Toho Electronics TTM-00BT Series User manual

?

?

?

TTM-00BT series

INSTRUCTION MANUAL

TOHO ELECTRONICS INC.

©All Rights Reserved

●Definition of warning symbol

※Definition of physical damage is damage to house, property and

animal so on.

●Definition of symbol

Ifmake miss handling, in case of possible to get

damage or physical damage.

●Prohibition of disassemble

Possible to get electronic shock by disassemble

of product.

●General

Notice of prohibition on non specific.

●General

Notice of warning, caution and danger on non

specific.

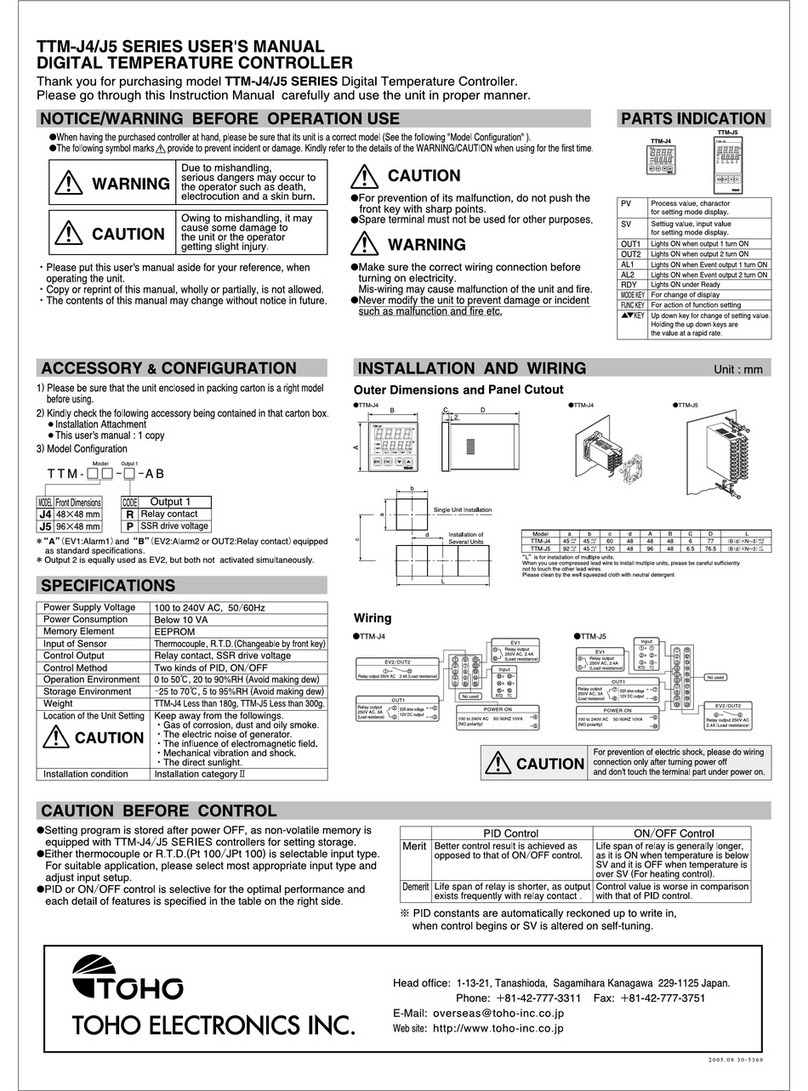

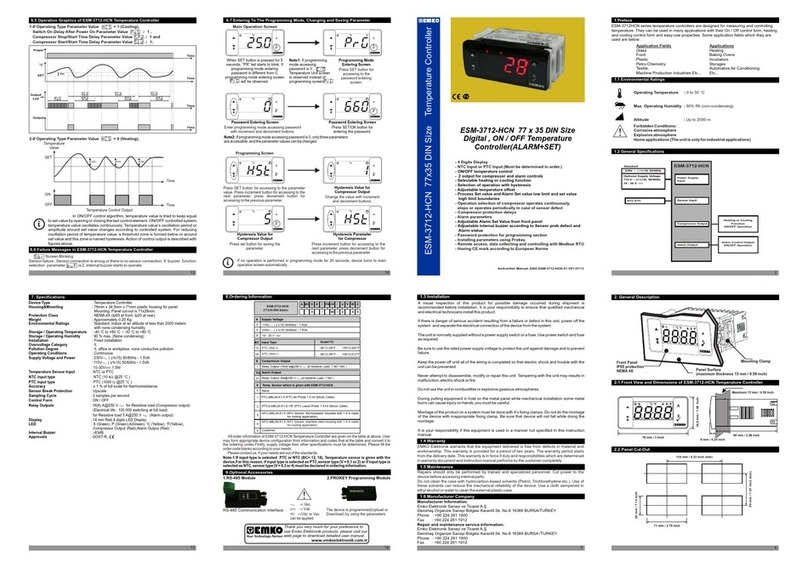

●Name and Function

1) SW1:Unit number converter switch・・・00〜0F(16 count)

