3

00++

①Function

0 : None

1 : Loop error

②

①

②Add-on function

0 : None

1 : Hold

for loop anormaly

9. EV1 alarm polarity setting

A1P

0

Normal open

Normal close

0

1

*8 *9

*8 *10

*8

*11

*12*14

*15

*12*14

*12*14

*12*17

*12

*12

*12

*16

0 : All modes

1 : RUN/ MANUAL mode only

2 : RUN mode only

*12

M key

M key

M key

M key

M key

2. Timer output setting

0

TMO

Non-use timer function

Control

EV1 output

EV2 output

※“3” is not selectable when Option-B is not specified.

0

‘1

‘2

‘3

3. Function setting

1

TMF

Auto start

Manual start

EV1 start

Auto start

Manual start

1

2

3

4

5

EV1 start

SV start

EV2 start

6

7

8

EV2 start

9

( ON delay )

( ON delay )

※“8” and “9” are not selectable

when Option-B is not specified.

4. Unit setting

H/M

1

Hour / Minute

Minute / second

1

2

5. Start SV permissible range setting

TSV

0

6. Time setting

TIM

00 :00 ~99 :59 (Hour/Minute)

00 :00 ~99 :59 (Minute/second))

7. Remaining time monitor

TIA

00 00

Screen for remaining time monitor

2. Brightness setting

LLV

100

5~100

%

3. Dimming function setting

LRFT

0

0~9999

seconds

※No dimming function when set to “0” .

4. Dimming Brightness setting

LRLV

5

0~100

%

:

00 00

:

*18

*18*19

*18

*18

*18

M key

M key

M key

M key

M key , return to 1

M key

M key

0.1 ~10.0

times

% per

SLL

〜

SLH

seconds

1〜120

%

0.0 ~110.0

%

MLL1 ~

100.0

%

0.0

~MLH1

Setting range

:

Setting unit

:

Setting range

:

Setting unit

:

Setting range

:

Setting unit

:

0.1 ~200.0

seconds

0~3600

Setting range

:

Setting unit

:

Setting range

:

Setting unit

:

Setting range

:

Setting unit

:

Setting range

:

Setting unit

:

Setting range

:

Setting unit

:

Setting range

:

Setting unit

:

Setting range

:

Setting unit

:

Setting range

:

Setting unit

:

*6 *4

1.

Setting item selection screen

Start and Reset are alternately switched by F key.

Digit under selection will blink.

M key , return to 1

M key

M key

Setting range

:

Setting range

:

Setting unit

:

Setting unit

:

Setting range

:

Setting unit

:

by F key.

0 〜999 or 0.0 〜999.9

Setting range

:

Setting unit

:

-199 ~999 or -199.9 ~999.9

Setting range

:

Setting unit

:

0~9999

seconds

Setting range

:

Setting unit

:

Setting range

:

Setting unit

:

Setting range

:

Setting unit

:

※At “0” setting,there is no loop error

PV change determination.

Setting range

:

Setting unit

:

Setting range

:

Setting unit

:

※At “0” setting,there is no loop error determination.

Setting range

:

Setting unit

:

seconds

Display amount

:

Setting amount

:

Setting range

:

Setting unit

:

Low to high limit

※Keep the difference of more than 5 degrees(℃or℉)

Setting range

:

Setting unit

:

Low to high limit

betweenLowand high limit of the SV limiter.

※At “0” setting,there is no loop error

PV threshold determination.

※At “0” setting,there is no loop error

PV change determination.

※At “0” setting,there is no loop error

PV threshold determination.

Setting range

:

Setting unit

:

Setting range

:

Setting unit

:

0~99

Minuites

Setting range

:

Setting unit

:

0~99

Minuites

Setting range

:

Setting unit

:

Setting range

:

Setting range

:

-100.0 ~100.0

℃or ℉

Setting unit

:

℃/min. or ℉/min.