2) SW2:Communication converter switch・・・Communication speed setting

3) CN1:Control output connector・・・NPN open corrector output 8points

4) CN2:Alarm output connector・・・NPN open corrector output 11points

5) CN3:CT input connector・・・CT input 8points

6) TB1:Thermocouple or R.T.D temperature input terminal

7) TB2:Power voltage terminal (power voltage: DC24V+10%-15%)

8) TB3:RS-232C or RS-485 of terminal for communication

9) TB4:Event input terminal (input voltage range: DC12〜24V±10%)

10) LED1:Communication(+)・RD lamp(green)

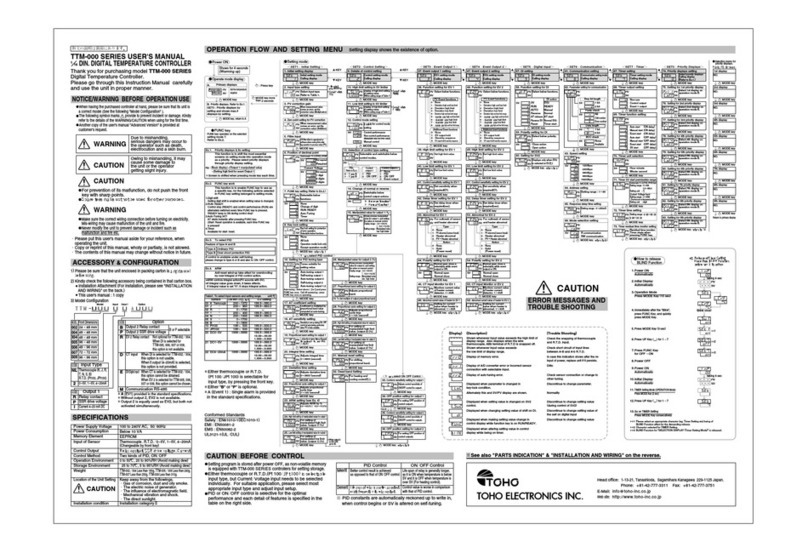

●About communication initial setting This product is required t

o set initial setting of [ Communication speed setting ] and [ Unit number setting ].

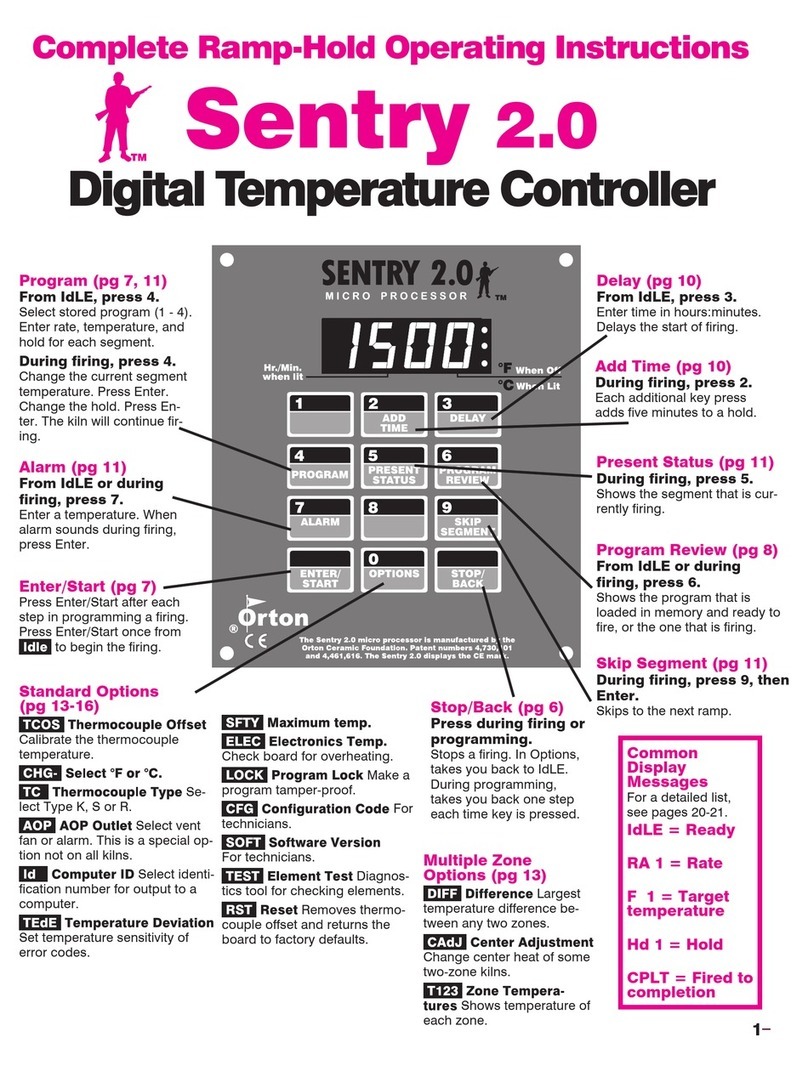

1) [Communication speed setting]・・・・・Setting by dip-switch (SW2).

12Communication speed

OFF OFF

4800bps Use dip-switch 1&2

ON OFF

9600bps (3&4 :Always OFF)

OFF ON 19200bps Combination will follow

ON ON 38400bps *Default=[1:ON, 2:OFF(9600bps)]

2) [Unit number setting]・・・Setting by rotary switch. Unit number set by 16 count (0〜F)

※

*Remark: Operate setting of [Communication speed sett

ing] & [Unit number setting] definitely without power on.

Refer to the following manual together with this instruction manual before

operating this product.

・Model TTM-00BT Users manual (No. 44-4739)

■Contents of Package

The following are provided together in the same package.

・Model TTM-00BT : 1unit

・Instruction Manual : 1pce

Do not allow metal fragments or lead wire

scraps to fall inside of this product.

These may cause electric shock, fire or

malfunction.

Never disassemble, repai

r or modify the

product.

Doing so may cause electric shock, fire or

malfunction.

Use the product within the rated load.

Not doing so may cause damage or

burning.

Use the product within the rated supply

voltage.

Not doing so may cause damage or

burning.

Be sure to tighten the terminal screw

and

the connectors rock securely.

Not doing so may cause damage or

malfunction.

Correctly set the setting on this product

matched

to the control target. If the

setting are not

compatible with the

control target, the product

might operate

in an unexpected manner, resulting in

damage to the product or an accident.

Tighten any terminal screw to torque

(about 0.5

N/m). If screw is not tighten

enough, this may cause fire or

malfunction.

To maintain safety in the event of a

product malfunction, we recommend

taking safety measures, for example,

installing an excessive temperature rise

prevention alarm on a separate line. If

malfunction prevents control, this may

result in a major accident.