Setting range

:

Setting unit

:

※Control back up function OFF at 0.0

Setting range

:

Setting unit

:

℃or ℉

℃or ℉

℃or ℉

℃or ℉

℃or ℉

℃or ℉

℃or ℉

℃or ℉

℃or ℉

℃or ℉

℃or ℉

℃or ℉

℃or ℉

1.Setting item selection screen

Setting range

:

Setting unit

:

℃or ℉

-1999 ~3276 or -199.9 ~999.9

※In case of thermocouple R/S/B : -1999 ~3276

Setting range

:

Setting unit

:

℃or ℉

Setting range

:

Setting unit

:

℃or ℉

Setting range

:

Setting unit

:

M key

M key

M key

③

Control mode interlocking function

0 : All modes

1 : RUN/ MANUAL mode only

2 : RUN mode only

M key , return to 1

M key , return to 1

2. EV2 setting mode

EV2 alarm function 1 setting

A2F1

000++

①Function

0 : None

1 : Deviation upper and lower limits

2 : Deviation upper limit

3 : Deviation lower limit

4 : Deviation range

5 :

Absolute value upper and lower limits

6 : Absolute value upper limit

7 : Absolute value lower limit

8 : Absolute value range

③

②

①

③Control mode interlocking function

②Add-on function

0 : None

1 : Hold

2 : Standby

3 : Delay

4 : Hold+Standby

5 : Hold+Delay

6 : Standby+delay

7 : Hold+standby+delay

3. EV2 alarm upper limit setting

A2H

0

-1999 ~3276 or -199.9 ~999.9

※In case of thermocouple R/S/B : -1999 ~3276

4. EV2 alarm lower limit setting

A2L

0

5. EV2 alarm sensitivity setting

A2C

0

0~999 or 0.0 ~999.9

6. EV2 alarm delay timer setting

A2T

0

0〜9999

seconds

7. EV2 alarm function 2 setting

EV2 alarm function 2 setting

for PV error

A2F2

000++

①Function

0 : None

1 : PV error

③

②

①

②Add-on function

0 : None

1 : Hold

2 : Delay

3 : Hold+Delay

8. EV2 alarm function 3 setting

EV2 alarm function 3 setting

A2F3

00++

①Function

0 : None

1 : Loop error

②

①

②Add-on function

0 : None

1 : Hold

for loop anormaly

9. EV2 alarm polarity setting

A2P

0

Normal open

Normal close

0

1

0 : All modes

1 : RUN/ MANUAL mode only

2 : RUN mode onl

M key

M key

M key

M key

M key

Setting range

:

Setting unit

:

℃or ℉

-1999 ~3276 or -199.9 ~999.9

※In case of thermocouple R/S/B : -1999 ~3276

Setting range

:

Setting unit

:

℃or ℉

Setting range

:

Setting unit

:

℃or ℉

Setting range

:

Setting unit

:

M key

M key

M key

③

Control mode interlocking function

0 : All modes

1 : RUN/ MANUAL mode only

2 : RUN mode only

M key , return to 1

1.Setting item selection screen

EV2 output function setting

1.Setting item selection screen

Setting concerned with

timer parameters

EV1 output function setting

1. Setting item selection screen

Setting related to LCD

Setting range

:

Setting unit

:

Setting range

:

Setting unit

:

Setting range

:

Setting unit

:

M key

M key

M key

M key , return to 1

( ON delay )

( OFF delay )

( OFF delay )

( OFF delay )

( OFF delay )

( ON delay )

( OFF delay )

0~999 or 0.0 ~999.9

Setting range

:

Setting unit

:

℃or ℉

Setting range

:

0 〜999 or 0.0 〜999.9

0 〜999 or 0.0 〜999.9

0 〜999 or 0.0 〜999.9

0 〜999 or 0.0 〜999.9

0 〜999 or 0.0 〜999.9

-199 ~999 or -199.9 ~999.9

0~9999

0.0 〜999.9

0 〜999 or 0.0 〜999.9

Setting range

:

Setting unit

:

0~3600

1〜120

Setting range

:

Setting unit

:

seconds

Setting range

:

Setting unit

:

Setting range

:

Setting unit

:

M key (Go to 33)

M key

M key

M key

※Timerstart and stop are alternately

switched by F key.