●

Caution Symbol

11) LED2:Communication(-)・SD lamp(red)

12) LED3:Power lamp(green)

13) LED4〜11:Alarm output lamp(red)

14) LED12:Heater Break alarm output lamp(red)

15) LED13:Heater Short alarm output lamp(red)

16) LED14:Internal Error output lamp(red)

17) LED15〜22:Control output lamp(orange)

Safety Precautions

CAUTION

CAUTION

NOTICE

Thank you for purchasing this TOHO product. Please read this

instruction manualand thoroughly familiarize yourself with the

functions and characteristics of the product before use.

Please retain this manual for future reference.

Use most updated manual from nearest TOHO representative.

Furthermore, please keep this instruction with you anytime

while your operation and make sure that this instruction must be

delivered to end users.

MULTIPOINT

TEMPERATURE

CONTROLLER Be sure to observe these precautions to ensure safe use

1) Make sure that the rated voltage is attained within two seconds of turning the power ON.

2) To ensure correct temperature measurement, allow at least 30 minutes for the Unit to

warm up.

3) When use of self turning, turn on temperature controller and load at same time or turn

on load first.

4) Do not wire the terminals which are not used.

5) Be sure to wire properly with correct polarity of terminals.

6) Do not touch the mounted parts or the rear surface of PCBs. To hold this

product, please hold ceiling, pole or edge.

7) In the time of installation, do not touch sharp edgessuch as electrical leads.

8) Connection of wiring

a) Crimp terminal: specified size (M3, width 6.9mm or below)

b) End soldered wire: use AWG 22 to 16(Length of exposed wire: 5 to 7mm)

9) A switch or circuit breaker should be placed close to theunit and should be indicated

properly.

10) To reduce induction noise, separate the high-voltage or large current power lines

from other lines, and avoid parallel or connect wiring with the power lines when

you

are wiring to the terminal. We recommend the use of separating pipes, ducts,

or shield lines.

11) Separate this product from machines generating powerful high frequency

electromagnetic waves or surge, such as high frequency welding machines or

high-frequency sewing machines.

12) When wiring signal lines of input/output with over 30m lines inside, put surge

control circuit for preventing surge.

When locating outside, set a surge control circuit

regardless of the length of lines.

13) Do not place at the following locations.

a) Location with large electromagnetic effects

b) Location with sulfide gas or corrosive gas

c) Location with dust or oil smoke d) Location with direct sunlight

e) Location with water splash f) Location with a risk of icing.

g)Location with high voltage cable, welding machine and origin of generating

electric noise.

h)Location with machinesusing high pressured igniter.

i)Location with excessive high humidity and where there is arisk of condensation

j)Location with mechanical vibration and shocks

k) Location with condensation as the result of severe changes in temperature.

l) Location with directly subject to heat radiated from heating equipment.

14) Location with temperature and humidity should be applicable with rated level, if

necessary please force to cool down.

15) To allow heat dissipation, be sure not to obstruct the area around the product or

ventilation ducts.

All manuals and user guides at all-guides.com

all-guides.com

●Wiring of Terminal

TB1 to TB4:: Terminal table For wiring, use M3 round terminal, Y terminal & welding wire

1) Temperature input(TB1: terminal table):

Thermocouple input ※refer to mark on the terminal table for terminal number

R.T.D input

‑

+

A1

B1

CH1

‑

+

A2

B2

CH2

‑

+

A3

B3

CH3

‑

+

A4

B4

CH4

‑

+

A5

B5

CH5

‑

+

A6

B6

CH6

‑

+

A7

B7

CH7

‑

+

A8

B8

CH8

A1

B1

A

B

B

C1

A2

B2

A

B

B

C2

A3

B3

A

B

B

C3

A4

B4

A

B

B

C4

A5

B5

A

B

B

C5

A6

B6

A

B

B

C6

A7

B7

A

B

B

C7

A8

B8

CH1

CH2

CH3

CH4

CH5

CH6

CH7

CH8

A

B

B

C8

・When extend cable, use appropriate compensation lead wire

for thermocouple ・Use wire material with wire resistance value below 5Ω/per

wire for connecting RTD with main body.

2) Event input (TB4:terminal table) 3)Communication(TB3:terminal table) 4)Power(TB2:terminal table)

DC24V

1

2

−+

IN

1

2

3

Master system

RS‑232C RXD

TXD

SG

RS

CS

DR

ER

RXD

TXD

SG

1

2

3

Master system

RS‑485 A(+)

B(‑) SG

A(+)

B(‑) SG

RS‑232C

RS‑485

DC24V

1

2

−

+

CN1 to CN3:XG4A-1634(OMRON)(Figures describe connector on the board)

5) Alarm output (CN2:Connector) 6) Control output (CN1: connector)

COM2

ALM8

ALM7

ALM6

ALM5

L

L

L

L

1

3

5

7

9

11

13

15

2

4

6

8

10

12

14

16

COM5

COM4

DC24V

ALM1

HBERR

HS

COM1

ALM4

ALM3

ALM2

L

L

L

L

L

L

L

DC24V

COM3

DC24V

DC24V

DC24V

COM5

COM4

COM3

COM2

COM1

1

3

5

7

9

11

13

15

2

4

6

8

10

12

14

16

COM8

COM7

CH1

O.C1

CH6

O.C6

CH8

O.C8

CH7

O.C7

CH5

O.C5

CH4

O.C4

CH3

O.C3

CH2

O.C2

COM6

DC24V

L

L

L

DC24V

DC24V

L

DC24V

DC24V

L

L

L

DC24V

DC24V

L

DC24V

ALM 1 to 8:Alarm output 1 to 8 HB:Heater Break Alarm output

HS: Heater Short Alarm output ERR: Internal Error output O.C1 to 8:Control output 1 to 8

COM1 to 8: Common

7) CT input (CN3: connector) PRECAUTIONS IN USING THE PRODUCT

When the product is used under the circumstances or environment below,ensure

adherence to limitations of the ratings and functions. Also, take countermeasures

for safety precautions such as fail-safe installations.

• Use under circumstances or environment which are not described in the

instruction manual.

• Use for nuclear power control, railway, aircraft, vehicle, incinerator, medical

equipment, entertainment equipment, safety device etc...

• Use for applications where death or serious property damage is possible and

extensive safety precautions are required.

CT5

CT4

CT3

CT2

CT1

1

3

5

7

9

11

13

15

2

4

6

8

10

12

14

16

CT8

CT7

CT1

CT6CT8

CT7

CT5

CT4

CT3

CT2

CT6

CT

CT

CT

CT

CT

CT

CT

CT

TOHO ELECTRONICS INC.

■Head Office 1-13-21 Tanashioda, Sagamihara-shi, Kanagawa 229-1125 Japan

Tel: +81-42-777-3311, Fax: +81-42-777-3751

■Tokyo Office The 3rd Wako Bldg, 7-17-6 Nishi-Shinjuku, Shinjuku-ku, Tokyo

160-0023, Japan

Tel: +81-3-3363-1331, Fax: +81-3-3363-3335

■Osaka Office Yachiyo Bldg East Wing 7F, 2-Kita 1-21 Tenjinbashi, Kita-ku,

Osaka-shi, Osaka 530-0041, Japan

Tel: +81-6-6353-9205, Fax: +81-6-6353-9273

30−3910−E

●Name and function of each parts

1) Product figure

●Installation

1) Dimension

2) Installation method:

・Install 9parts(φ3.5)by screw(M3).

・Place horizontal or vertical with input terminal facing below.

・Install board with over 8mm upper by using spacer.

・For plural installation, keep 50mm distance from the other.

All manuals and user guides at all-guides.com

Other Toho Electronics Temperature Controllers manuals