0~99

Minuites

0~99

Minuites

~~~~

Displays whenever input value exceeds the high limit of display range.

Also displays when the wire is snapped off thermocouple and that of R.T.D.

____

Displays whenever input value exceeds the low limit of display range.

ERR0cv

Displays at memory error.

ERR1cv

Displays at input circuit error.

ERR2cv

Displays when auto-tuning does not end after 3 hrs.,

or when error occurs during the auto-tuning.

Displays when the parameter change is attempted during key lock mode.

LOC

Displays when the control mode change is attempted

FUNC

during which function keys are allocated to RUN/READY.

Displays during auto-tuning.

AT

Displays when the control mode change is attempted

TIME

Other Display Indication

during which the timer is in use..

TOHO ELECTRONICS INC.

2-4-3 NISHIHASHIMOTO MIDORI-KU SAGAMIHARA KANAGAWA

252-0131 JAPAN

Phone: +81-50-3535-9960 Fax: +81-42-700-2118

http://www.toho-inc.com

Head office:

E-Mail:

URL:

▲KEY

▼KEY

▲KEY

▼KEY

▲KEY

▼KEY

▲KEY

▼KEY

▲KEY

▼KEY

M key

M key

M key

M key

M key

M key

M key

M key

M key

M key

M key

M key

M key

M key

M key

M key

M key

M key

M key

M key

M key

M key

M key

M key

Run mode B

Run mode B

Run mode B

Run mode B

Run mode B

Run mode B

Run mode B

Run mode B

Magnification to

MV1

Displays operating amount for OUT1

and set the amount on manual control.

0.0 ~100.0(%)

MLL1 ~MLH1

(%)

Display amount

:

Setting amount

:

※Keep the difference of more than 5 degrees(℃or℉)

betweenLowand high limit of the SV limiter.

M key

<When select PID control>

<When select ON/OFF control>

Blind setting mode

****

ON

Value is indicated.

No indication

ON

OFF

**** :

Selected parameter is indicated.

M key (Press for 10 seconds)

Indication disappears momentarily

SET0

ON

SET1

ON

▲

▼

SET2

ON

▲

▼

SET3

ON\

▲

▼

SET4

ON

▲

▼

SET5

ON

▲

▼

SET6

ON

▲

▼

▲

▼

SET7

ON

PRI1

ON

INP

ON

FU

ON

SLH

ON\

A1F1

ON

A2F1

ON

TMO

ON

LLV

ON

▲

▼

M key M key M key M key M key M key M key M key

to

SET0

M key (Press for 2 seconds)

Reset the power for Blind setting mode OFF.

Shift to Blind setting mode

※

ON/OFF is changed by F key.

●POWER ON

“Input type setting screen” appears for 4 seconds,

then it will procceed to “Run mode” .

●RUN mode

F

key (Press for once)

M

key (Press for once)

●RUN mode

Please select parameters to be blinded

through the Blind setting mode.

Table of contents

Other Toho Electronics Temperature Controllers manuals

Popular Temperature Controllers manuals by other brands

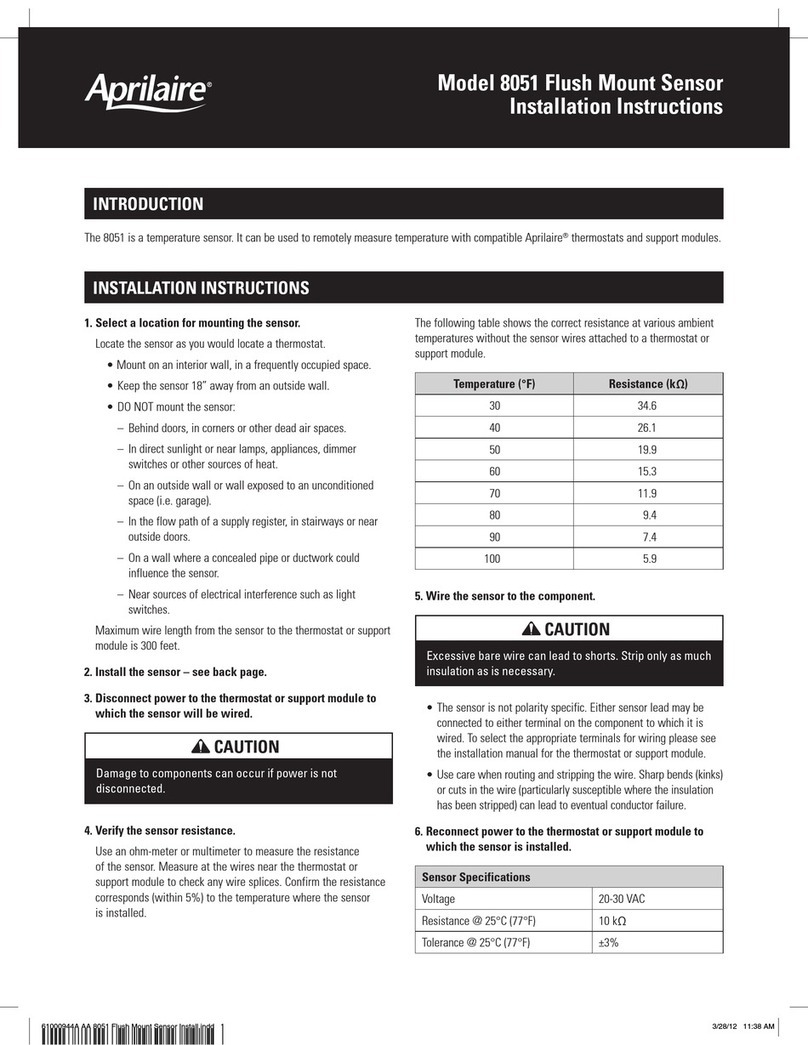

Aprilaire

Aprilaire 8051 installation instructions

Vaillant

Vaillant VRC 470 installation instructions

Autonics

Autonics TK Series User Manual for Communication

Powtier Controls

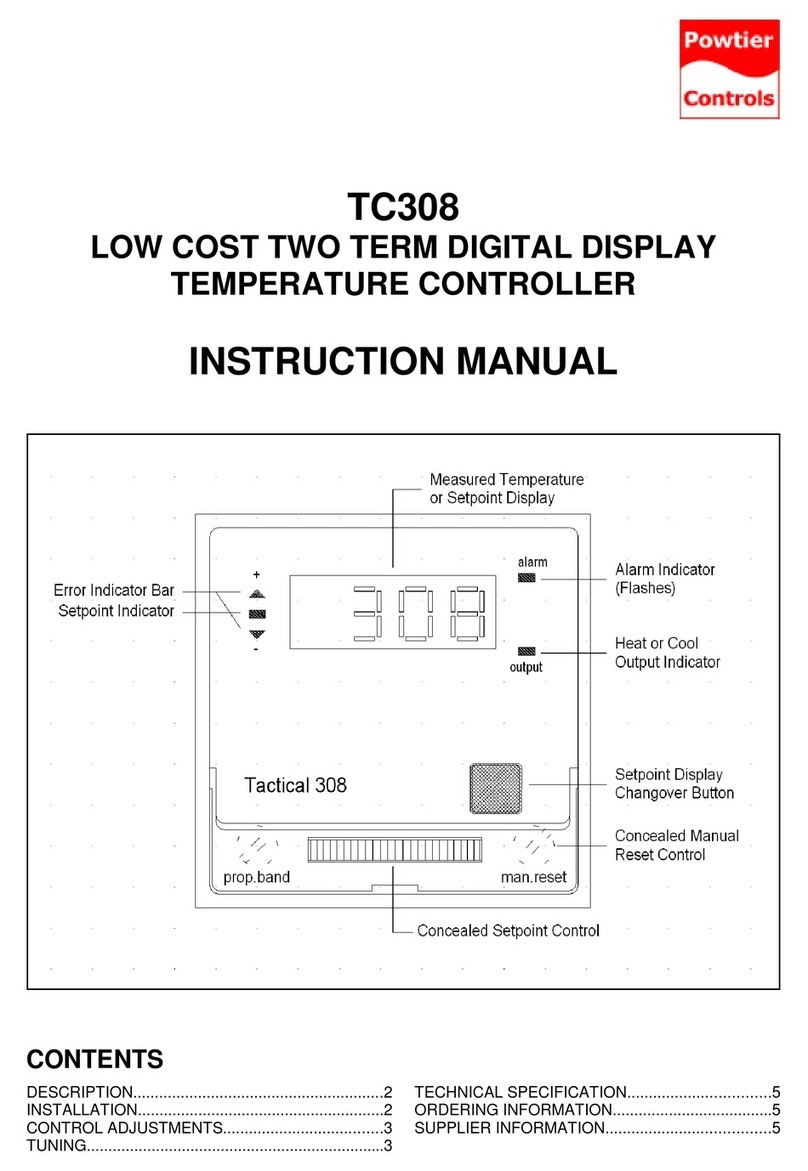

Powtier Controls TC308 instruction manual

PPI

PPI Zenex-ultra user manual

Auber Instruments

Auber Instruments SYL-1512A instruction manual